Backflow time and regeneration volume testing system and method for composite dryer

A test system, dryer technology, applied in machine/structural component testing, vehicle testing, mechanical component testing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

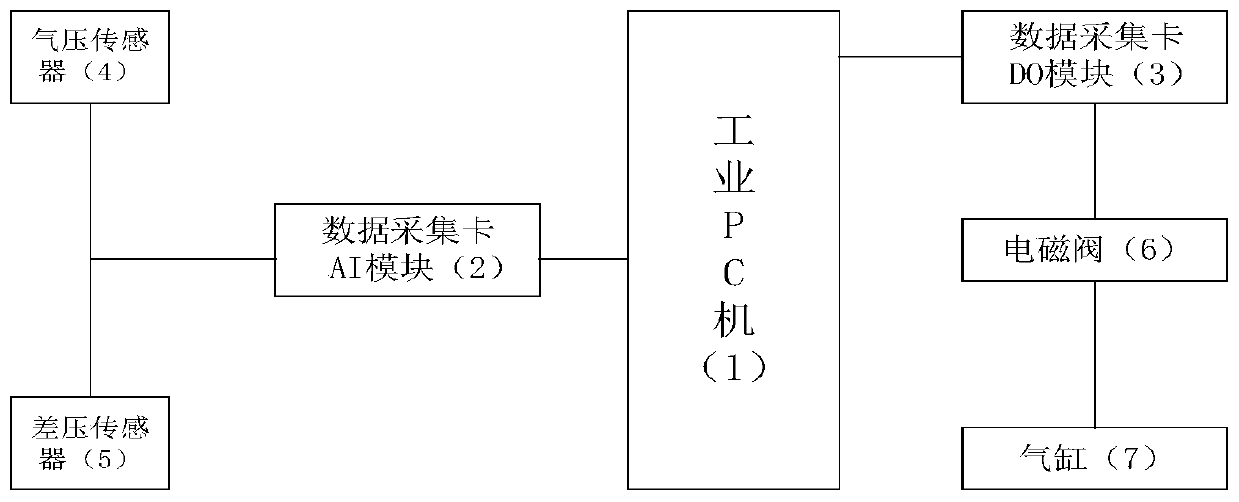

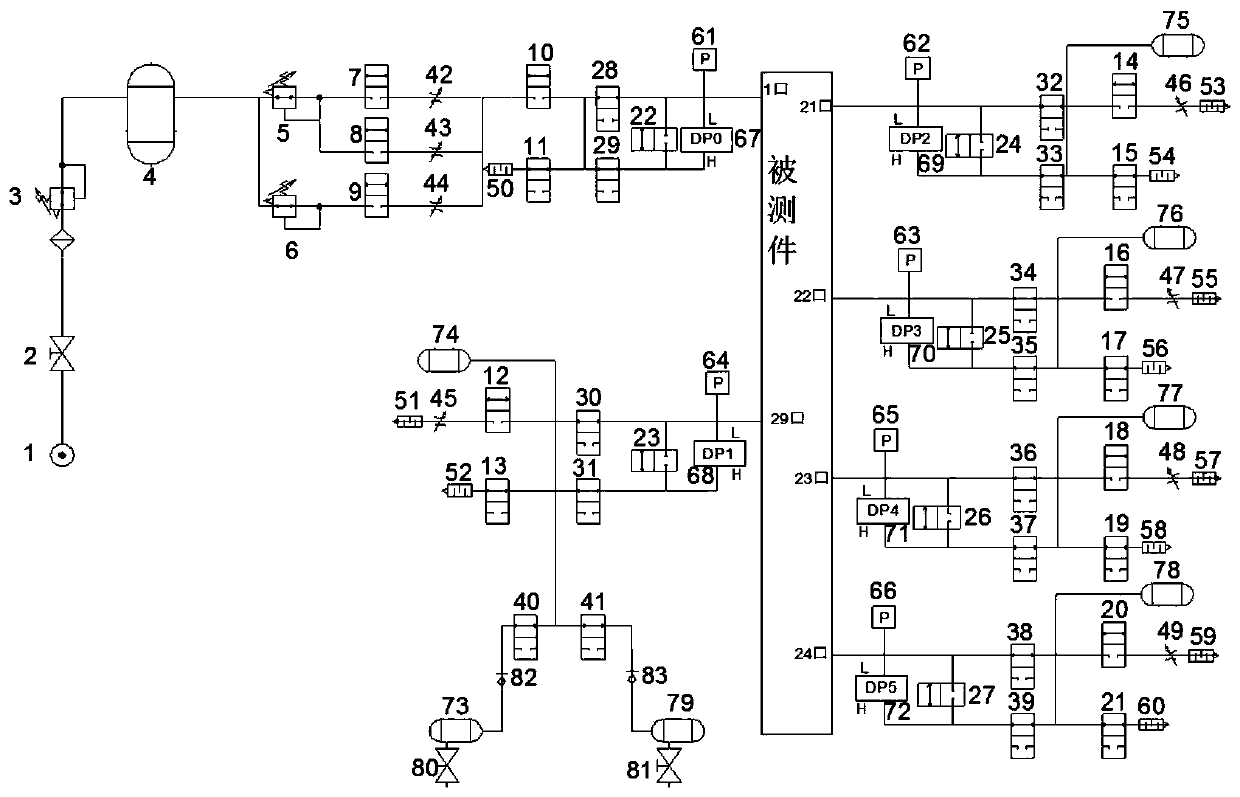

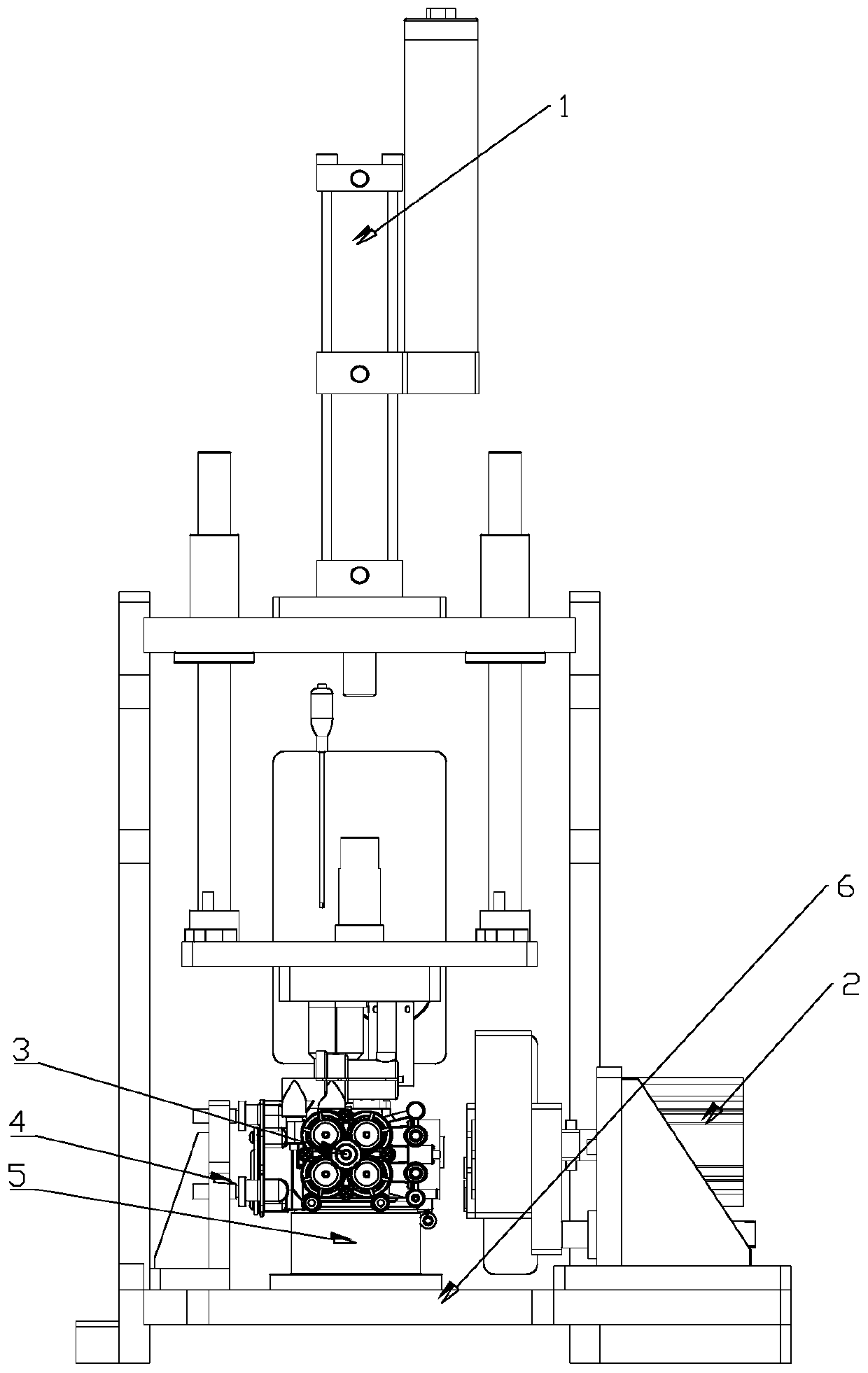

[0021] A test system for reflux time and regenerative volume of a composite dryer, including industrial PC, data acquisition card AI module, air pressure sensor, differential pressure sensor, data acquisition card DO module, gas storage tank, solenoid valve, cylinder and reference chamber ; The industrial PC is connected to the data acquisition card AI module and the data acquisition card DO module at the same time, the data acquisition card AI module is connected to the air pressure sensor and the differential pressure sensor, and the data acquisition card DO module is connected to the solenoid valve. The air pressure sensor is set at the air inlet of the composite dryer With the exhaust port, the differential pressure sensor is arranged at the air inlet and the exhaust port of the composite dryer. The industrial PC is used to control the AI module of the data acquisition card and the DO module of the data acquisition card, and record and calculate the data fed back by the A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com