Tubing structure

一种管件、磁性件的技术,应用在管件结构领域,能够解决固持力不足、管件结构弯折角度易受到外力而改变、管件结构无法被调整到弯折角度等问题,达到使用方便的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

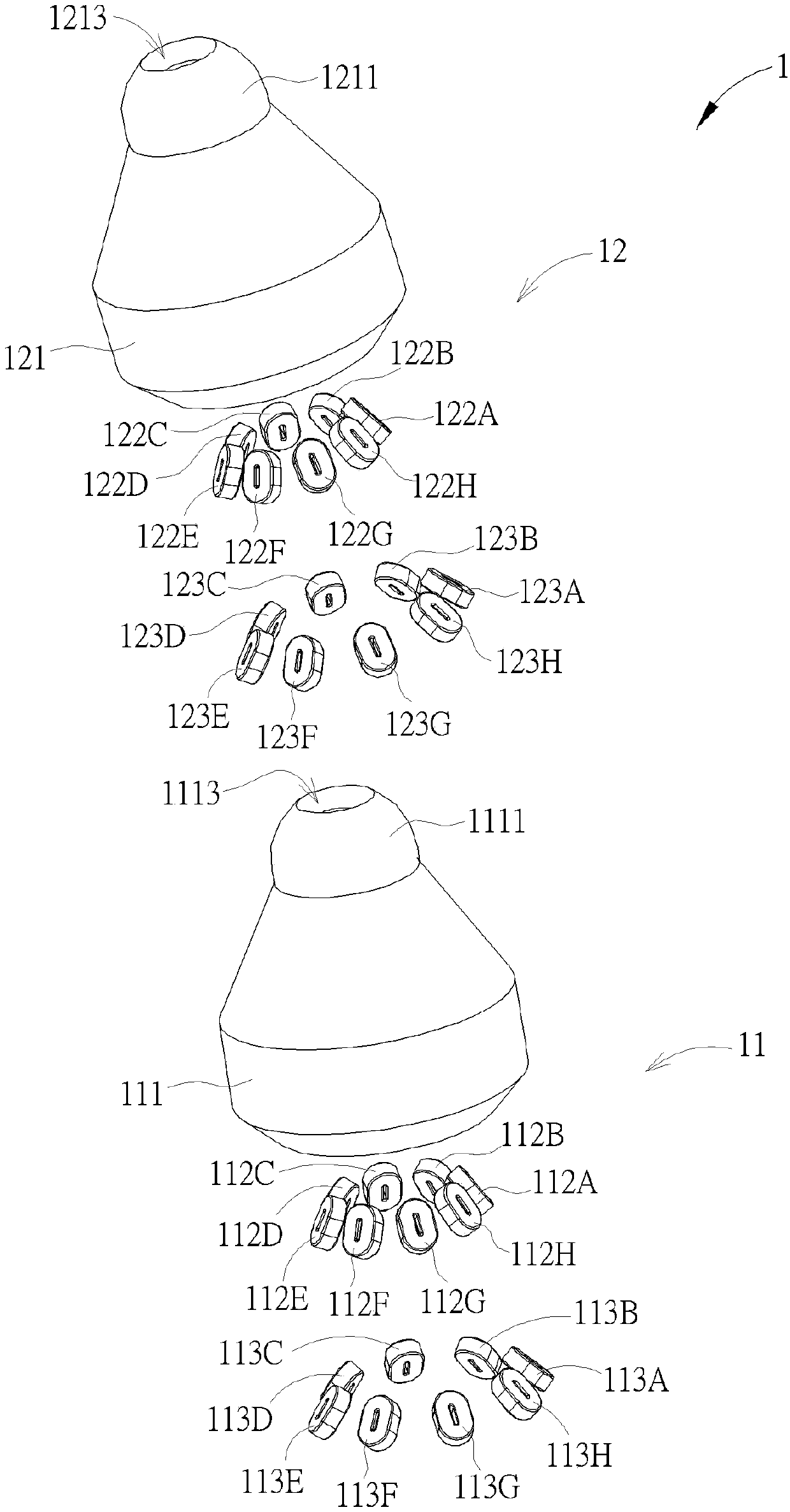

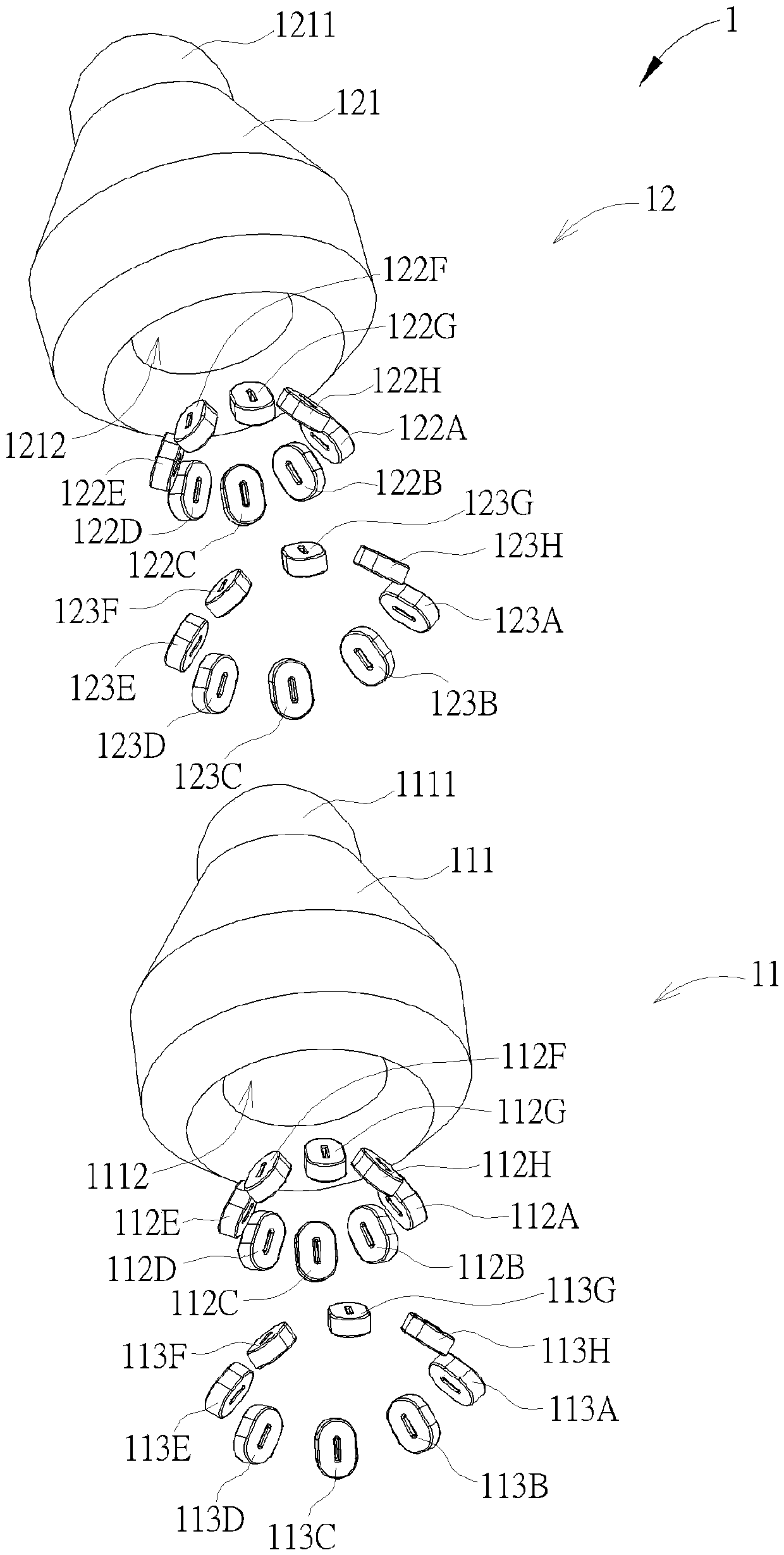

[0061] In order to have a clearer understanding of the technical solutions, objectives and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0062] The directional terms mentioned in the following embodiments, such as: up, down, left, right, front or back, etc., are only directions referring to the attached drawings. Accordingly, the directional terms are used to illustrate and not to limit the invention.

