High efficiency liquid-permeable and gas-barrier fluid composite membrane system

A composite membrane, liquid-permeable technology, applied in semi-permeable membrane separation, membrane, membrane technology and other directions, can solve problems such as obstruction of liquid flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

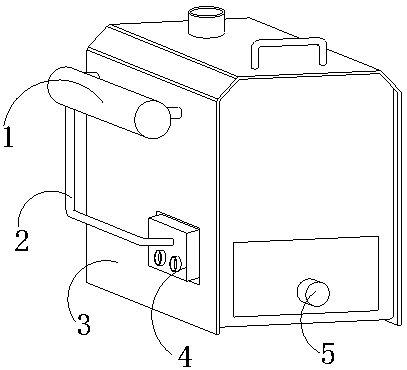

[0026] see Figure 1-Figure 8 , the present invention provides a high-efficiency liquid-permeable and gas-blocking fluid composite membrane system. 3, the bottom of the membrane separation device 3 is provided with an output pipe 5, the output pipe 5 penetrates the membrane separation device 3, the connecting pipe 2 connects the outer pipe 1 and the communication block 4, and the communication block 4 is connected with the membrane separation device 3;

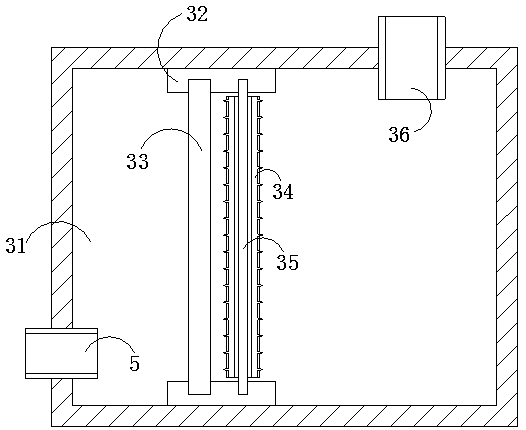

[0027] The membrane separation device 3 is composed of a separation chamber 31, a fixed block 32, a separation membrane 33, a defoaming mechanism 34, a central shaft 35, and an inlet pipe 36. The inner wall of the separation chamber 31 is provided with a fixed block 32, and the fixed block 32 are provided with two and set up in an up-and-down structure. The fixed block 32 is fixedly connected to the inner wall of the separation chamber 31. A separation film 33 is fixed between the fixed blocks 32. The separation film 33 block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com