Gas conveying pipe network pressure maintaining detection method and system

A detection method and delivery pipe technology, applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of repeated investment, low work efficiency, and low detection accuracy, so as to improve enterprise management level and reduce manpower The effect of input cost and guarantee of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

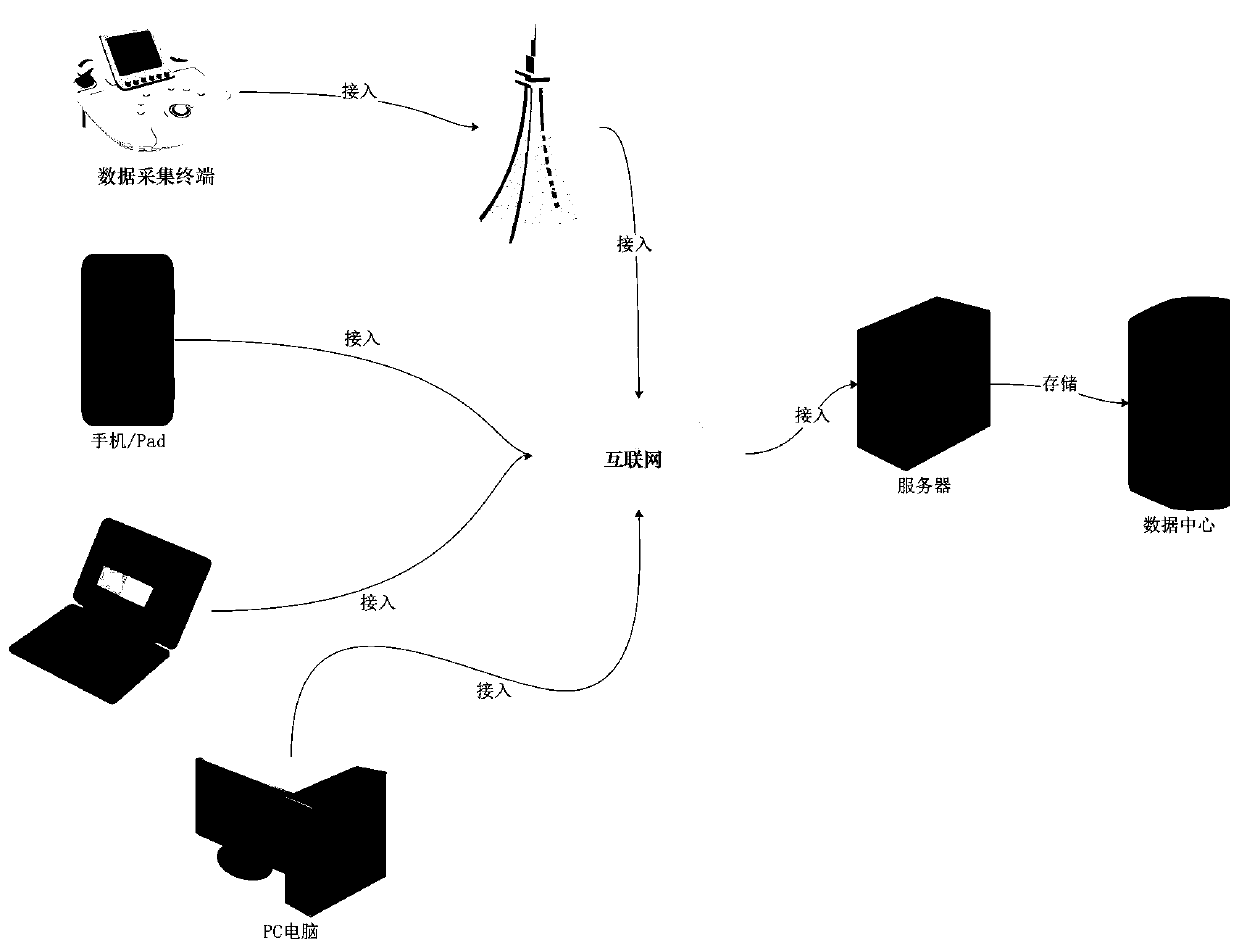

Method used

Image

Examples

Embodiment 1

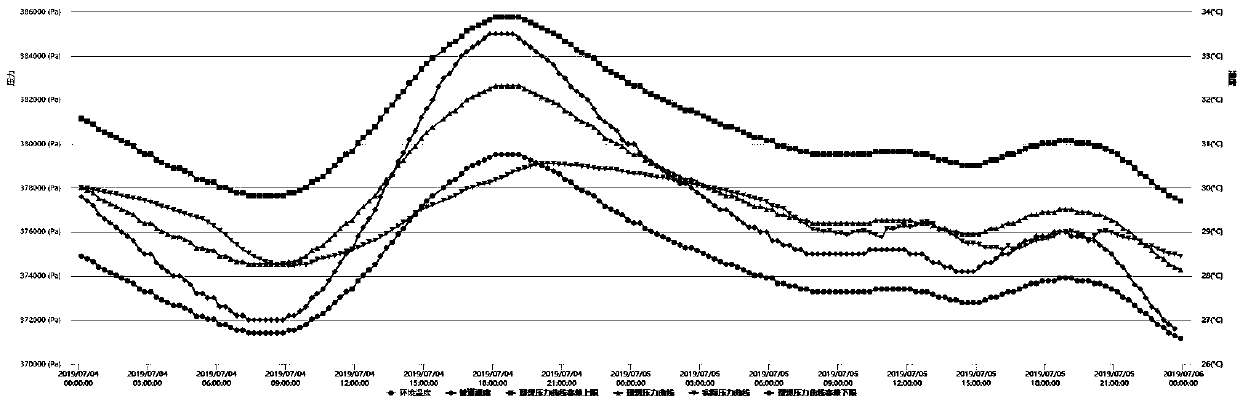

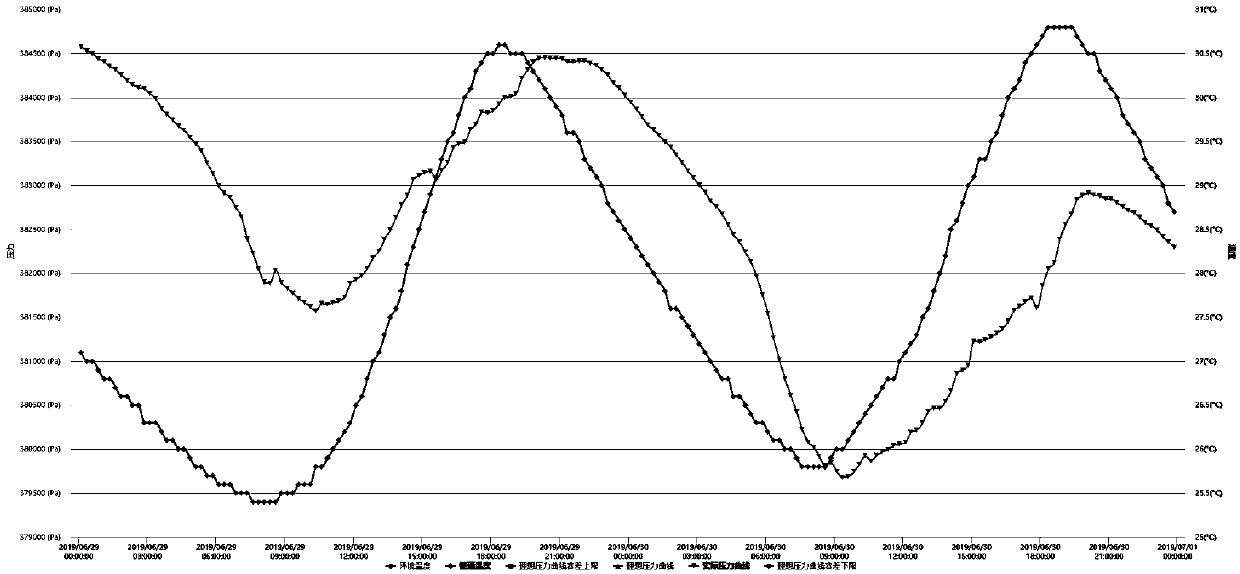

[0030] A pressure-holding detection method for a gas delivery pipeline network, the pressure-holding detection method comprising: constructing a temperature-pressure pressure-holding detection model of a gas delivery pipeline to be tested, and collecting the actual temperature value and temperature in the gas delivery pipeline to be tested through a data acquisition terminal The actual pressure value, according to the temperature-pressure holding detection model and the actual temperature value, obtain the ideal pressure value in the gas delivery pipeline to be tested; calculate the pressure error value and temperature error value of the data acquisition terminal, according to the pressure Error value, the temperature error value and the ideal pressure value, calculate the ideal pressure tolerance upper limit value and the ideal pressure tolerance lower limit value; within the preset time, if the actual pressure value inside the gas delivery pipeline to be measured is within If...

Embodiment 2

