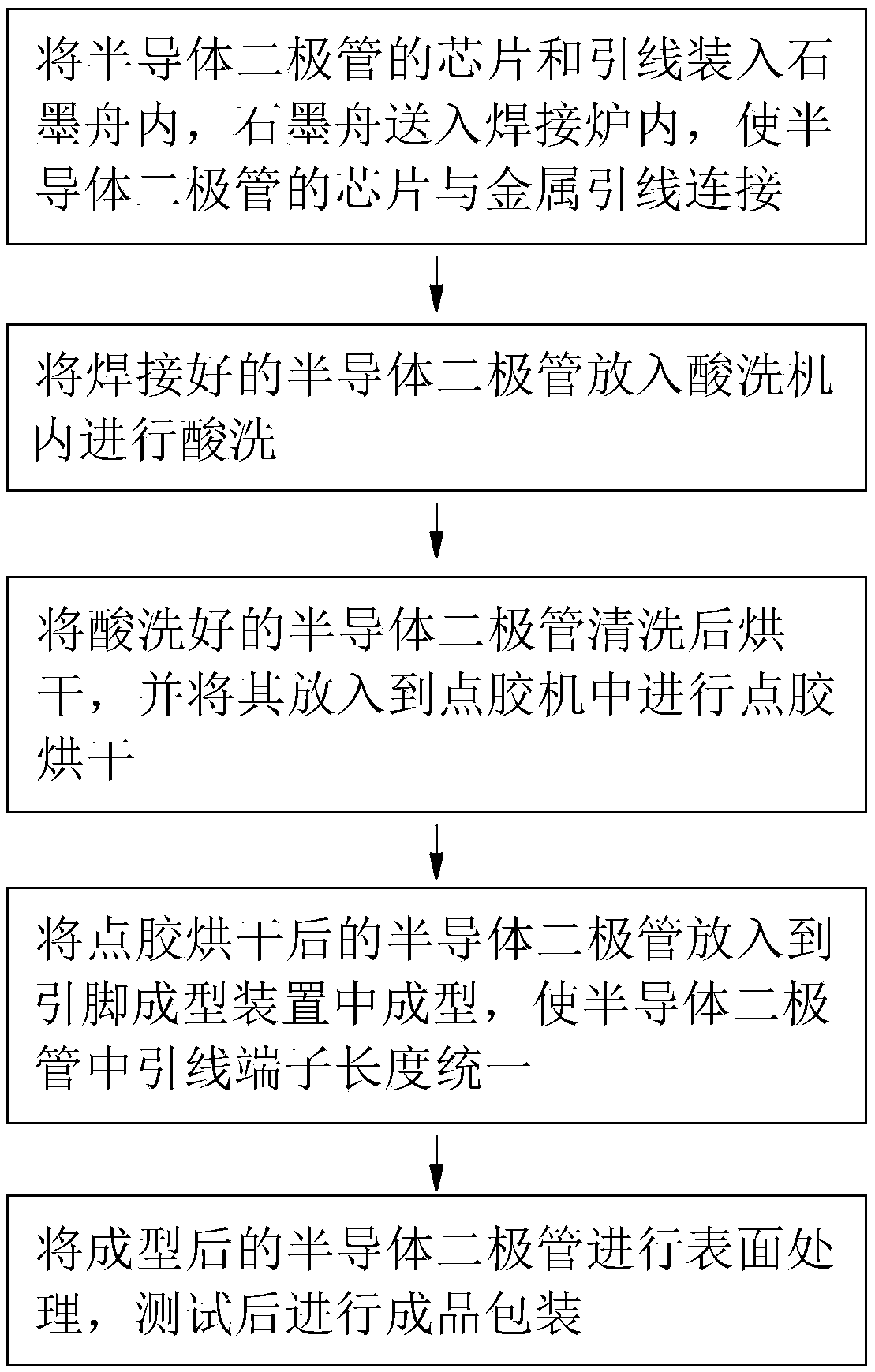

Production process of semiconductor diode

A production process and diode technology, applied in the field of semiconductor diode production process, can solve the problems of pin scratches, unadjustable pin bending angle, low product applicability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

