Floor heating insulation board and floor heating system

A thermal insulation board and floor heating technology, which is applied in the field of decoration and decoration, can solve the problems of thermal insulation board bursting, high space occupation, and long working time, and achieve the effects of preventing moisture deterioration, increasing load-bearing capacity, and reducing loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0030] Embodiment one

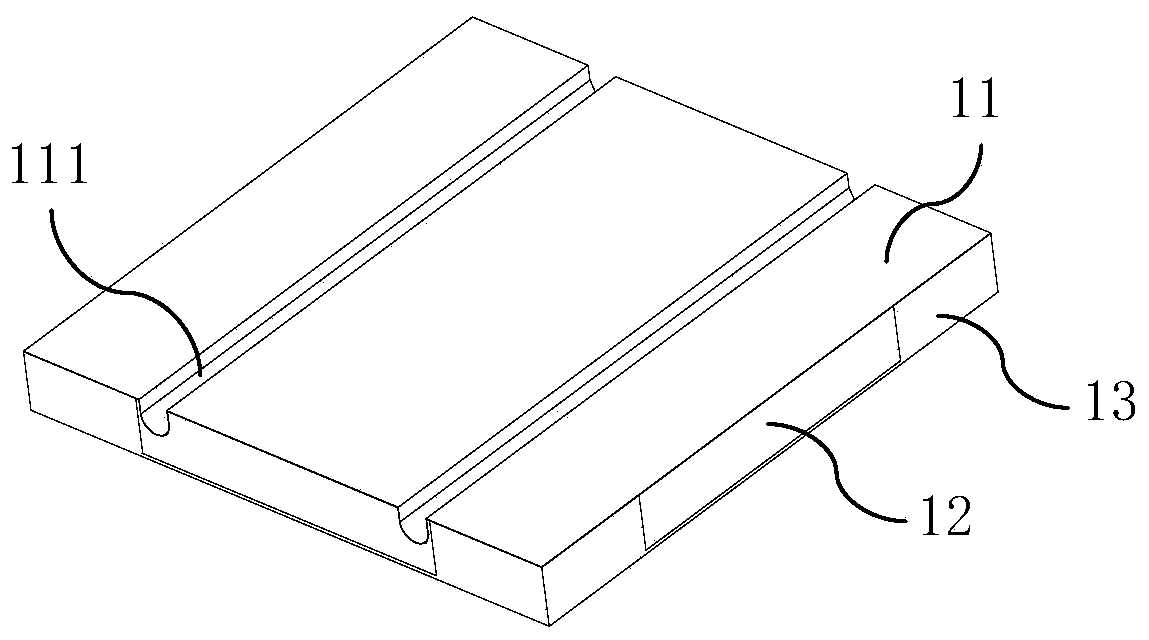

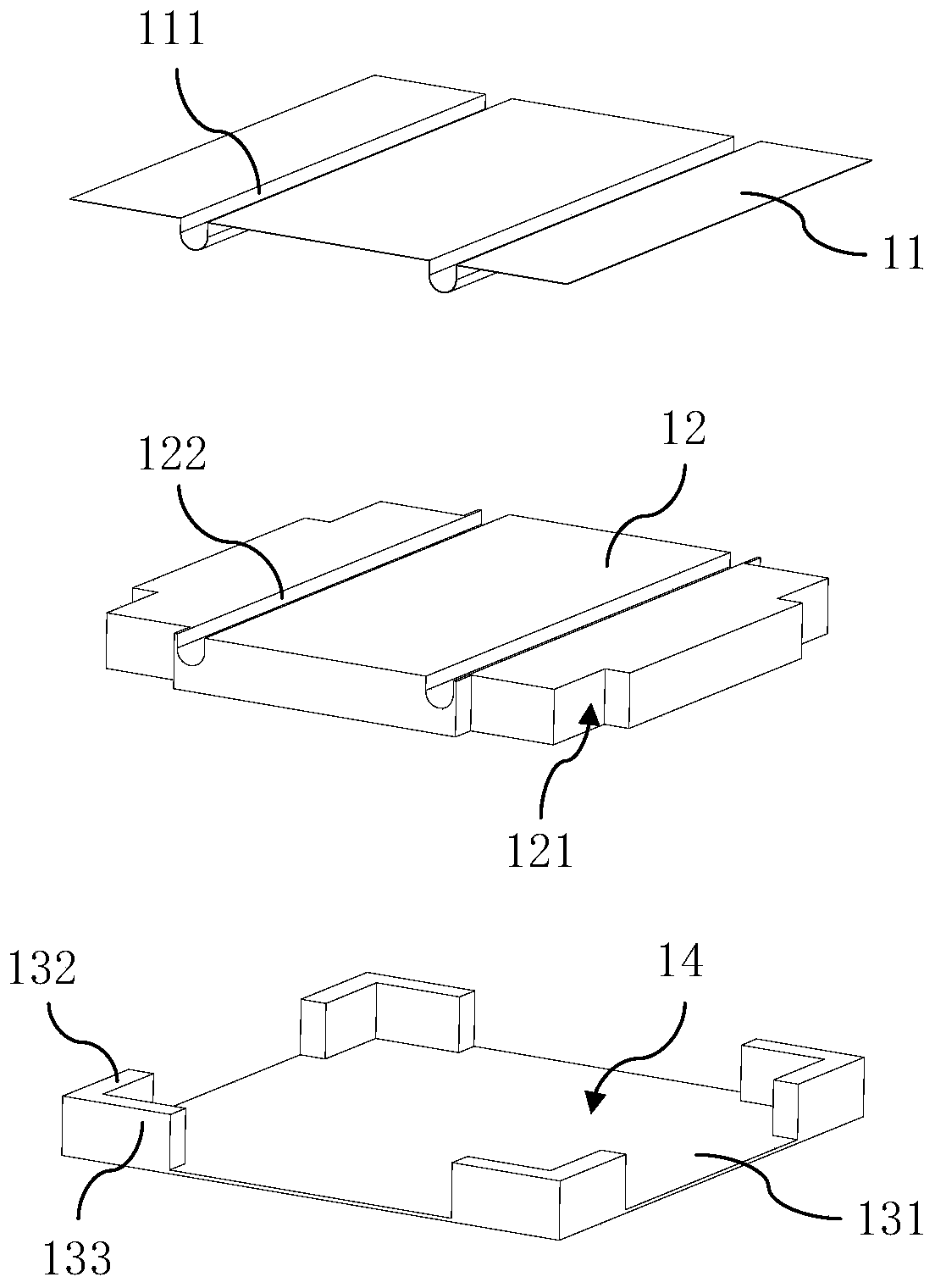

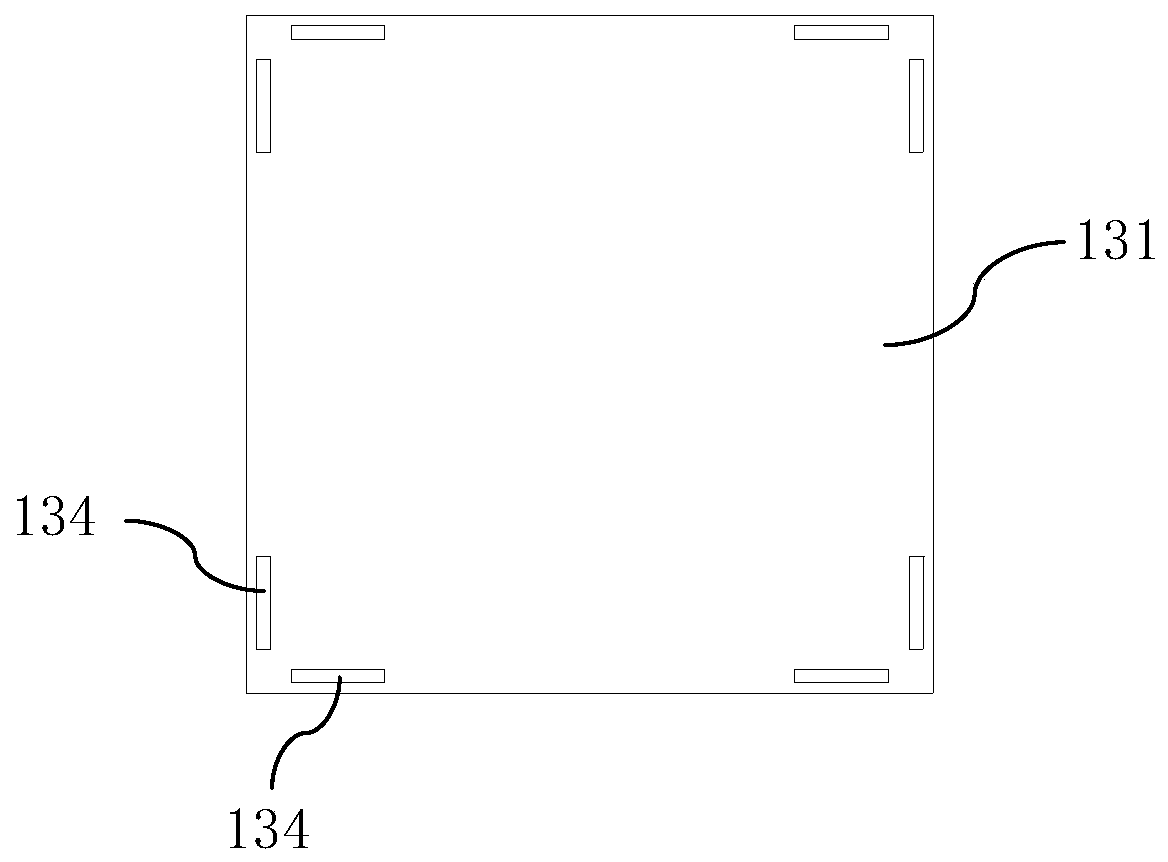

[0031] like Figure 1-Figure 3 as shown, figure 1 It is a schematic structural diagram of a floor heating insulation board provided in Embodiment 1 of the present invention, figure 2 Yes figure 1 explosion map, image 3 Yes figure 1 The bottom view of the shown support plate, the