A device and method for detecting backlash in a spiral bevel gear assembly

A technology of spiral bevel gears and detection devices, which is applied in measuring devices and instruments, can solve problems such as complex backlash, troublesome operation, and complex structure of spiral bevel gears, so as to improve the installation qualification rate and reduce meshing abnormal noise and the effect of wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

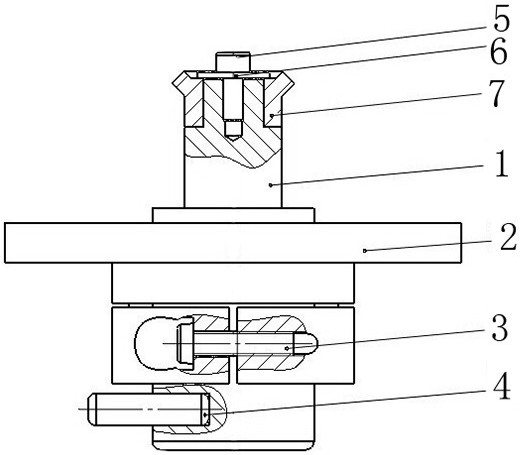

[0032] Embodiment 1: A backlash detection device for spiral bevel gear assembly, such as figure 1 shown.

[0033] A backlash detection device for spiral bevel gear assembly, comprising an adjustment support rod 4, a first bolt 3, a positioning flange 2, an adjustment shaft 1, a gasket 6 and a second bolt 5, and the positioning flange 2 is sleeved on the adjustment shaft 1 outside, the first bolt 3 is installed at the lower part of the positioning flange, the adjusting rod 4 is installed at the lower part of the adjusting shaft 1, and the arc gear 7 to be tested is fixed at the shaft end of the adjusting shaft 1 through the gasket 6 and the second bolt 5.

[0034] In this embodiment, the function of the adjustment rod 4 is to assist the rotation of the adjustment shaft 1 during the adjustment process, which is convenient for operation; the function of the first bolt 3 is to realize the axial stop function of clamping the adjustment shaft 1 adjusted to the theoretical position; ...

Embodiment 2

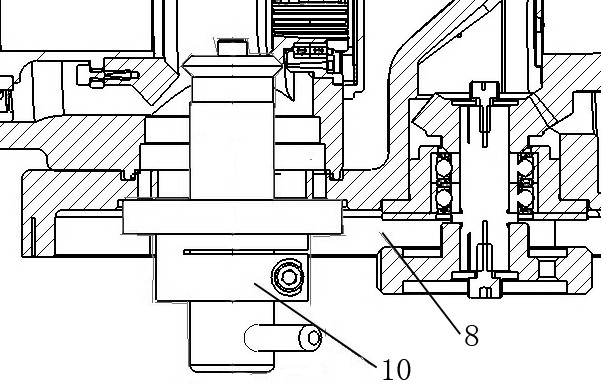

[0035] Embodiment 2: A method for detecting backlash in a spiral bevel gear assembly, such as Figure 1-5 shown.

[0036] A method for detecting the backlash of a spiral bevel gear assembly, using the robot joint body 8 pre-installed with the bevel gear and the detection device for the assembly of the spiral bevel gear described in Embodiment 1 to detect the detection size, the specific steps are as follows:

[0037] S1, pre-install and lock the arc gear 7 to be tested to the shaft end of the adjustment shaft 1, and ensure that the shoulder of the adjustment shaft 1 and the end face of the arc gear 7 fit tightly without gaps to avoid measurement errors;

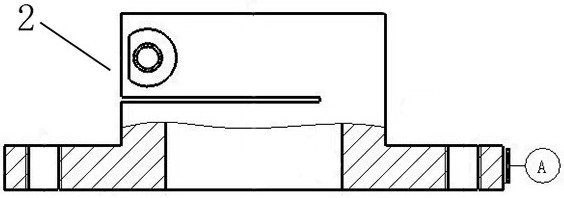

[0038] S2, install the positioning flange 2 on the adjustment shaft 1, the end face of the positioning flange 2 is the installation datum plane, and the outer circular surface of A is the centering datum (such as figure 2 As shown), realize the function of simulating the installation conditions of the original pre-installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com