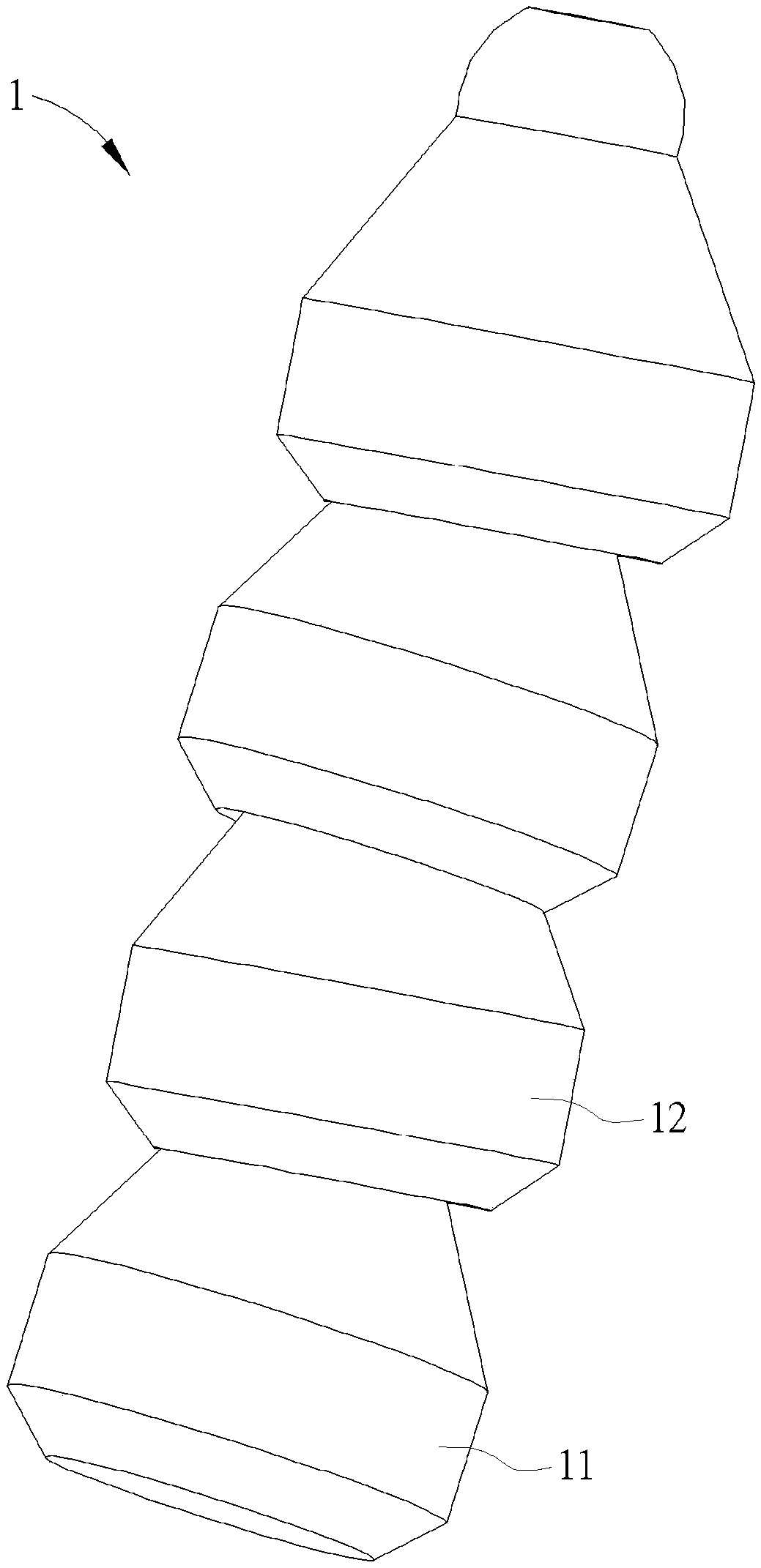

[0063] see figure 1 , figure 1 It is a schematic view of the appearance of a pipe structure 1 according to the first embodiment of the present invention. Such as figure 1 As shown, the pipe structure 1 can be composed of a plurality of units including at least a first unit 11 and a second unit 12. The number of units included in the pipe structure 1 is not limited to that shown in the accompanying drawings of the present invention. Depending on the design re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com