Patents

Literature

31results about How to "Adjust the bend angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

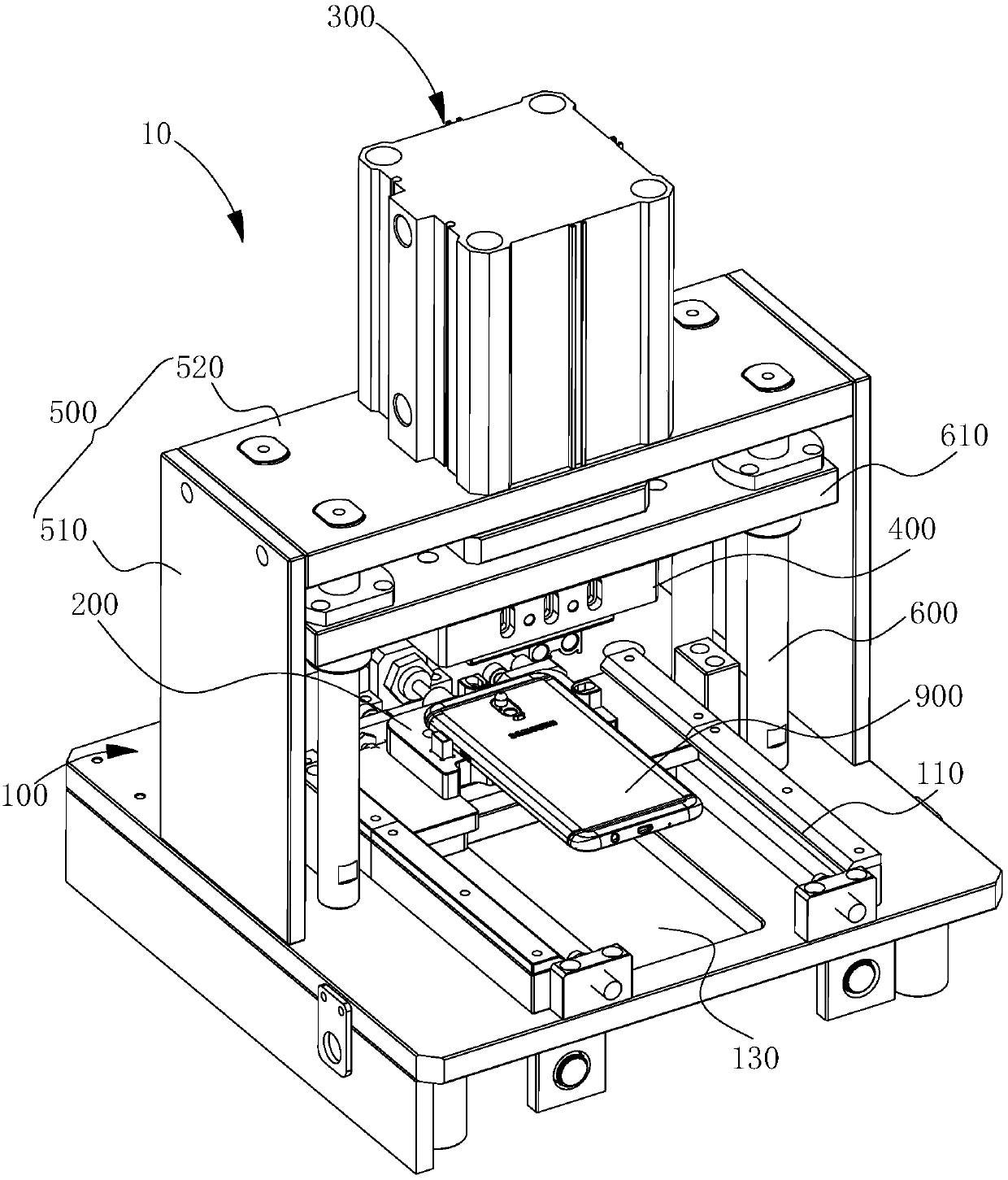

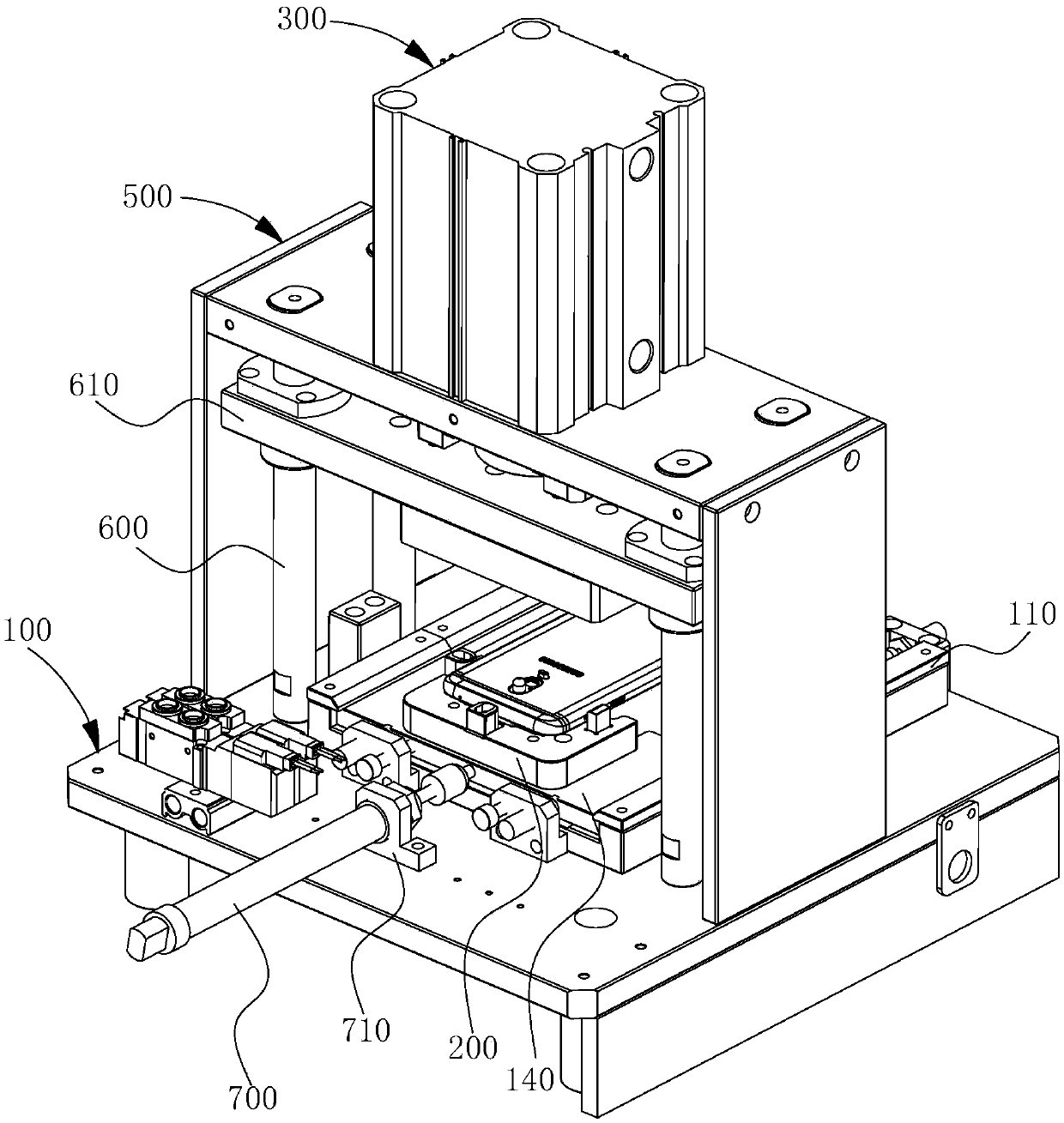

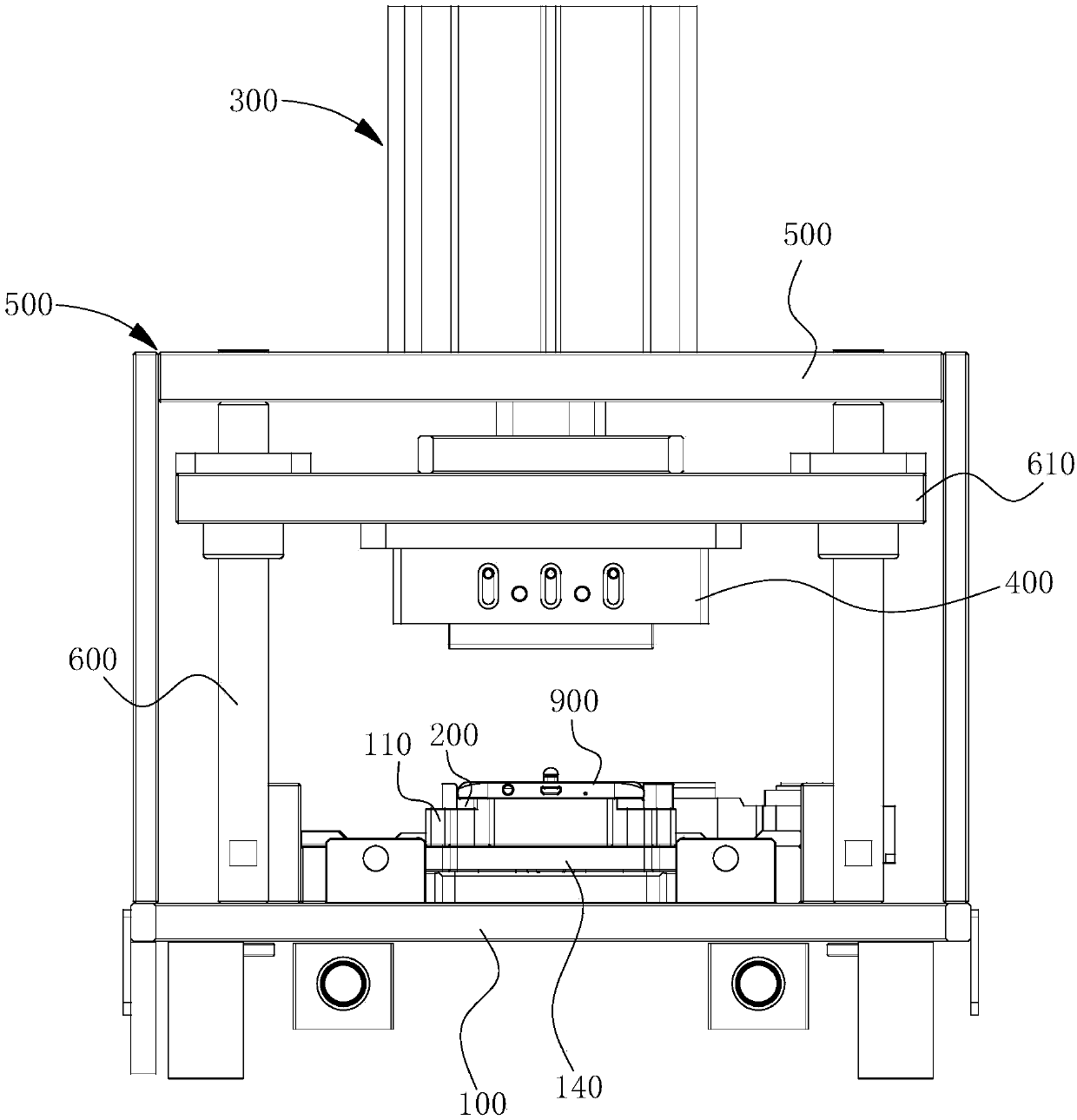

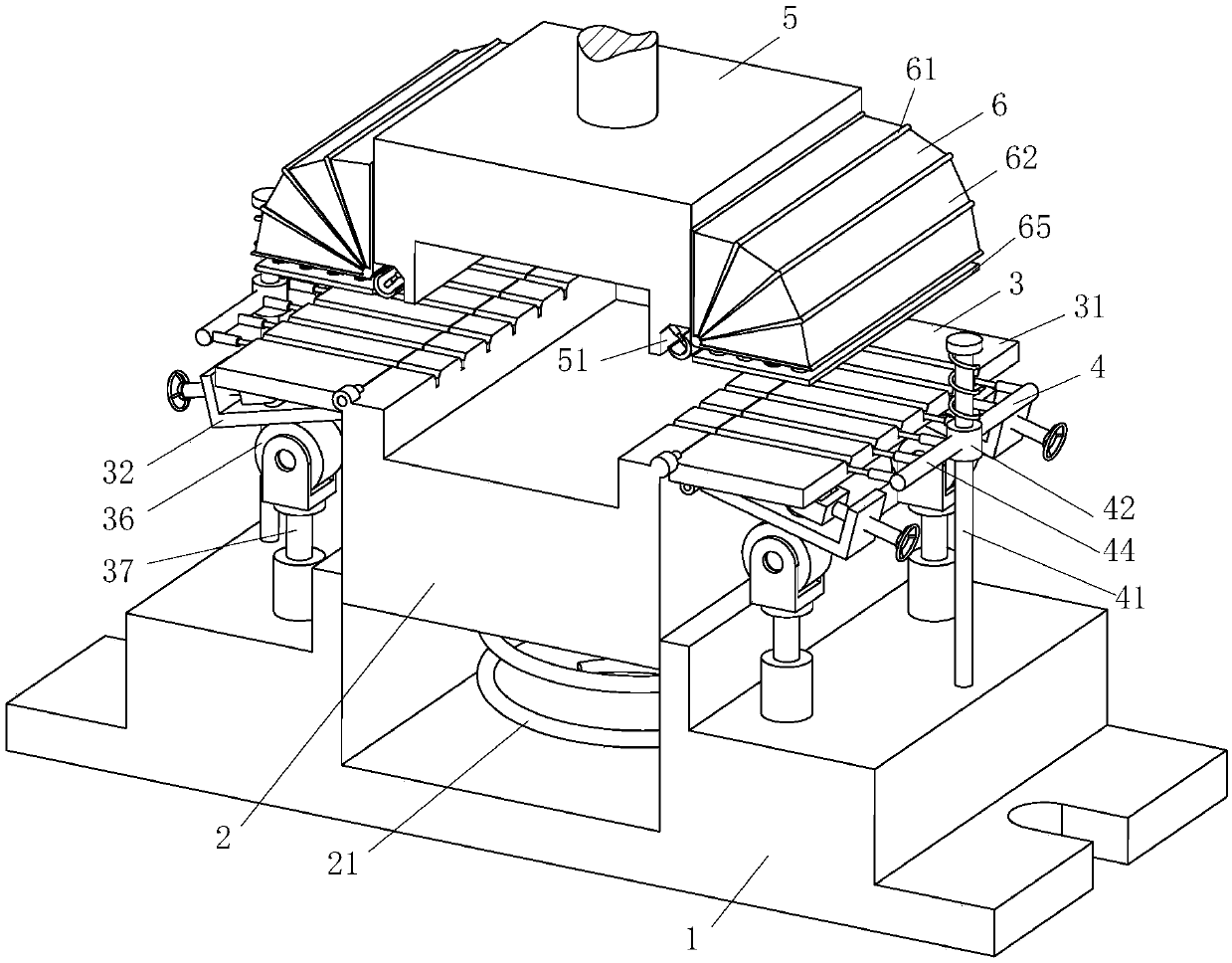

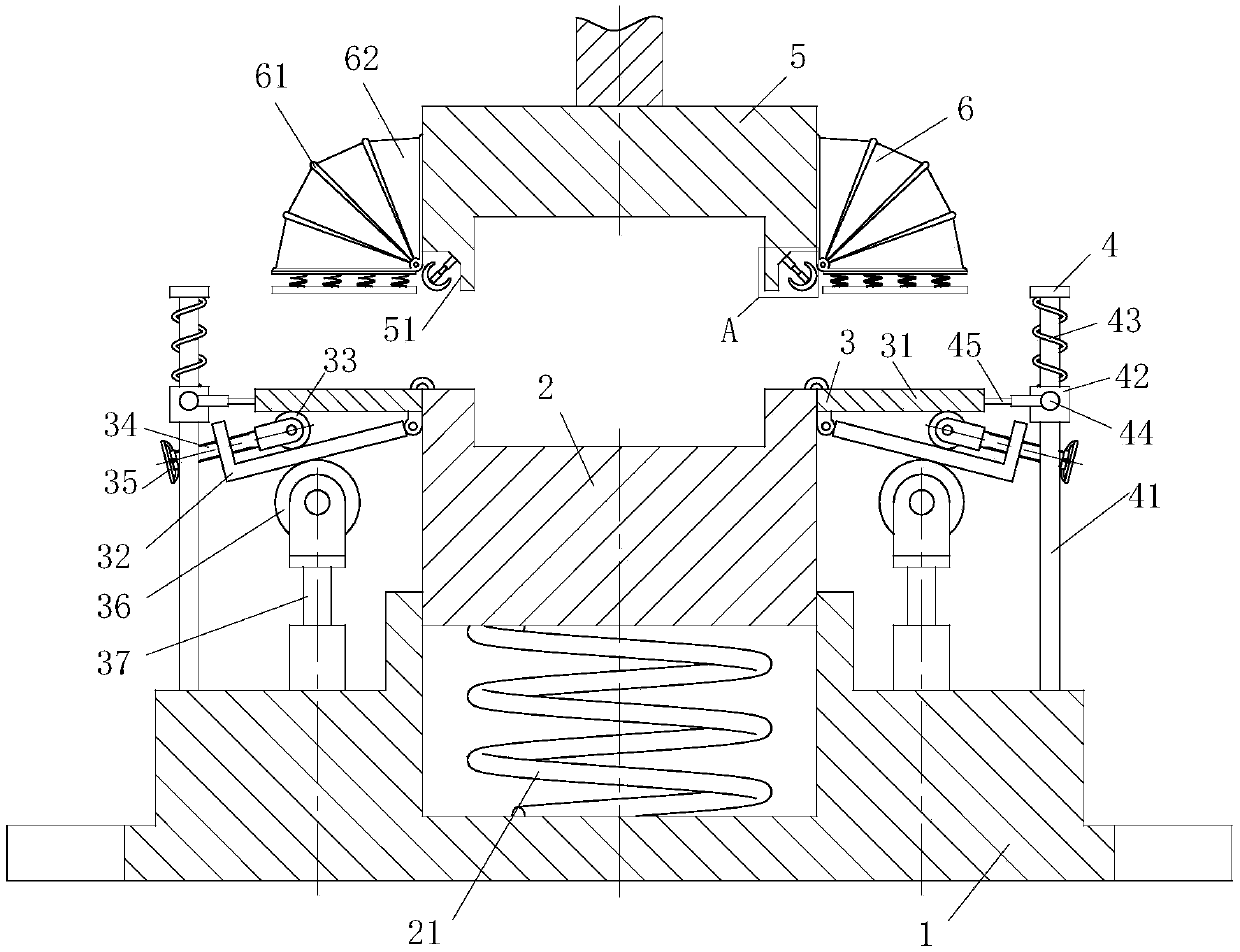

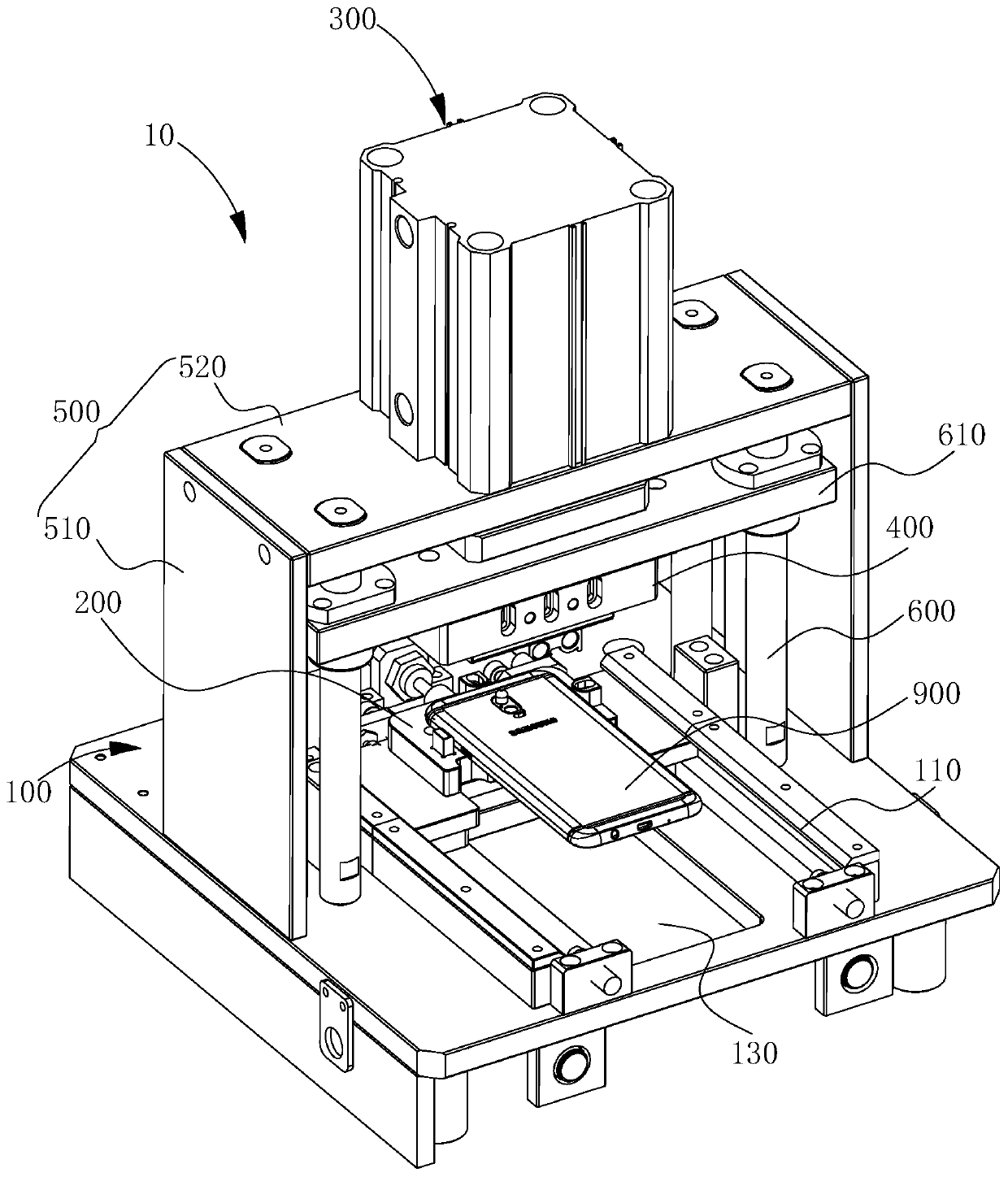

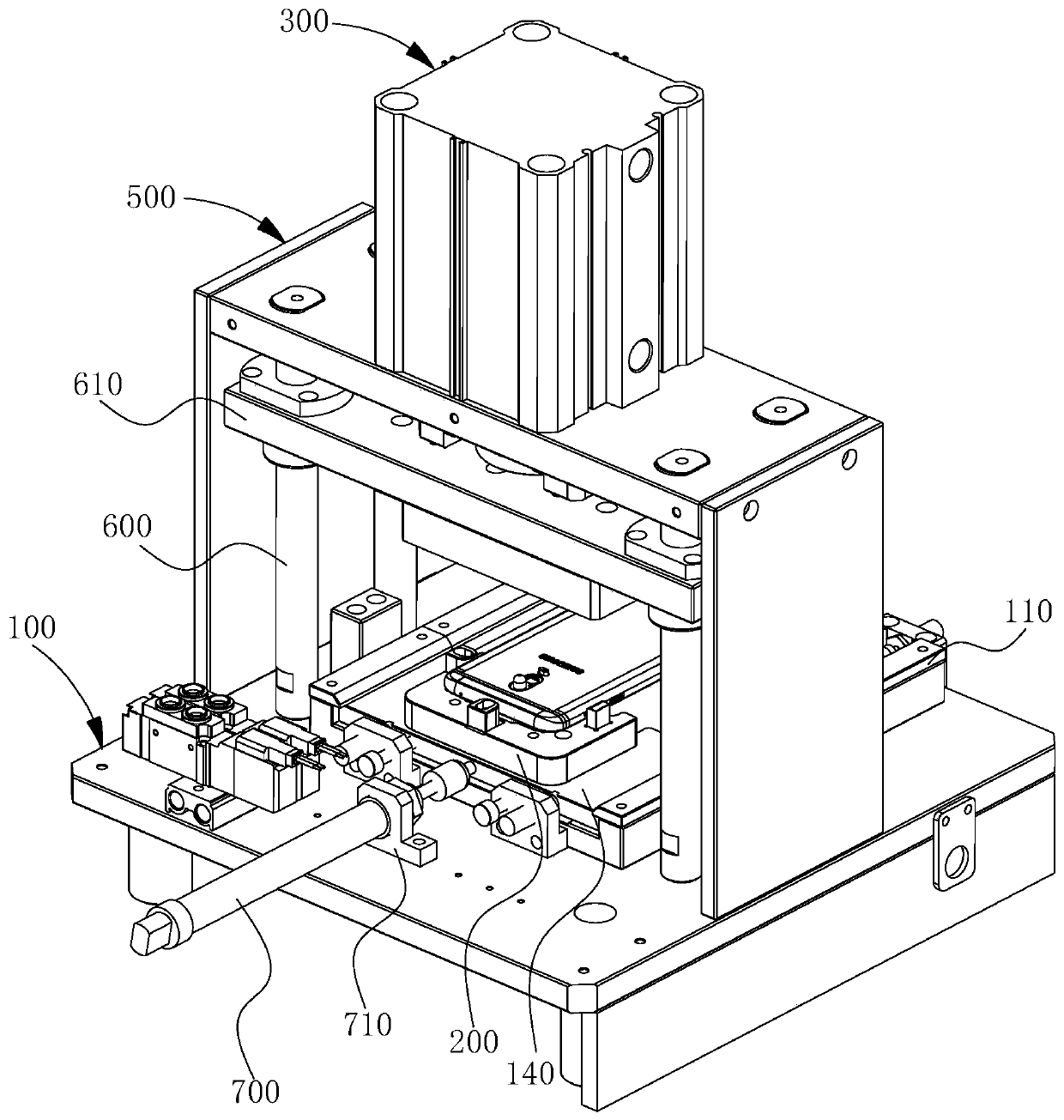

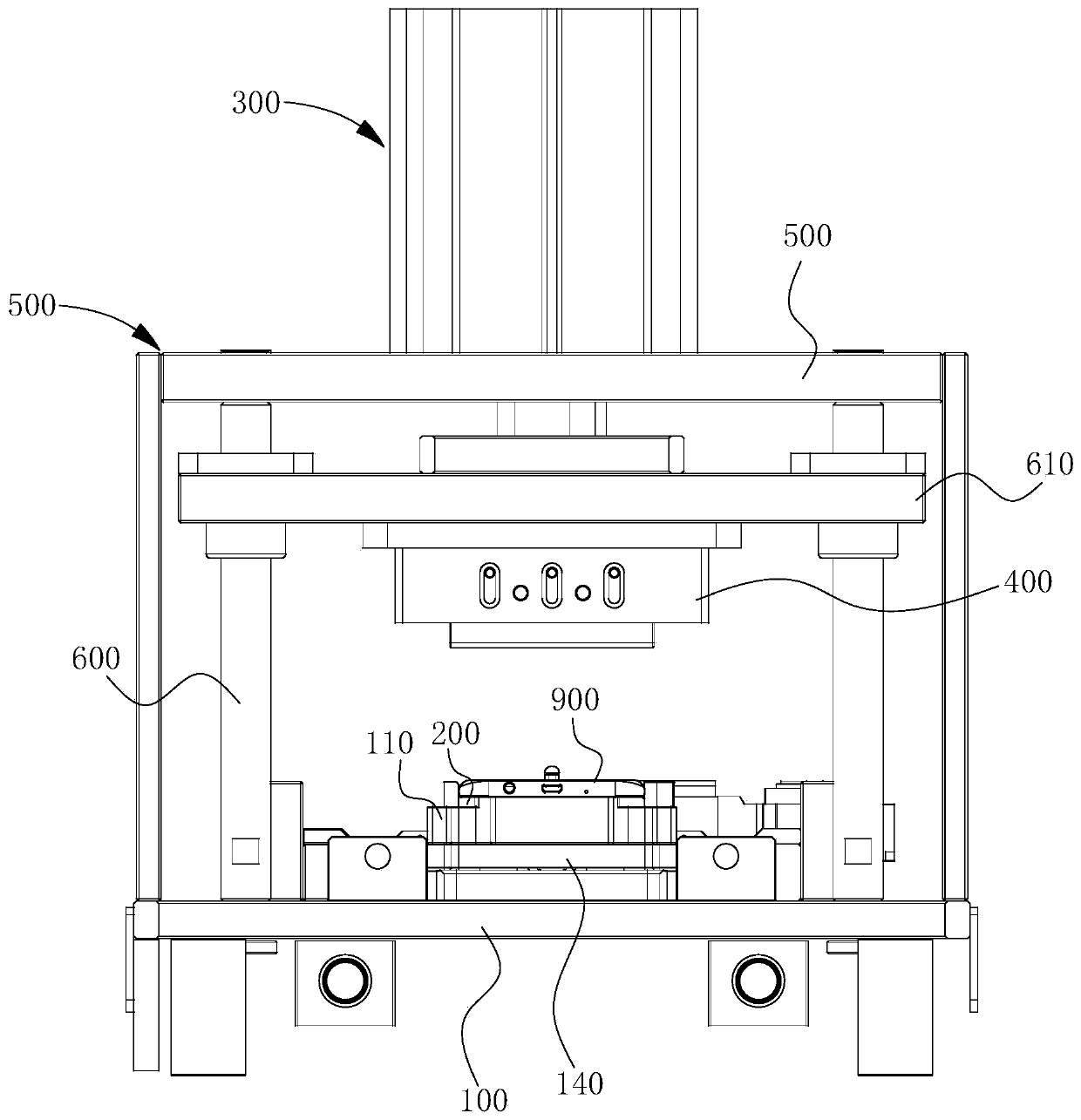

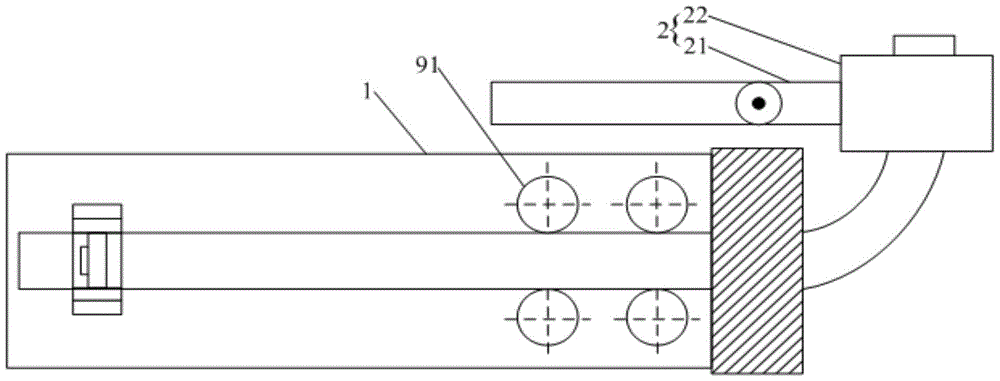

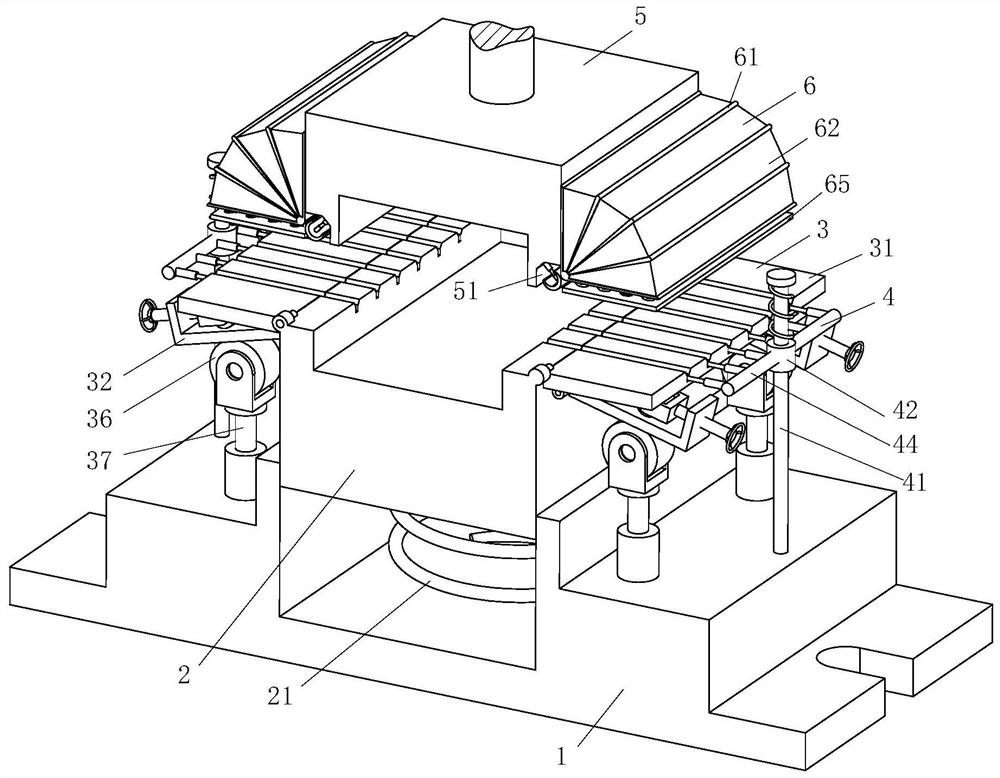

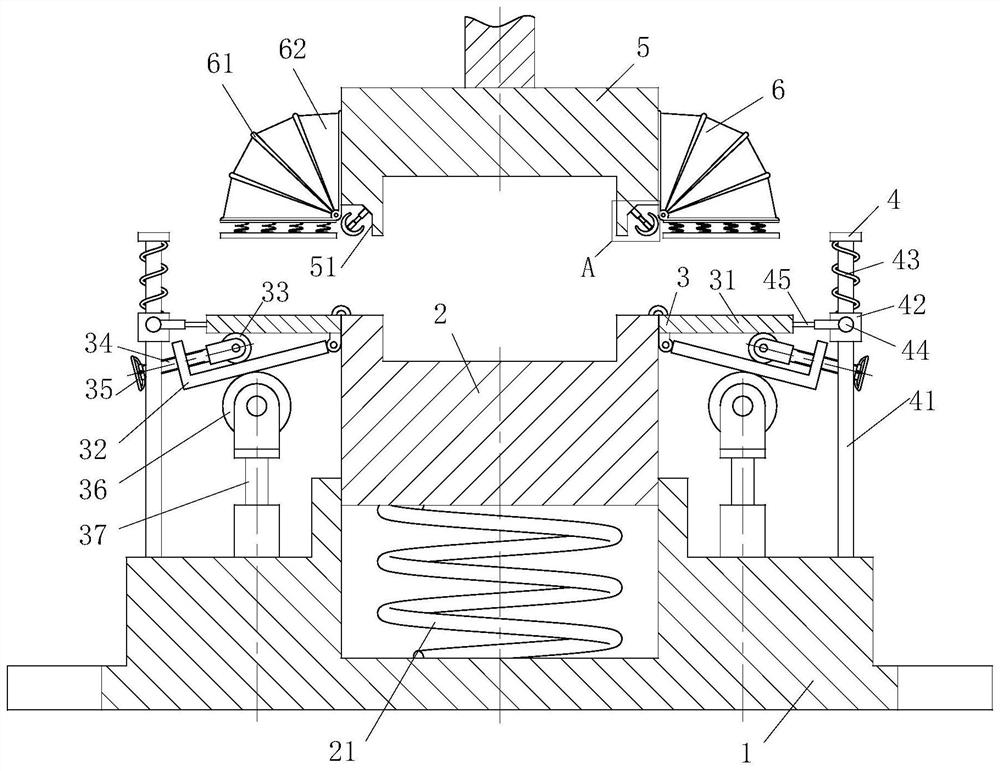

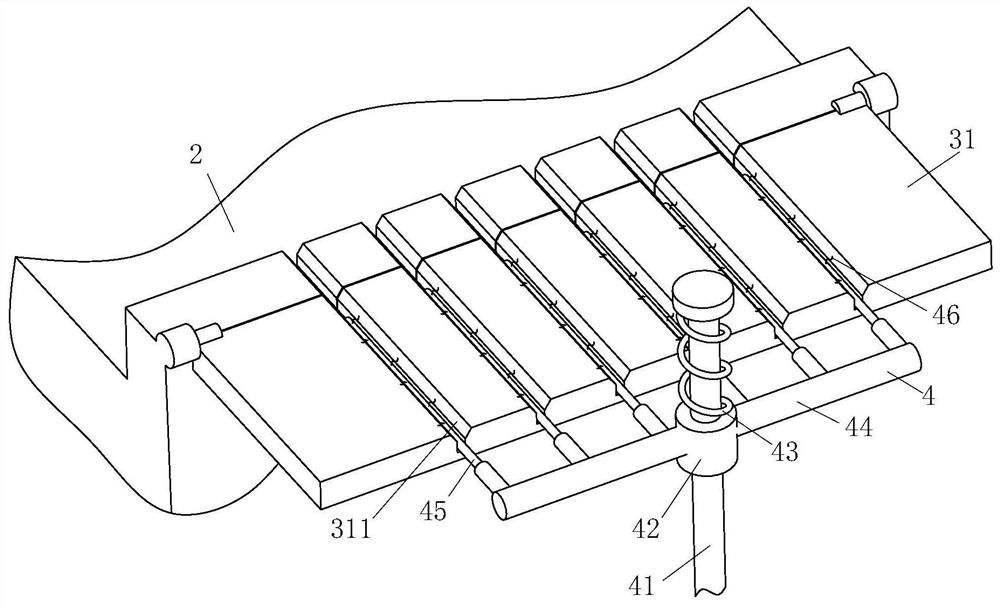

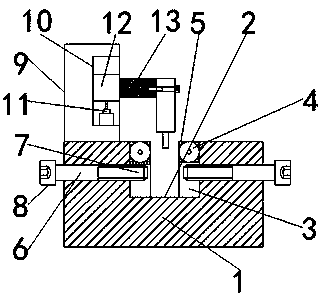

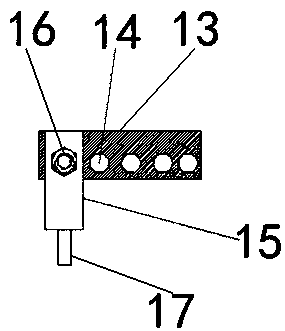

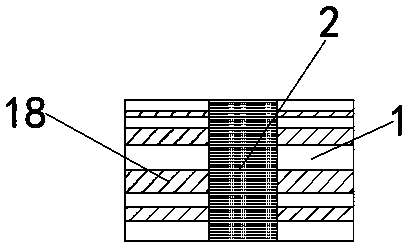

Rapid bending forming device of multi-angle sheet metal parts and forming method of rapid bending forming device

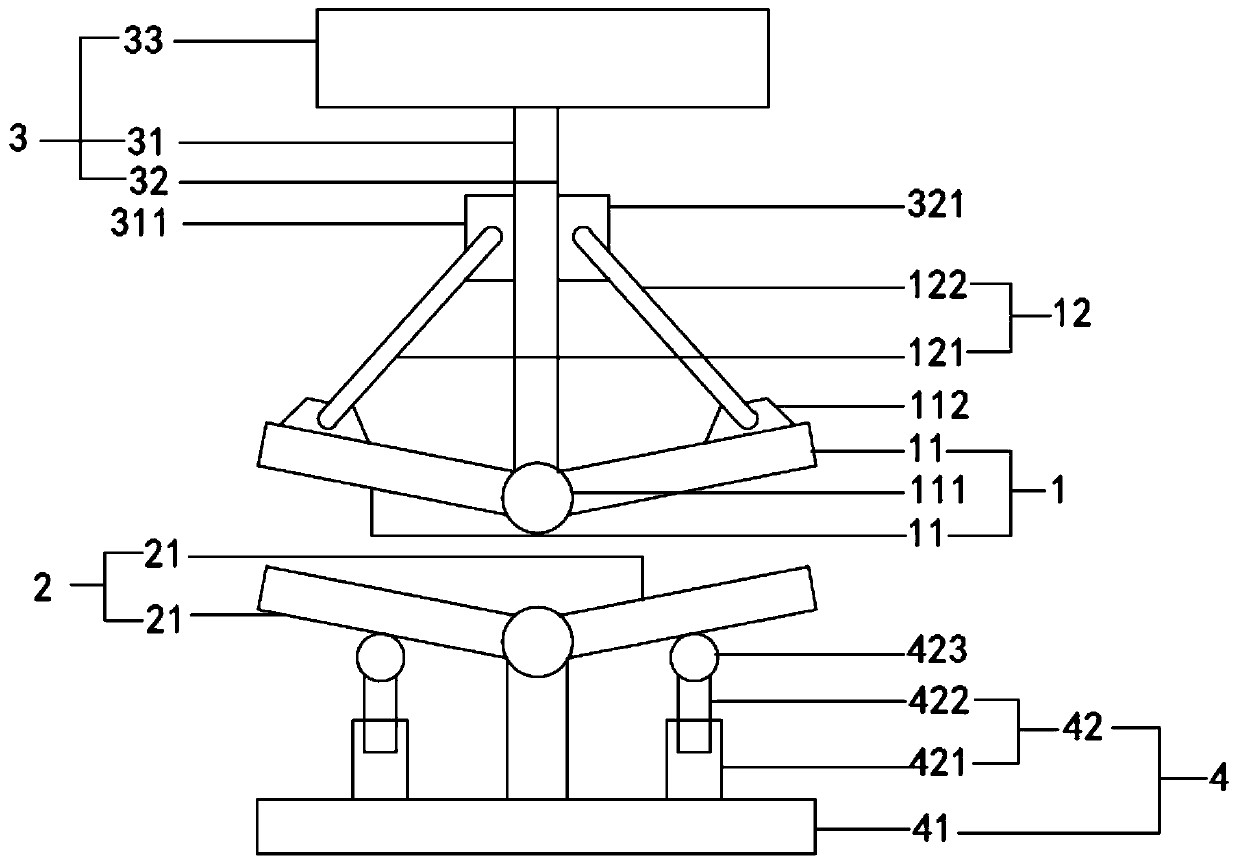

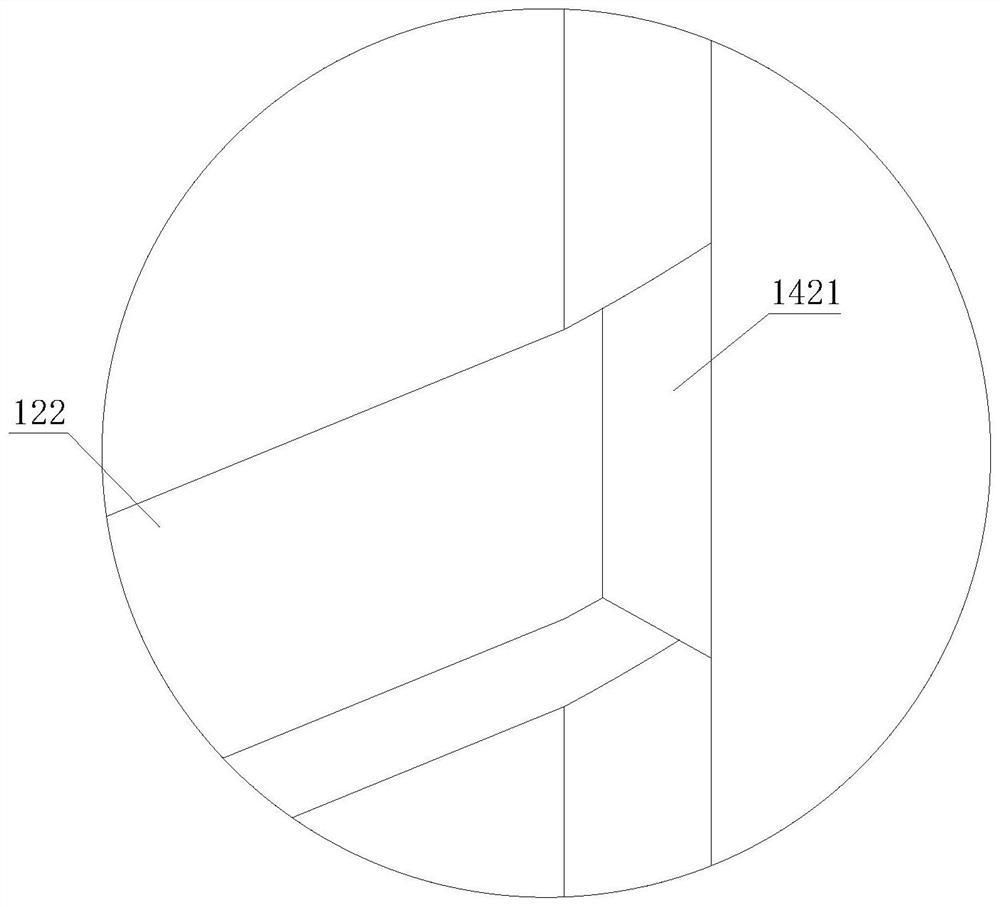

The invention provides a rapid bending forming device for multi-angle sheet metal parts. The rapid bending forming device is provided with an upper mold and a lower mold at first; the upper mold comprises two first mold plates hinged to each other, a first lifting mechanism comprises a first guide track, a second guide track and a motor, a first sliding block is slidably mounted on the first guidetrack, a second sliding block is slidably mounted on the second guide track, the ends of the two first mold plates are respectively connected with the first sliding block and the second sliding blockthrough transmission rod assemblies, and the first sliding block and the second sliding block slide under the driving effect of the motor; and the lower mold comprises two second mold plates hinged to each other, and the second mold plates are driven by a second lifting mechanism to rotate. Compared with the prior art, the rapid bending forming device has the advantages that the bending angle ofthe molds can be adjusted accurately to rapidly form sheet metal parts bent at various angles. Meanwhile, the invention also provides a rapid bending forming method of the multi-angle sheet metal parts, and the rapid bending forming method involves the bending forming principle of the device.

Owner:SHENZHEN EVA PRECISION TECH GRP CO LTD

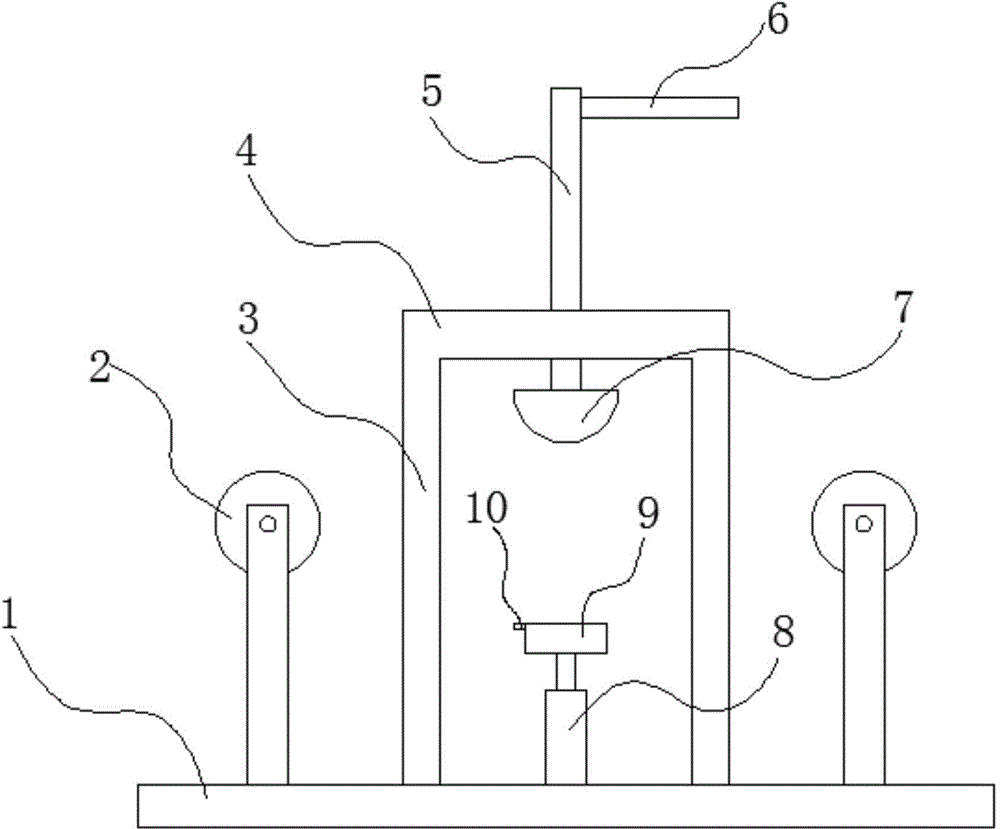

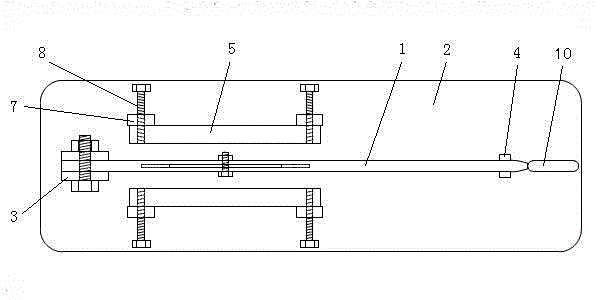

Pipe-bending machine

