Three-dimensional printing head with high product integrity

A three-dimensional printing, integrated technology, applied in coating devices, additive manufacturing, processing heating elements, etc., can solve the problems of fracture, the smoothness of conveying raw materials needs to be improved, and the integrity of three-dimensional printed products is poor, and achieves strong integrity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

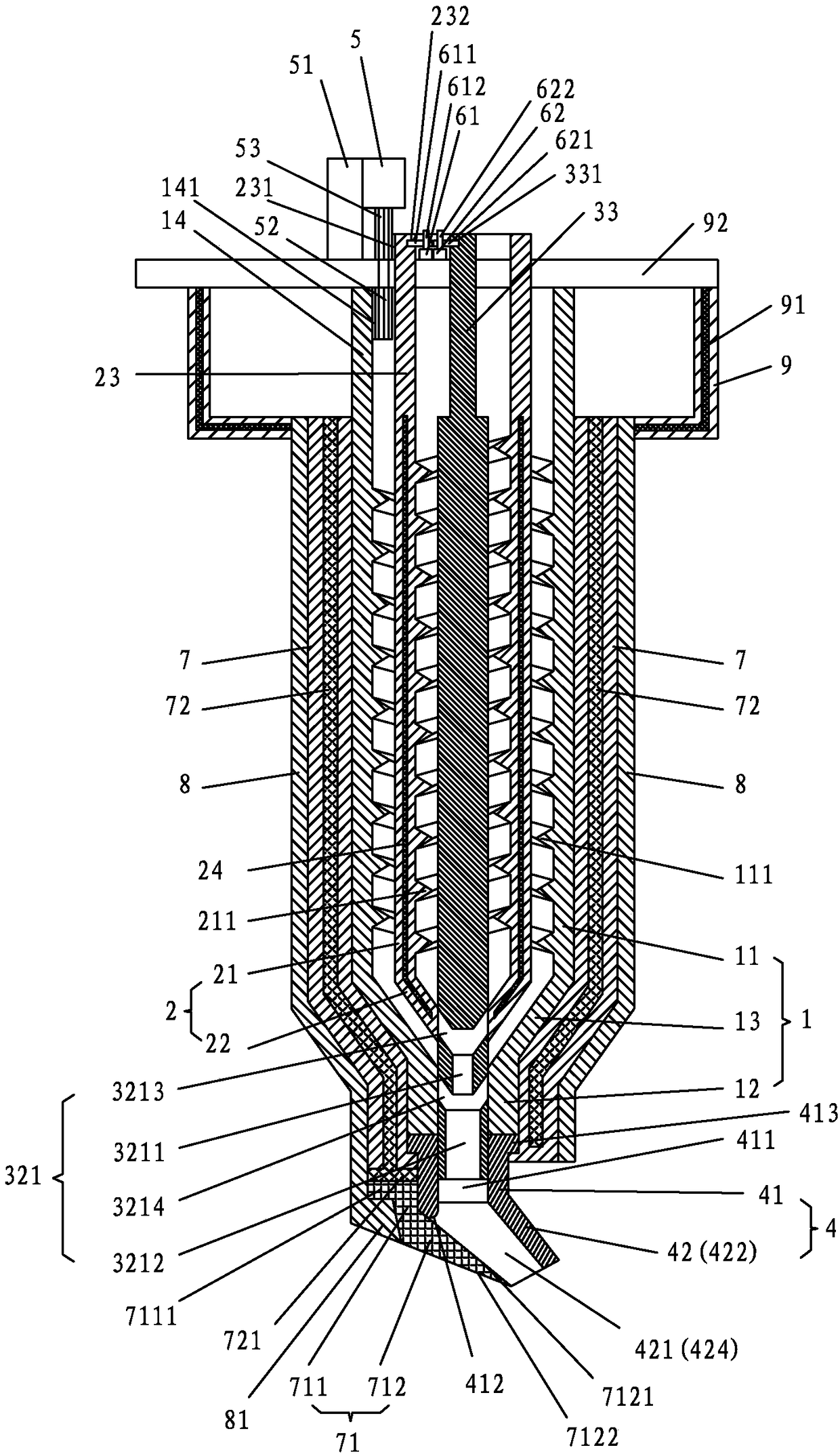