floor heating and heat preservation plate includes a heat dissipation plate 11, a heat preservation plate body 12 and a support plate 13 sequentially connected from top to bottom, the support plate 13 includes a base plate 131, and the top of the base plate 131 is provided with a protrusion ( (not shown in the figure), the accommodation cavity 14 for accommodating the insulation board body 12 is formed between the base plate 131 and the heat dissipation plate 11 through protrusions.

[0032] The heat dissipation plate 11 is used to diffuse the heat on the insulation plate body 12 to achieve a rapid heat dissipation effect, which is more energy-saving and environment-frien...

Example Embodiment

[0053] Embodiment two

[0054] On the basis of the first embodiment, the second embodiment is a floor heating system structure including the first embodiment, so the same parts as the first embodiment will not be repeated. like Figure 4 As shown, the floor heating system includes a plurality of floor heating insulation panels 10 as described above, and the plurality of floor heating insulation panels 10 are spliced with each other.

[0055] When paving the floor heating system, multiple floor heating insulation boards 10 are sequentially spliced into a joint plane, and the extension direction of the second groove 111 on any two floor heating insulation boards 10 is guaranteed to be consistent. The conduction between the parallel grooves can be realized by laying two adjacent floor heating insulation boards 10 provided with two floor heating insulation boards 10 with double elbow grooves. For the inflection point, starting point, and end point of the circuit, the floor h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com