Circular conveying type automatic polishing equipment

An equipment and feeding technology, applied in the field of cyclic feeding automatic grinding equipment, can solve the problems of low interaction efficiency of the interactive platform, affecting the grinding process, poor flexibility, etc., and achieve the effect of reducing labor waiting time, improving work efficiency and saving labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

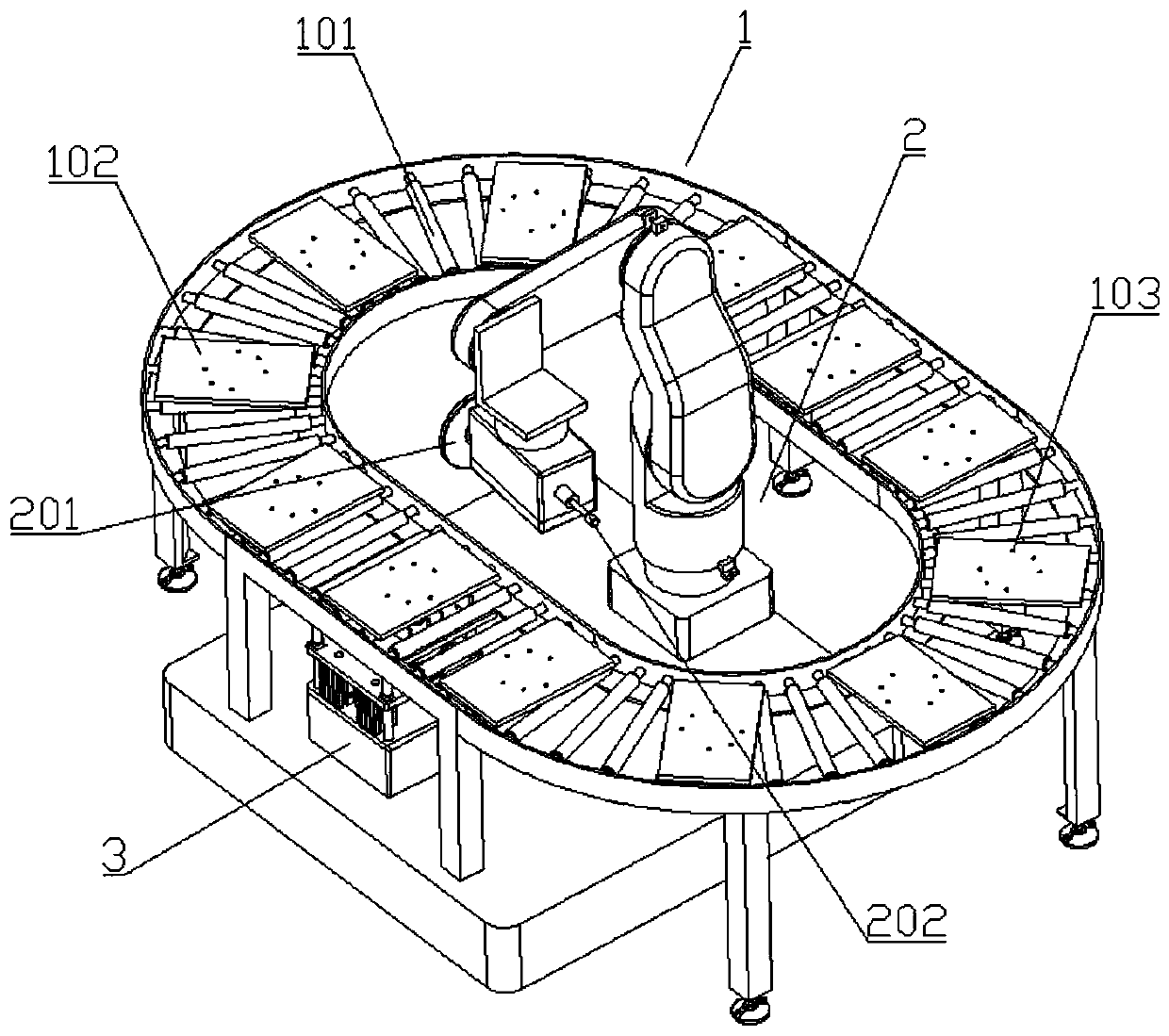

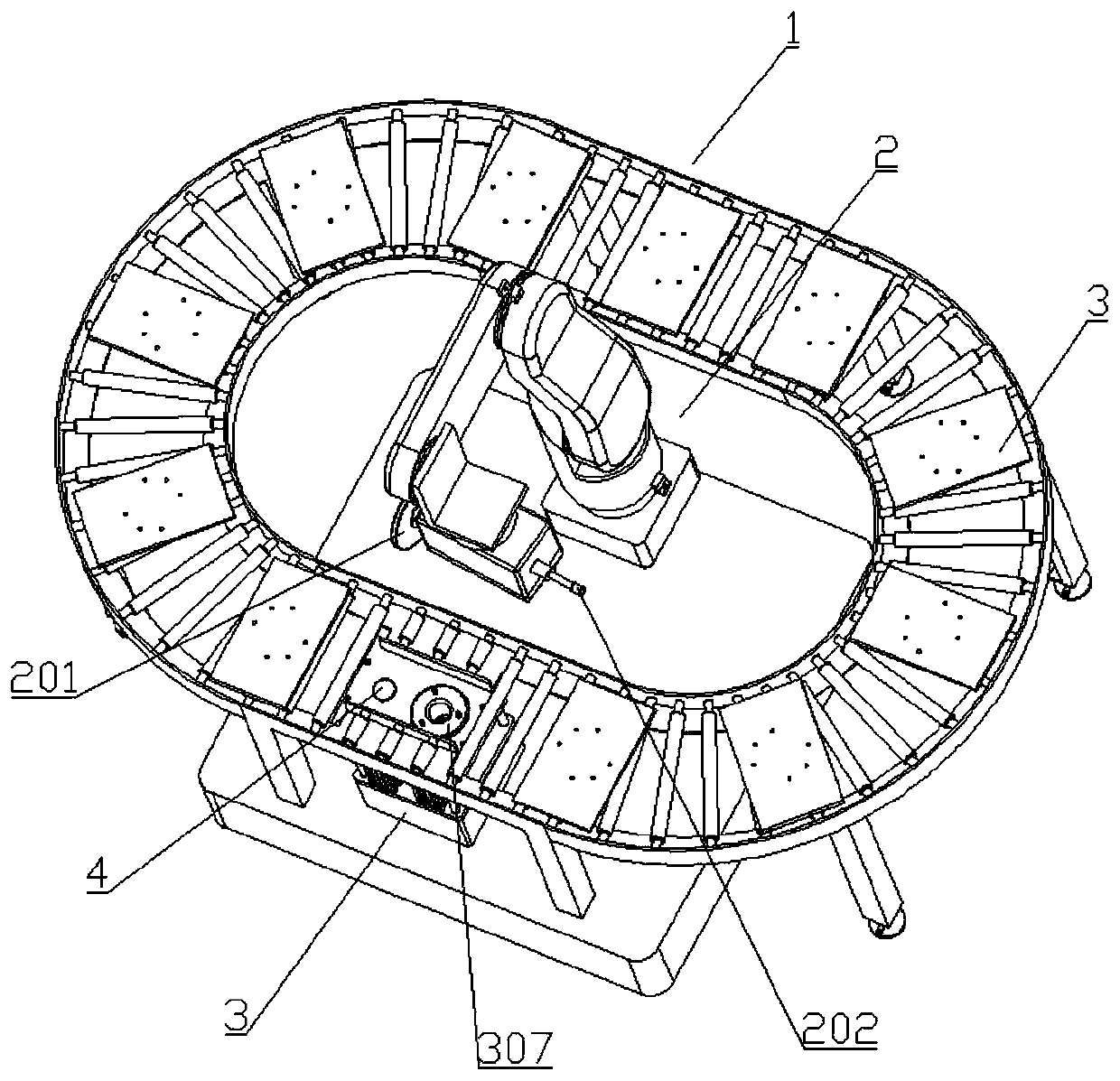

