A power selection device with a manually operated dial shaft

A technology for manual operation and selection of devices, which is applied in the direction of control devices, transportation and packaging, and vehicle parts, and can solve problems such as small dimensions, complex structures, and inability to ensure the engagement of engaging elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

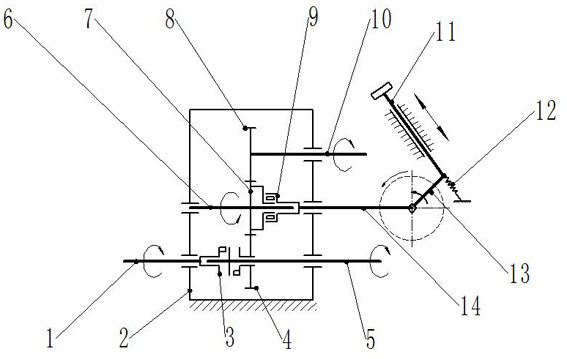

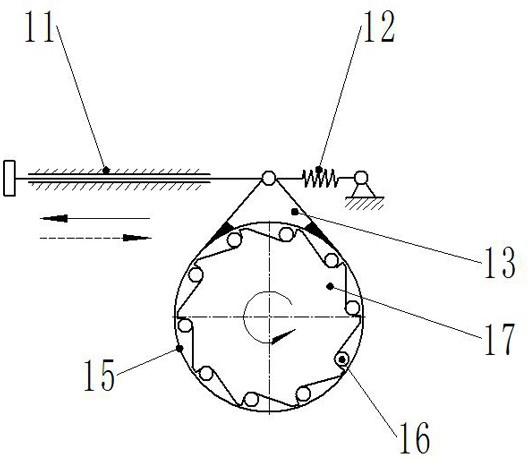

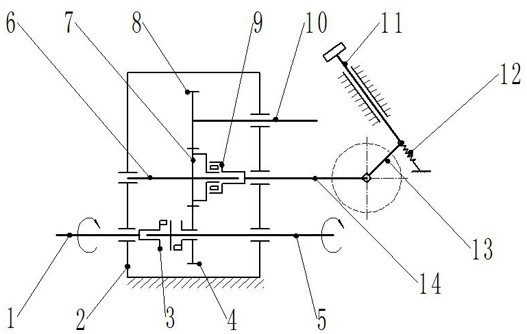

[0016] refer to Figure 1 to Figure 6 The invention is further elaborated, the upper, middle and lower axes are distributed in the box body 2, the motor input shaft 10 and the motor input shaft gear 8 are arranged at the upper axis, and the motor input shaft gear 8 is fixed on the motor input shaft 10, and the motor input shaft gear 8 is fixed on the motor input shaft 10. The shaft 10 rotates together; the central axis is provided with an intermediate gear shaft 6, an intermediate shaft gear 7 and a one-way overrunning clutch 9. The intermediate shaft gear 7 is fixed on the intermediate gear shaft 6 and rotates together with the intermediate gear shaft 6. The one-way overrunning clutch 9 The inner star wheel 17 of the one-way overrunning clutch and the countershaft gear 7 are fixed together and rotate together with the countershaft gear 7. The countershaft gear 7 meshes with the motor input shaft gear 8, and the one-way overrunning in the one-way overrunning clutch 9 The clutc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com