Tubular metal bending equipment with adjustable bending angle for metal forming

A bending angle and metal forming technology, applied in metal processing equipment, feeding devices, positioning devices, etc., can solve the problems of inconvenient movement, high labor intensity, inconvenient metal, etc., and achieve the advantages of easy cleaning, high efficiency and high automation level Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

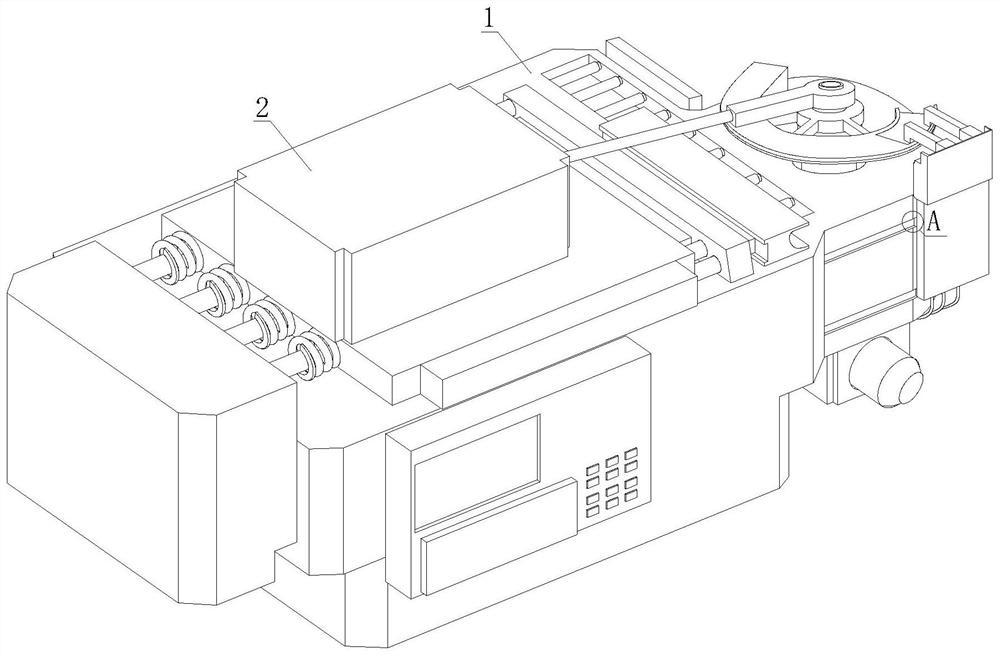

[0032] refer to figure 1 , figure 2 , Figure 4 and Image 6 , a tubular metal bending equipment with adjustable bending angle for metal forming, comprising a bearing mechanism 1 and a positioning and clamping mechanism 2, the upper end surface of the bearing mechanism 1 is equipped with the positioning and clamping mechanism 2, and the bearing mechanism 1 includes a main bearing platform 11. Arc-shaped workbench 12, turntable assembly 13 and bending assembly 14. A control platform 111 is installed on the outer wall of the main bearing platform 11, and an arc-shaped workbench 12 is welded on one side of the main bearing platform 11. The arc-shaped workbench The bottom end of 12 is provided with a rotating motor 121, the output end of the rotating motor 121 is connected to the turntable assembly 13, and the outer wall of the arc-shaped workbench 12 is movably connected to the bending assembly 14, and the upper end surface of the main bearing table 11 is fixed with a position...