The invention discloses a pipe-bending machine. The pipe-bending machine comprises a base; carrier rollers, wherein two carrier rollers are respectively suspended and installed at two sides of the base, and the circumference faces of two carrier rollers are provided with arc grooves for containing the pipes; a bracket installed in the middle of the base; a screw which is thread connection with the upper end of the bracket, wherein the upper end of the screw is fixedly provided with a handle; a pressure head which is fixedly installed at the lower end of the screw, wherein the lower end of the pressure head is provided with arc grooves for containing the pipes; and a positioning table which is suspended and installed in the middle of the base through a lifting installing frame, wherein the positioning table is located below the pressure head. The pipe-bending machine is capable of ensuring the uniformity of the pipe forming in the process of bending pipes in batches, saving time and labor, and conveniently adjusting the bending angle of the pipe.

Owner:GUANGXI UNIV

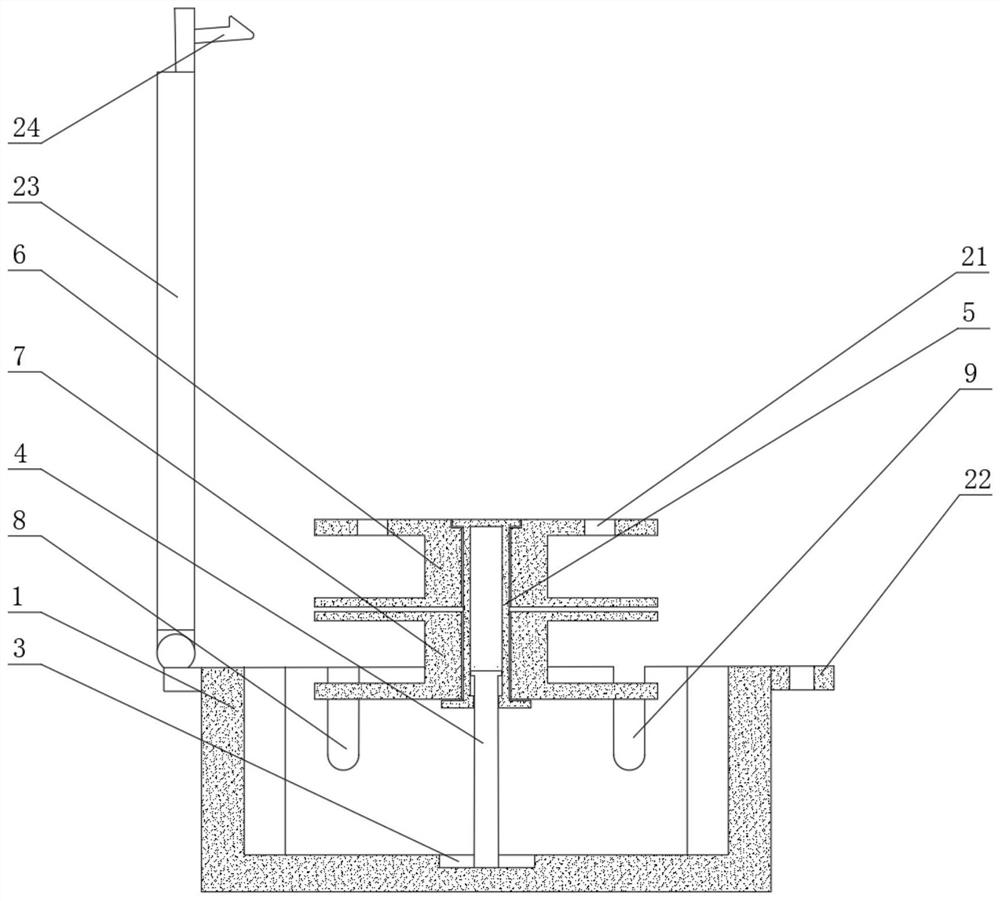

Orthopedic joint replacement surgery device

InactiveCN112168582ARapid responseSave idle time during surgeryDiagnosticsOperating tablesOrthopedic departmentEngineering

The invention discloses an orthopedic joint replacement surgery device. The orthopedic joint replacement surgery device comprises a bed board, wherein one side of the bed board is connected with a supporting table through a fixing bolt; guide rail grooves are symmetrically formed in the supporting table; sealing pipes are arranged in the guide rail grooves; piston blocks are slidably connected inthe sealing pipes; connecting rods are fixedly connected to the piston blocks; a plurality of permanent magnet sliding blocks are fixedly inserted into the connecting rods in a penetrating mode; the plurality of permanent magnet sliding blocks are arranged at equal intervals; a plurality of magnetic sliding sleeves are slidably connected to the sealing pipes in a sleeving mode; and the plurality of magnetic sliding sleeves correspond to the plurality of permanent magnet sliding blocks one by one. According to the orthopedic joint replacement surgery device, a piston plate slides up and down byrotating a current adjusting knob forwards and backwards, so that the magnetic sliding sleeves drive foot supporting pads to move leftwards and rightwards, after the adjustment is completed, only a valve needs to be closed, the current adjusting knob is rotated to enable an electromagnet to be powered off, then the angle of a joint can be maintained, the whole adjusting process is free of noise pollution, the reaction is rapid, and unnecessary operation idle time is saved.