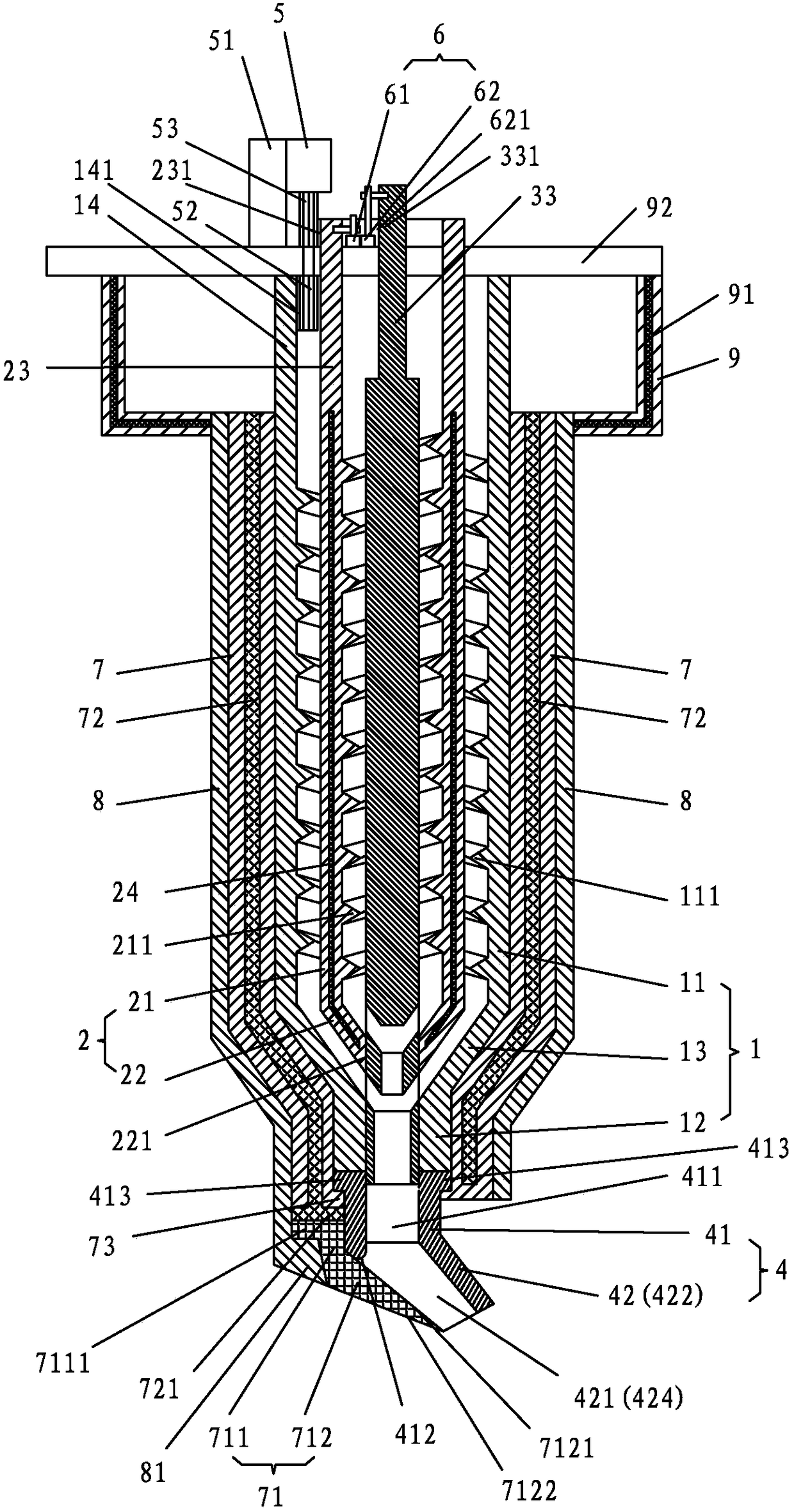

[0034] A kind of three-dimensional printing head with strong product integrity of the present invention, such as Figure 1-5 As shown, it includes the outer delivery tube 1 on the outside, the inner delivery tube 2 sleeved in the outer delivery tube 1, the middle rod 3 sleeved in the outer delivery tube 1 and the inner delivery tube 2, and connected to the lower end of the outer delivery tube 1 The discharge nozzle 4;