Embodiment 2

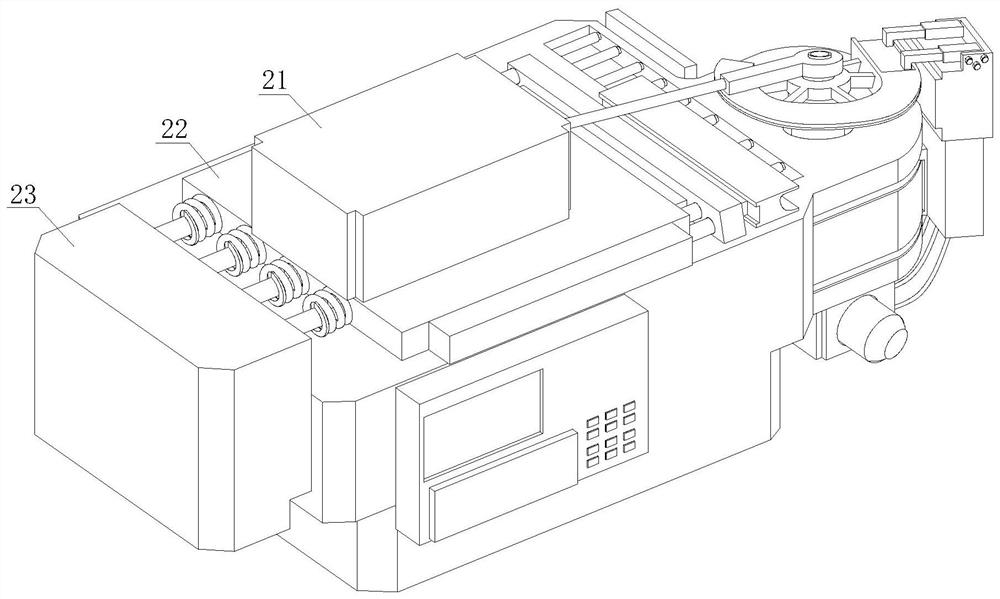

[0034] refer to image 3 and Image 6 The positioning and clamping mechanism 2 includes a mounting block 21, a base plate 22 and an air pump 23. The bottom end of the mounting block 21 is provided with a base plate 22. The output end of the air pump 23 is connected to the base plate 22 through a compression spring column 231, and the base plate 22 is far away from the air pump 23. One side is equipped with a positioning block 221; the side of the bottom plate 22 away from the air pump 23 is also equipped with a positioning clamp 222, and the side of the positioning clamp 222 close to the fixing groove 113 is processed with a positioning groove 2221, and the positioning groove 2221 is an arc-shaped groove body; the inner side of the positioning clamp 222 is provided with a chute 2222, and the outside of the positioning block 221 is provided with a slide block 2211 corresponding to the chute 2222, the positioning block 221 is flexibly connected to the positioning clamp 222 by th...

Embodiment 3

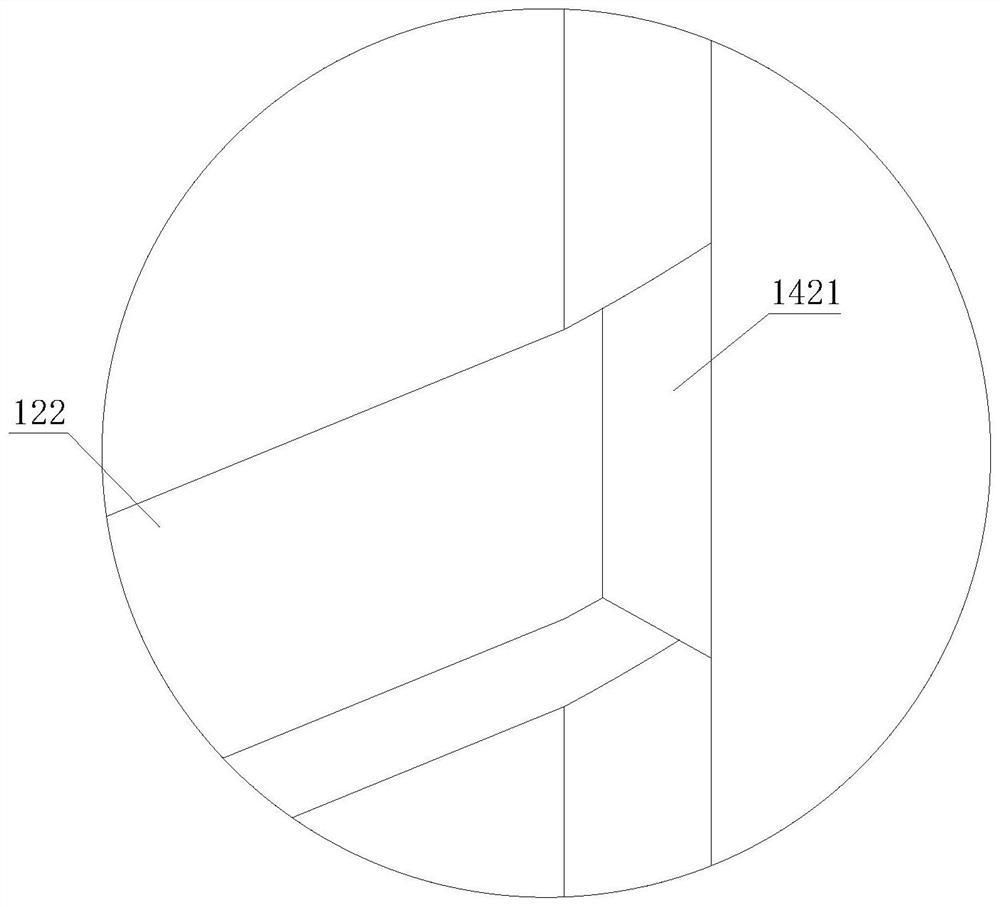

[0036] refer to Figure 5-8 , a tubular metal bending equipment with adjustable bending angle for metal forming. The turntable assembly 13 includes a turnrod 131, an arc-shaped turntable 132 and a fixing piece 133. The output end of the rotating motor 121 is connected to the turnrod 131, and the turnrobe 131 The upper end is fixed with an arc-shaped turntable 132, and the top of the rotating rod 131 is equipped with a fixing piece 133, and one end of the fixing piece 133 is connected to the mounting block 21 through an extension rod 1331; the bending assembly 14 includes a bending piece 141 and a servo motor 142, The upper end of the servo motor 142 is equipped with a bending piece 141, the top of the bending piece 141 is screwed with two sets of fixed sleeves 1411, and the inner cavity of the fixed sleeve 1411 is sleeved with an L-shaped telescopic fastener 14111, and the arc-shaped turntable One side of 132 is processed with a mounting groove 1321 near the upper end of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com