Owner:马冉

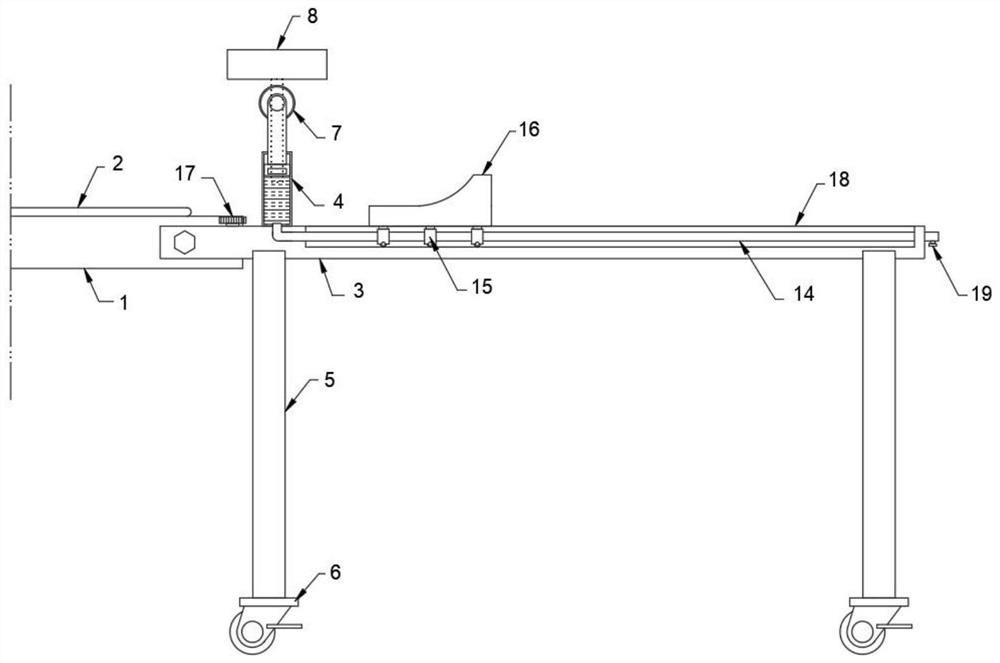

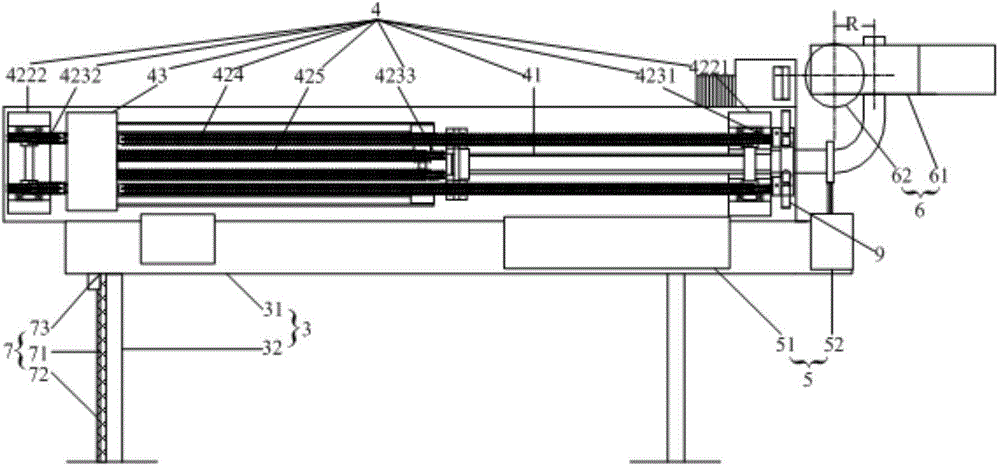

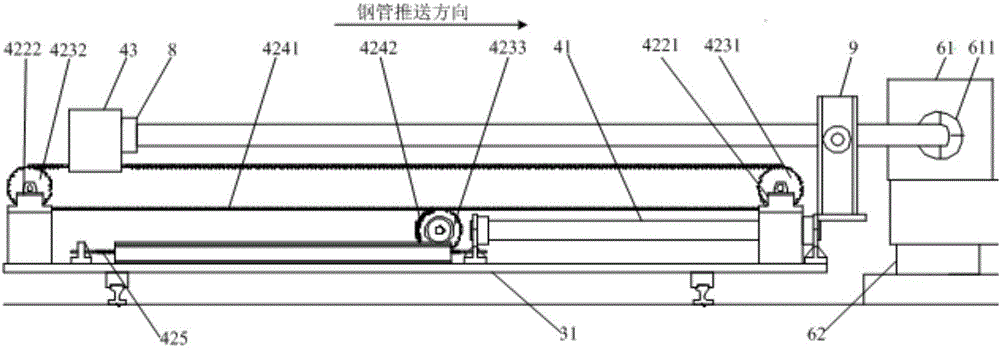

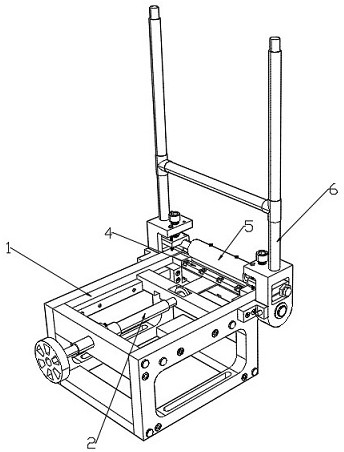

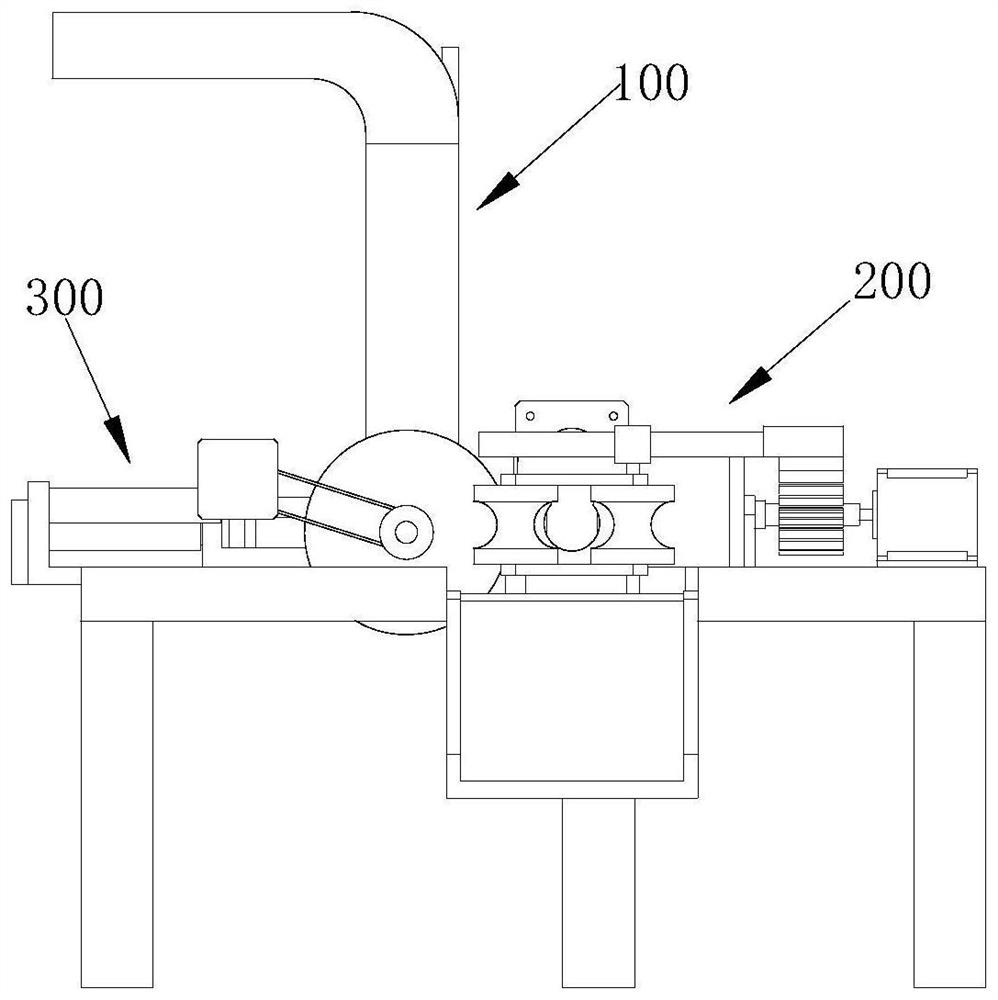

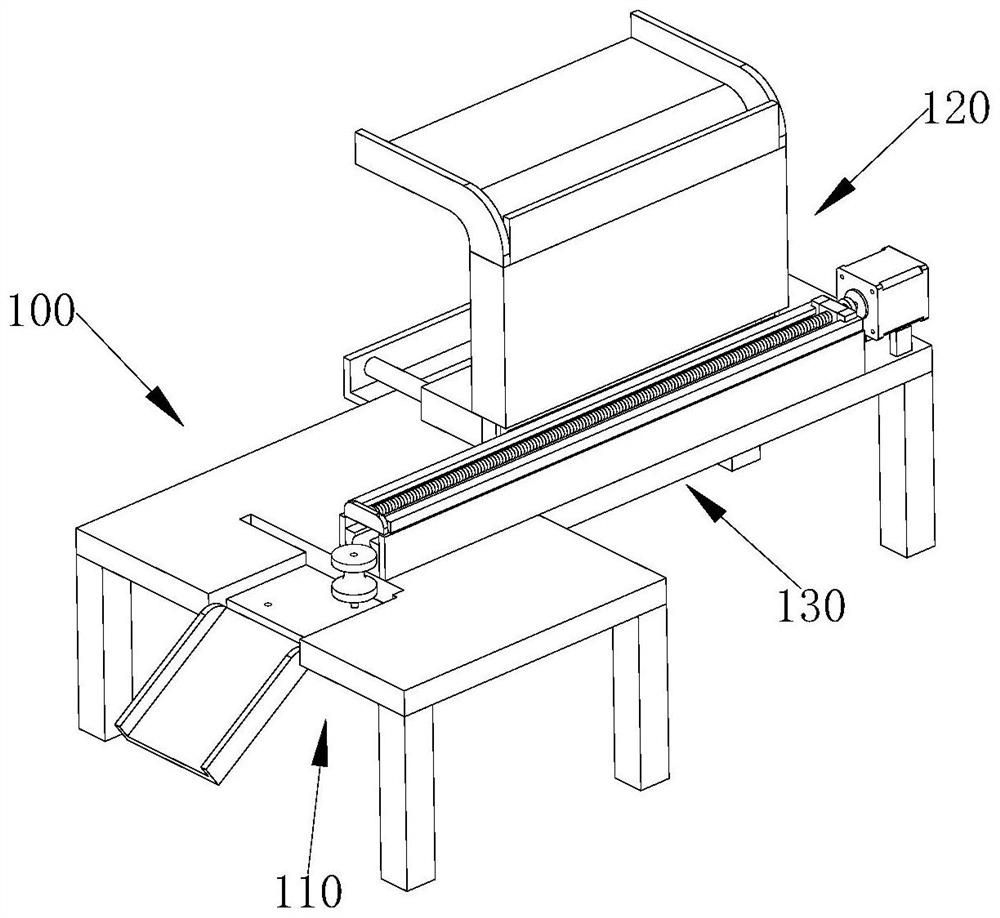

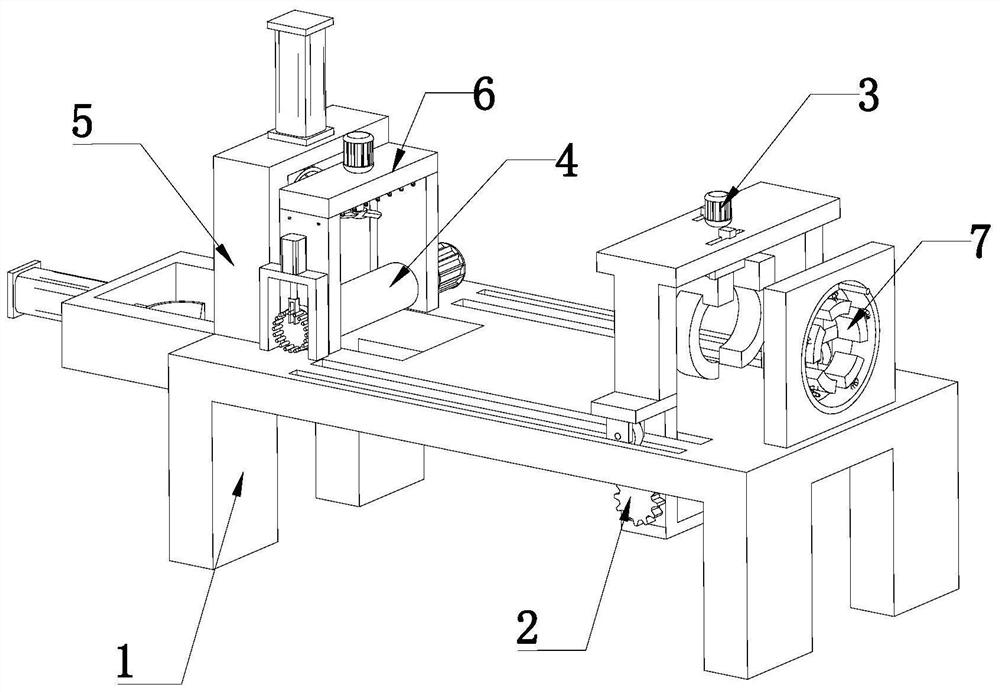

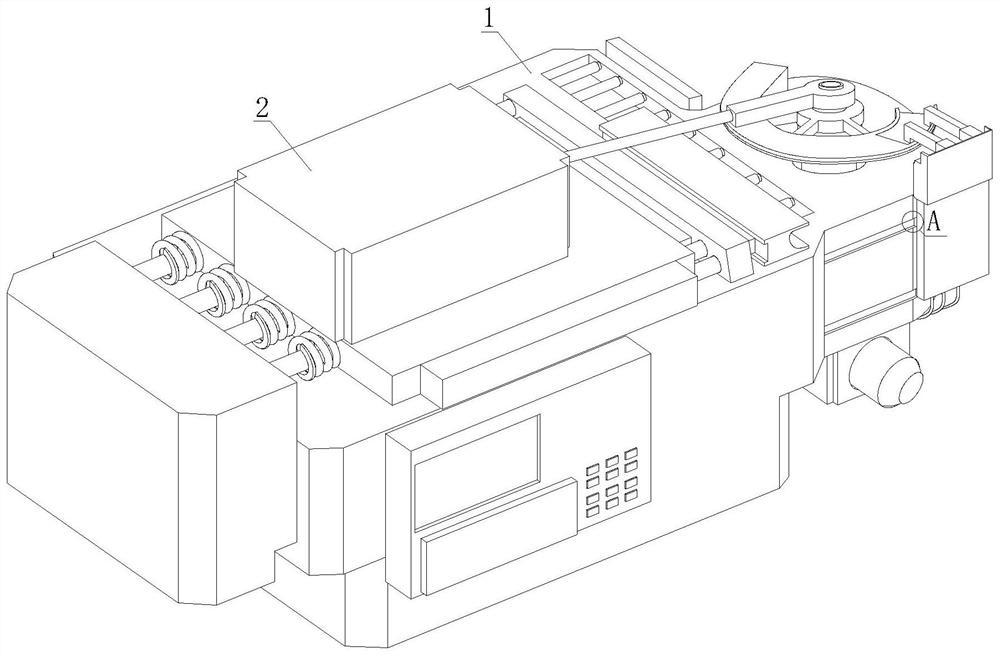

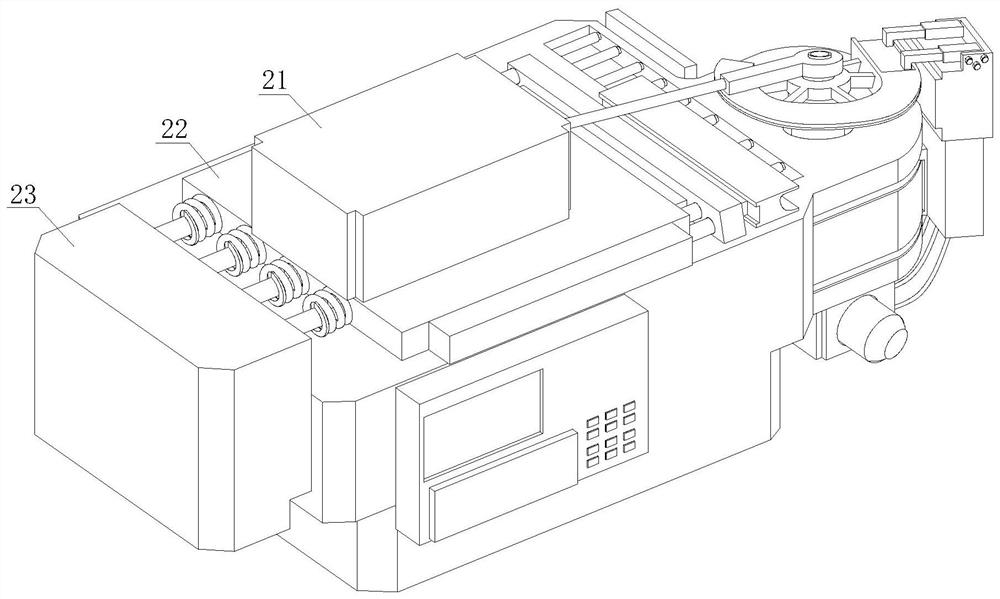

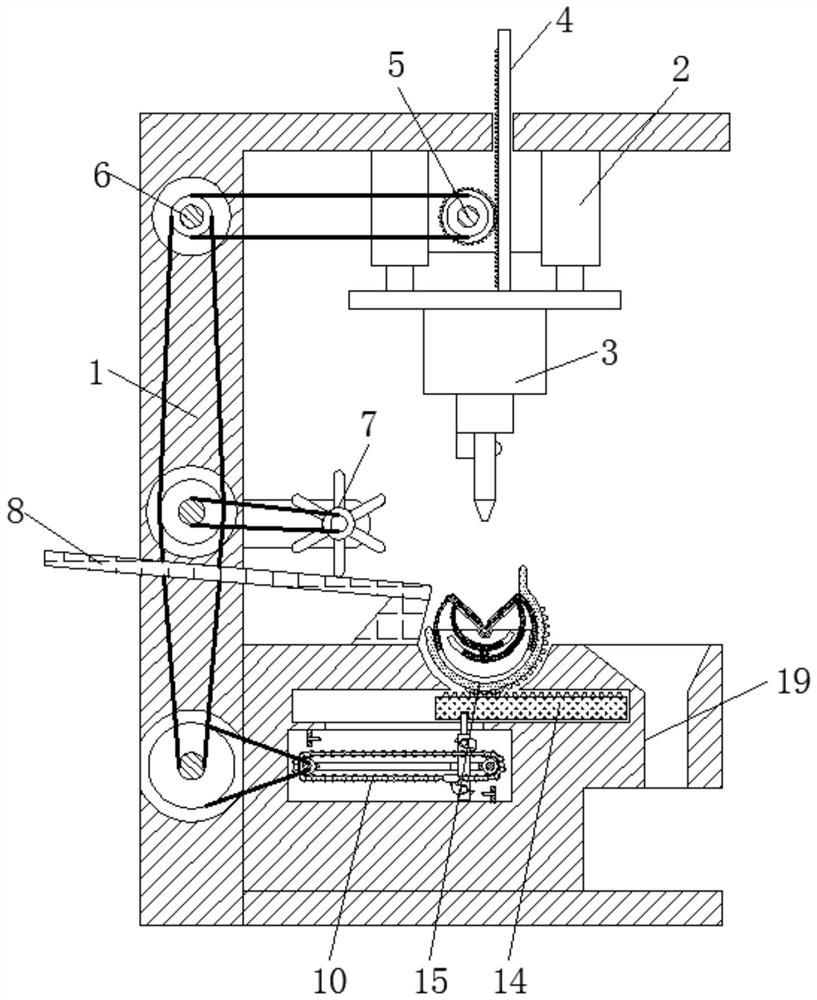

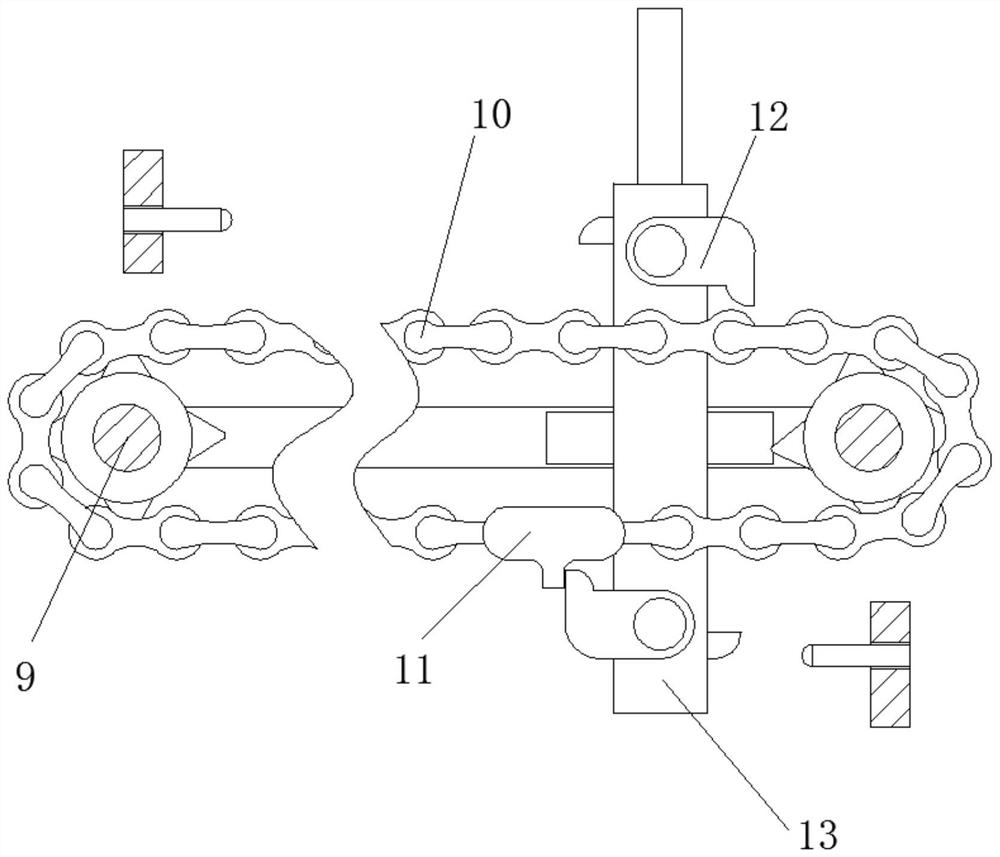

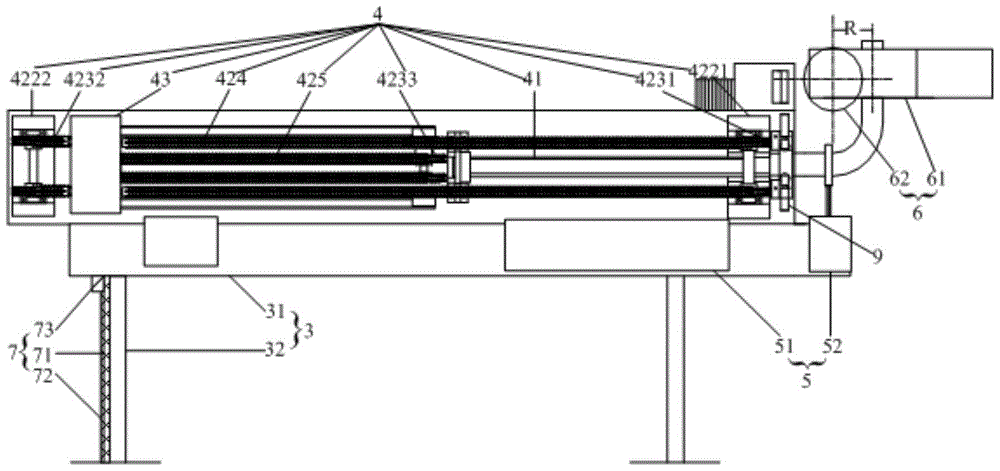

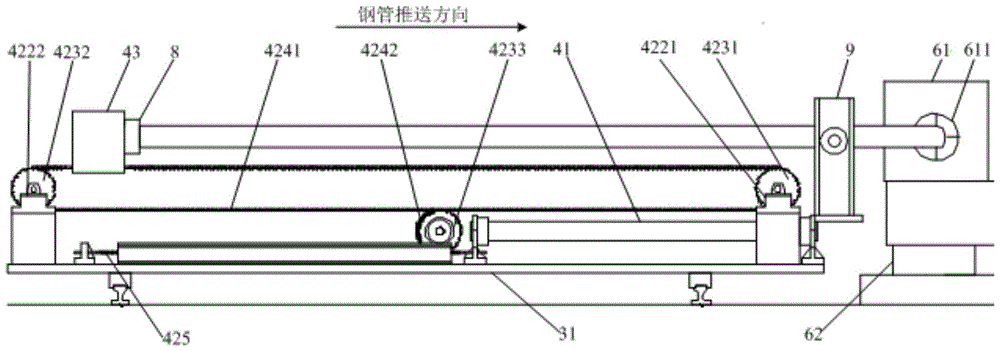

Induction-heating pipe bender

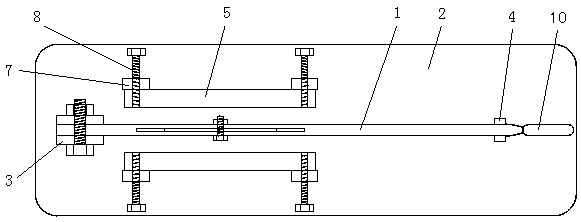

The invention provides an induction-heating pipe bender which comprises a machine tool system, a transmission system, an induction heating system and a clamp system, wherein the transmission system, the induction heating system and the clamp system are arranged on the machine tool system. The machine tool system comprises a machine tool body and horizontal guide rails, the transmission system is borne by the machine tool body, the horizontal guide rails are arranged on the lower portion of the machine tool body, and machine tool body sliders are arranged at the positions, corresponding to the horizontal guide rails, of the machine tool body; the transmission system comprises a longitudinal oil cylinder, chain row devices and a pipe trolley, the longitudinal oil cylinder is fixed on the machine tool body, a piston rod of the longitudinal oil cylinder is connected with the chain row devices, and the pipe trolley is fixed at the upper ends of the chain row devices; the induction heating system is arranged between the machine tool system and the clamp system; the clamp system comprises a clamping piece and a vertical rotating shaft, and the clamping piece is arranged on the upper portion of the vertical rotating shaft and connected with the vertical rotating shaft. By means of the technical scheme of the induction-heating pipe bender, limitation to the bending range of steel pipes can be reduced.

Owner:ZHUZHOU HAN HE IND EQUIP

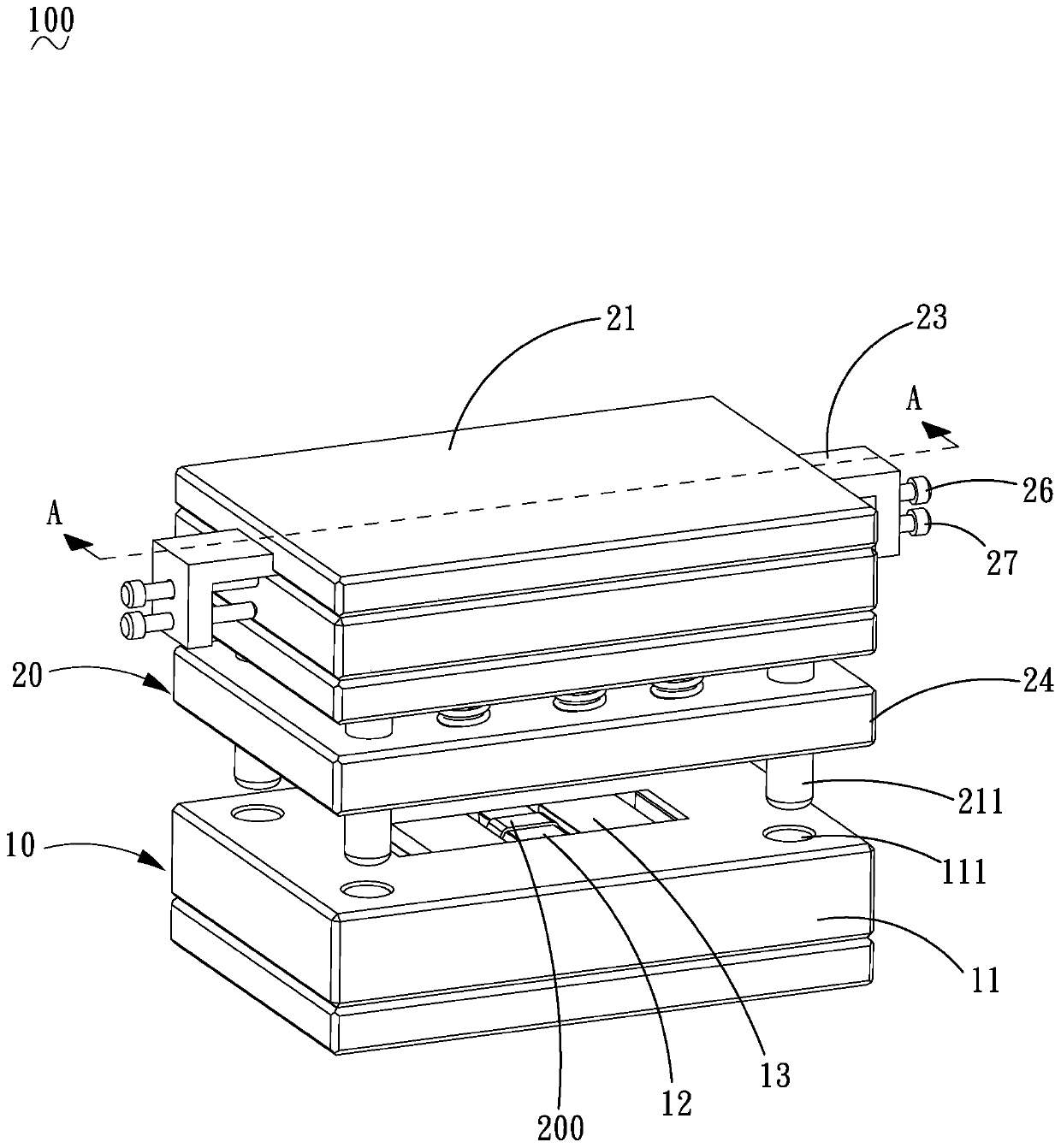

Bending device

ActiveCN108051315AWide versatilitySimple structureMaterial strength using steady bending forcesEngineeringMechanical engineering

