High-performance concrete prepared from waste materials

A high-performance concrete and waste technology, applied in the field of high-performance concrete, can solve problems such as shrinkage cracking, and achieve the effect of reducing dosage, saving production cost and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

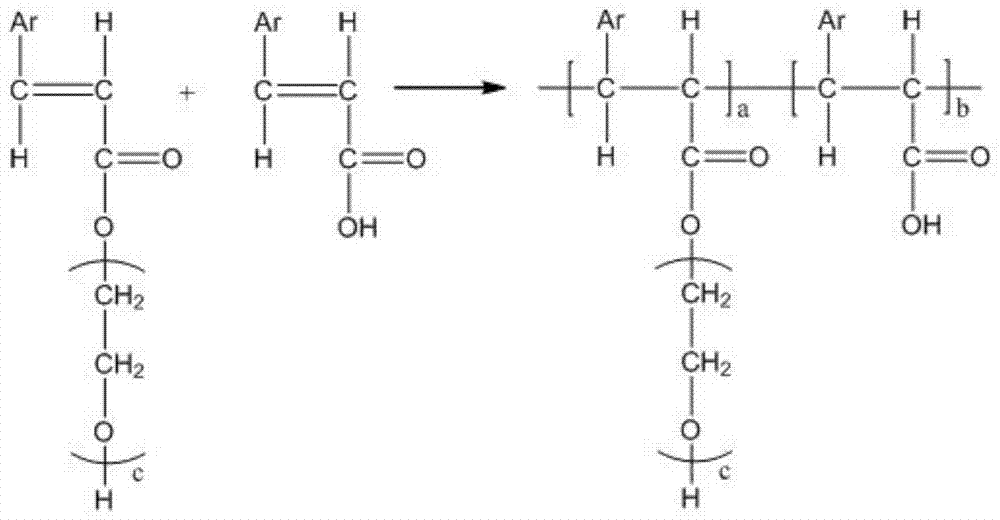

Method used

Image

Examples

Embodiment 1

[0048] The mixing ratio of the high performance concrete prepared from the waste material in Table 1 Example 1

[0049] cement

[0050] Wherein, the cement is P.O42.5 Portland cement; the fly ash is grade II fly ash; the mineral powder is grade S95 mineral powder; the water reducing agent is copolymer I; the plasticizer is a copolymer II; the anti-segregation agent is copolymer III; the retarder is purchased from Kunshan Guanyuan Jianghong Building Materials International Trade Co., Ltd.

Embodiment 2

[0052] The mixing ratio of the high performance concrete prepared from the waste material in the second embodiment of table 2

[0053] cement

[0054] Wherein, the cement is P.O42.5 Portland cement; the fly ash is grade II fly ash; the mineral powder is grade S95 mineral powder; the water reducing agent is copolymer I; the plasticizer is a copolymer II; the anti-segregation agent is copolymer III; the retarder is purchased from Kunshan Guanyuan Jianghong Building Materials International Trade Co., Ltd.

Embodiment 3

[0056] The mixing ratio of the high performance concrete prepared from the waste material in the third embodiment of table 3

[0057] cement

[0058] Wherein, the cement is P.O42.5 Portland cement; the fly ash is grade II fly ash; the mineral powder is grade S95 mineral powder; the water reducing agent is copolymer I; the plasticizer is a copolymer II; the anti-segregation agent is copolymer III; the retarder is purchased from Kunshan Guanyuan Jianghong Building Materials International Trade Co., Ltd.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com