Insert positioning device with automatic positioning function and assembly device

A technology of positioning device and assembling device, which is applied in workpiece clamping devices, manufacturing tools, metal processing and other directions, can solve problems such as high risk factor and deviation strength, and achieve the effect of ensuring accuracy, overcoming errors, and realizing precise positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing.

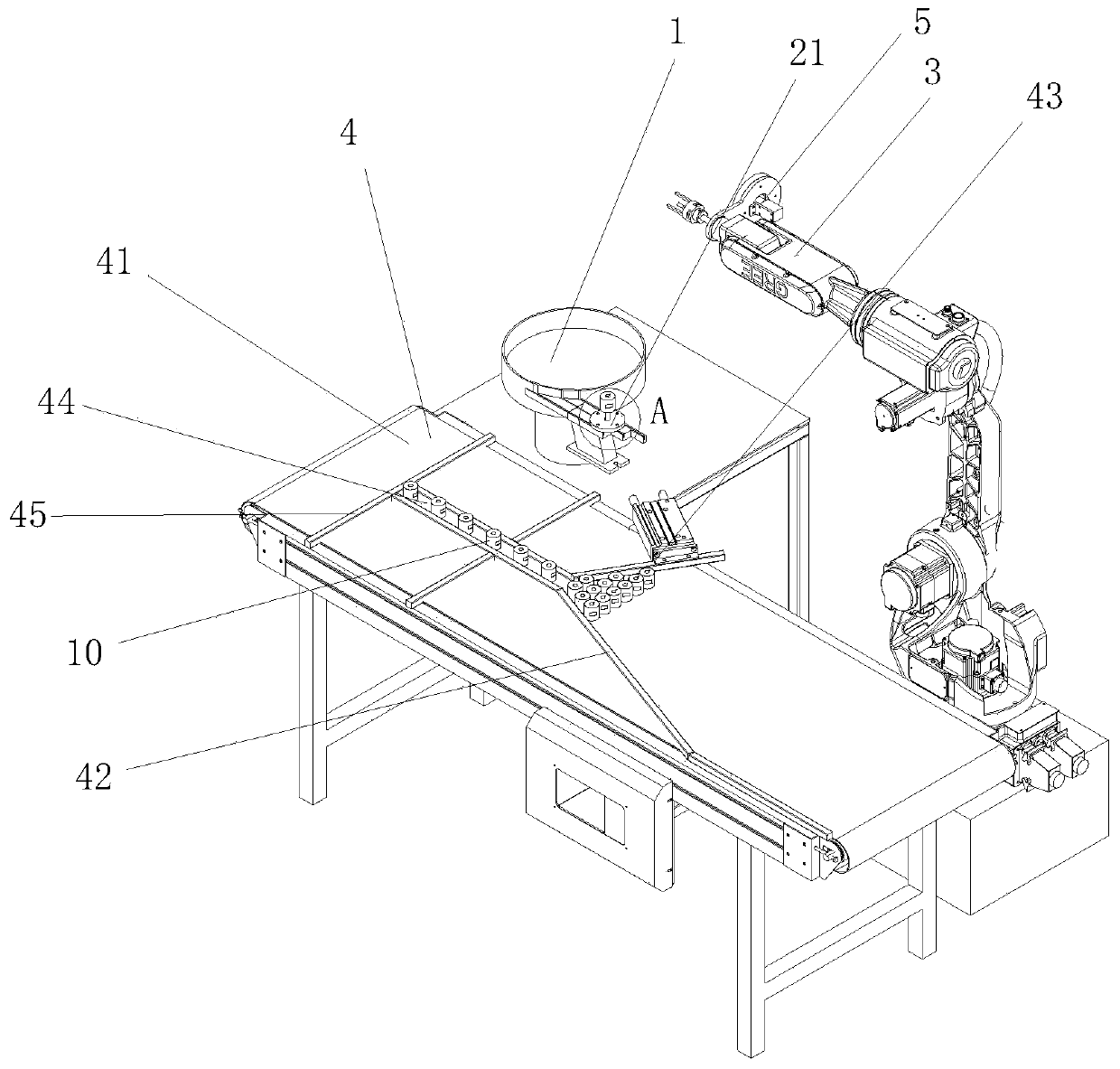