Owner:GUANGDONG EVERWIN PRECISION TECH

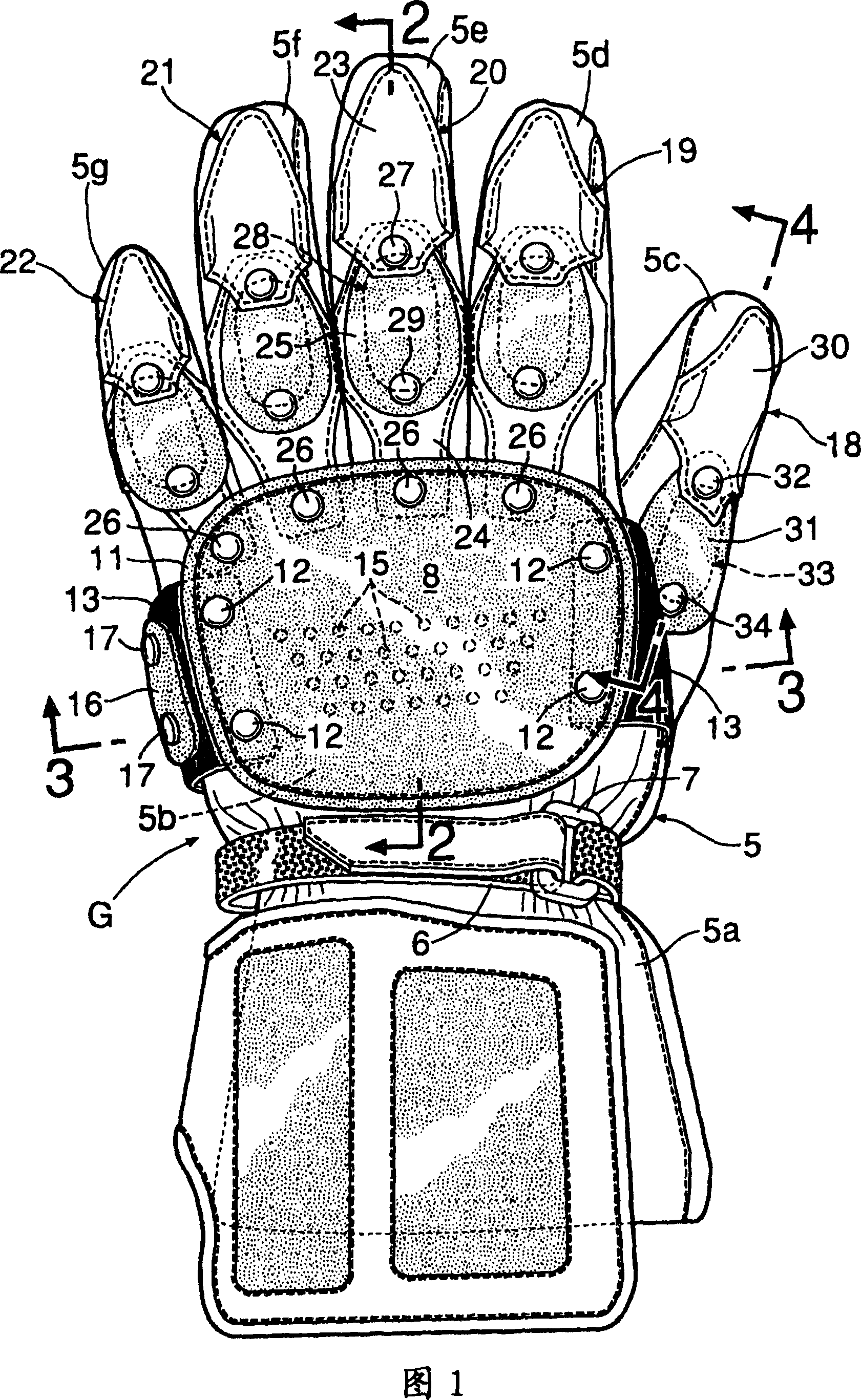

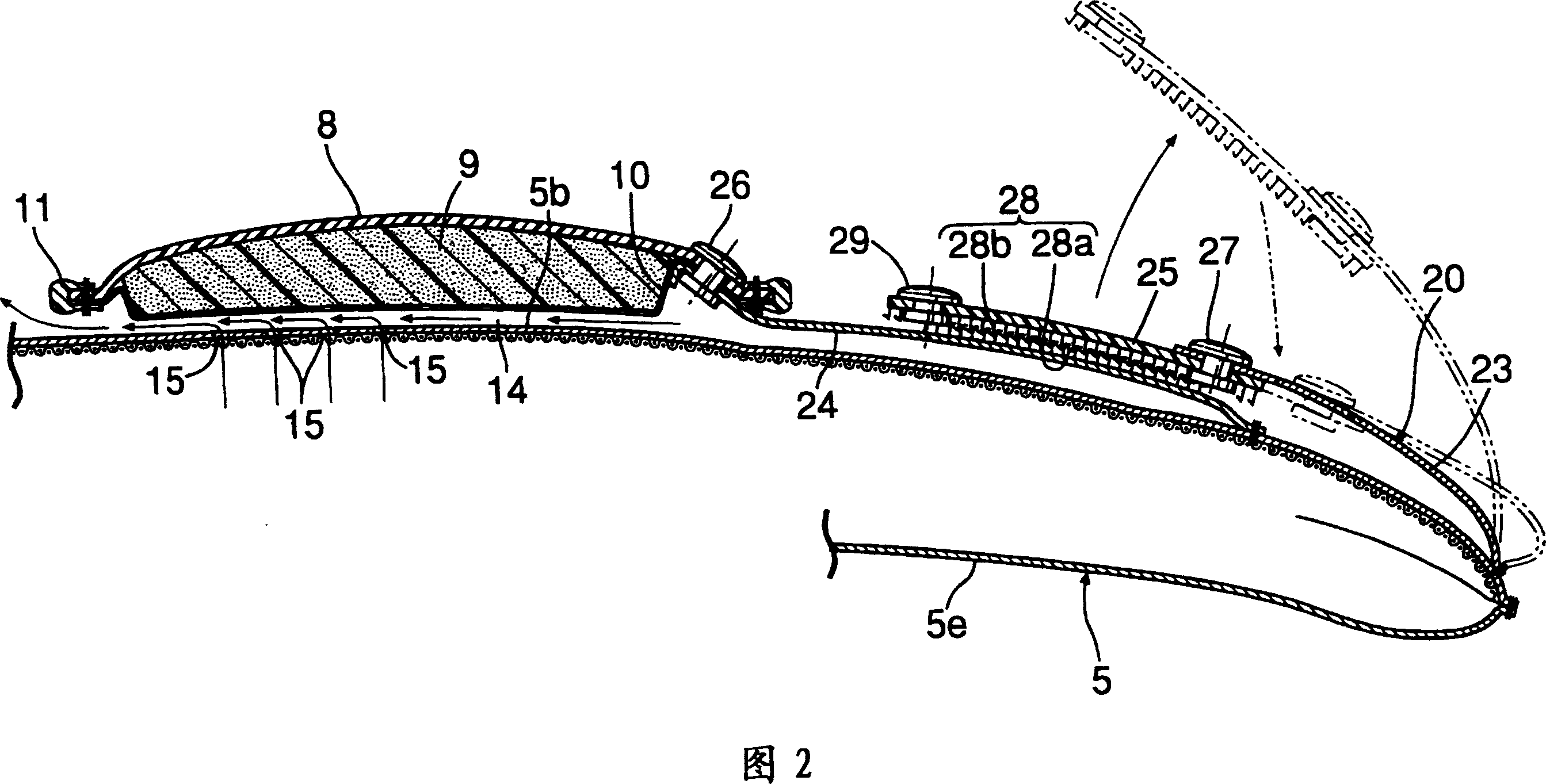

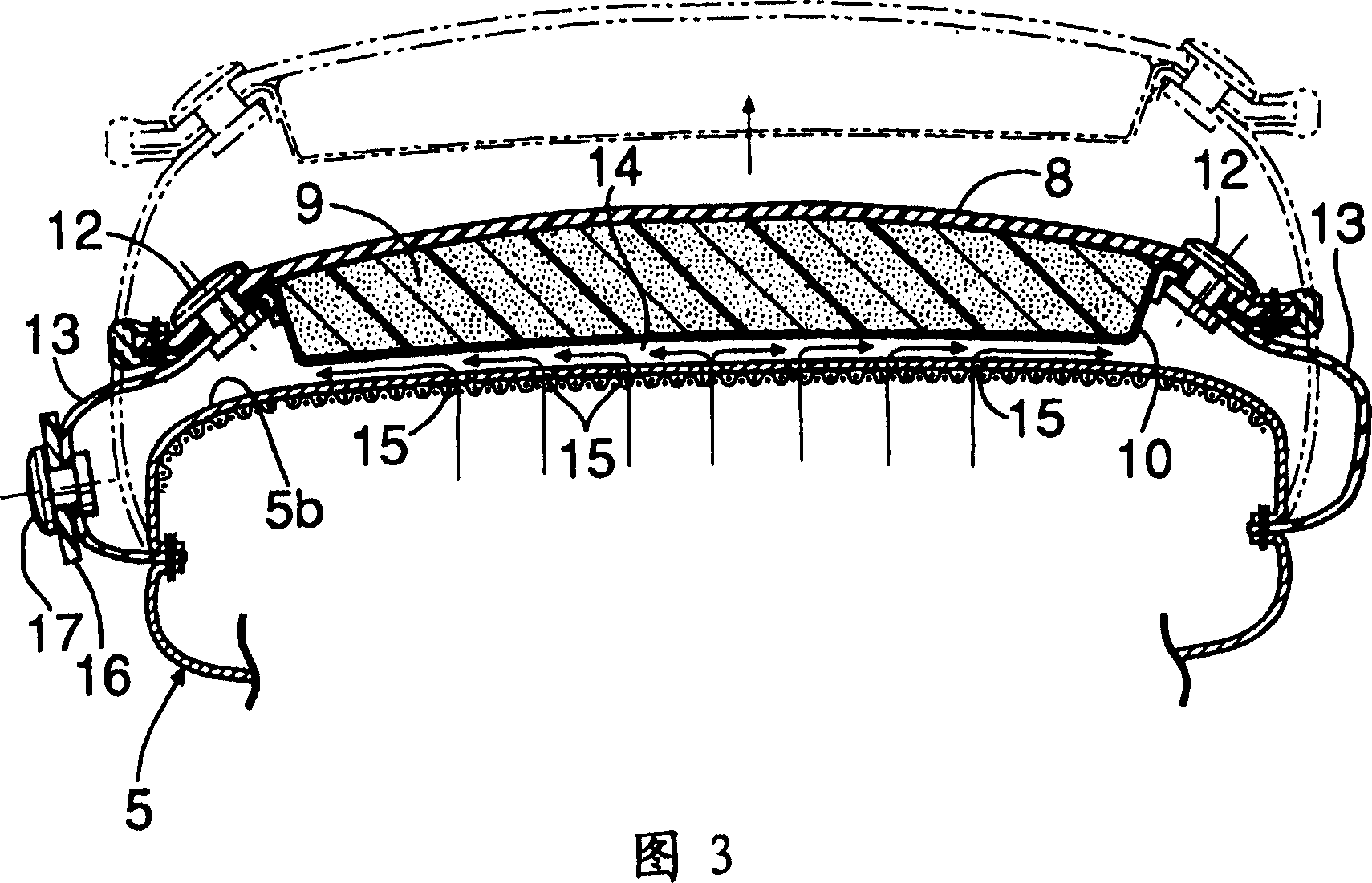

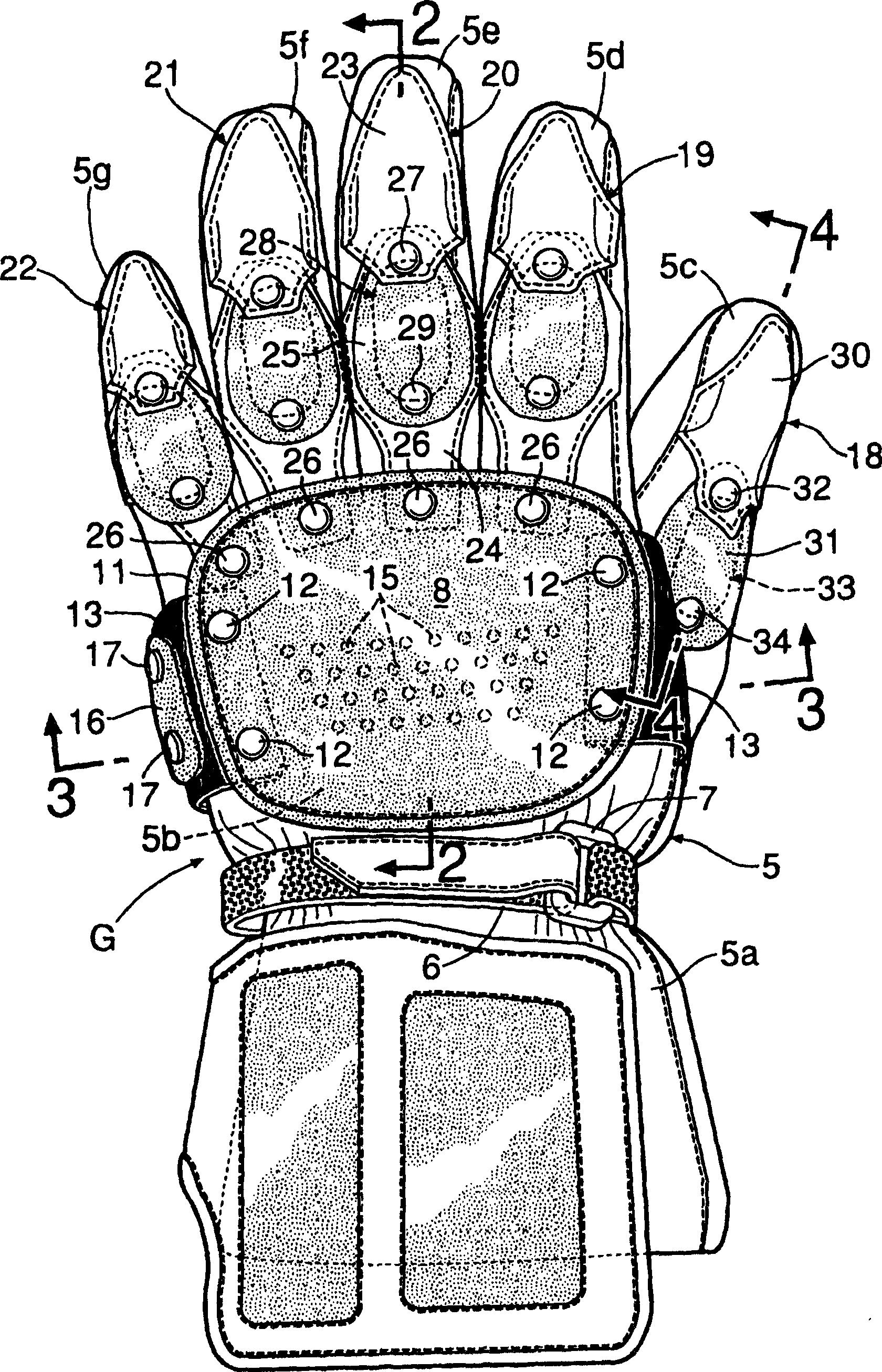

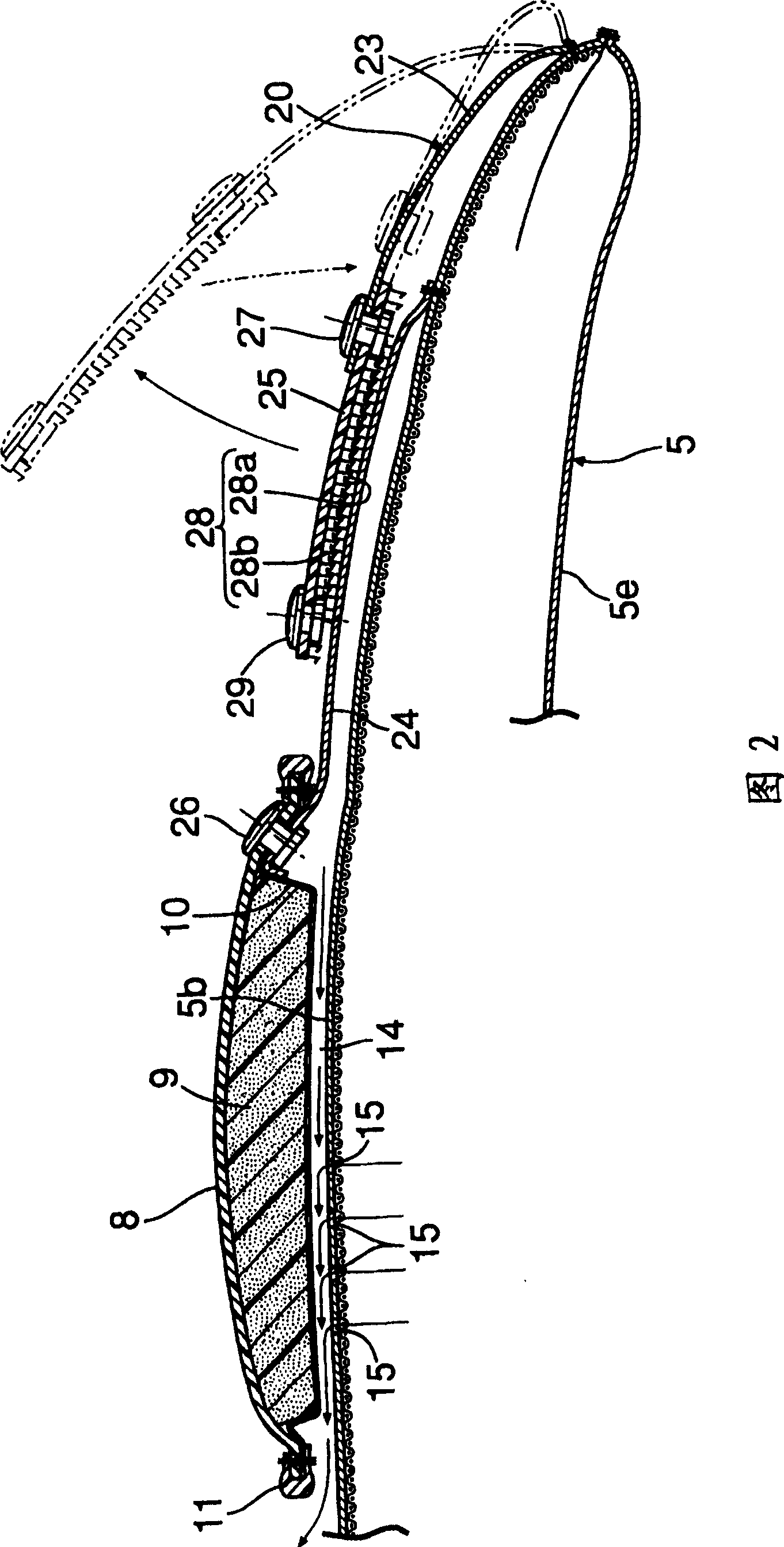

Sports gloves

InactiveCN101041110ALess touchSoft grip operationGlovesSport apparatusDorsum manusMechanical engineering

Owner:HONDA MOTOR CO LTD

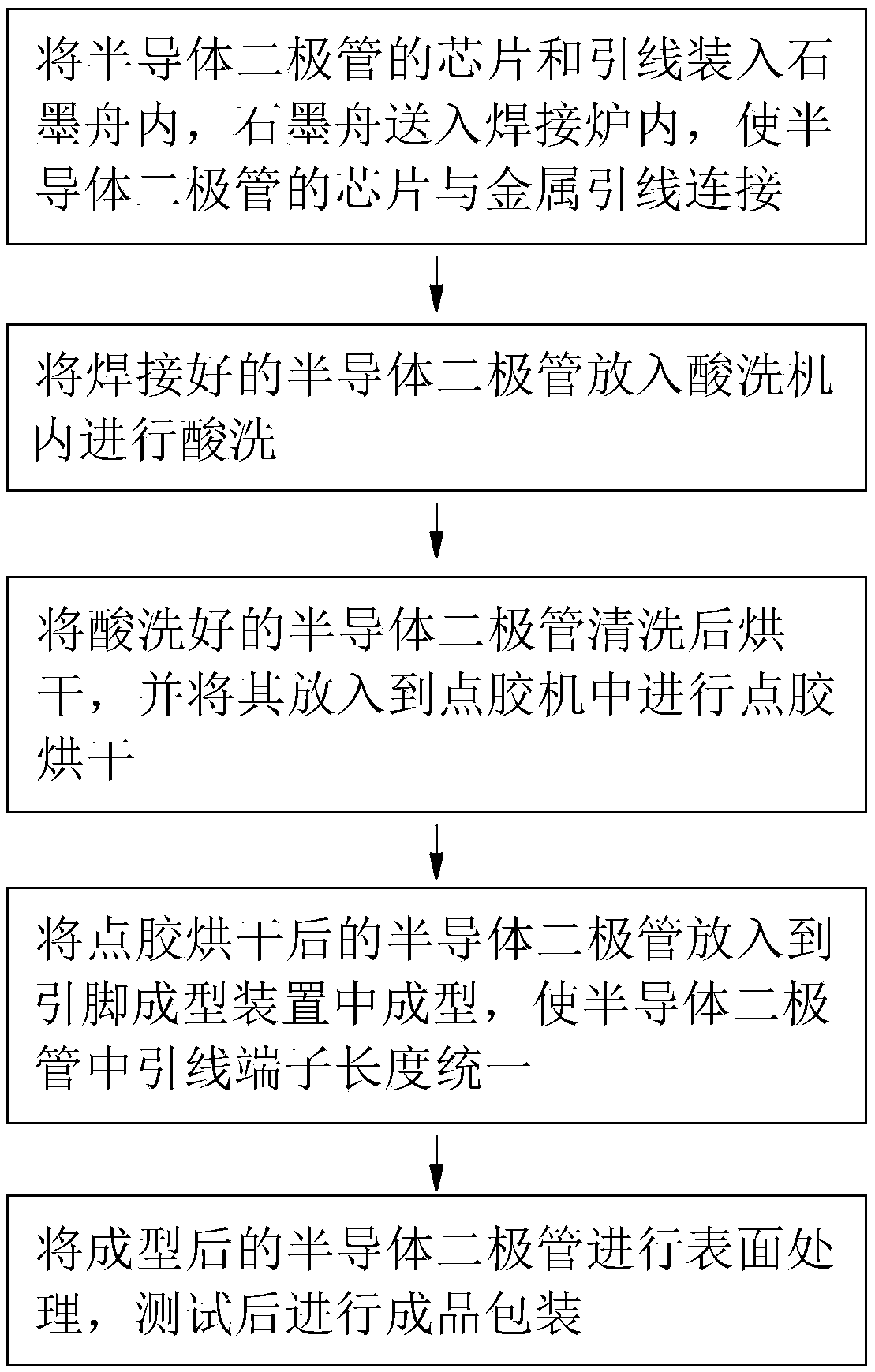

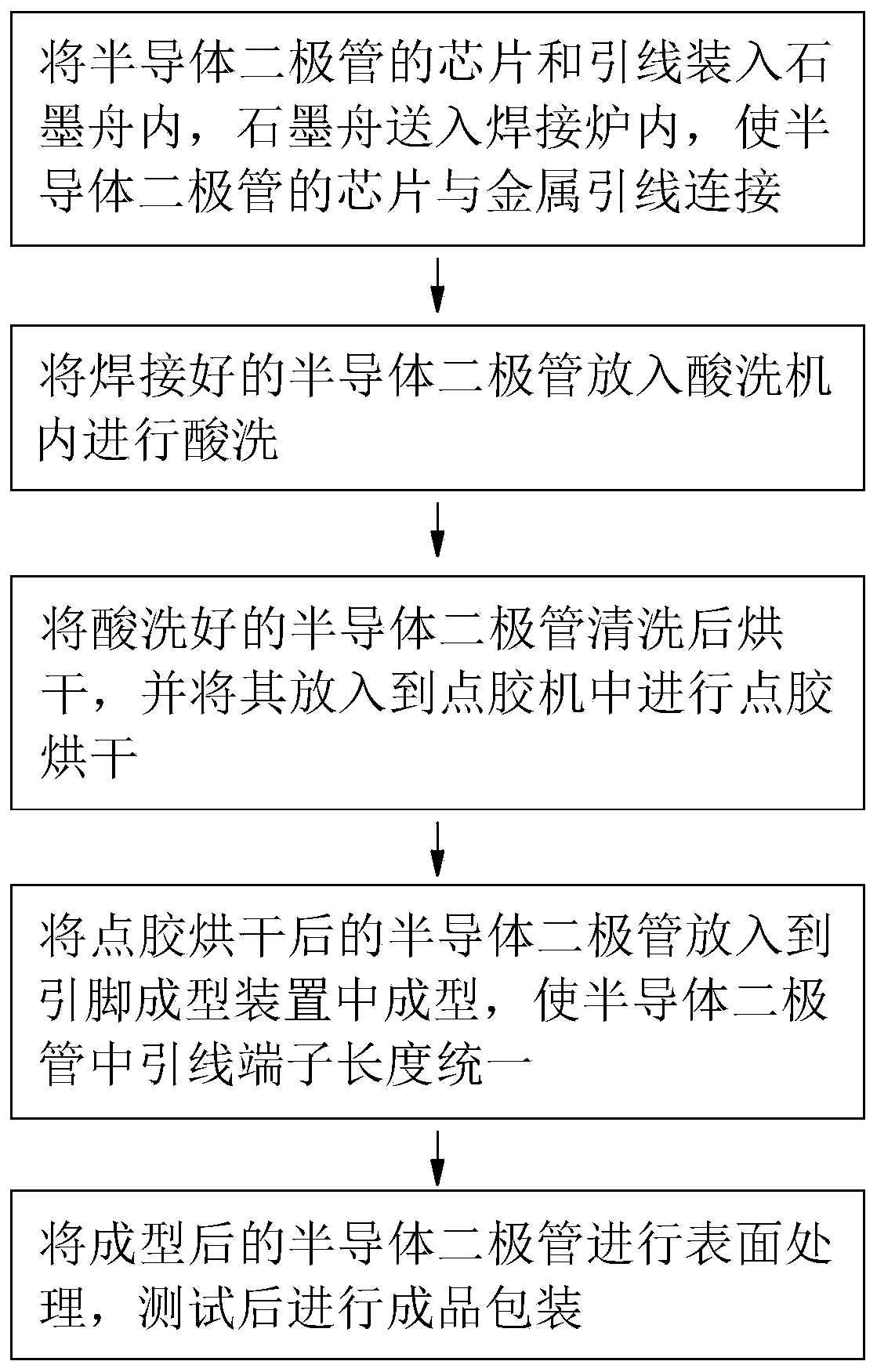

Production process of semiconductor diode

The invention belongs to the technical field of semiconductor diode manufacturing, and particularly relates to a production process of a semiconductor diode. The process comprises the following stepsthat a chip and a lead of the semiconductor diode are installed into a graphite boat, the graphite boat is fed into a welding furnace, and the chip of the semiconductor diode is connected with the metal lead; the welded semiconductor diode is placed in an acid pickling machine for acid pickling; the semiconductor diode subjected to acid pickling is dried after being cleaned, and the semiconductordiode is placed into a dispensing machine for dispensing drying; the semiconductor diode obtained after dispensing drying is placed into a pin forming device to be formed; and the formed semiconductordiode is subjected to surface treatment, and after testing, finish product packaging is carried out. According to the production process, bending modules are hinged to the two sides of the top of a lower mold, and the bending modules swing around the hinged portions when the lower mold moves downwards to achieve pin bending; and a dust removal module is arranged on the non-hinged side of each bending module, and dust in first locating grooves of the bending modules is removed.

Owner:吉林瑞能半导体有限公司

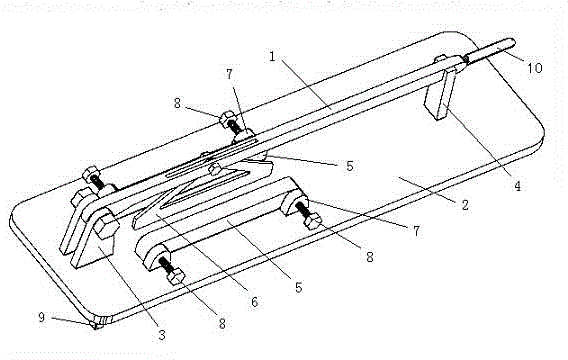

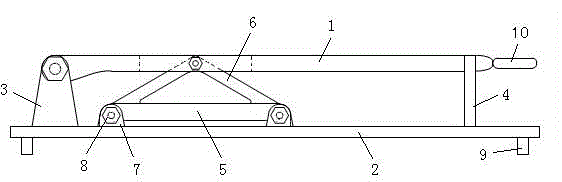

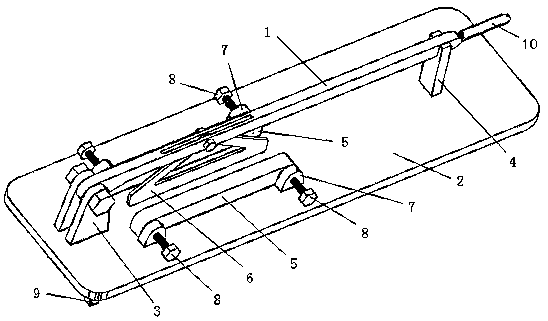

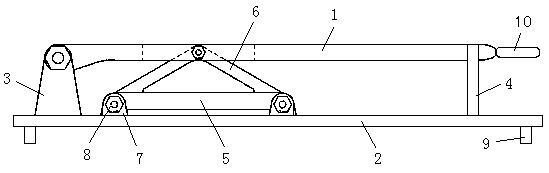

Sheet steel bending machine for construction site

The invention provides a sheet steel bending machine for a construction site, and relates to the technical field of building construction, which aims at solving the technical problem of difficulty in sheet steel bending at the construction site. The bending machine comprises a bottom plate and an upper form, wherein the left part of the top surface of the bottom plate is fixedly provided with a hinge support seat, the right part of the top surface of the bottom plate is fixedly provided with a lever frame, the top surface of the bottom part is provided with two lower forms which can slide front and back, the hinge support seat is provided with a lever, the left end of the lever is pivoted with the hinge support seat, the right part of the lever is arranged on the lever frame, the two lower forms are respectively arranged at the front side and the back side of the upper form, the top surface of the bottom plate is fixedly provided with a plurality of adjusting support seats, each adjusting support seat is provided with adjusting bolts for fixing the two lower forms, the upper form is a triangular frame body with an upward vertex angle, and is positioned between the hinge support seat and the lever frame, and the vertex angle part of the upper form is pivoted with the lever in a free rotating way. The bending machine is suitable for bending sheet metals at the construction site.

Owner:上海建科结构新技术工程有限公司 +1

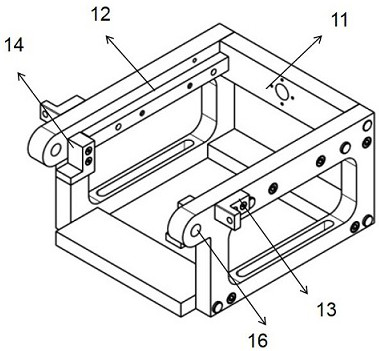

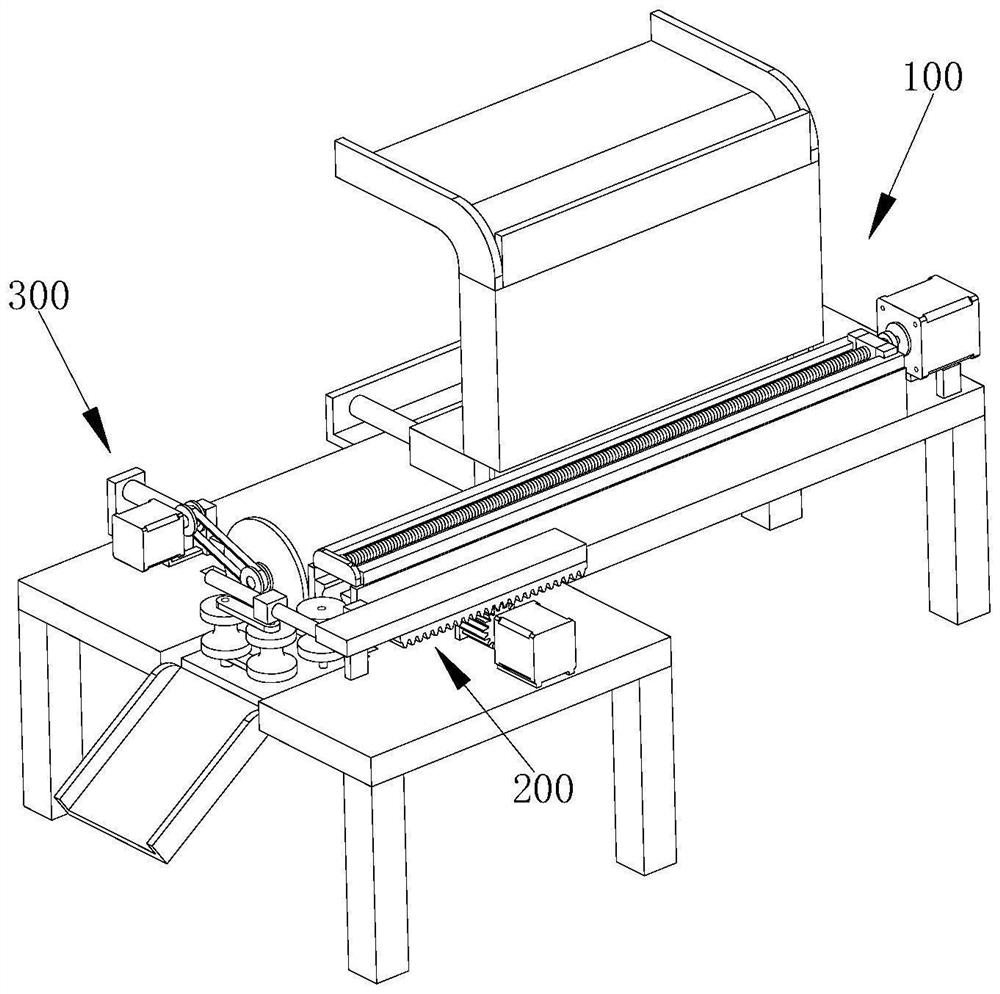

Novel flexible plate bending device

ActiveCN114733966AImprove surface qualityLow manufacturing costShaping toolsMetal-working feeding devicesRocker armManufacturing engineering

The invention relates to the technical field of industrial manufacturing, in particular to a novel flexible plate bending device. A novel flexible plate bending device comprises a base, a positioning lead screw, a clamping module, a bending module and a driving module. The base comprises a base body, and the clamping module comprises a fillet mold and a pressing plate; the front end of the base body is connected with a driving module; the driving module comprises two rocker arm brackets which are symmetrically arranged; a height limiting block is installed in the rocker arm support, and a bending module is installed in the height limiting block. The bending module comprises a bending rolling wheel and a rolling wheel shaft, the rolling wheel shaft is installed in the assembling through hole, and the bending rolling wheel is rotationally connected to the outer side of the rolling wheel shaft. Through mutual matching and combination of the fillet dies with different radiuses, the height-adjustable bending rollers and the positioning devices at different positions, a high-precision and low-cost bending process can be carried out on parts with different materials, different thicknesses and different bending sizes.