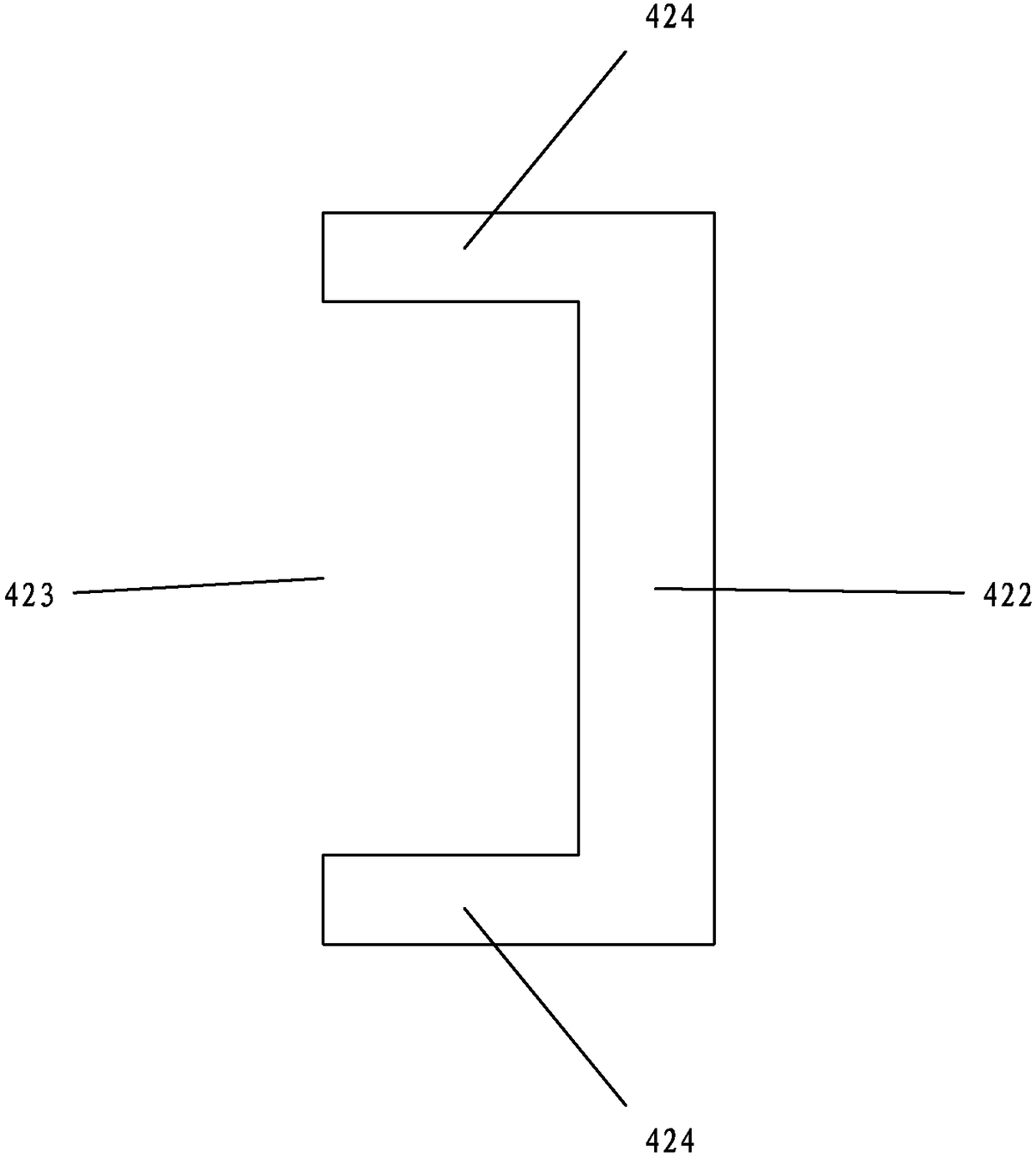

[0035] The outer conveying pipe 1 includes a first outer conveying section 11 that is thicker at the top, a second outer conveying section 12 that is thinner at the bottom and connected to the discharge nozzle 4, and is connected to the first outer conveying section 11 and the second outer conveying section 11. The third outer conveying section 13 between the sections 12 and gradually tapered from top to bottom; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com