Device for forming circuit on touch panel and circuit forming method

A touch panel and circuit technology, which is applied in the field of hot pressing process to form a circuit device, can solve the problems of different strengths of the double rollers, different thickness of the panel material 6, and inability to produce products according to the order, so as to improve the yield rate , the effect of avoiding storage costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

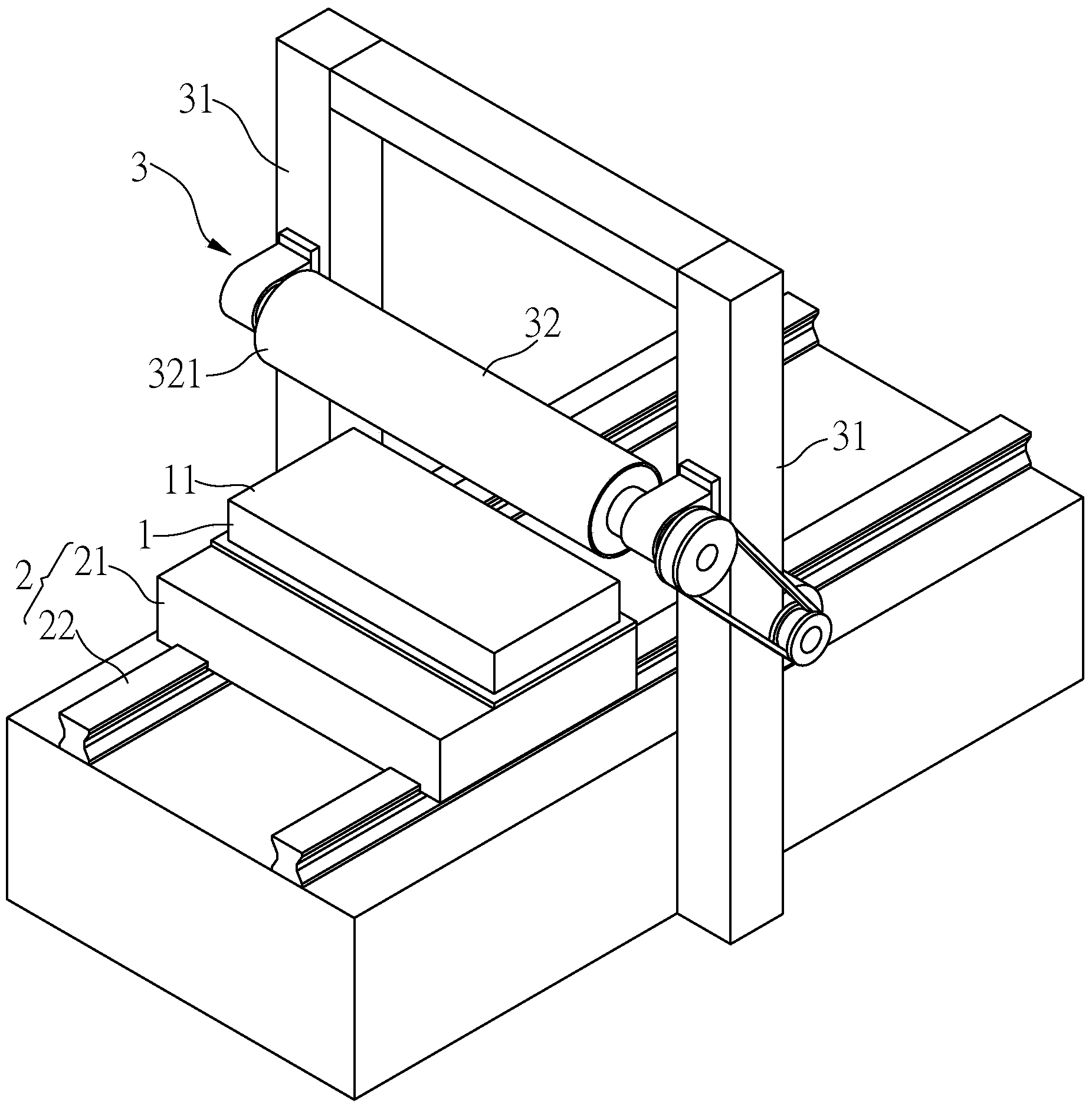

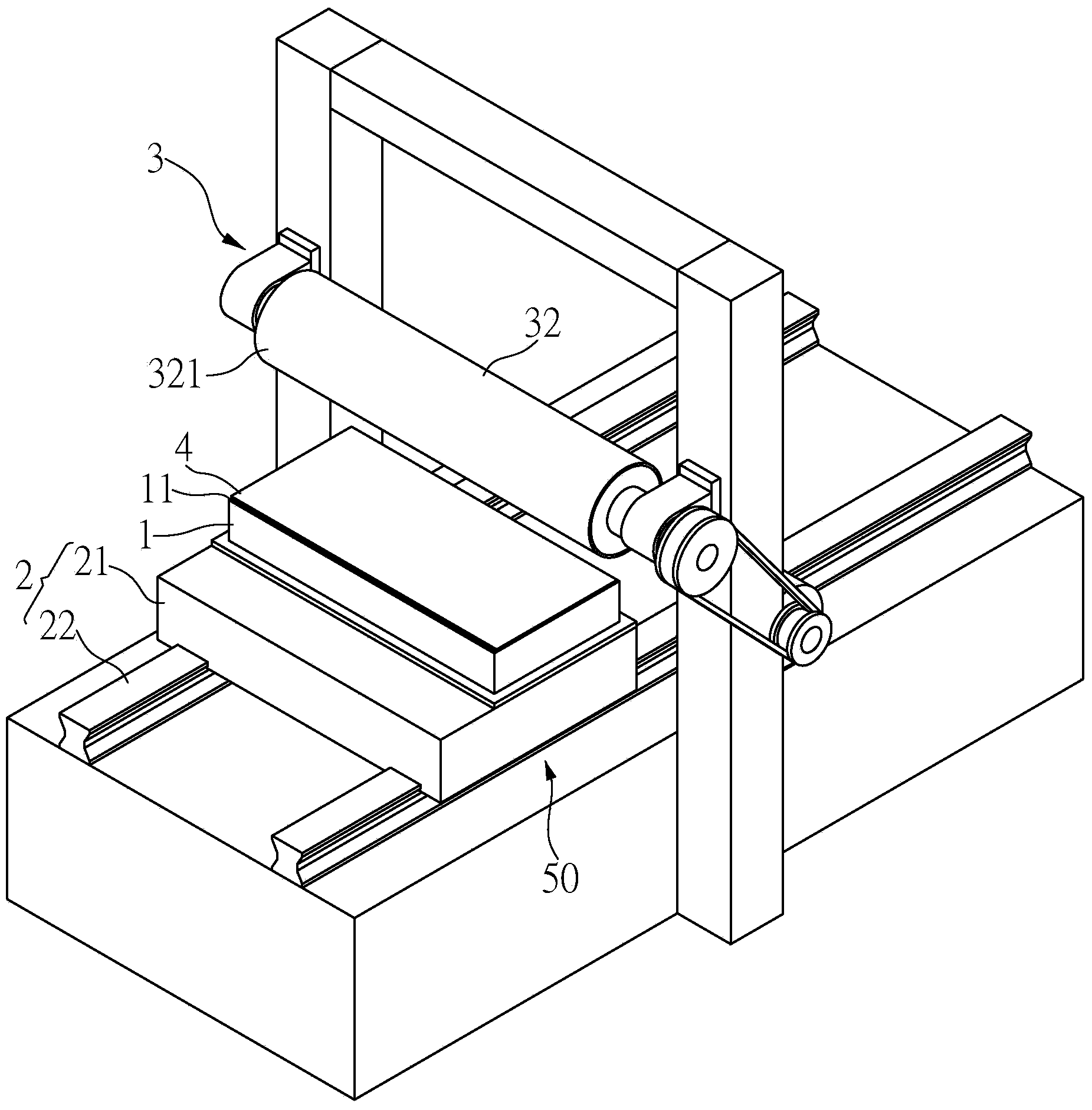