Owner:SOUTHWEST UNIVERSITY

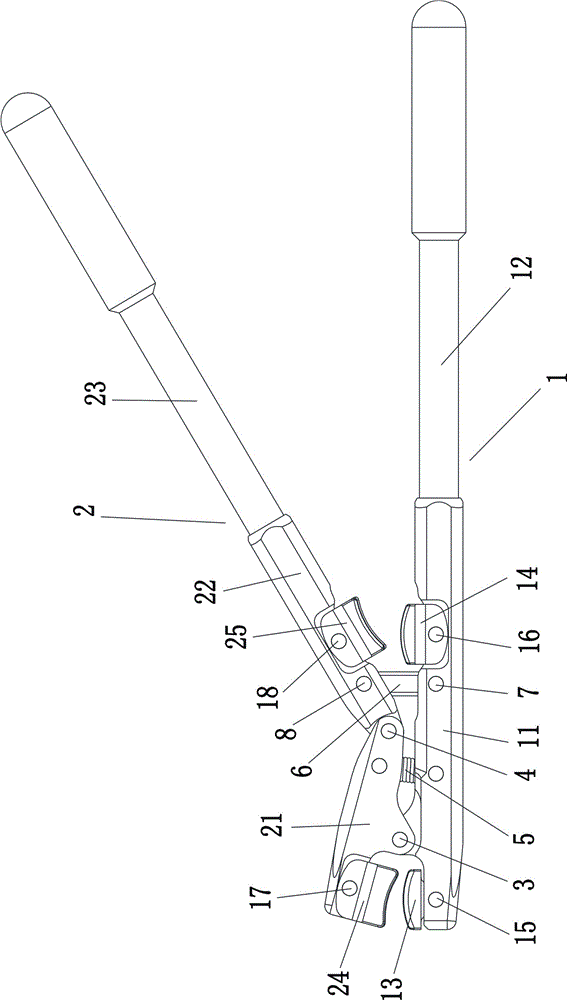

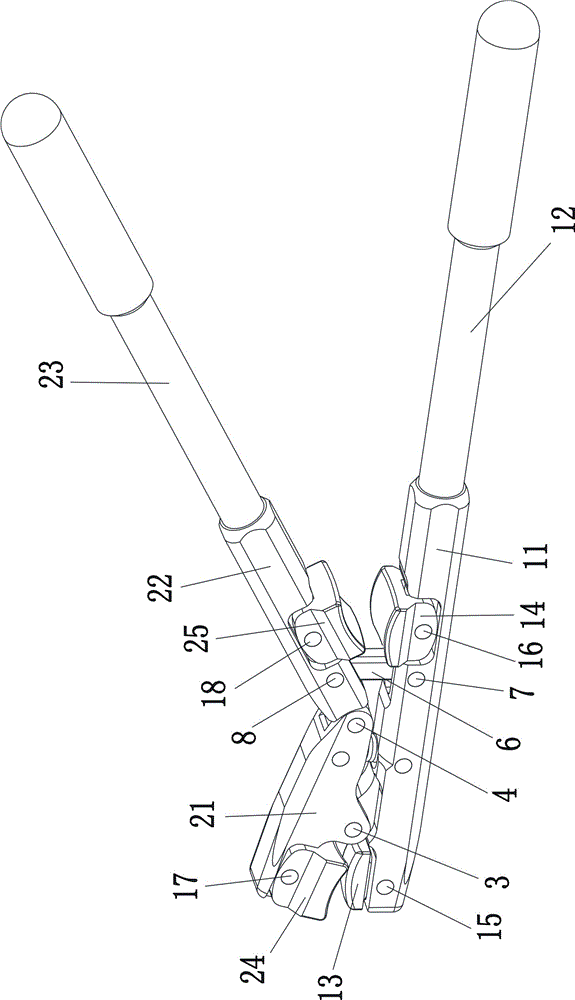

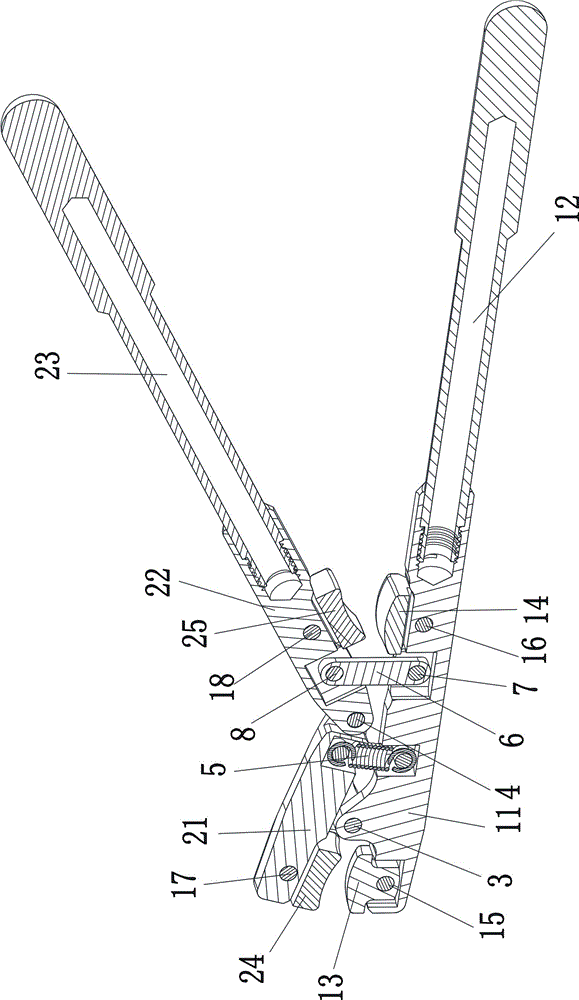

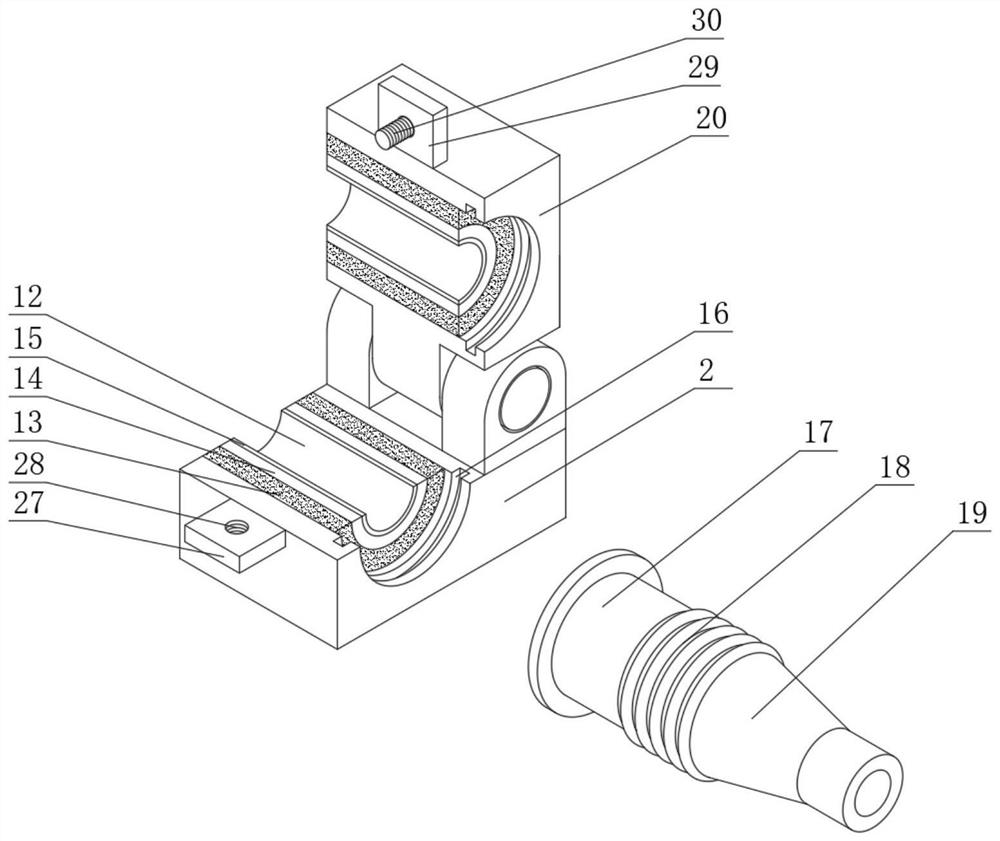

Dual-joint board bending forceps

ActiveCN106236239APress firmlyNot easy to come outSurgical forcepsBone platesCERVICAL FIXATIONOn board

The invention discloses dual-joint board bending forceps being used by cooperating with an anterior cervical fixation system in a spinal fixation operation. The board bending forceps are provided with a left forceps handle and a right forceps handle which are movably connected through a first connecting shaft. The dual-joint board bending forceps are structurally characterized in that the left forceps handle is composed of a left pincer head and a left handle which are fixedly connected; the right forceps handle is composed of a first right forceps head, a second right forceps head and a right handle, one end of the second right forceps head is movably connected with the first right forceps head through a second connecting shaft, and the other end of the second right forceps head is fixedly connected with the right handle; a spring is connected between the first right forceps head and the left forceps head, and a connecting rod is movably connected between the second right forceps head and the left forceps head; the head of the left forceps head is provided with a first left cushion block, and the head of the first right forceps head is provided with a first right cushion block matched with the first left cushion block; a forceps body of the left forceps head is provided with a second left cushion block, and a forceps body of the second right forceps head is provided with a second right cushion block matched with the second left cushion block. The board bending forceps have the advantages of being easy and convenient to operate, accurate in positioning, firm in clamping and high in stability.

Owner:ZHEJIANG KANGCI MEDICAL TECH

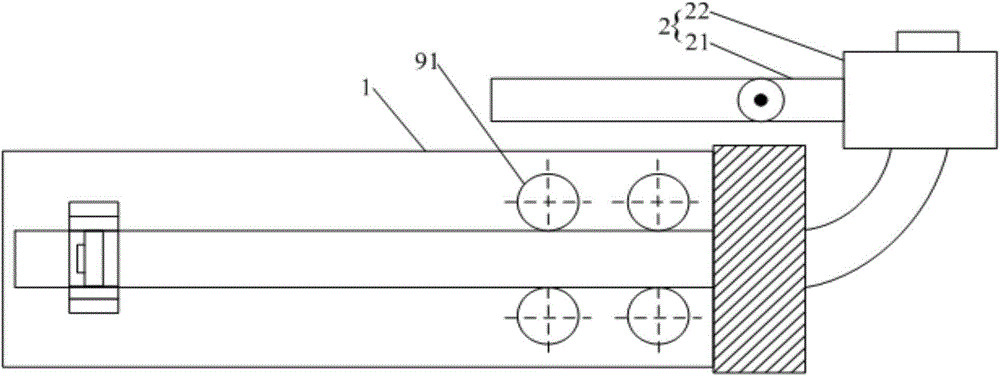

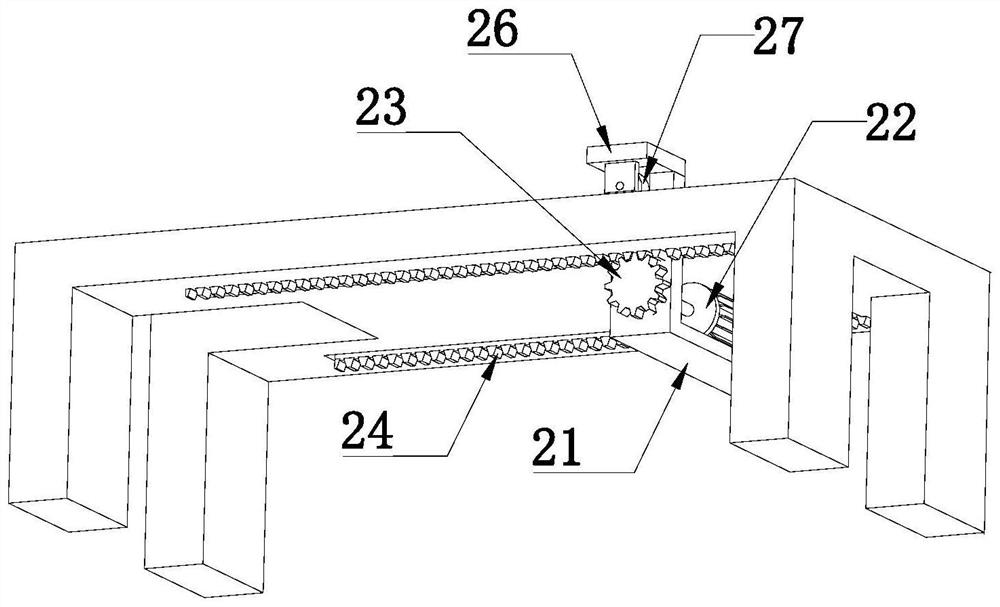

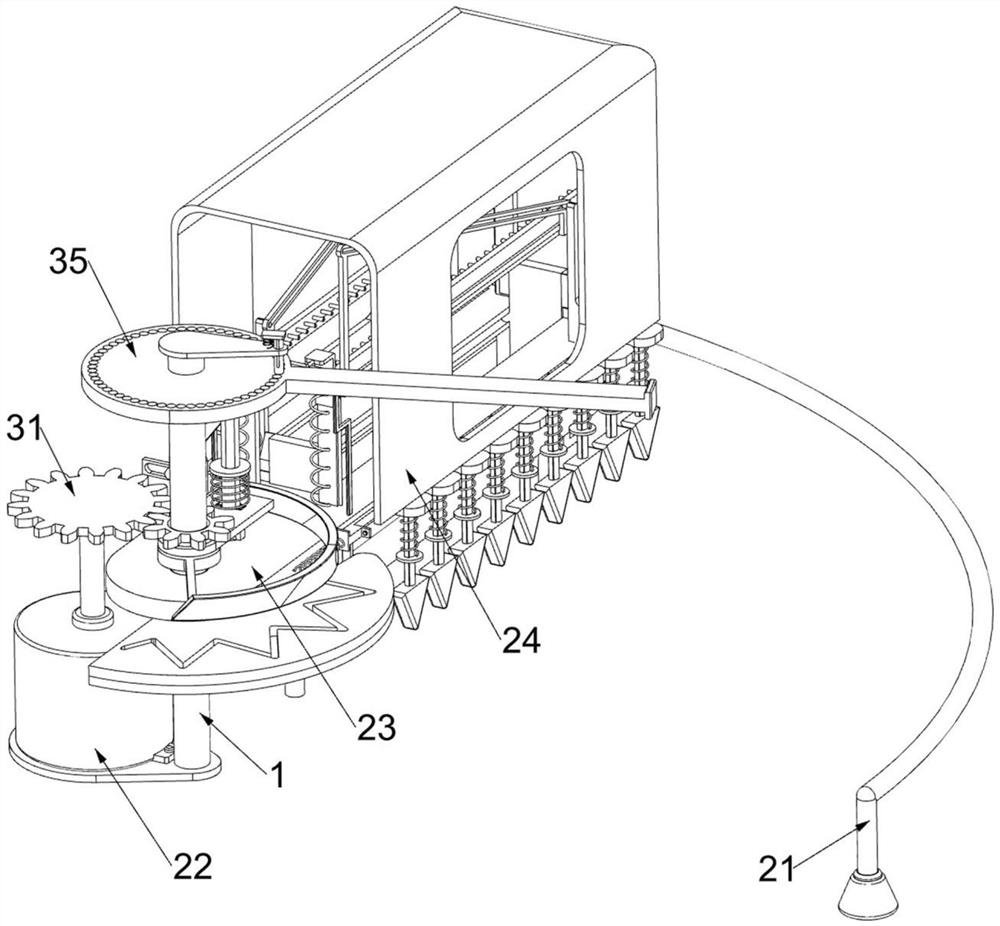

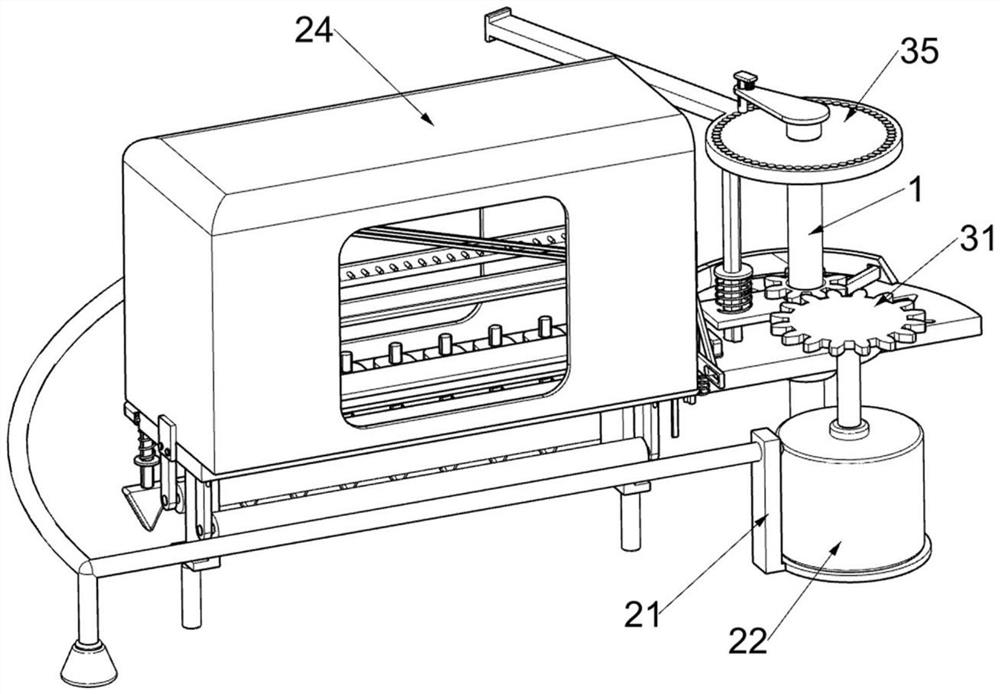

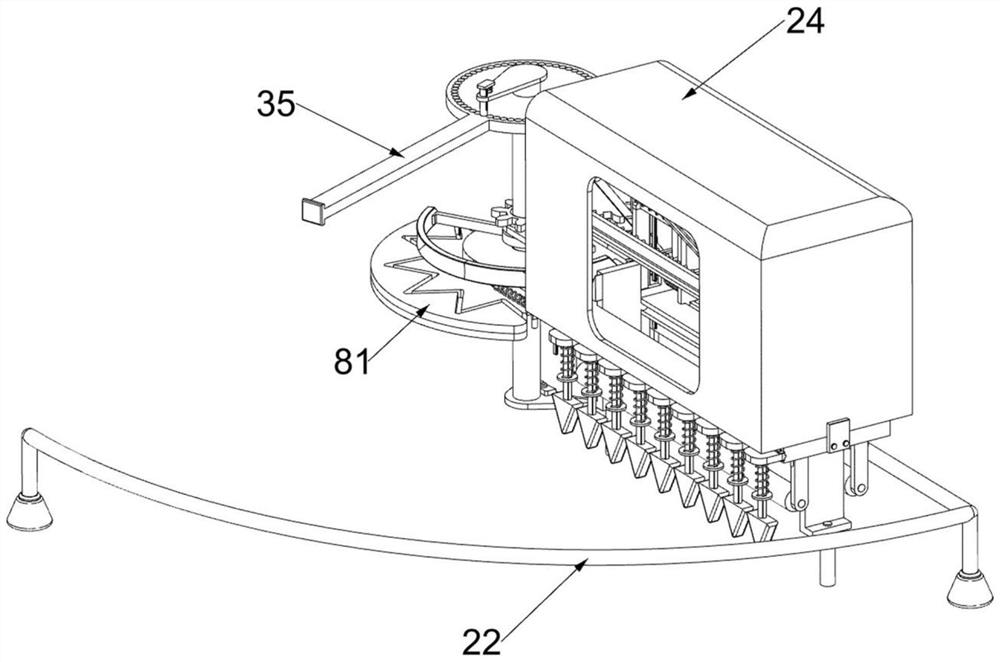

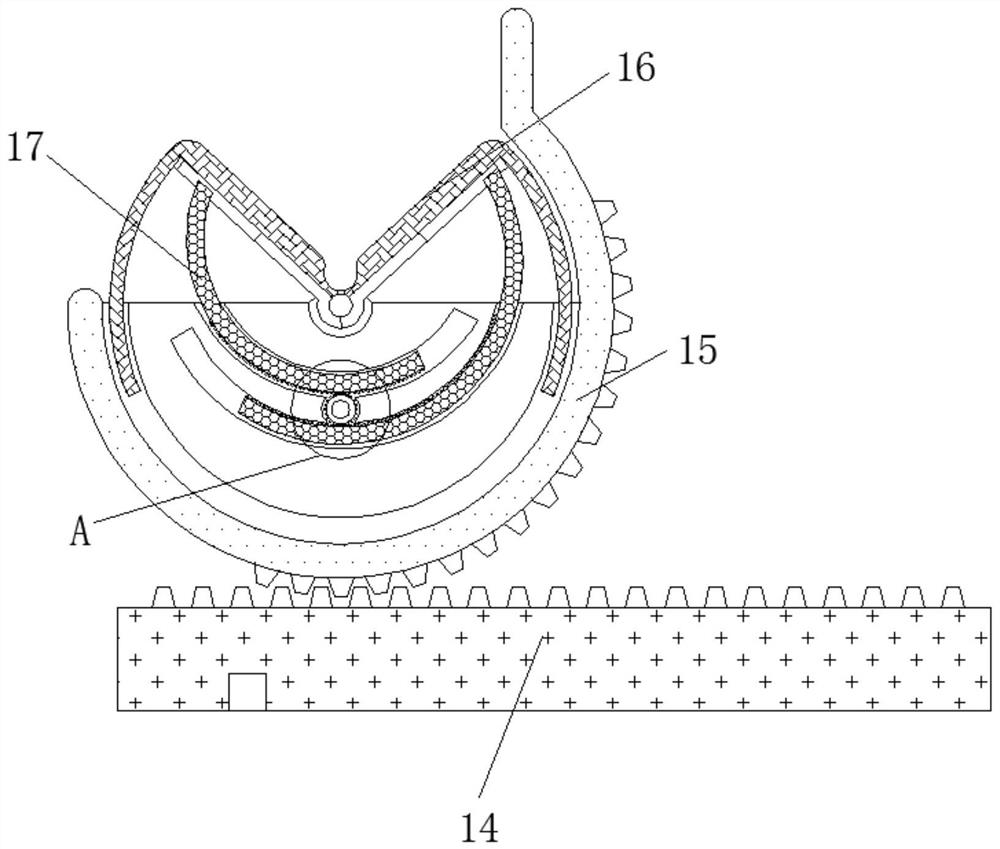

Circular pipe cutting and bending device and using method thereof

InactiveCN113333526APrevent slippingEasy to bendMetal-working feeding devicesPositioning devicesGear wheelClassical mechanics

The invention relates to the technical field of circular pipe cutting and bending, in particular to a circular pipe cutting and bending device and a using method thereof. The circular pipe cutting and bending device comprises a feeding mechanism, the feeding mechanism comprises a supporting frame unit, the supporting frame unit comprises an L-shaped operation table, a feeding unit used for conveying a circular pipe is fixedly arranged at the top of the L-shaped operation table, and a bending mechanism used for bending the circular pipe is fixedly arranged at one end of the top of the L-shaped operation table. According to the circular pipe cutting and bending device, a circular steel pipe is clamped and positioned through a first positioning wheel, a second positioning wheel and a bending wheel, and a gear can be driven to rotate through an output end of a second driving motor, so that a moving plate can be driven to move in the direction of a circular rod, a sliding block can be driven to slide on the circular rod through the circular rod, the sliding block can drive the bending wheel to rotate around a first rotating shaft, the bending wheel can bend one end of the circular steel pipe, the rotating angle of the bending wheel can be adjusted by adjusting the moving distance, and the bending angle of the circular steel pipe can be accurately adjusted.

Owner:梁云招

Bending mold

InactiveCN109985969AReduce processing costsShorten the development cycleShaping toolsMold testingMachining

The invention relates to a bending mold. The bending mold comprises a lower mold assembly and an upper mold assembly parallel to the lower mold assembly. The lower mold assembly includes a lower moldbase, a forming block connected to the lower mold base and a bending push block slidably connected to the lower mold base. The upper mold assembly includes an upper mold base, a slotting tool slidablyconnected to the upper mold base and an adjusting block slidably connected to the upper mold base. One end of the slotting tool extends out of the upper mold seat and extends toward the lower mold seat to drive the bending push block to slide toward the forming block. The adjusting block is slidably disposed on the upper mold base and one end of the adjusting block extends to the outer side of the upper mold base. The adjusting block is slidably connected with the slotting tool to adjust the amount of extension of the slotting tool relative to the upper mold base. According to the bending mold, in the mold-testing process, by adjusting the adjusting block without modifying the angle of a forming part in the mold, the purpose of adjusting the bending angle of a product can be achieved, themold machining cost can be reduced, and the development cycle of the mold can be shortened.

Owner:GUANGDONG EVERWIN PRECISION TECH

Hydraulic pipe bending machine

ActiveCN113751559AAdjust the bend angleAvoid offsetMetal-working feeding devicesPositioning devicesStructural engineeringMachine

The invention discloses a hydraulic pipe bending machine, and belongs to the technical field of pipe bending equipment. The hydraulic pipe bending machine comprises a workbench, a conveying assembly, a fixing assembly, an adjusting assembly and a bending assembly, the conveying assembly is arranged on the workbench, the conveying assembly is in sliding fit with the workbench, the fixing assembly is arranged on the conveying assembly, the adjusting assembly is arranged on the workbench, and the bending assembly is arranged beside the adjusting assembly. According to the hydraulic pipe bending machine, one end of a pipe is clamped and fixed through the fixing assembly, the conveying assembly works to drive the fixing assembly and the pipe to move forwards, the part, needing to be bent, of the pipe is moved to the position above the adjusting assembly, the adjusting assembly adjusts the bending angle of the pipe, the bending assembly works to bend the pipe, and the bending angle of the pipe is adjusted according to equipment applied to the pipe.