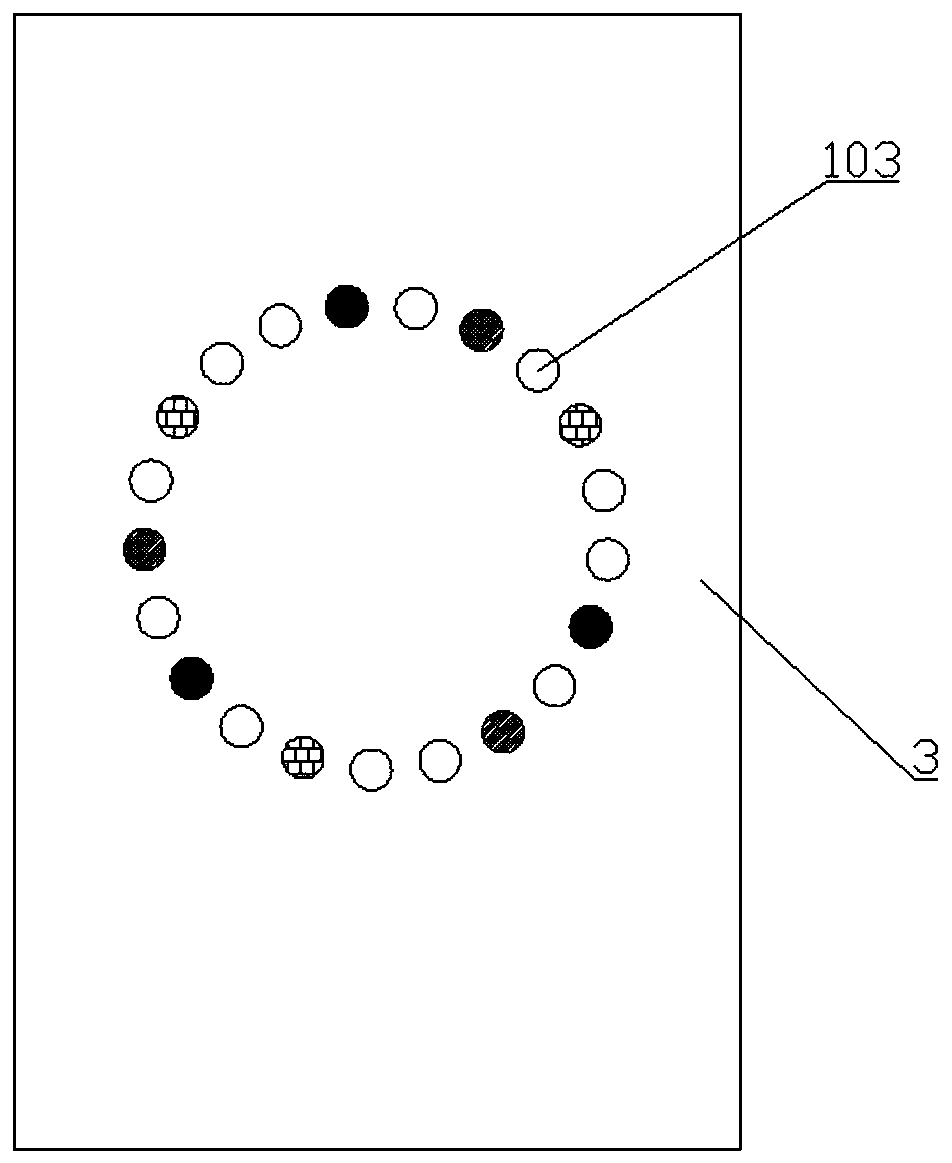

[0018] A kind of circulating feeding automatic grinding equipment, such as Figure 1-2 As shown, it includes a grinding table 1 for placing workpieces, a grinding mechanism 2 for grinding workpieces, and a controller for coordinating operations. The grinding table 1 is mainly conveyed by a closed roller conveyor 101 arranged on the roller The machine consists of several workpiece pallets 102; the grinding mechanism 2 is arranged inside the roller conveyor 101. The pallet with the workpiece fixed rotates circularly along the roller conveyor, and any area of the roller conveyor can be selected for loading and unloading, which can be loaded in advance or delayed, reducing manual waiting time and improving interaction efficiency. Of course, in actual operation, it is preferable to perform loading and unloading at a position far away from the working area of the grinding mechanism, so as to improve the safety of loading and unloading. This loading and unloading structure also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com