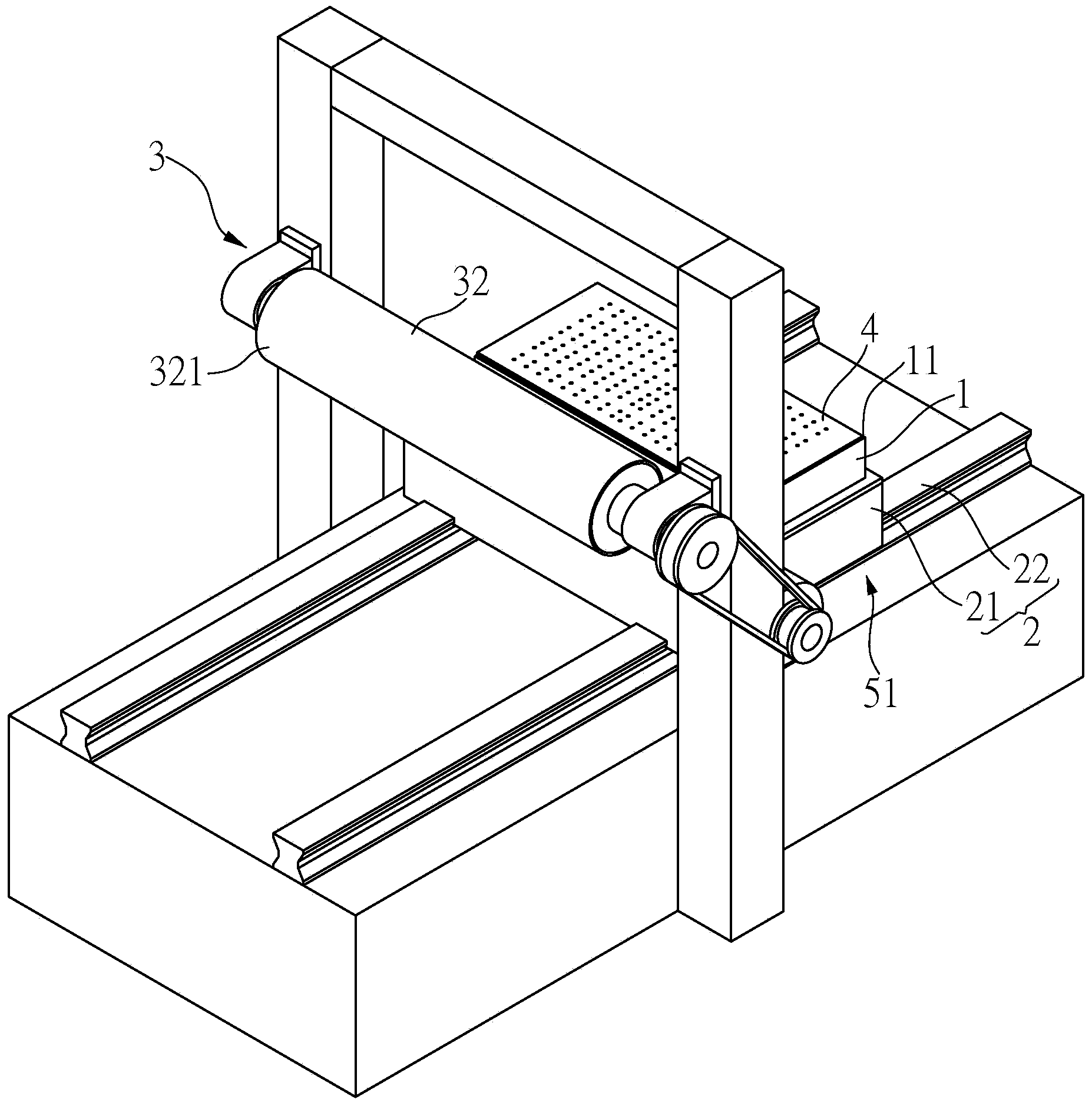

[0021] see figure 1 , which is a device for forming a circuit on a touch panel provided by the present invention, used for printing a circuit on the surface of a flexible substrate, the device includes a plane mold 1, and its top surface is a substrate for a (not shown in the figure) placed pressure surface 11; the plane mold 1 can be heated to a working temperature, so that the substrate placed on it increases flexibility due to heating. The planar mold 1 can be displaced by a sliding means. In this embodiment, the planar mold 1 is arranged on a sliding device 2. As shown in the figure, the sliding device 2 includes a sliding seat 21, which can be moved along the A track 22 is driven to slide.

[0022] And the top of the plane mold 1 is provided with a roller heat press device 3, the roller heat press device 3 is provided with a support 31 on both sides of the track 22, and a rotatable cylinder 32 is arranged on the support 31, and the cylinder 32 is placed horizontally on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com