[0052] The difference between this embodiment and the above-mentioned embodiment is that the pressure maintaining detection method further includes: calculating the pressure drop in the gas delivery pipeline to be tested, and judging whether the tightness of the gas delivery pipeline to be tested is qualified according to the pressure drop; The upper limit value of the ideal pressure tolerance and the lower limit value of the ideal pressure tolerance determine that the airtightness of the gas delivery pipeline to be tested is qualified, and the airtightness of the gas delivery pipeline to be tested is determined to be qualified according to the pressure drop, then the airtightness of the gas delivery pipeline to be tested is determined Qualified; otherwise, it is determined that the tightness of the gas delivery pipeline to be tested is unqualified. Wherein, the unqualified sealing performance indicates that the gas delivery pipeline to be tested is in a leaking state.

[0053...

Embodiment 3

[0060] The difference between this embodiment and Embodiment 2 is that the pressure holding detection method further includes: calculating the actual pressure difference inside the gas delivery pipeline to be tested under the same actual temperature value, and determining the pressure to be tested according to the actual pressure difference. Whether the tightness of the gas delivery pipeline is qualified; if the tightness of the gas delivery pipeline to be tested is determined to be qualified according to the upper limit of the ideal pressure tolerance and the lower limit of the ideal pressure tolerance, and the tightness of the gas delivery pipeline to be tested is determined according to the actual pressure difference If the airtightness of the gas delivery pipeline to be tested is qualified, it is determined that the airtightness of the gas delivery pipeline to be tested is qualified; otherwise, it is determined that the airtightness of the gas delivery pipeline to be tested ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com