Electromagnetic membrane pump

A diaphragm pump and electromagnetic technology, applied in the direction of pumps, pump components, variable capacity pump components, etc., can solve the problems of pump surface temperature rise, affecting product life, and becoming smaller, etc., to reduce the pump surface temperature and stabilize the pump body. The effect of pumped liquid flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

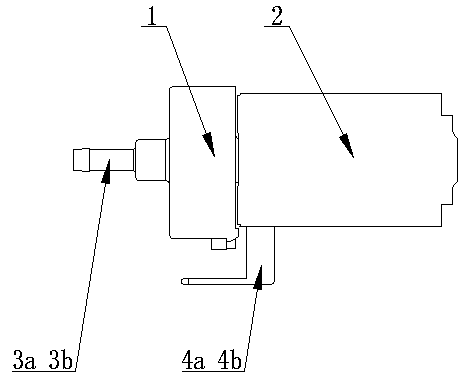

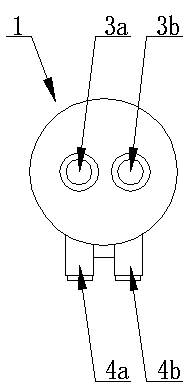

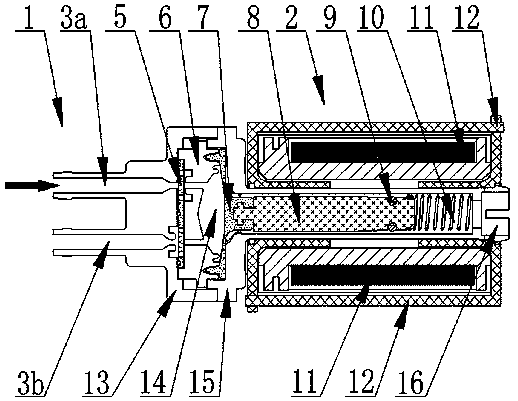

[0028] In this specific example, as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, an electromagnetic diaphragm pump includes a pump body 1 and an electromagnet 2;

[0029] The pump body 1 is set in a "T" shape as a whole, including an outer pump sleeve 13 and an inner pump sleeve 15, and the outer pump sleeve 13 and the inner pump sleeve 15 can be tightly combined and separated;

[0030] The left end of the outer pump sleeve 13 is fixedly provided with a pair of liquid inlet and outlet pipes 3a, 3b, and the pair of liquid inlet and outlet pipes 3a, 3b includes a liquid inlet pipe 3a and a liquid outlet pipe 3b;

[0031] A pump seat 6 is movable in the cavity formed by the tight combination of the outer pump sleeve 13 and the inner pump sleeve 15, and the outer pump sleeve 13 and the pump seat 6 are tightly combined to form a one-way valve cavity 18, The upper part of the one-way valve cavity 18 is composed of an "E"-shaped cavity 18a slight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com