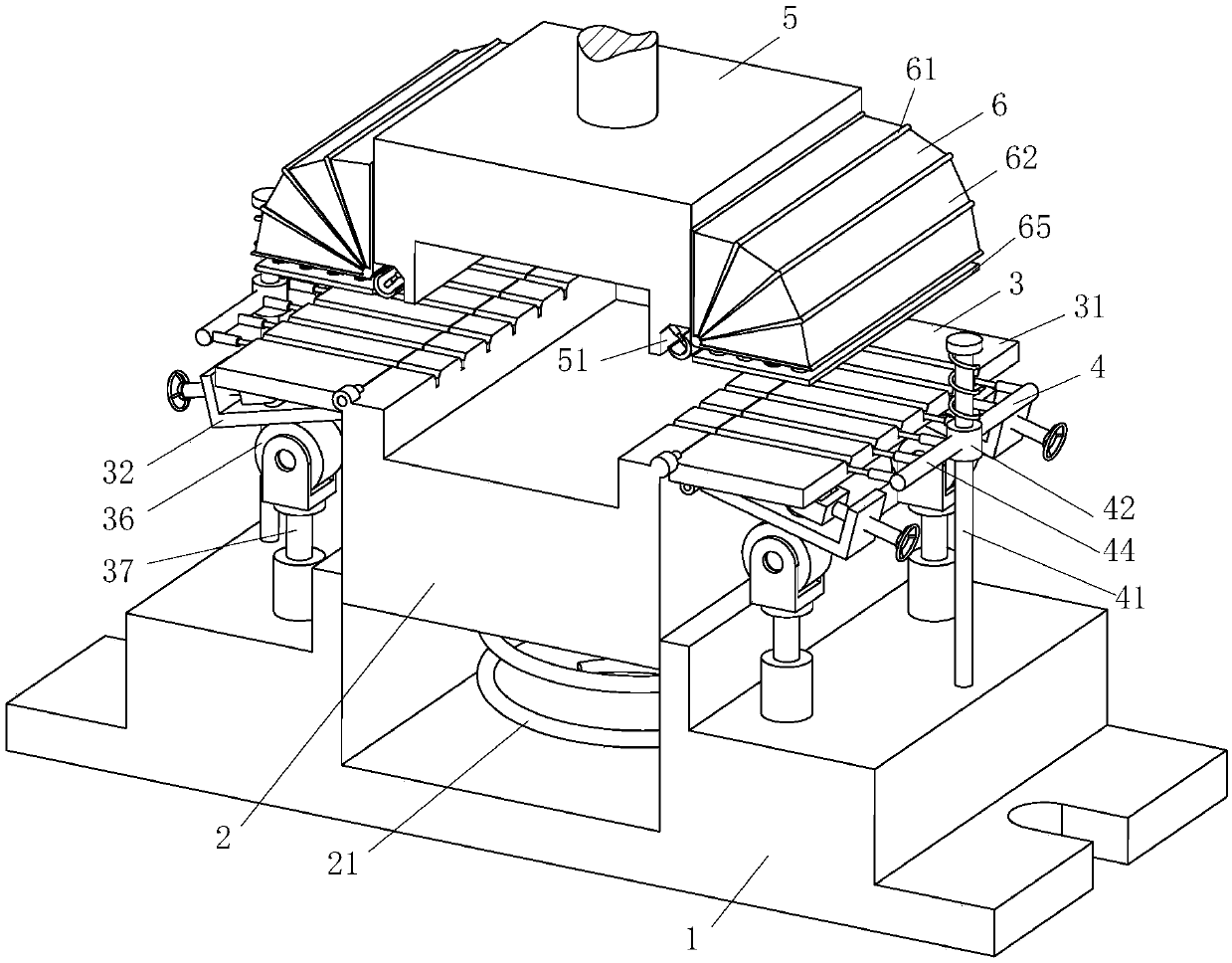

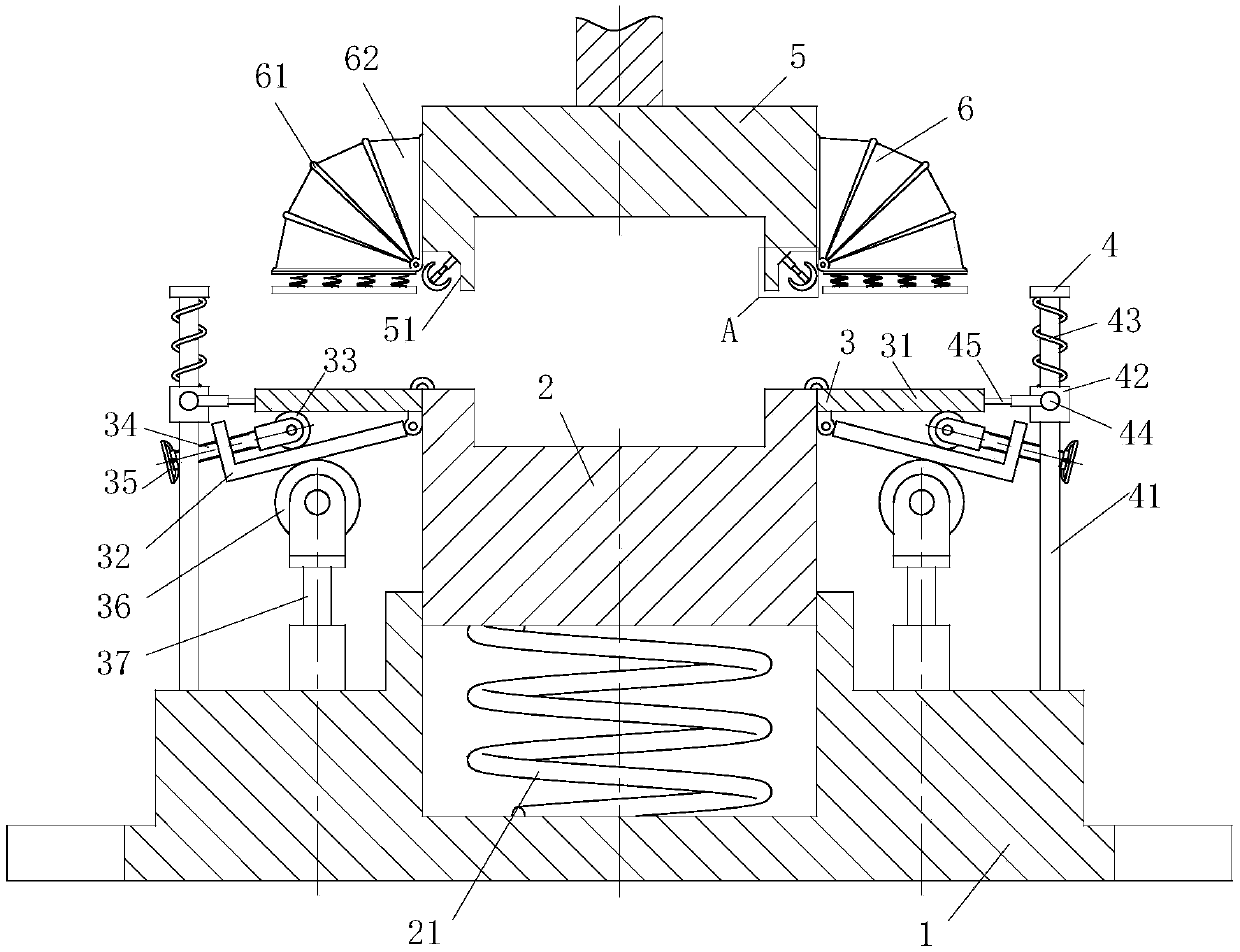

[0038] As an embodiment of the present invention, the bending module 3 includes a positioning plate 31, an adjusting plate 32, a No. 1 roller 33, an adjusting screw 34, a hand wheel 35, a No. 2 roller 36, and an electric cylinder 37. The positioning plate One end of 31 is hinged to the edge of the top side of lower die 2; the top surface of the positioning plate 31 is provided with a group of No. 1 positioning grooves 311, and the bottom surface of one end of the positioning plate 31 is hinged to one end of the adjusting plate 32; the adjusting plate 32 is L-shaped; The adjusting screw 34 is connected with the adjusting plate 32 by threads; one end of the adjusting screw 34 is fixedly connected with the handwheel 35, and the other end of the adjusting screw 34 is connected with the No. 1 roller 33 through a rotating shaft; Between 32, the No. 1 roller 33 is driven by the adjusting screw 34 to realize the adjustment of the angle between the positioning plate 31 and the adjusting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com