Owner:广东科欣电气有限公司

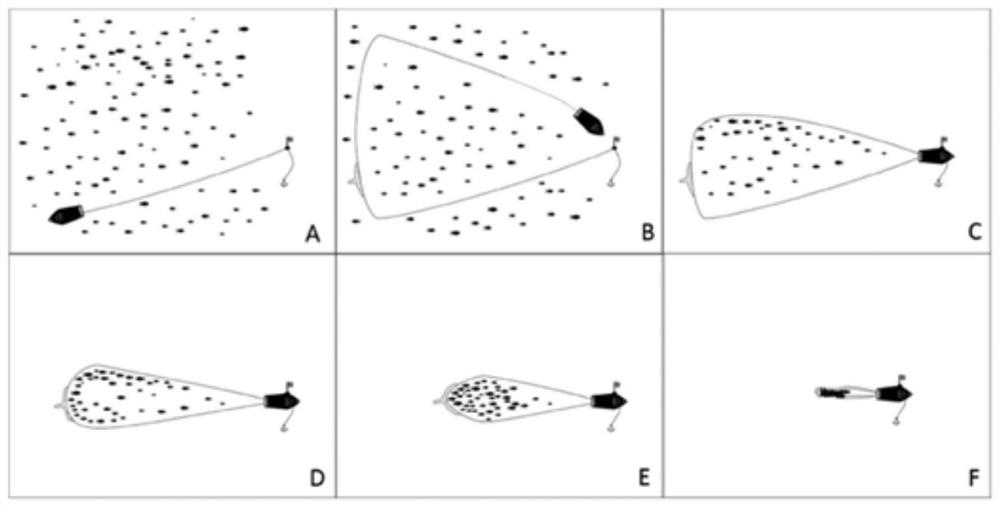

Emergency shrimp fishing purse net and use method therefor

ActiveCN111972364AWill not cause overfishingExtended service lifeFishing netsClimate change adaptationShrimpEngineering

The invention discloses an emergency shrimp fishing purse net and a use method therefor. The emergency shrimp fishing purse net comprises a plurality of netting sheets and air bags arranged at edges of single sides of the netting sheets, wherein a plurality of sinkers are arranged at single sides, symmetric to the air bags, of edges of the netting sheets and are distributed at intervals; a plurality of grooves are formed in the air bags at intervals along a length direction, a hauling cable is arranged at end parts of the air bags, a free end of the hauling cable is connected with a tractor tug, and the tractor tug can drive the netting sheets to move to form an encircled space; at least one light source member are arranged on a water surface in the encircled space and are at least partially arranged below the water surface, and floating members are arranged on the light source members and can be used for adjusting a ratio of a water-surface upper part to a water-surface lower part ofeach light source member; and monitoring members are arranged at bottoms of the light source members, and the quantity of shrimps in a water area below the light source members can be monitored through the monitoring members.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Wiring bending device with cable arrangement function for communication cables

PendingCN113878852AEffects of Autorouting BendsChange angleOptical articlesDomestic articlesTelecommunicationsReciprocating motion

Owner:邓福河

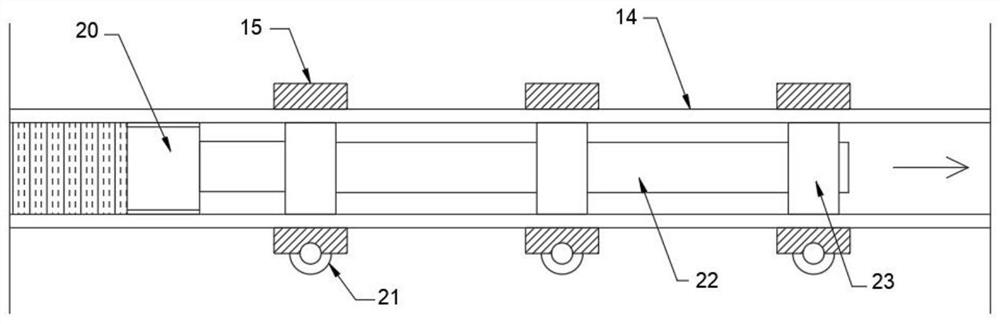

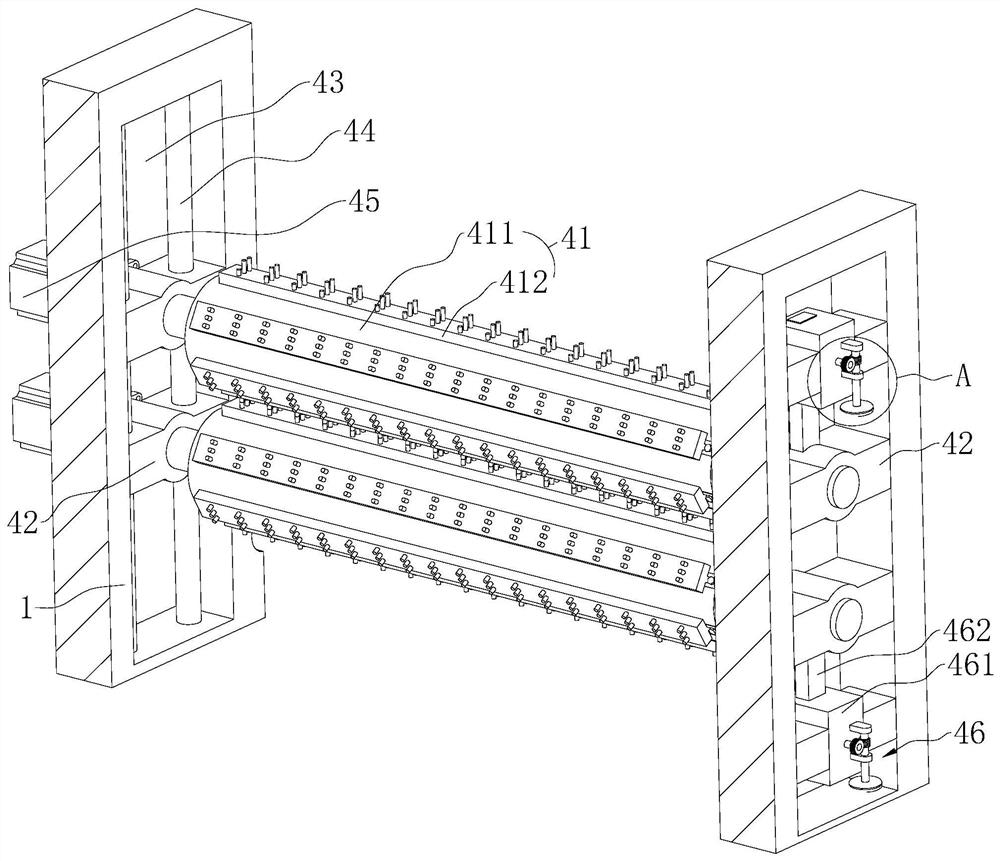

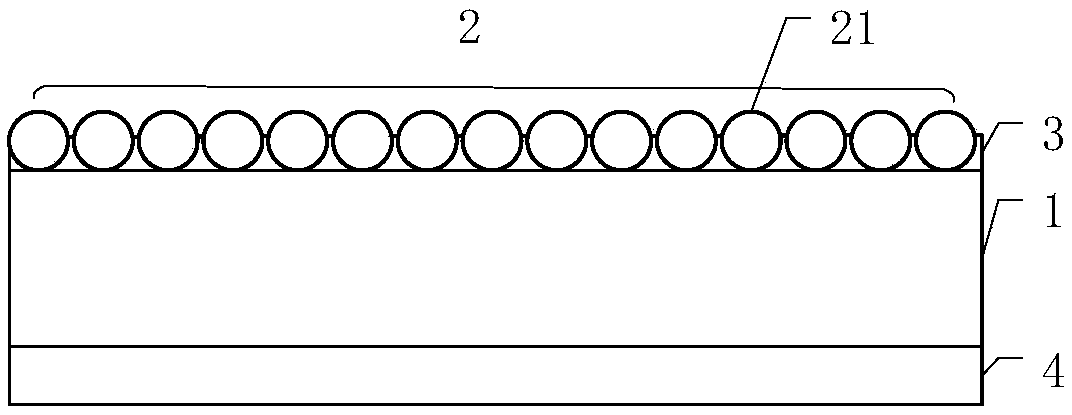

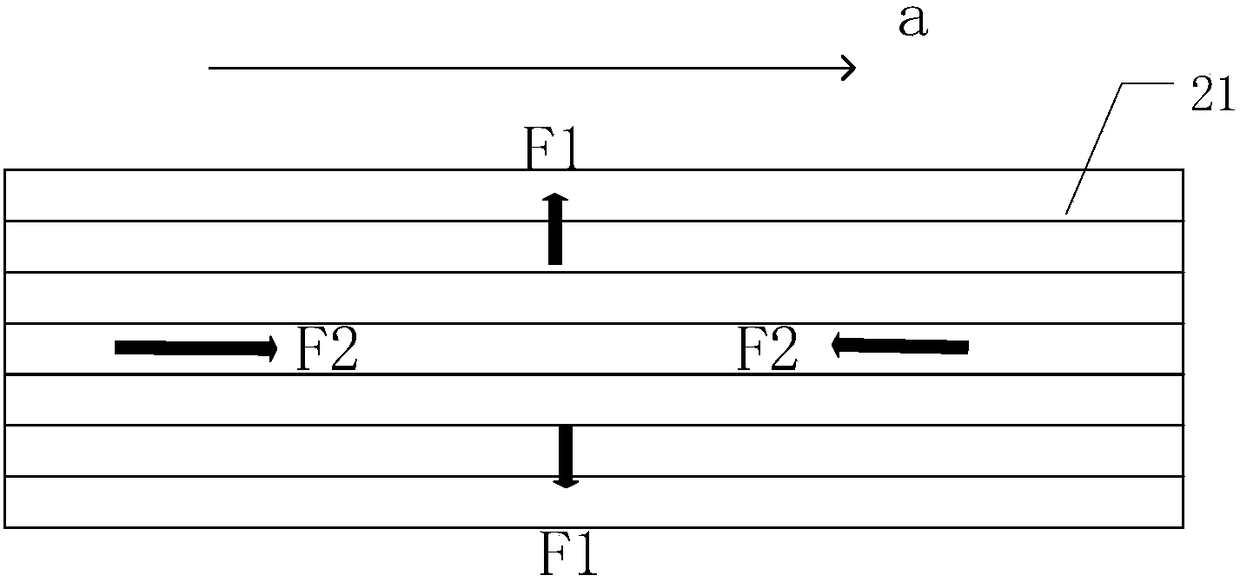

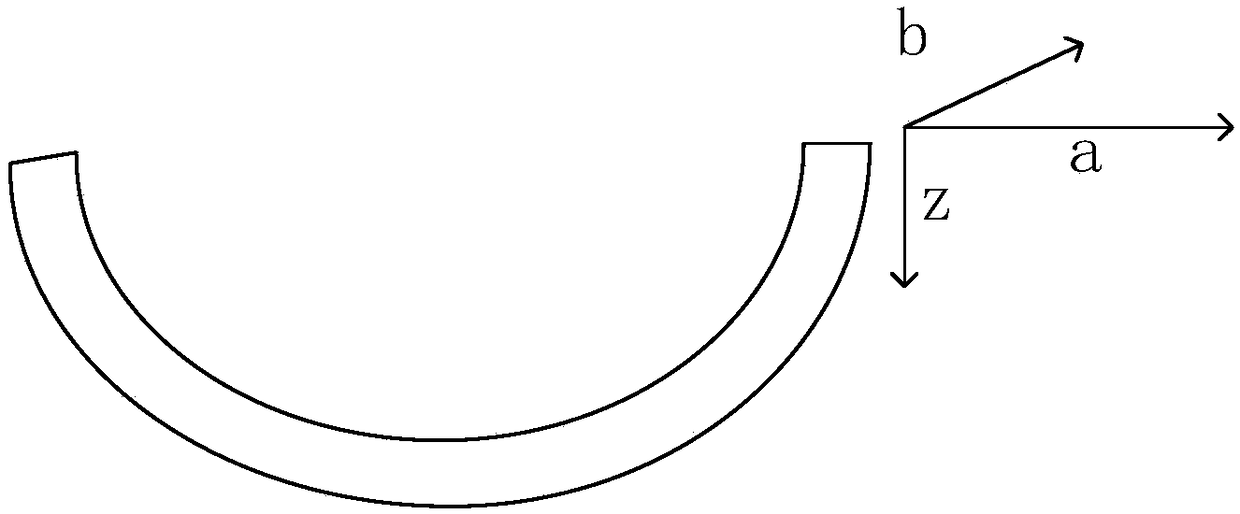

A pretreatment device for pickling steel coils

ActiveCN109504979BEasy pickling workImprove effective utilizationStructural engineeringMechanical engineering

Owner:浙江协和薄钢科技有限公司

Semiconductor structure and method of forming the same

InactiveCN108493161ASimple structureReduce volumeDecorative surface effectsSemiconductor/solid-state device detailsSemiconductor structureCarbon nanotube

The invention provides a semiconductor structure and a method of forming the same. When the semiconductor structure is heated or exposed to light, bending of a flexible substrate is promoted by an ester material layer and carbon nano tubes because the thermal expansion coefficient of the ester material layer is larger than that of the flexible substrate. Furthermore, the gaps between the flexiblesubstrate and the carbon nano tubes and gaps between the carbon nano tubes are filled with the ester material layer, so that the spaces between the carbon nano tubes are increased by the ester material layer. The carbon nano tubes can constrain the expansion of the ester material layer, so that the semiconductor structure is bent; and when not being heated or exposed to light, the semiconductor structure becomes flat again. The semiconductor structure having advantages of small size, simple structure, and great convenience in controlling can be applied to various devices like a switch or a sensor.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

A kind of semiconductor diode production process

ActiveCN108672597BAchieve clearingAchieve hold downSemiconductor/solid-state device manufacturingCleaning using toolsGraphiteSemiconductor

The invention belongs to the technical field of semiconductor diode manufacturing. Specifically, it is a semiconductor diode production process. The process includes the following steps: putting the chips and leads of the semiconductor diode into a graphite boat, and sending the graphite boat into a welding furnace to make the semiconductor diode Connect the chip to the metal lead; put the welded semiconductor diode into the pickling machine for pickling; clean and dry the pickled semiconductor diode, and put it into the dispensing machine for dispensing and drying ; Put the glue-dispensed and dried semiconductor diode into the pin forming device for molding; perform surface treatment on the molded semiconductor diode, and then package the finished product after testing; the present invention realizes by hinged bending modules on both sides of the top of the lower mold. When the lower mold moves downward, the bending module swings around the hinge to bend the pin; a dust removal module is provided on the non-articulated side of the bending module to remove dust in the No. 1 positioning slot of the bending module.

Owner:吉林瑞能半导体有限公司

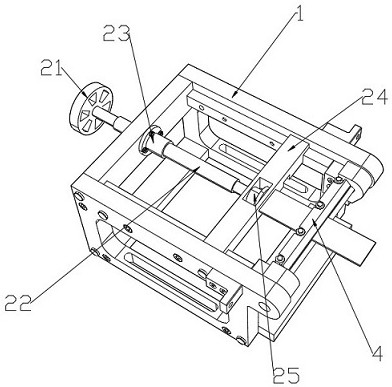

Tubular metal bending equipment with adjustable bending angle for metal forming

InactiveCN112058963AAdjust the bend angleImprove efficiencyMetal-working feeding devicesPositioning devicesMetal formingElectric machine

The invention discloses tubular metal bending equipment with an adjustable bending angle for metal forming. The equipment comprises a bearing mechanism and a locating and clamping mechanism, wherein the locating and clamping mechanism is mounted on the upper end face of the bearing mechanism. According to the equipment, a fixing groove is formed in the upper end of the side, close to an arc-shapedworkbench, of a main bearing table, and a plurality of rolling shafts are arranged in an inner cavity of the fixing groove; tubular metal can be firstly placed in the fixing groove before being bent,a bending assembly returns to the initial position, meanwhile, the inner side of a bending piece makes contact with the tubular metal, and the tubular metal is fixed; during bending, a servo motor and a rotating motor are started,the fixed tubular metal is driven to be bent by the arc movement of an arc-shaped electric sliding block in an arc-shaped sliding groove and the rotation of an arc-shaped rotating disc, the servo motor and the rotating motor can be stopped at any time in the moving process of the arc-shaped electric sliding block, and therefore the purpose of adjusting the bending angle is achieved; and compared with a traditional manual bending mode, the efficiency and the automation level are higher.

Owner:秦素容

Sports gloves

Owner:HONDA MOTOR CO LTD

Bending device

ActiveCN108051315BWide versatilitySimple structureMaterial strength using steady bending forcesEngineeringMechanical engineering

Owner:GUANGDONG EVERWIN PRECISION TECH

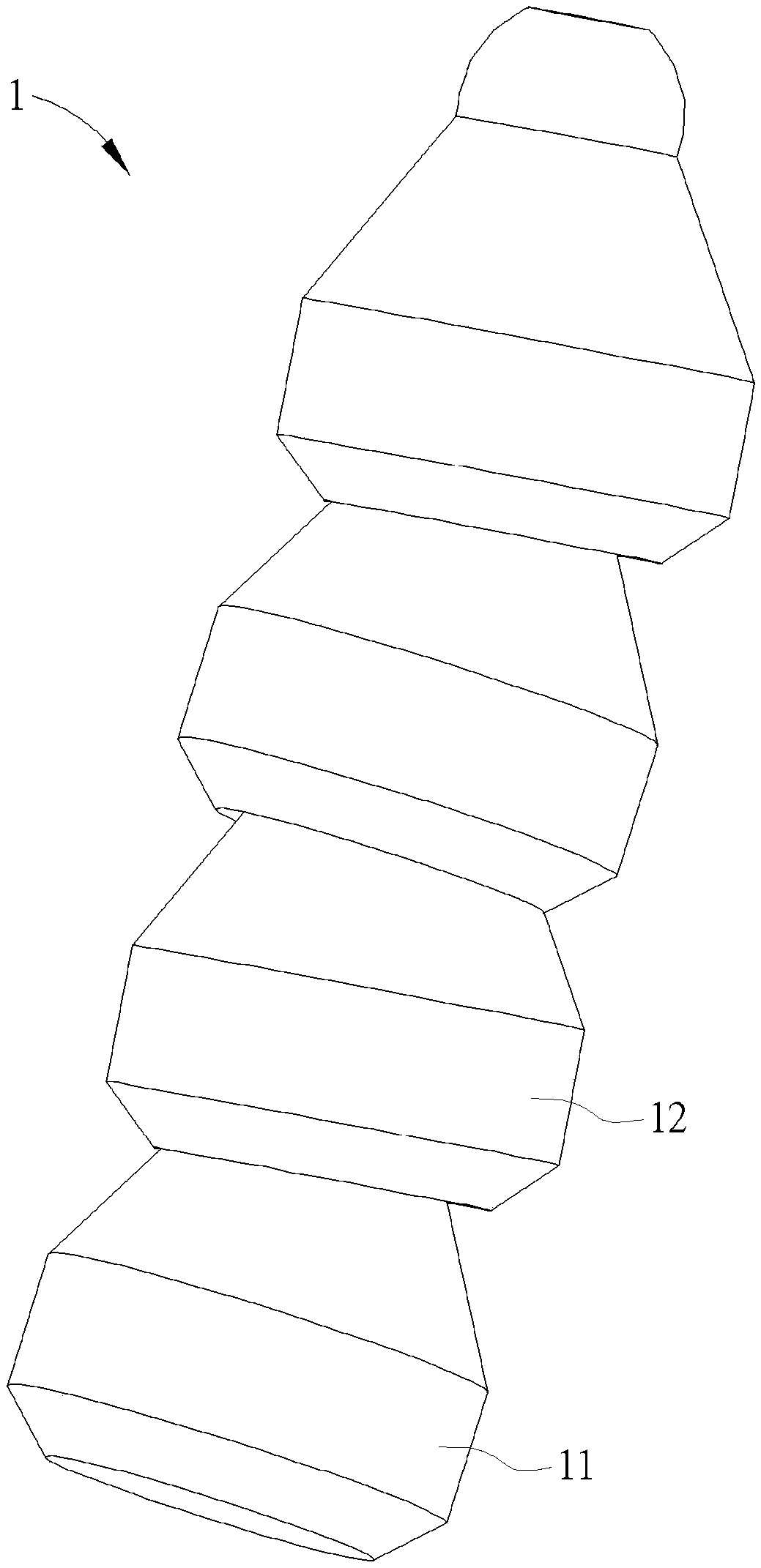

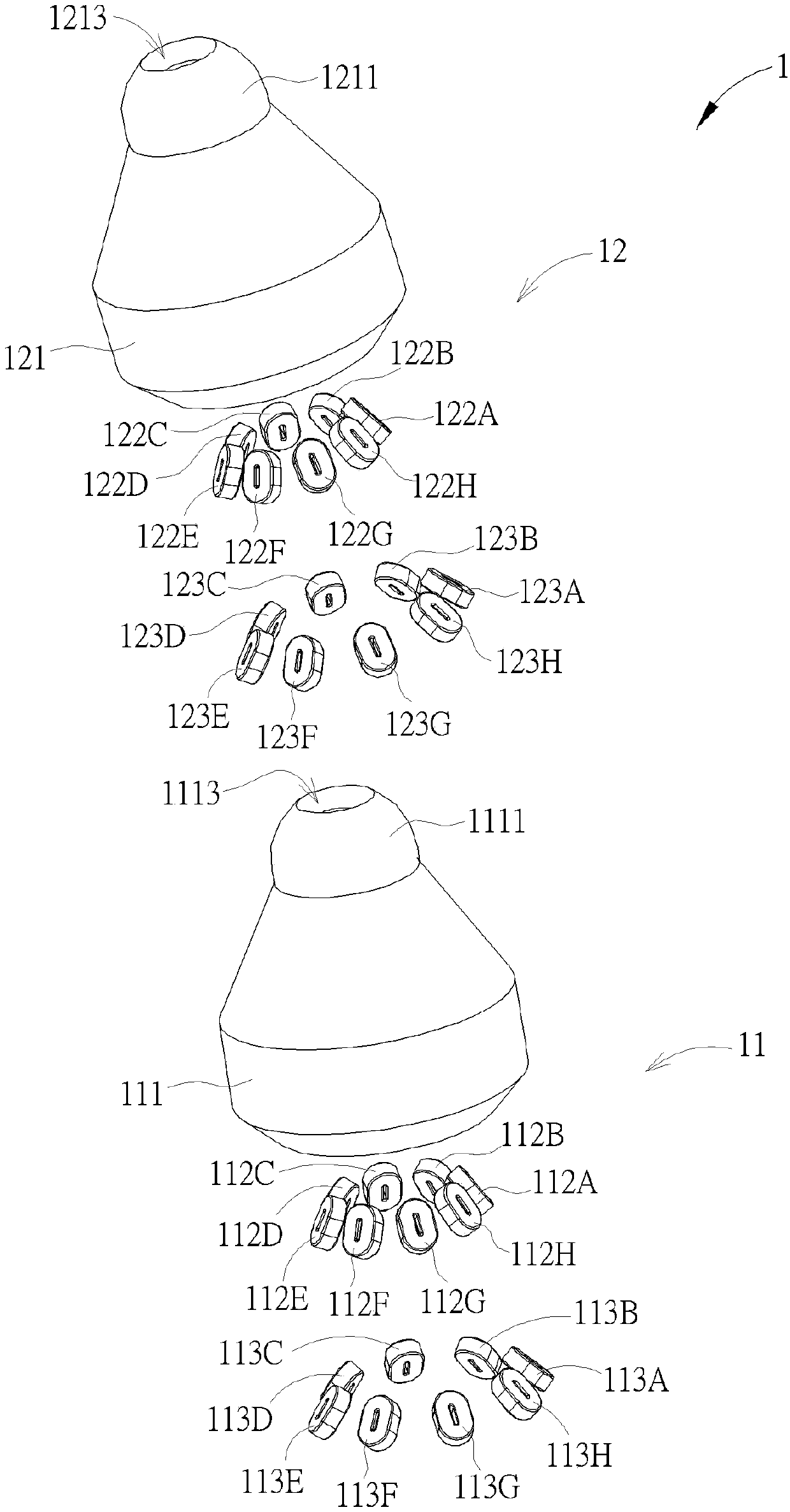

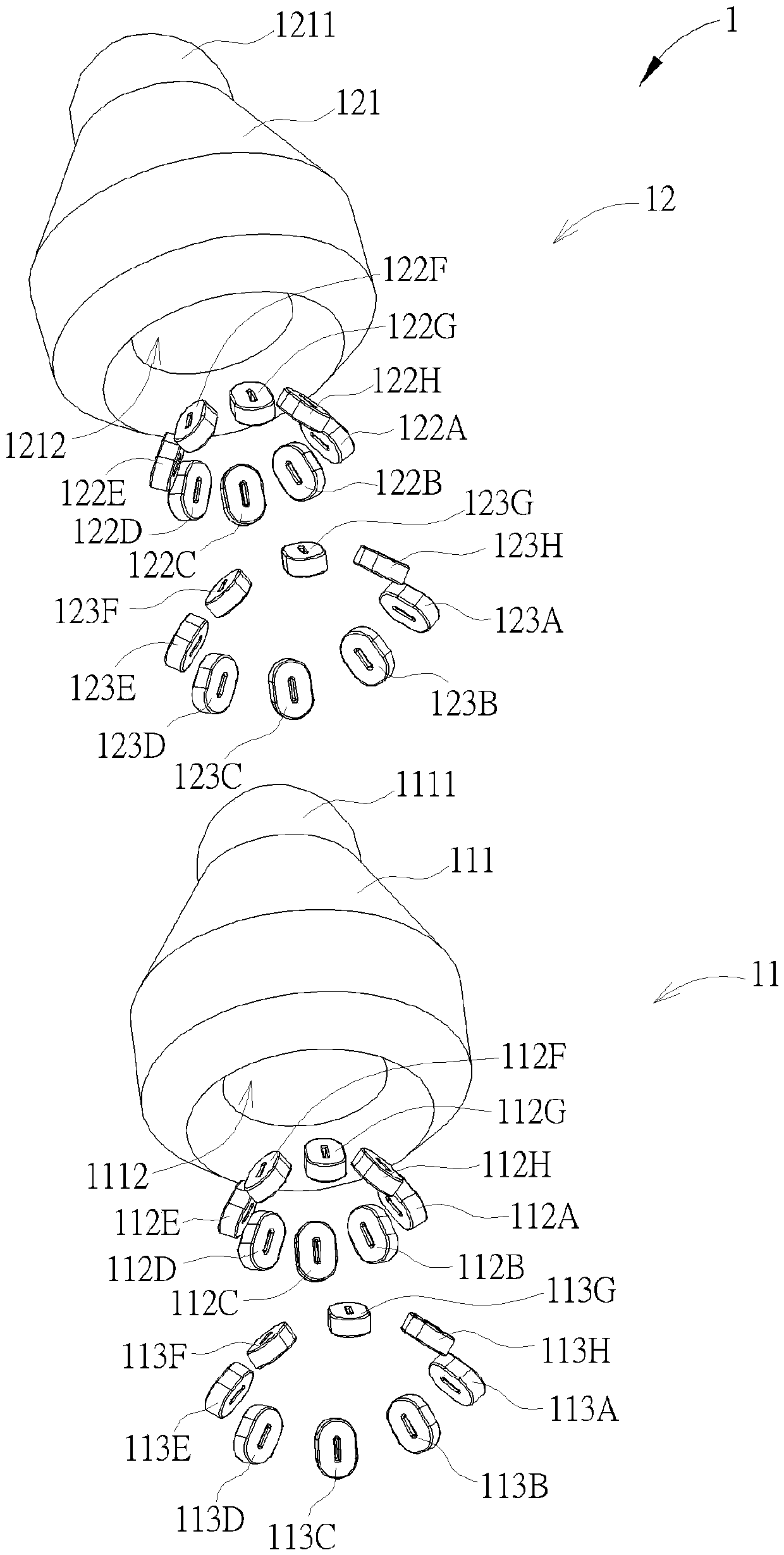

Tubing structure

ActiveCN110556753AAdjust the bend angleAdjustable lengthAdjustable jointsFlexible pipesEngineeringMagnetic components

