High-frequency power amplifier

A power amplifying and high-frequency technology, applied in the field of high-frequency power amplifying devices, can solve the problems that the capturing cylinder 32 cannot be reliably vacuum-adsorbed to hold and transport the hollow coil 9, the vacuum adsorption force of the capturing cylinder is increased, and the coil arrangement is disordered, etc. Installation cost, efficient installation work, and the effect of reliable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0127] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. In addition, in all the drawings for explaining the embodiments of the present invention, parts having the same functions are denoted by the same reference numerals, and overlapping descriptions are omitted.

[0128] (Embodiment 1)

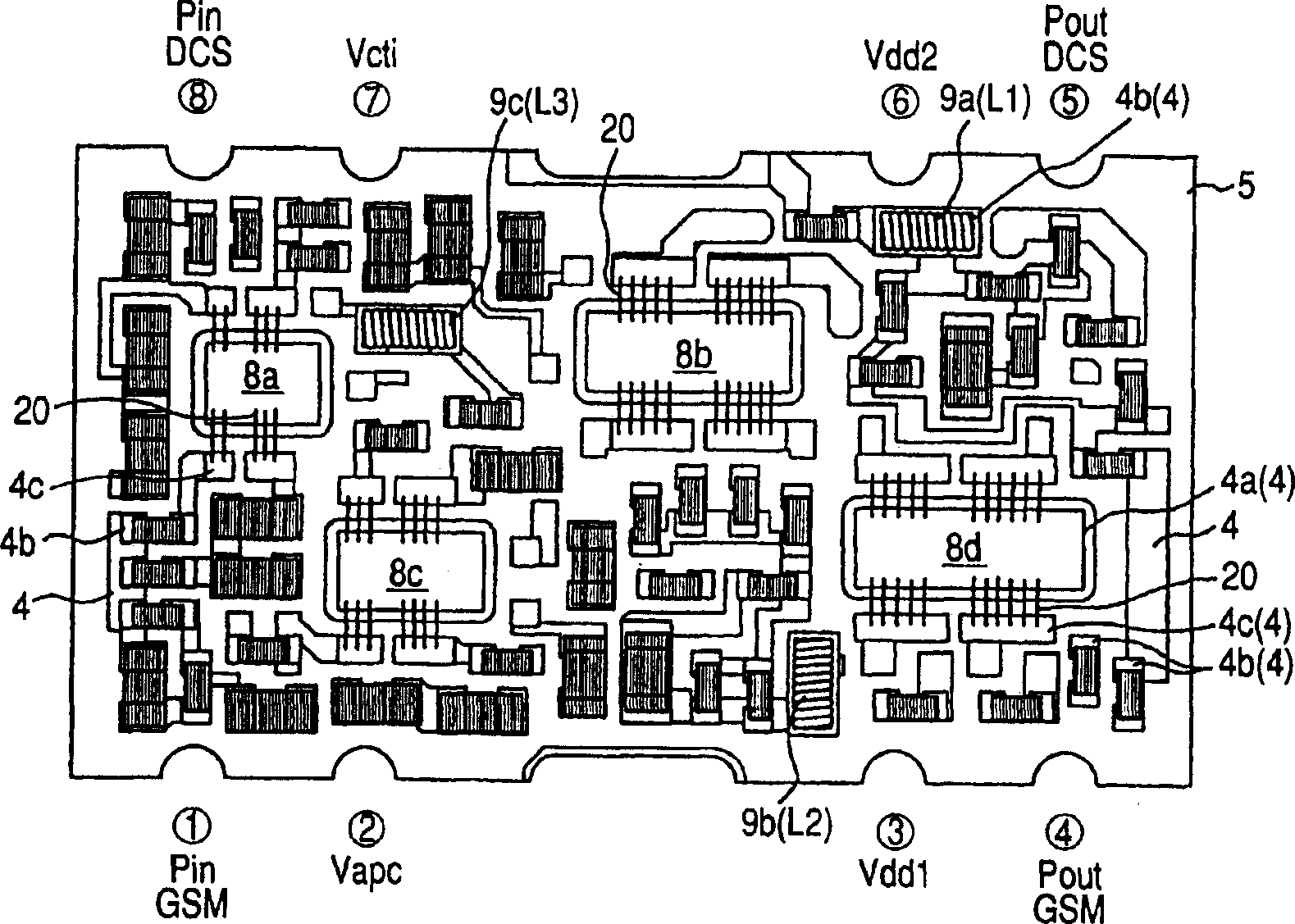

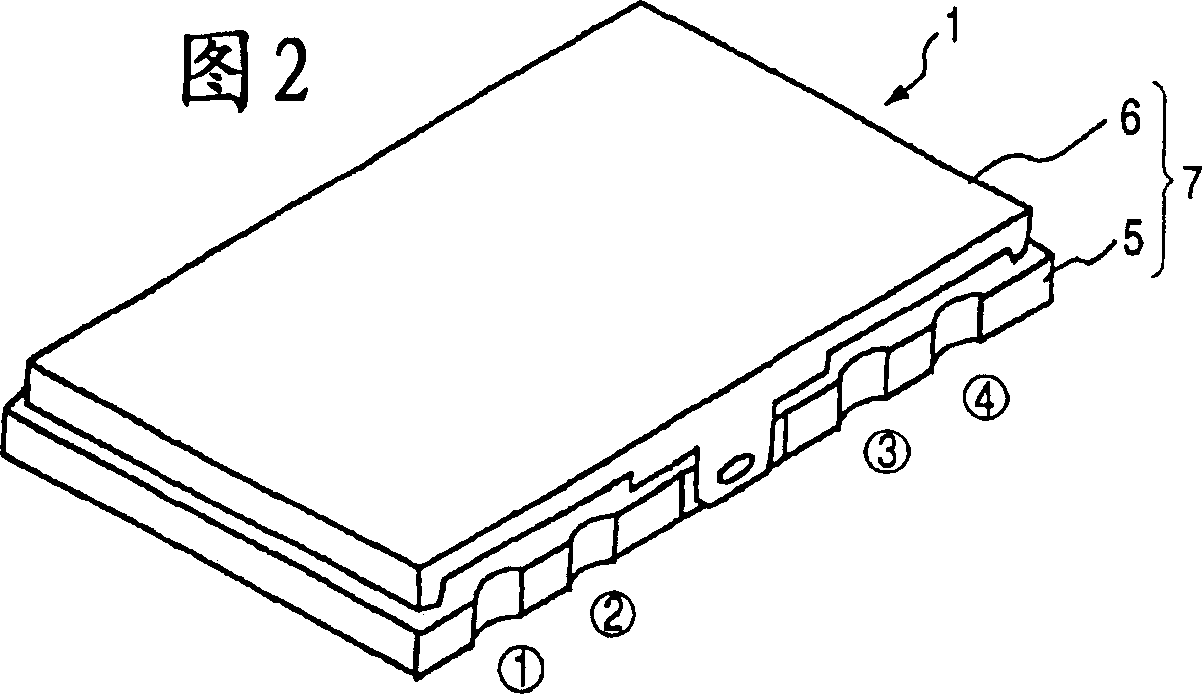

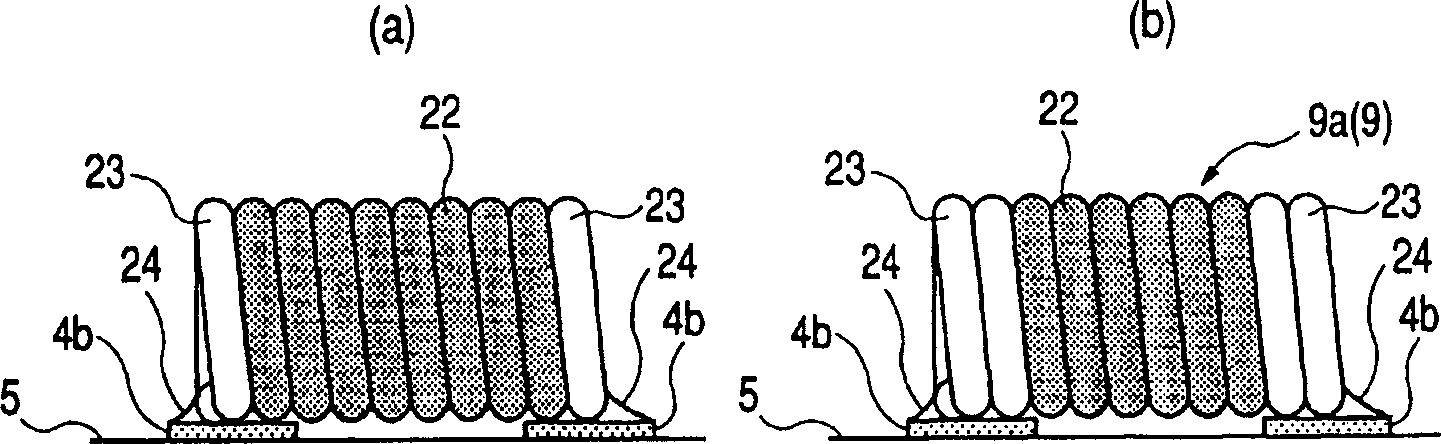

[0129] Figure 1 to Figure 31 It is a diagram of a semiconductor device (high-frequency power amplifying device) and its manufacturing technology and a wireless communication device (electronic device) according to one embodiment (Embodiment 1) of the present invention.

[0130] In Embodiment 1, an example in which the present invention is applied to a high-frequency power amplifying device (hybrid integrated circuit device) as a semiconductor device will be described. The high-frequency power amplifying device of the first embodiment is for dual-band, and is a high-frequency power amplifying device for dual-band built in, for exa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com