A hollow line design method for automobile glass screen

A design method and technology for automotive glass, which can be applied in motor vehicles, transportation and packaging, etc., can solve the problems of high labor cost, high labor intensity of employees, and large labor volume, and achieve reduced pretreatment work, guaranteed quality and safety, and reduced personnel. Configure the effect of reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

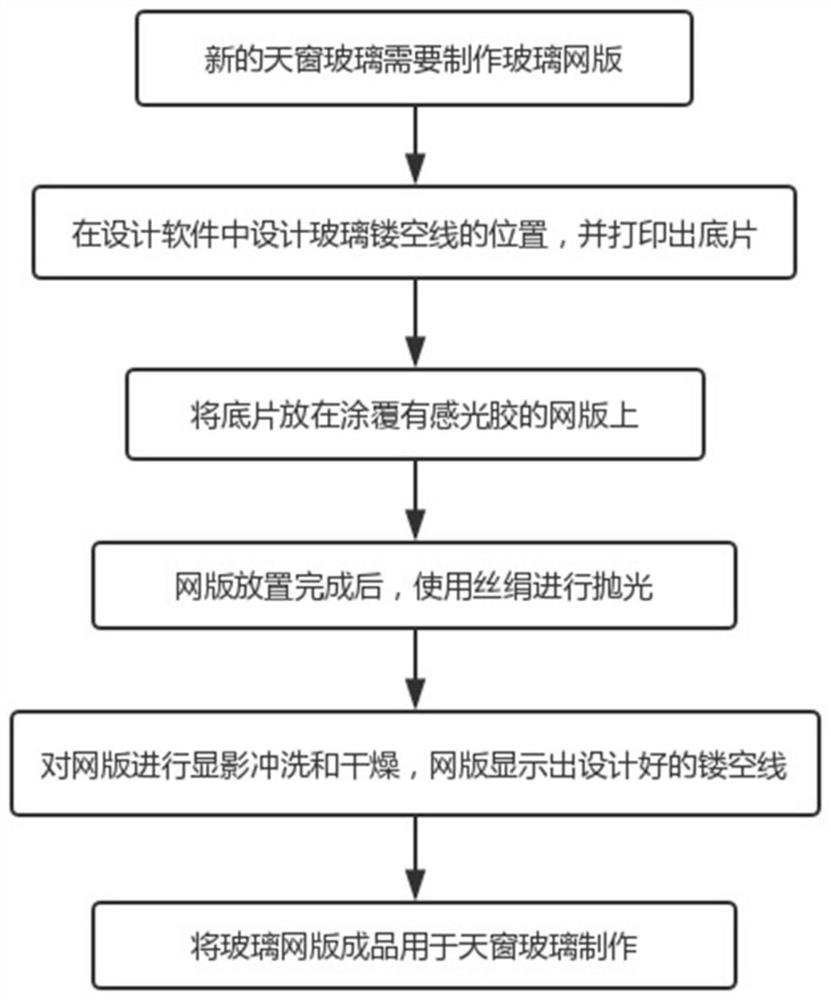

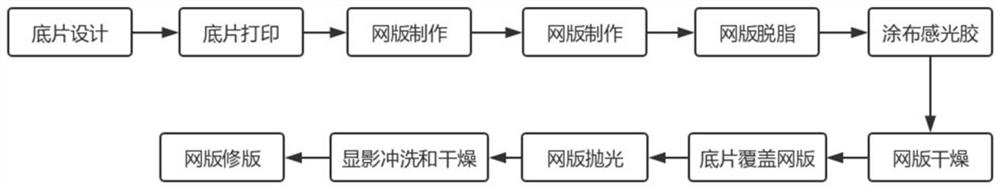

[0045] like figure 2 As shown, first design the position of the hollow line in the CAD software, and print out the negative, then select the mesh and frame according to the material of the glass, use the pneumatic stretcher to make the screen, and degrease the screen. Coat the photosensitive adhesive on the screen, dry it in the environment of 45 degrees, put the negative film on the dried screen, and then polish the screen, develop, rinse and dry the screen after polishing. The hollowed-out marking line corresponding to the designed hollowed-out line in the film can be displayed on the plate, which can be used for the production of skylight glass after the revision is completed. Because the trajectory of the hollow line is clear, the control of the primer trajectory is more accurate.

Embodiment 2

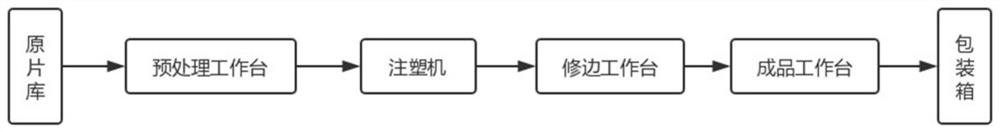

[0047] like image 3 As shown, according to the prepared glass screen with hollow marking lines, the glass raw materials are pretreated first, and then sent to the injection molding machine for processing. The excess raw materials can be buffered in the pretreated workbench. The edge workbench is used for edge trimming and cleaning, and the inspection tools are used to check the qualified rate of the finished glass, and finally the finished workbench is handed over to the finished workbench to coat and pack the finished glass of the skylight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com