Oil tube sealing cap swelling riveting pressing device

A technology of press-fitting device and sealing cap, which is applied in the field of oil pipe sealing cap riveting press-fitting device, can solve the problems that cannot be completely guaranteed not to fall off, and achieve the effect of not being easy to make mistakes, preventing falling off, and accurate product size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

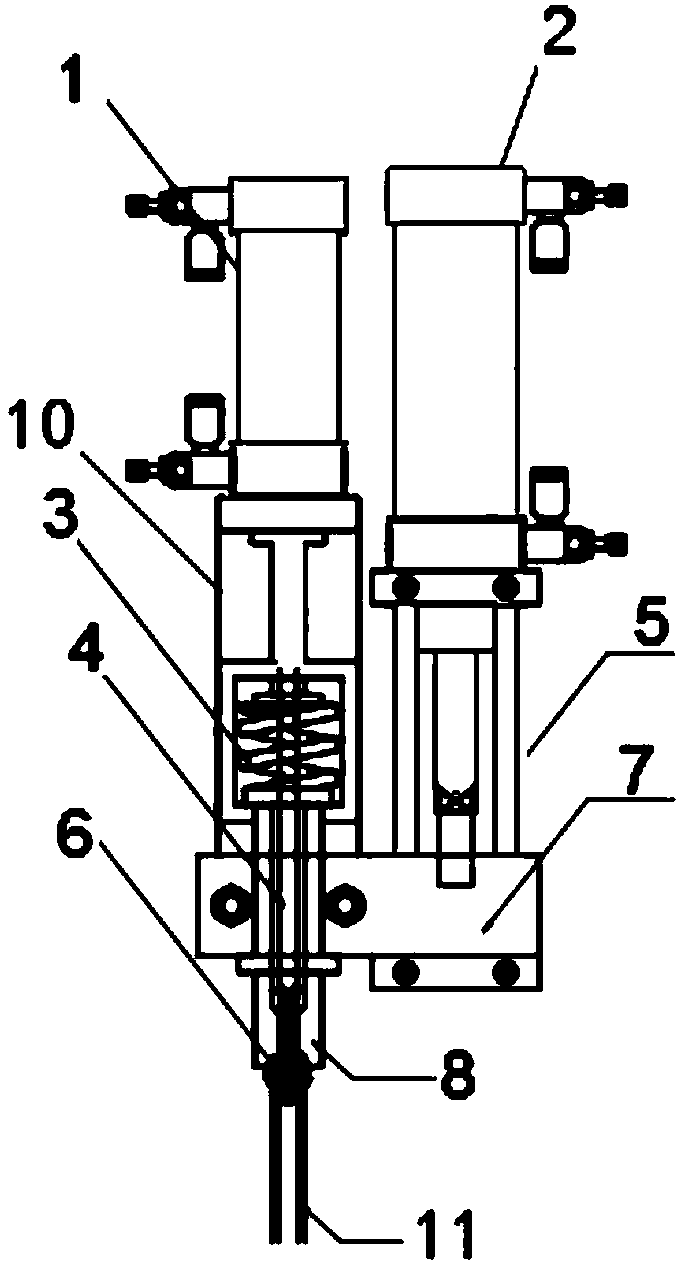

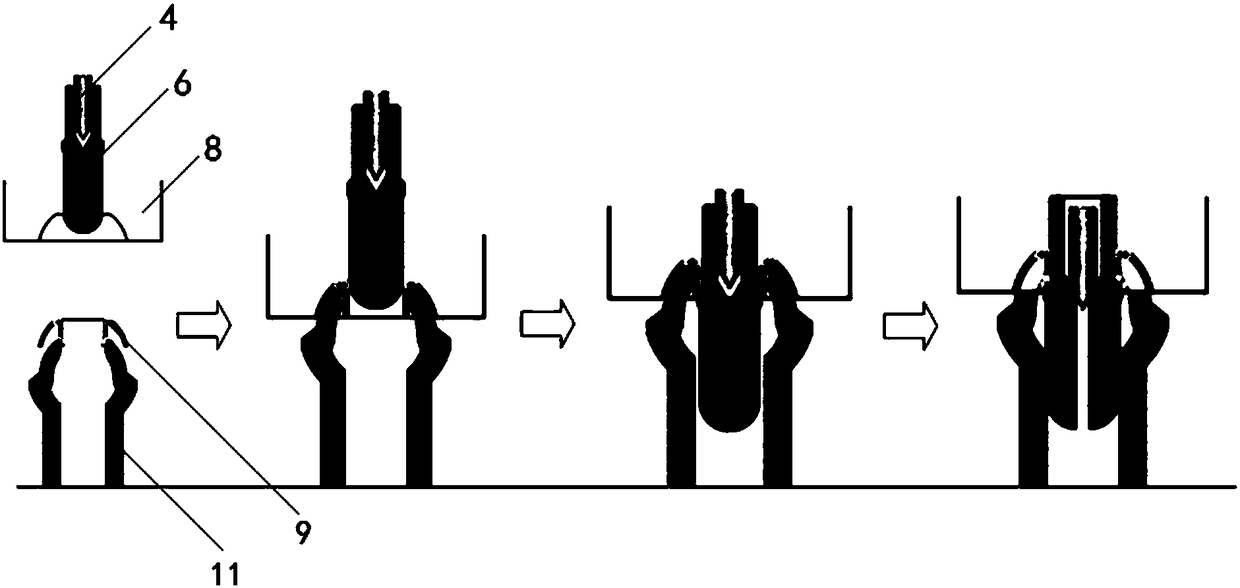

[0021] like figure 1 , a kind of riveting and pressing device for oil pipe sealing cap, including a riveting cylinder assembly and an expansion cylinder assembly arranged side by side, the riveting cylinder assembly and the expansion cylinder assembly are connected by a cylinder bracket 7 arranged at their lower parts, the riveting cylinder assembly includes a pressure riveting cylinder assembly The riveting cylinder 2 and the linear guide rail 5 located at the bottom of the riveting cylinder 2, the output shaft of the riveting cylinder 2 is connected to the cylinder bracket 7, the expansion cylinder assembly includes an expansion cylinder 1 and a connecting bracket 10, and the stretching cylinder assembly is connected to the connecting bracket 10 and The cylinder bracket 7 is connected. The cylinder support 7 is provided with a press-fitting die 8, the press-fitting die 8 is provided with a riveting mandrel 6, and the riveting mandrel 6 is provided with an expansion mandrel 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com