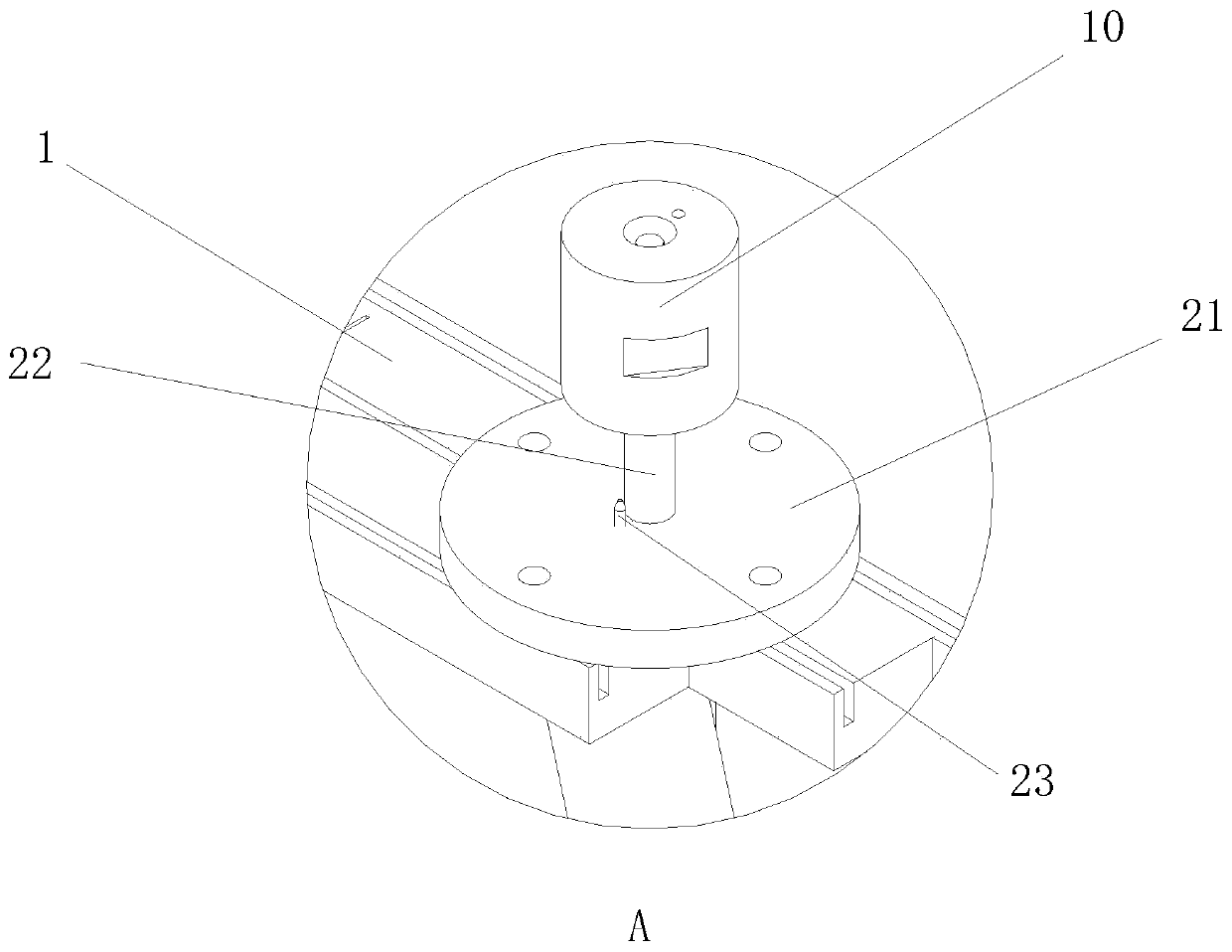

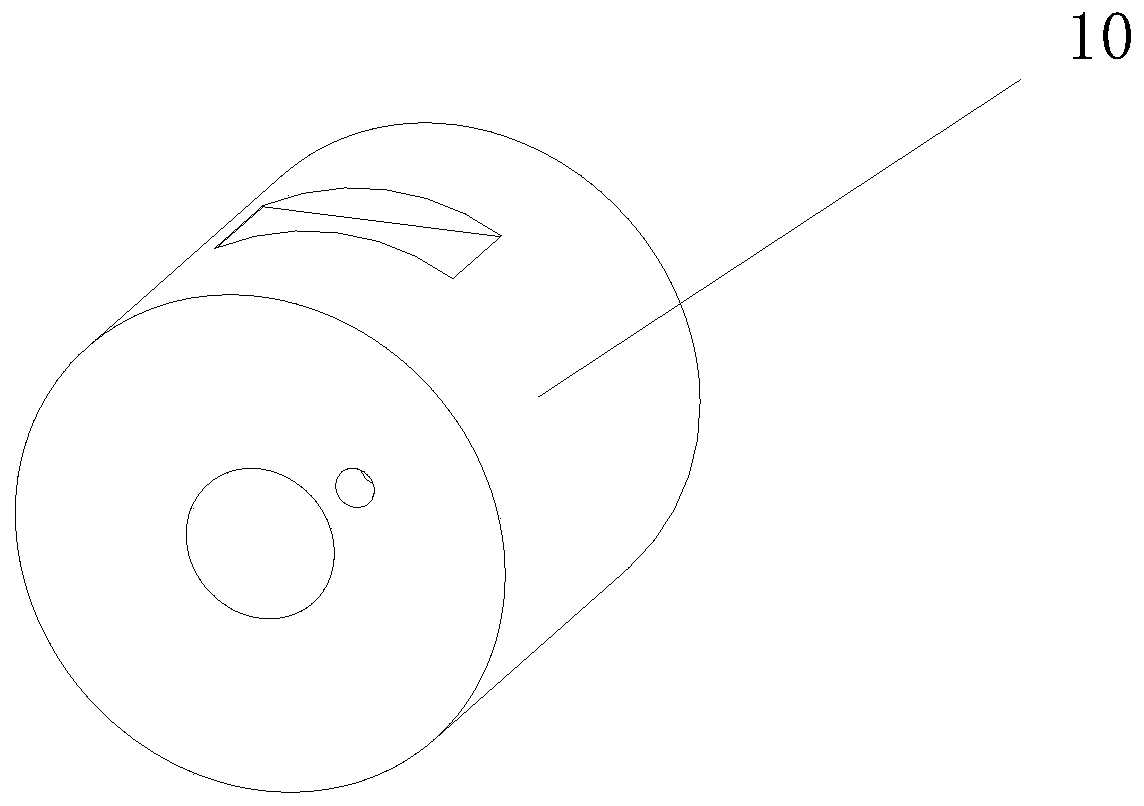

[0036] Such as Figure 1 to Figure 3 As shown, the insert positioning device of the present invention includes: a vibration mechanism 1, which generates vibration in the horizontal direction and / or vertical direction; a positioning mechanism, which is arranged on the vibration mechanism 1 and can Driven to vibrate; the positioning mechanism is configured to adjust the vibration of the insert 10 to a set state when the insert 10 is placed on it, and use the vibration generated by the vibration mechanism 1 to drive the insert 10 in the positioning mechanism During the vibration process, the insert 10 will change relative to the positioning mechanism, such as the insert 10 rotates on the positioning mechanism and / or generates displacement on the positioning mechanism, and finally the insert 10 reaches the assembly process. The required setting state, so as to complete the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com