Owner:WISTRON CORP

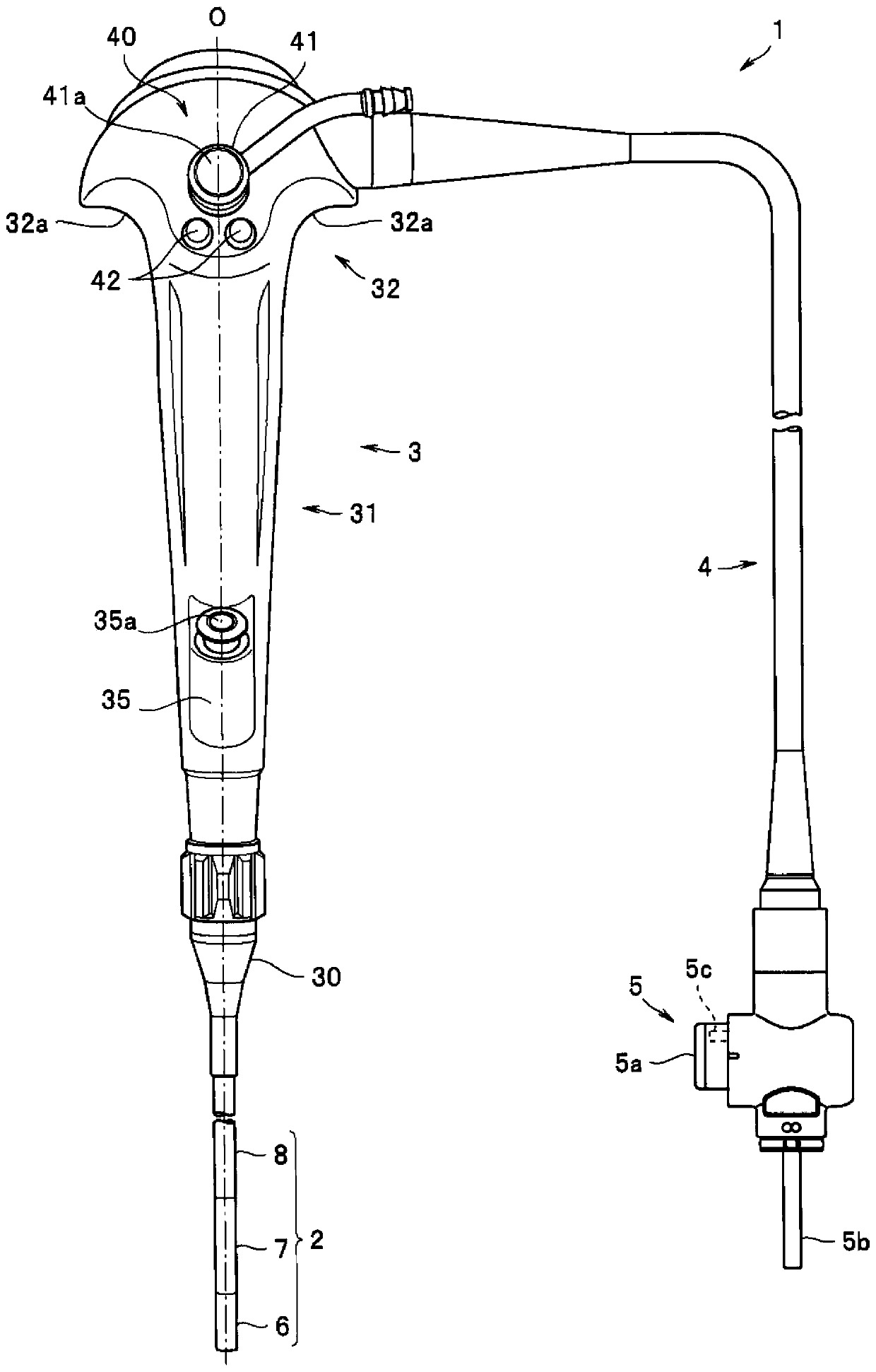

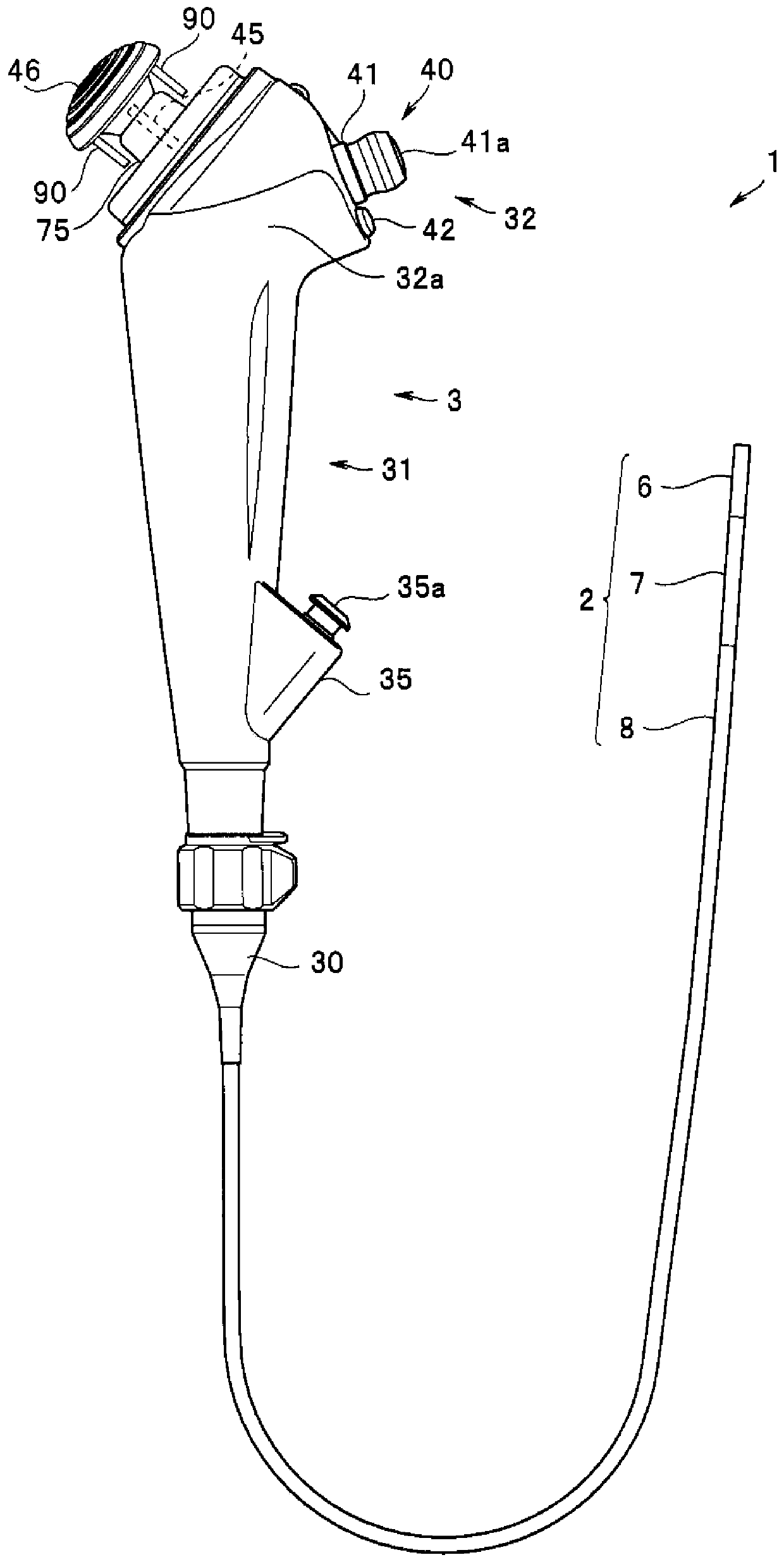

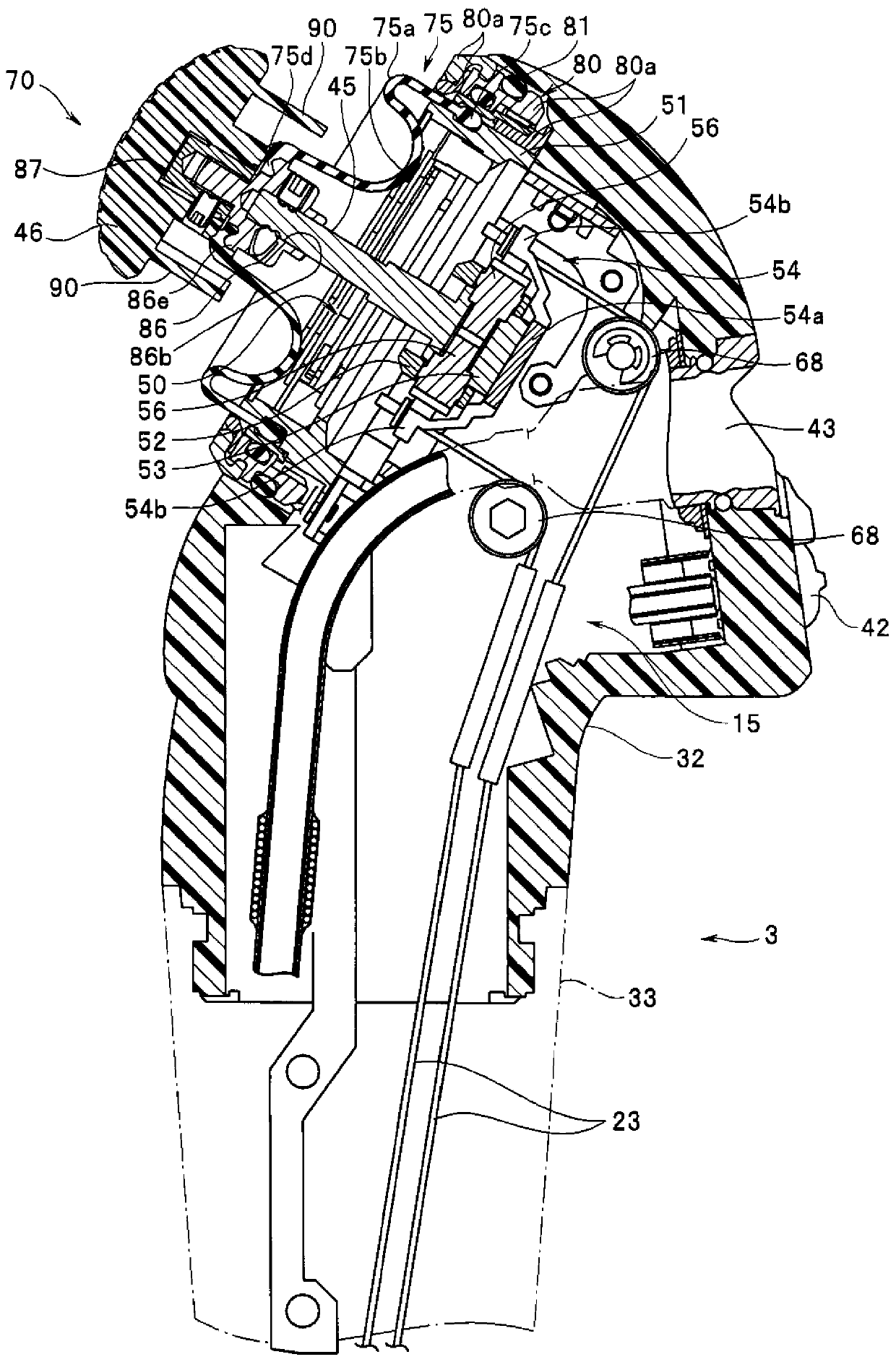

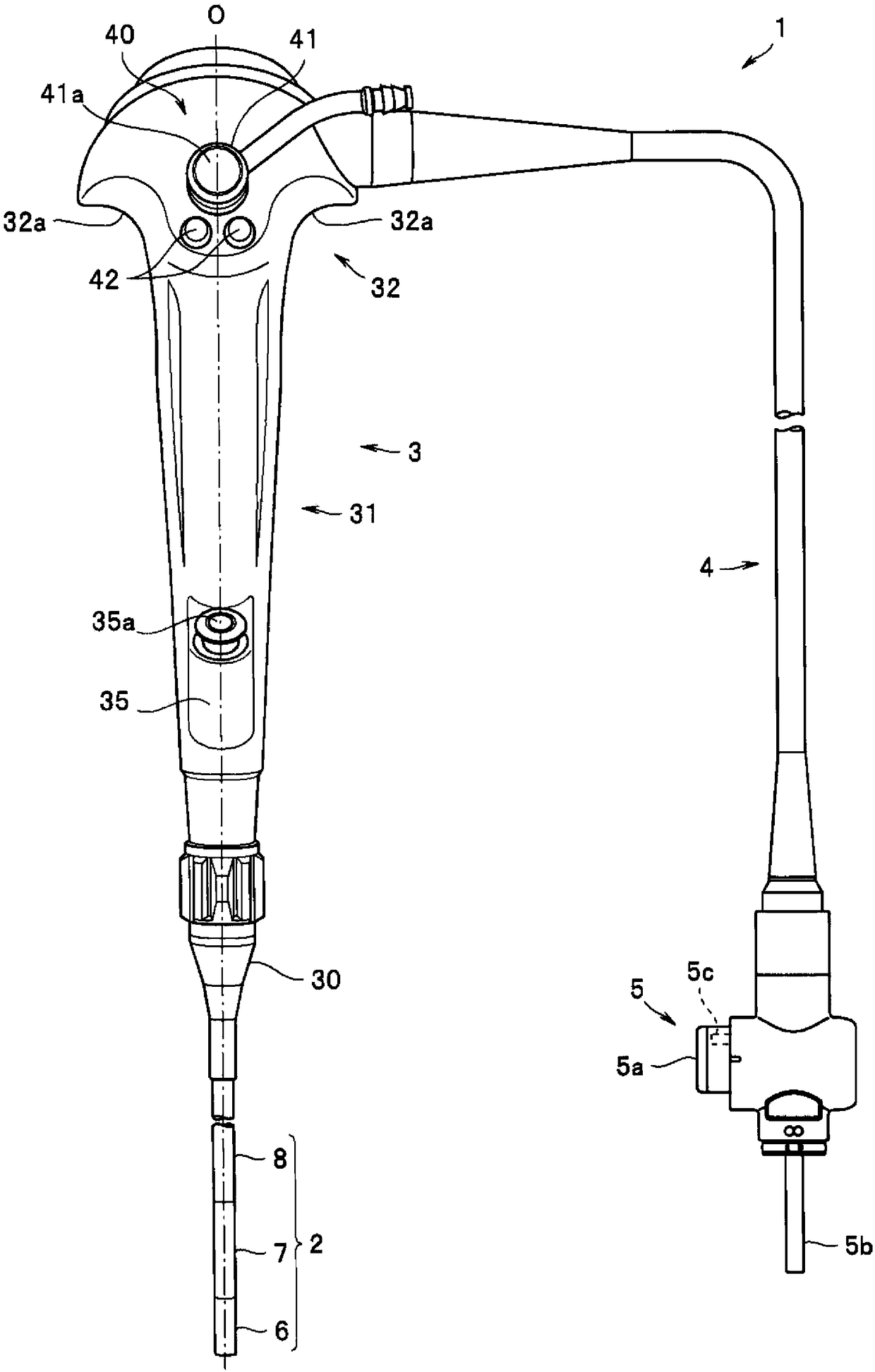

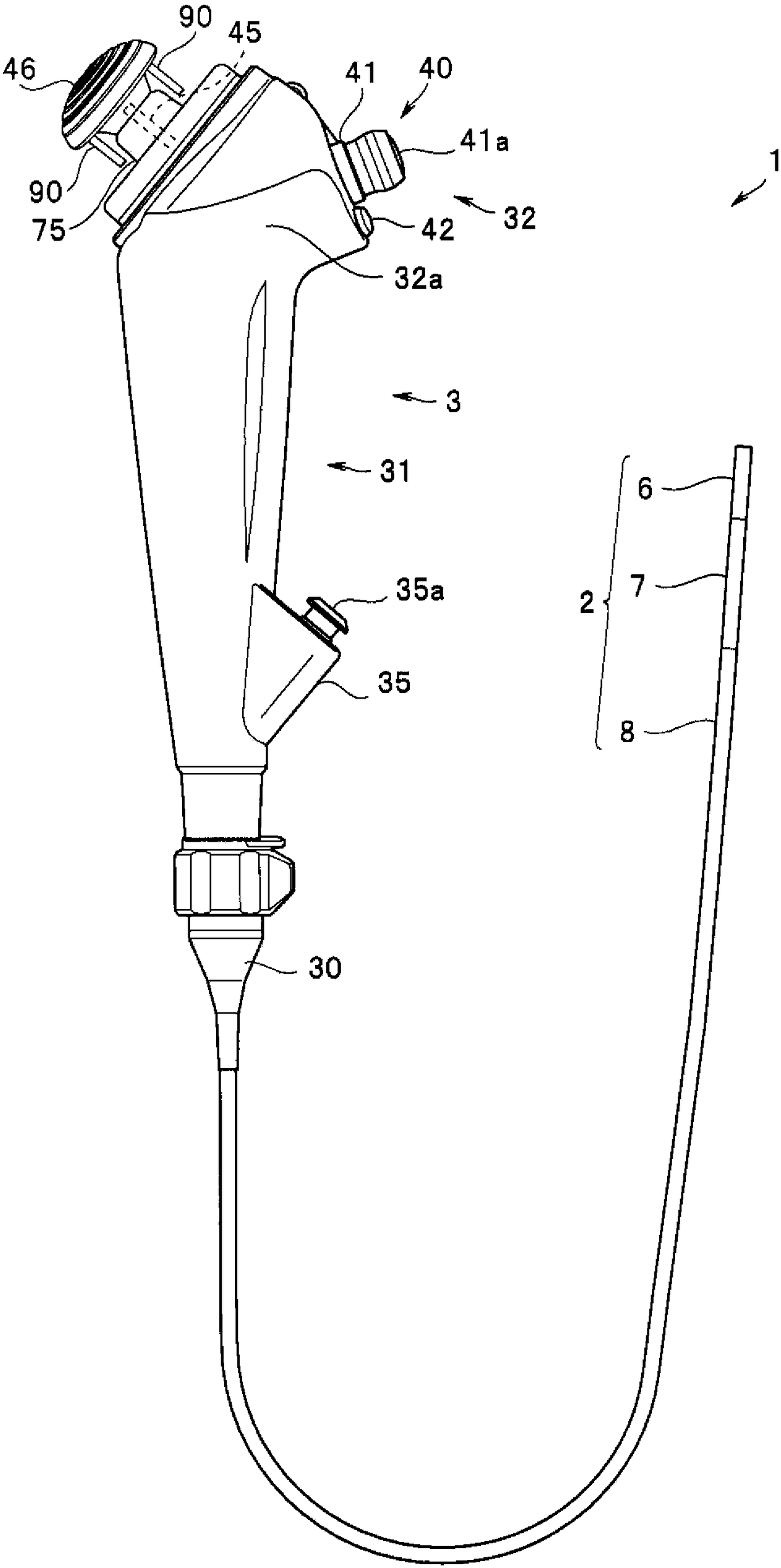

endoscope

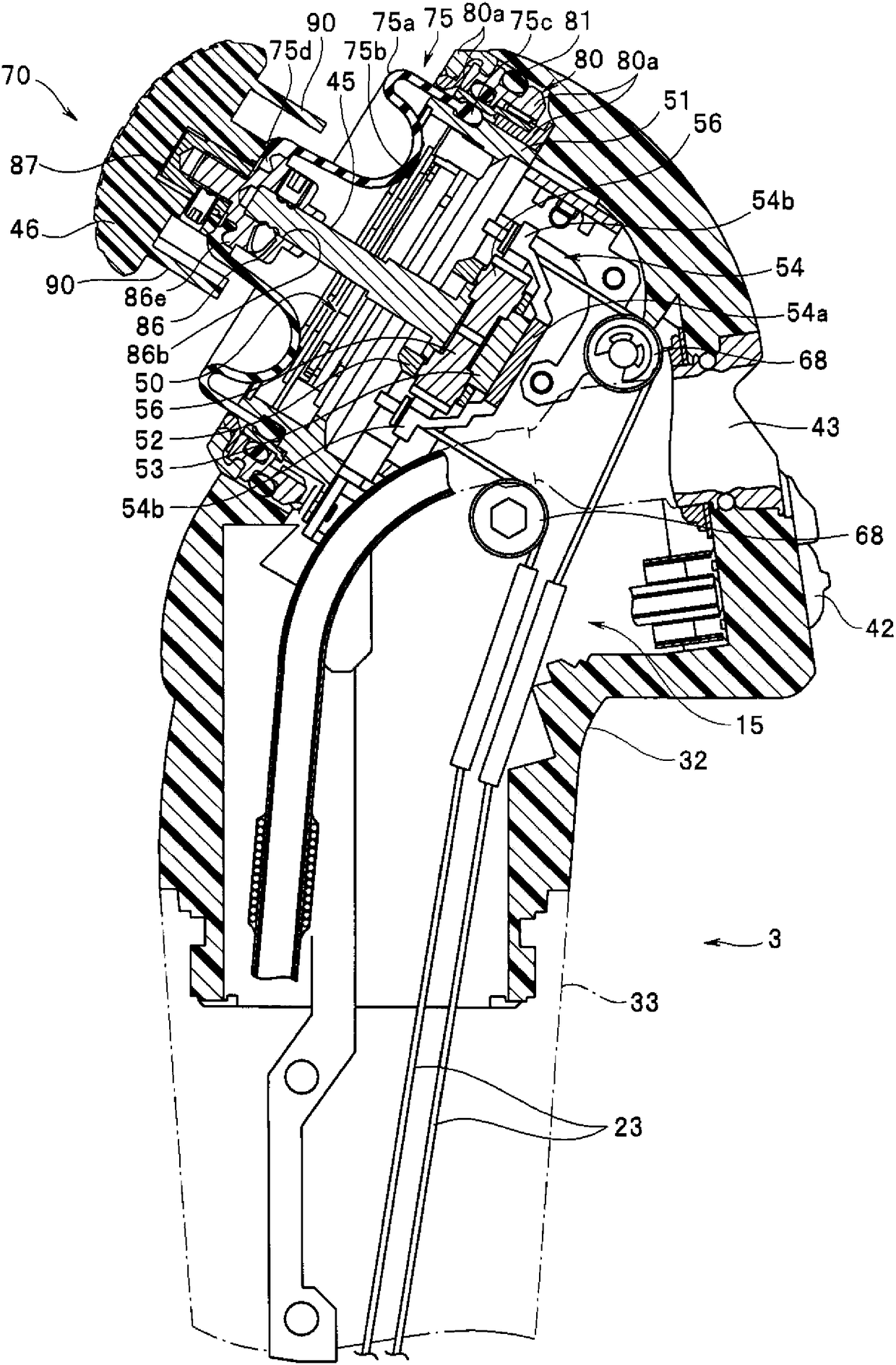

ActiveCN108471928BAdjust the bend angleEndoscopesSurgical manipulatorsEngineeringMechanical engineering

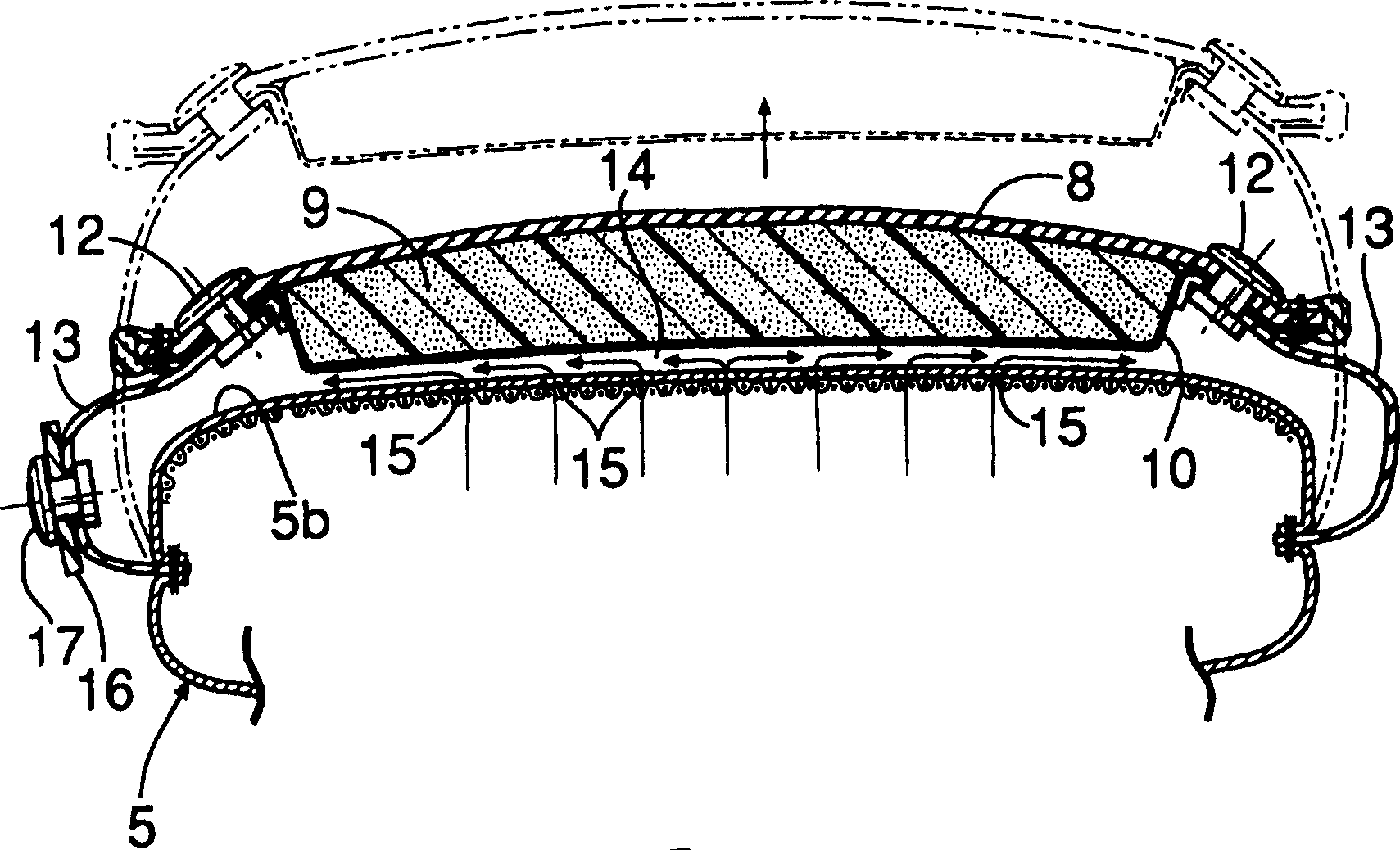

A control member (90) for restricting expansion caused by a change in internal pressure of the external cover (75) is provided to a control lever type (joystick type) endoscope (1) having an operating rod (45) and an external cover (75). ), wherein the operating lever (45) can adjust the bending angle of the bending portion (7) in conjunction with the tilting action of the operating portion (3), and the outer peripheral edge portion of the exterior cover (75) is watertightly fixed to the operating portion main body (32) (operating portion (3)) and the inner peripheral portion covers the outer periphery of the operating rod (45) watertightly, and can be changed according to the pressure inside the operating portion (3) (that is, formed inside the endoscope (1) The pressure fluctuation of the confined space (15)) deforms.

Owner:OLYMPUS CORP

Sheet steel bending machine for construction site

The invention provides a sheet steel bending machine for a construction site, and relates to the technical field of building construction, which aims at solving the technical problem of difficulty in sheet steel bending at the construction site. The bending machine comprises a bottom plate and an upper form, wherein the left part of the top surface of the bottom plate is fixedly provided with a hinge support seat, the right part of the top surface of the bottom plate is fixedly provided with a lever frame, the top surface of the bottom part is provided with two lower forms which can slide front and back, the hinge support seat is provided with a lever, the left end of the lever is pivoted with the hinge support seat, the right part of the lever is arranged on the lever frame, the two lower forms are respectively arranged at the front side and the back side of the upper form, the top surface of the bottom plate is fixedly provided with a plurality of adjusting support seats, each adjusting support seat is provided with adjusting bolts for fixing the two lower forms, the upper form is a triangular frame body with an upward vertex angle, and is positioned between the hinge support seat and the lever frame, and the vertex angle part of the upper form is pivoted with the lever in a free rotating way. The bending machine is suitable for bending sheet metals at the construction site.

Owner:上海建科结构新技术工程有限公司 +1

Storage device of computer communication network cables

Owner:浙江长兴山石电子有限公司

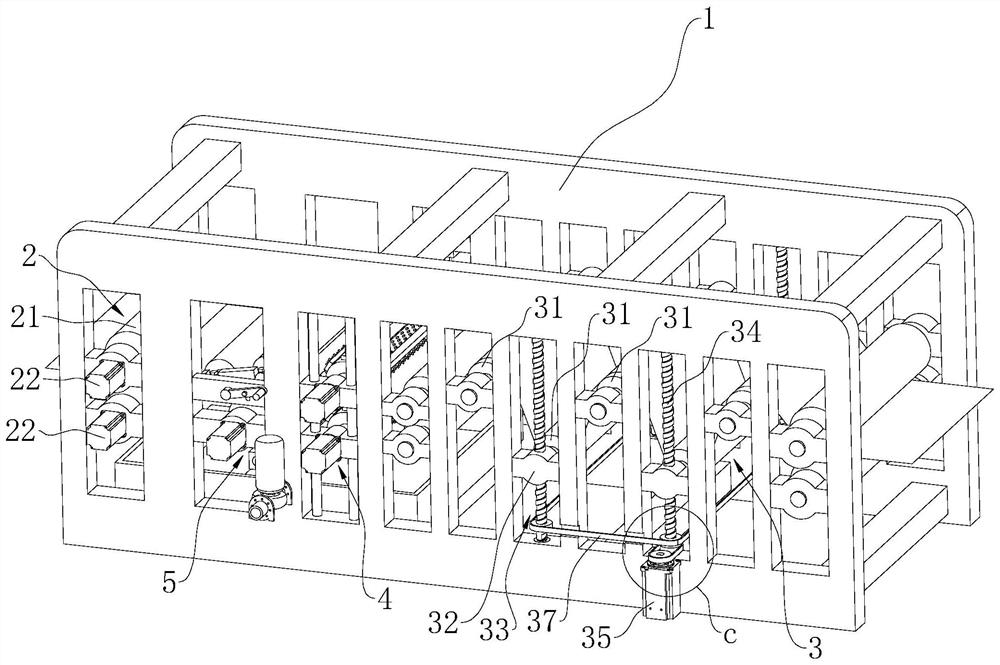

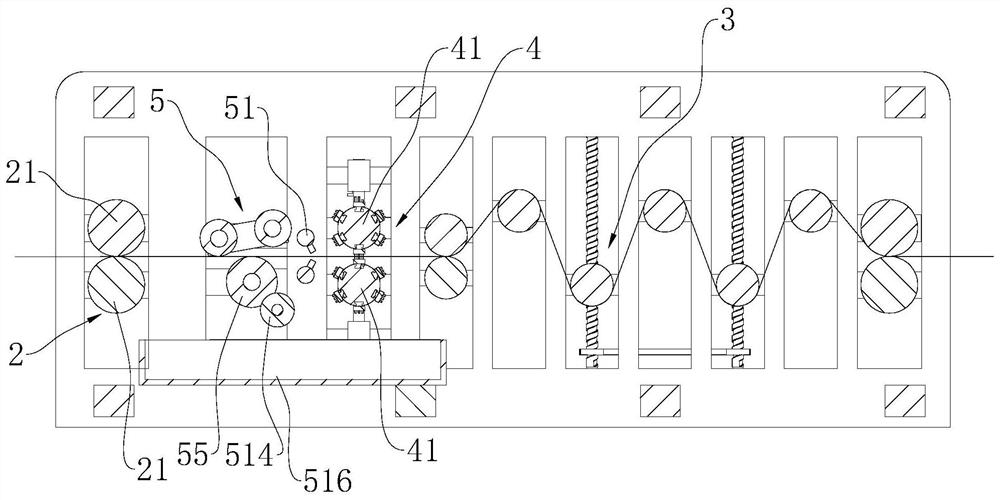

A metal plate bending device based on the principle of gear transmission

ActiveCN111618138BFast processingImprove work efficiencyMetal-working feeding devicesStripping-off devicesGear wheelSprocket

The invention relates to the technical field of Wujinjiaodian, and discloses a metal plate bending device based on the principle of gear transmission, including a support frame, a hydraulic device is fixedly connected to the inside of the support frame, and a hydraulic device is fixedly connected to the bottom of the hydraulic device The upper mold base, the top of the upper mold base is fixedly connected with a gear bar, the outer meshing connection of the gear bar is connected with a flywheel, the outer part of the flywheel is movably connected with a transmission wheel, and the outer part of the transmission wheel is movably connected with a feeding plate, The outside of the feeding plate is movably connected with a material guide plate, and the outside of the transmission wheel is movably connected with a sprocket, through gear rod, flywheel, transmission wheel, feeding plate, material guide plate, sprocket, chain, push block , block, sliding rod, unloading block and positioning block are used together to achieve the effect of automatic loading and unloading, effectively improve the processing speed of metal plate bending processing, improve the working efficiency of bending processing, and effectively Reduce the work intensity of workers, thereby improving the use effect of the device.

