A multi-channel continuous pressure water supply type water heating equipment

A water heating and multi-channel technology, applied in lighting and heating equipment, water heaters, mechanical equipment, etc., can solve the problems of weak continuous water output, low power, low water pressure of water heating devices, etc., to shorten the heating time, The heating speed is fast and the effect of reducing the waste of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

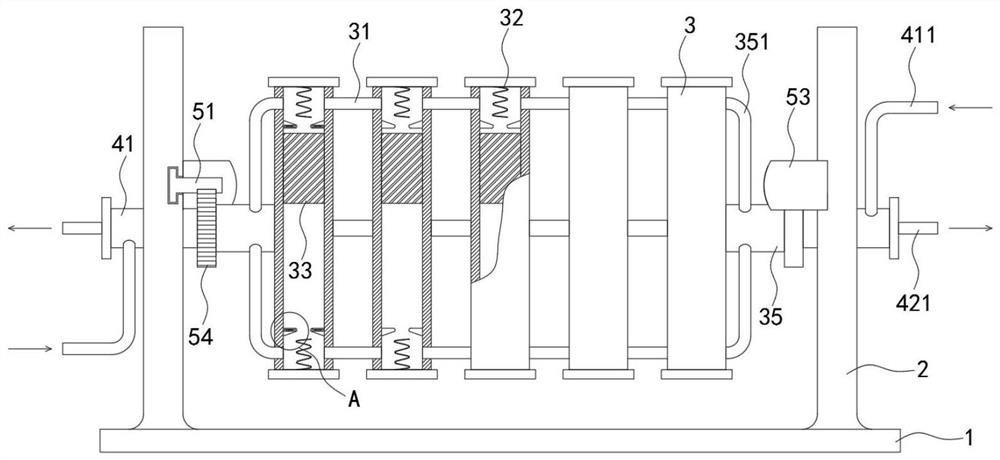

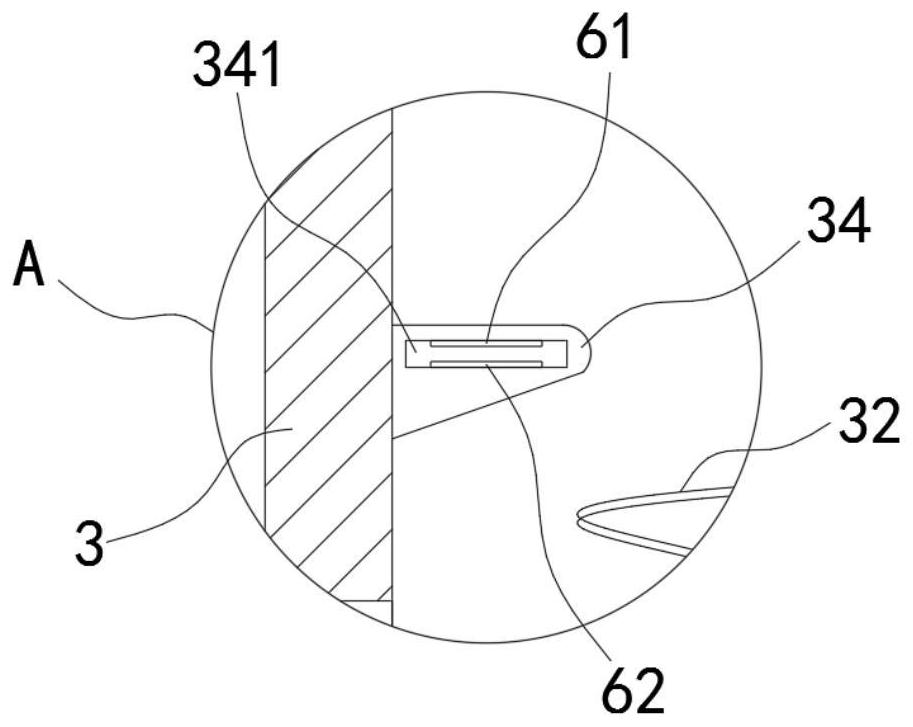

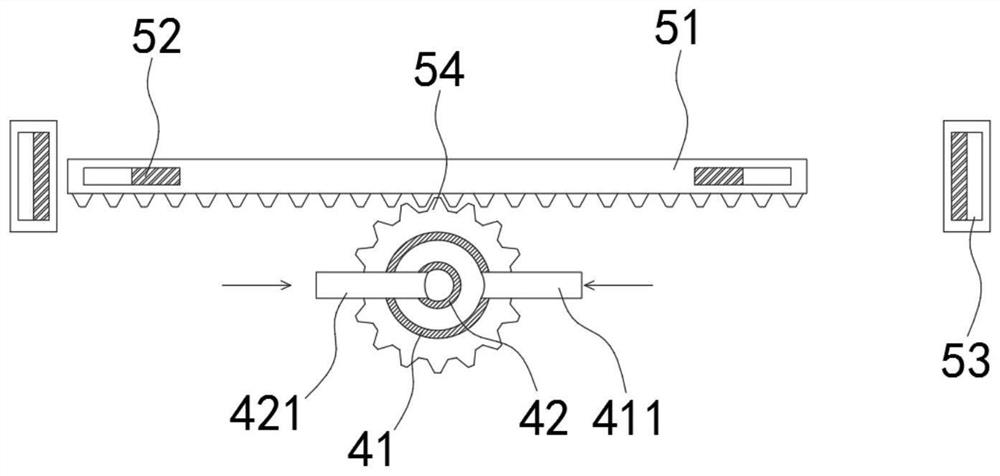

[0035] Such as Figure 1-3 As shown, a multi-channel continuous steady-pressure water supply type water heating equipment includes a base 1, and both sides of the upper end of the base 1 are fixedly connected with a fixing frame 2, and a circulation mechanism is installed on the fixing frame 2, between the two fixing frames 2 There are multiple sets of heating tubes 3 arranged side by side, and the adjacent heating tubes 3 are connected through a plurality of connecting tubes 31. The fixing frame 2 is provided with a driving mechanism for driving the heating tubes 3 to turn over. The heating tubes 3 are provided with:

[0036] Two heating wires 32 are fixedly installed at both ends of the heating tube 3 respectively;

[0037] Counterweight slider 33, counterweight slider 33 is arranged between two electric heating wires 32, and counterweight slider 33 is connected with the inner wall of heating tube 3 in a sliding seal, and counterweight slider 33 can adopt high temperature re...

Embodiment 2

[0046] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the trigger switch includes an upper conductive sheet 71 arranged on the upper side wall of the cavity 341, and a lower conductive sheet 72 is arranged on the lower side wall of the cavity 341, and the lower conductive sheet 72 is arranged on the lower side wall of the cavity 341. The upper end of the sheet 72 is fixedly connected with a magnetic conductive sheet 74 via a spring 73 , and the counterweight slider 33 is embedded with a permanent magnet block that attracts opposite poles of the magnetic conductive sheet 74 .

[0047] In this embodiment, by embedding permanent magnets in the counterweight slider 33 , not only the trigger sensitivity to the trigger switch can be improved, but also the water body can be magnetized under the action of the permanent magnets to reduce the generation of scale.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com