Owner:湖南华涟智能智造科技有限公司

Induction heating pipe bending machine

The invention provides an induction-heating pipe bender which comprises a machine tool system, a transmission system, an induction heating system and a clamp system, wherein the transmission system, the induction heating system and the clamp system are arranged on the machine tool system. The machine tool system comprises a machine tool body and horizontal guide rails, the transmission system is borne by the machine tool body, the horizontal guide rails are arranged on the lower portion of the machine tool body, and machine tool body sliders are arranged at the positions, corresponding to the horizontal guide rails, of the machine tool body; the transmission system comprises a longitudinal oil cylinder, chain row devices and a pipe trolley, the longitudinal oil cylinder is fixed on the machine tool body, a piston rod of the longitudinal oil cylinder is connected with the chain row devices, and the pipe trolley is fixed at the upper ends of the chain row devices; the induction heating system is arranged between the machine tool system and the clamp system; the clamp system comprises a clamping piece and a vertical rotating shaft, and the clamping piece is arranged on the upper portion of the vertical rotating shaft and connected with the vertical rotating shaft. By means of the technical scheme of the induction-heating pipe bender, limitation to the bending range of steel pipes can be reduced.

Owner:ZHUZHOU HAN HE IND EQUIP

Endoscope

An operating lever-operated (joystick-operated) endoscope 1 comprises: an operating lever 45 capable of regulating the bending angle of a bendable section 7 in coordination with tilting action in an operating section 3; and an outer cover 75 having an outer peripheral edge which is affixed in a watertight manner to an operating section body 32 (operating section 3), the outer cover 75 also havingan inner peripheral edge which covers in a watertight manner the outer periphery of the operating lever 45, the outer cover 75 being capable of being deformed by a variation in pressure within the operating section 3 (that is, by a variation in pressure within an enclosed space 15 formed within the endoscope 1). The endoscope 1 is provided with a restriction member 90 for restricting the expansionof the outer cover 75 caused by a variation in the pressure within the outer cover 75.

Owner:OLYMPUS CORP

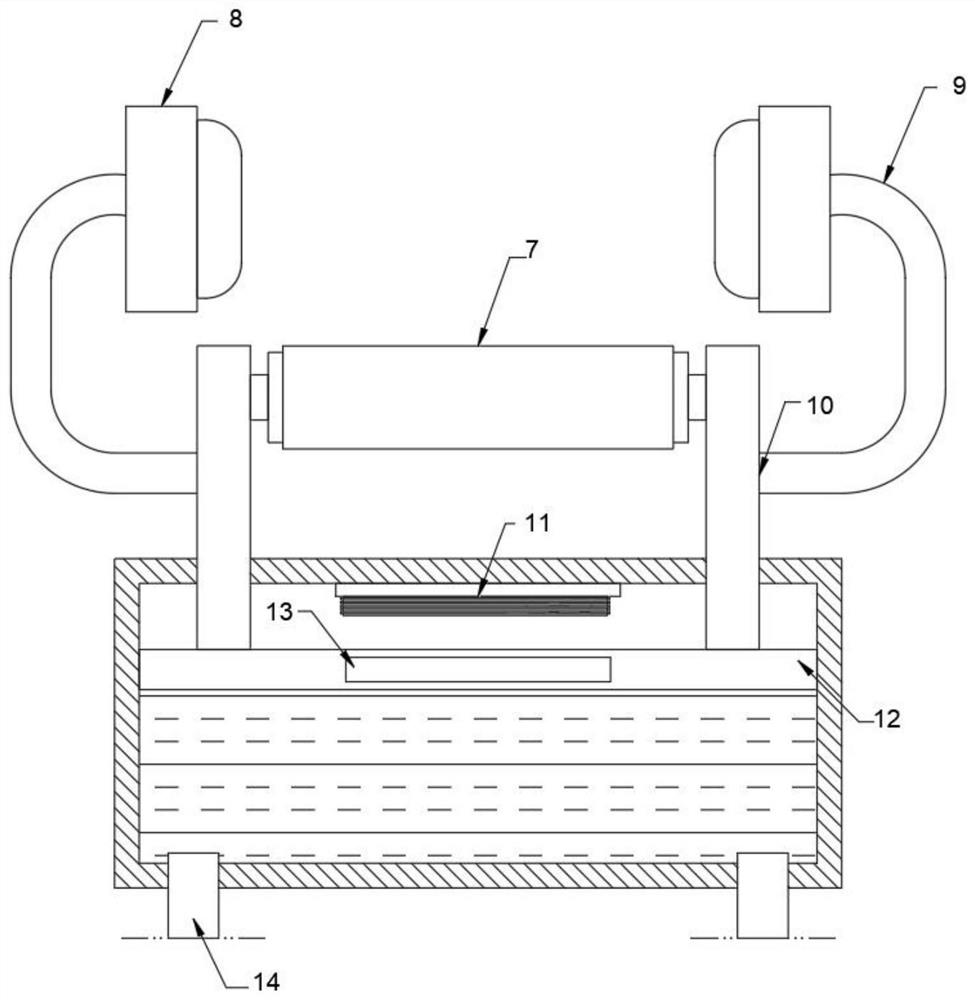

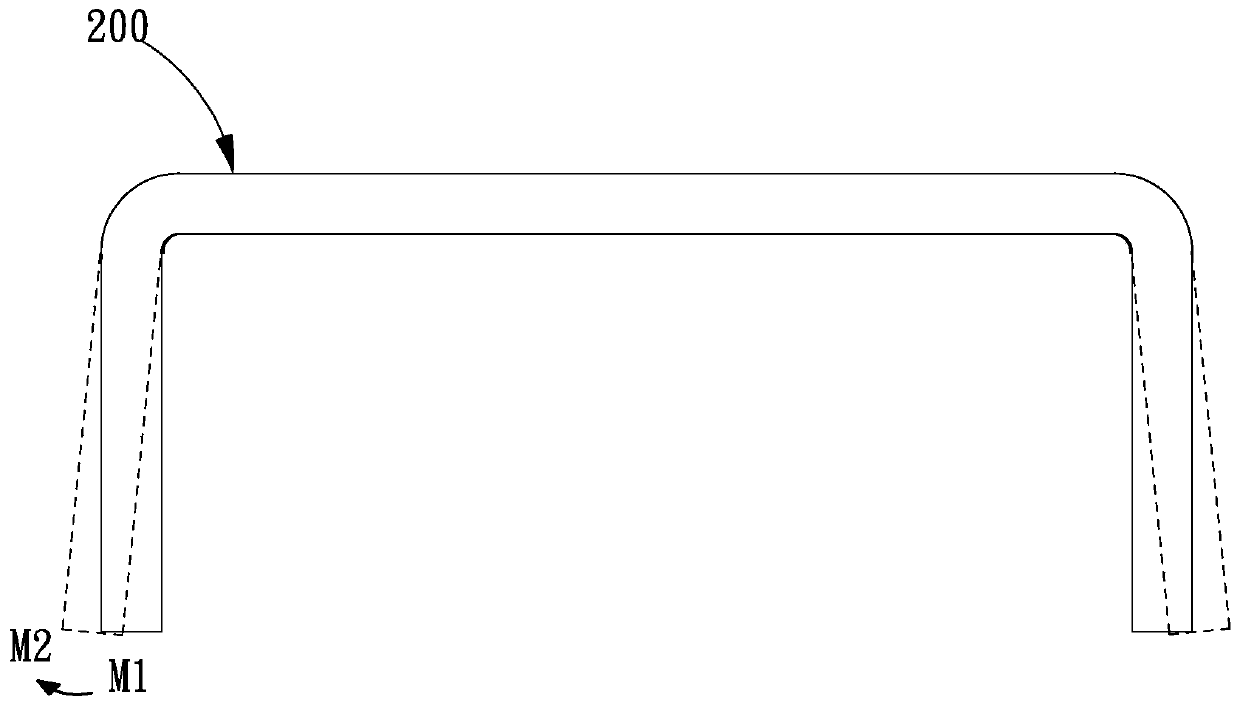

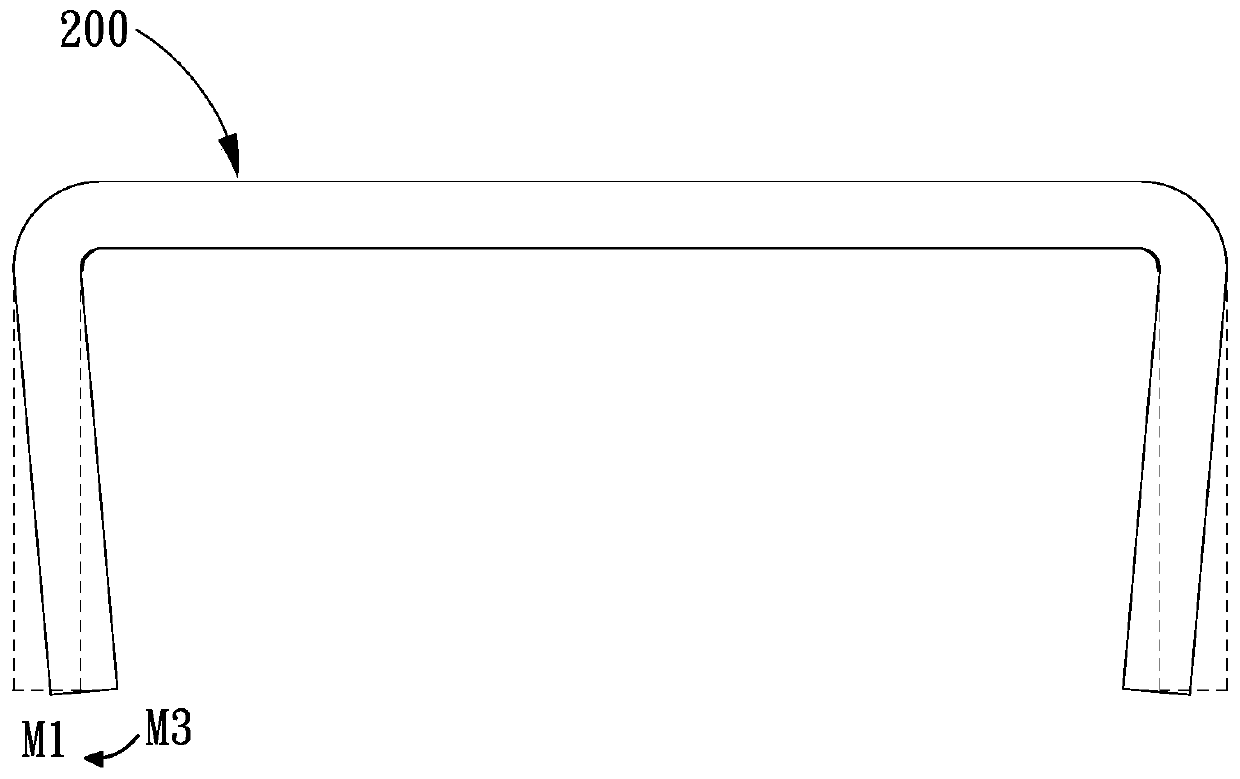

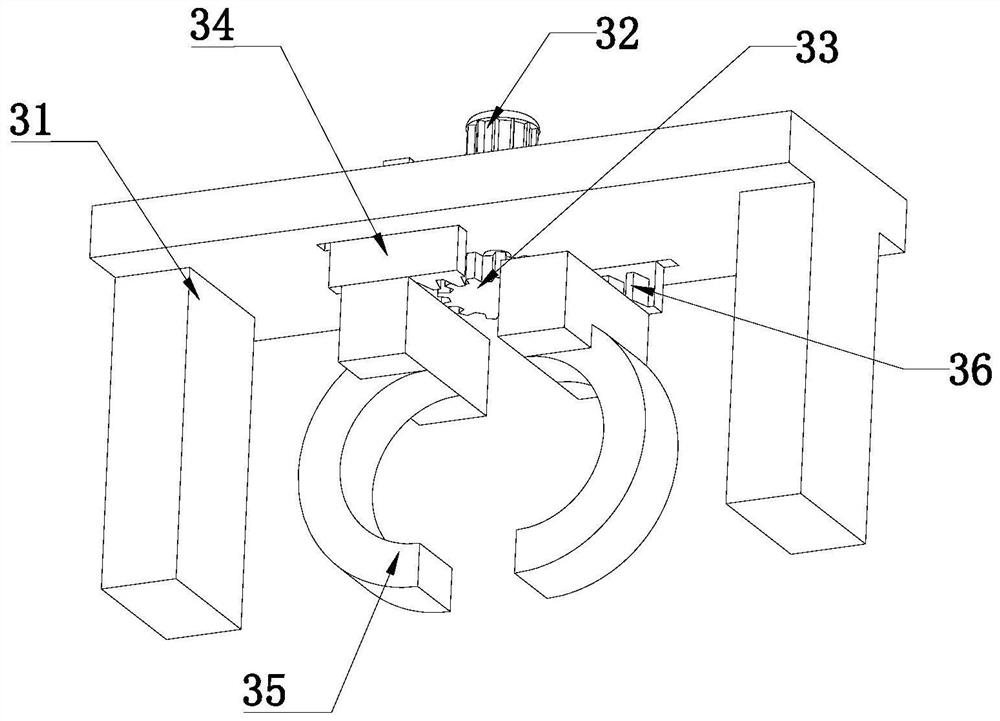

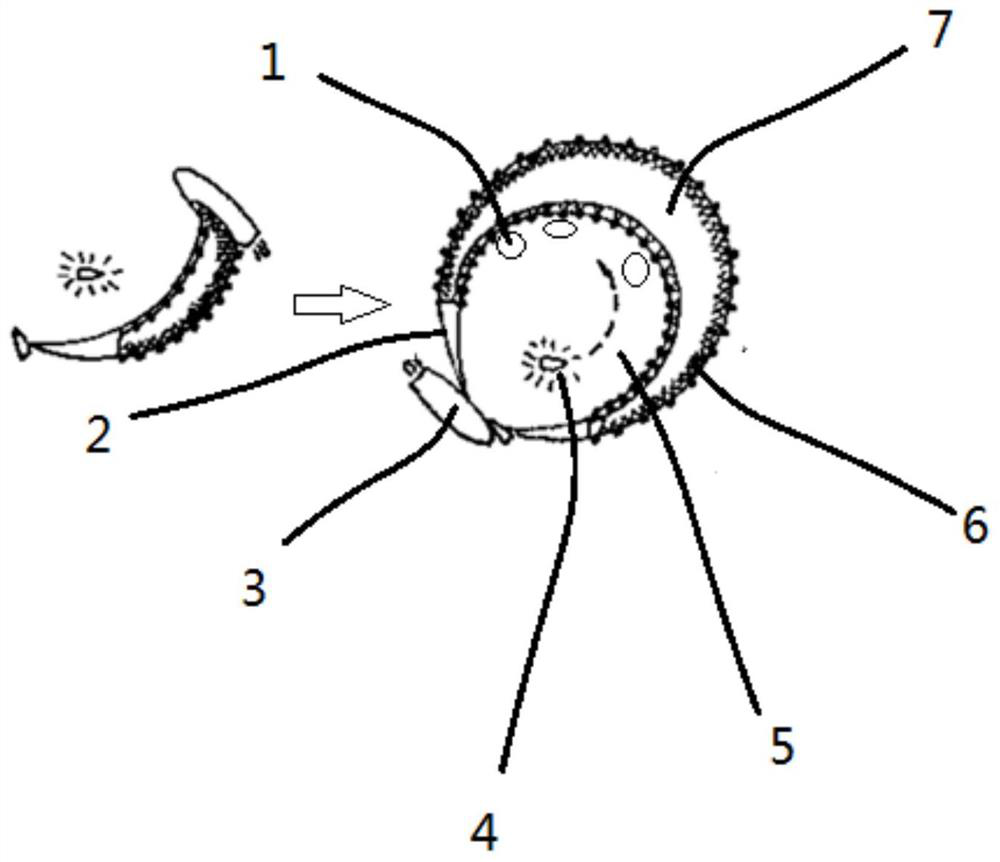

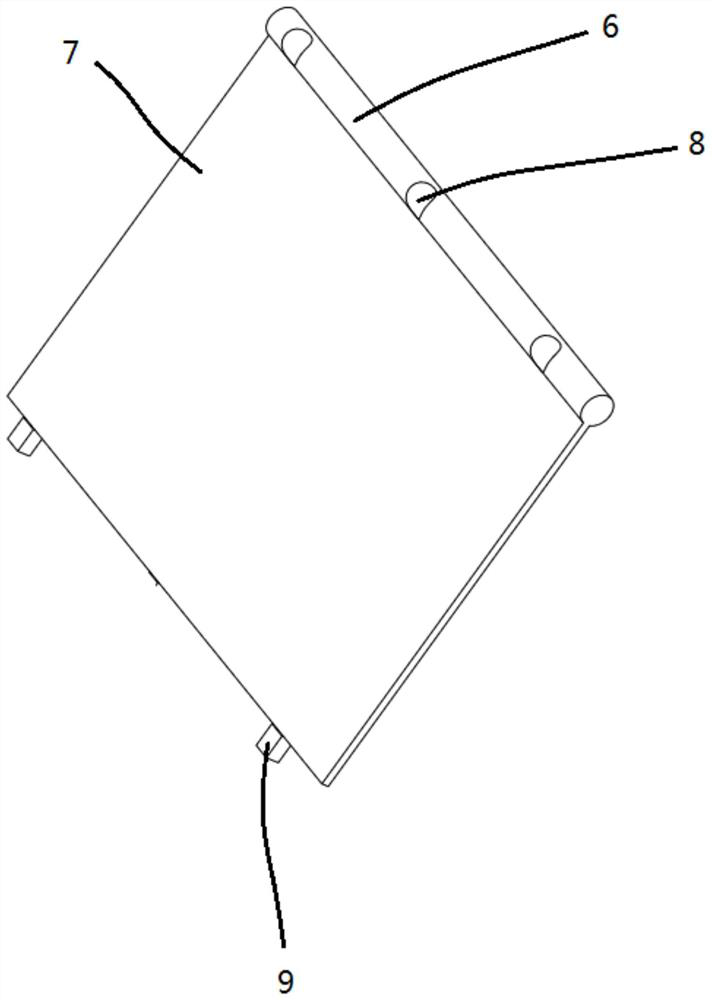

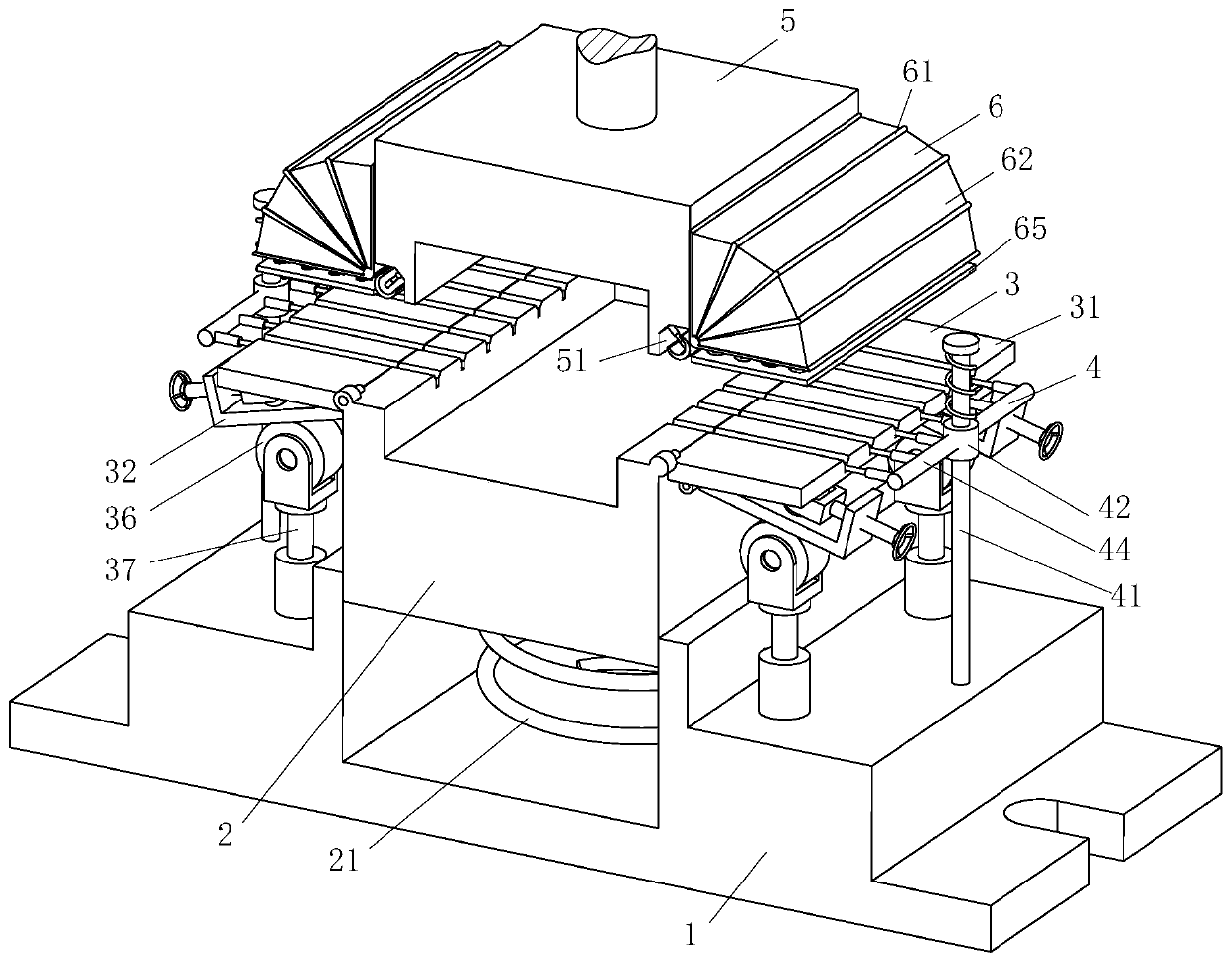

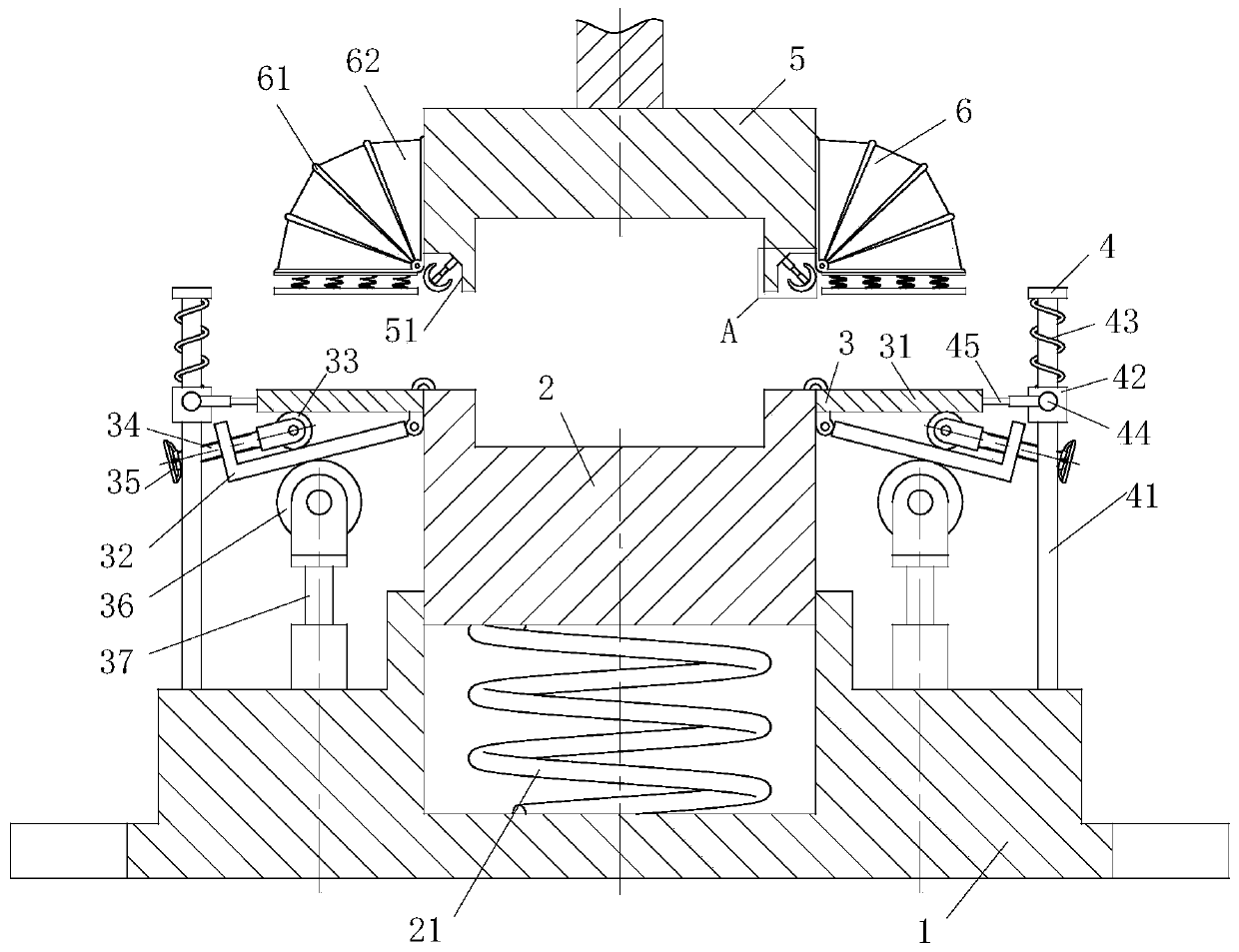

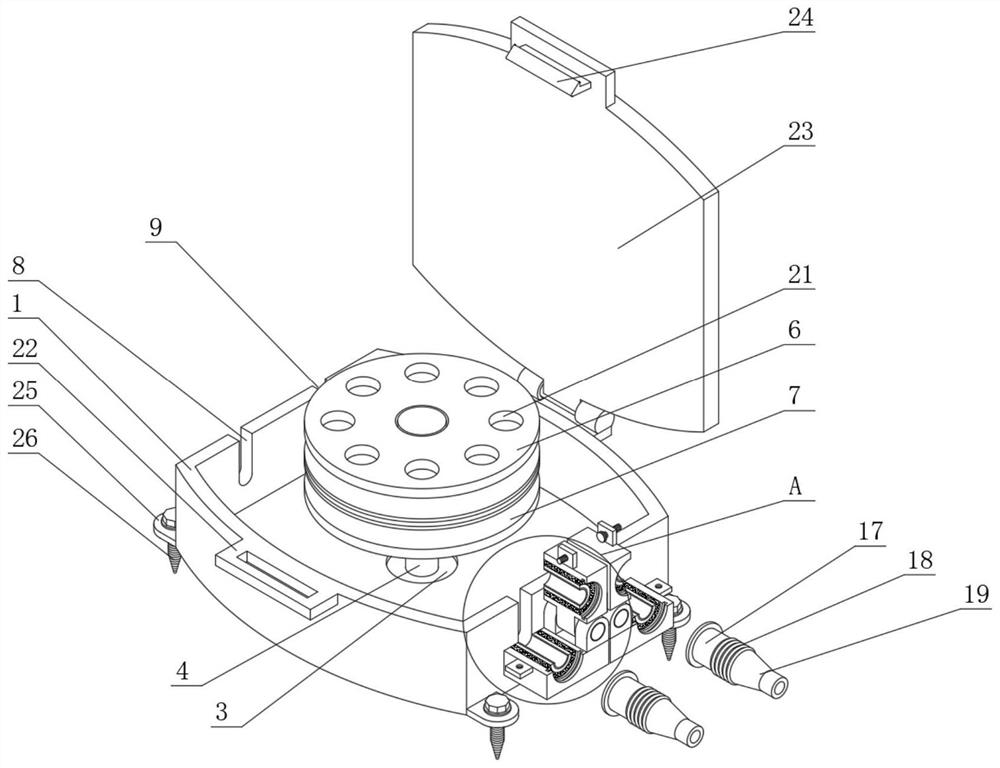

A semiconductor diode pin forming device

ActiveCN108735579BAchieve clearingAdjust the bend angleSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

The invention belongs to the technical field of semiconductor diode manufacturing, in particular to a semiconductor diode pin forming device. The semiconductor diode pin forming device comprises a fixed base, a lower die, a bending module, a dust removal module, an upper die and a compressing module; the lower die is slidably connected in a cavity in the top of the fixed base; the bending module is hinged to the two sides of the top of the lower die, and the dust removal module is arranged on the non-hinged side of the bending module; the bottom of the dust removal module is fixedly connectedto the step surface of the fixed base; the upper die is arranged above the lower die; the top of the upper die is fixedly connected with the output end of a crimping machine; and the two sides of theupper die are fixedly connected with the compressing module. According to the semiconductor diode pin forming device, the bending module is hinged to the two sides of the top of the lower die, so thatwhen the lower die moves downwards, the bending module swings around the hinged position to realize pin bending; meanwhile, the bending angle of the bending module can be adjusted; and the dust removal module is arranged on the non-hinged side of the bending module, so that dust in the number one positioning groove of the bending module can be removed.

Owner:滨州高新高端装备制造产业园有限公司

Bending angle adjustable bending die

InactiveCN107824694AAdjust the bend angleImprove bending effectShaping toolsMetal-working feeding devicesArchitectural engineeringFixed position

The invention relates to the technical field of moulds, and discloses a bending mold with adjustable bending angle, which includes a base, the top of which is provided with stamping grooves, and the front and back of the movable block are fixedly equipped with bearing bayonets, two bearings Bearing rods are movably connected between the bayonet sockets, bearing rods are movably connected between the bearing bayonets, through holes are opened on the left and right sides of the base, and there are holes on the side of the movable block corresponding to the through holes. Positioning hole, the inner wall of the through hole is inserted with an adjusting bolt that runs through the through hole and extends to the inner wall of the positioning hole, the top of the base is fixedly installed with a support block on the left side of the punching groove, and the bottom of the inner wall of the sliding groove Fixed installation with telescopic rod. The bending mold with adjustable bending angle has the advantage of adjustable bending angle, and the positioning groove can well fix the position of the bending material in the bending mold so that the bending effect is better.

Owner:孝昌县宝德智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com