Carbon slag cleaning mechanism and method for hanging chain production line

A production line and catenary technology, applied in cleaning methods and utensils, separation methods, chemical instruments and methods, etc., can solve problems such as waste of production materials, energy, scratches on the surface of the wire core, and generation of slubs, etc., to ensure that the wire core Quality, reduce the effect of various losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

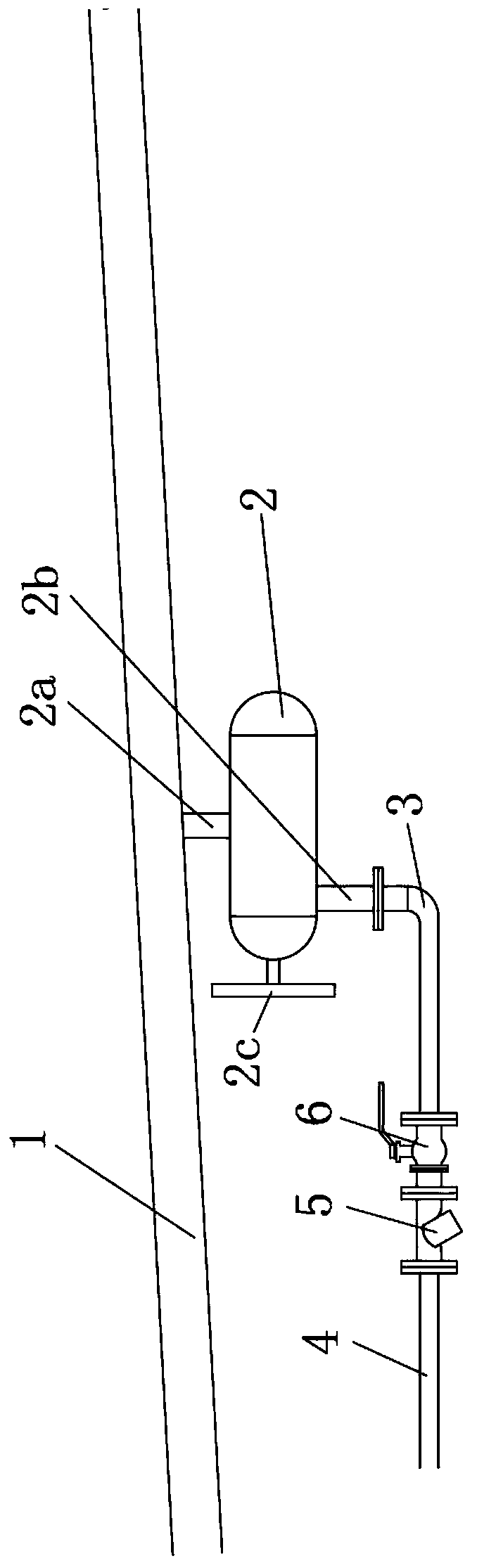

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0021] A method for cleaning carbon slag in a catenary production line, comprising the following steps:

[0022] 1) Connect the return water pipeline to the cross-linked pipeline of the catenary production line, and install ball valves and filter valves on the return water pipeline;

[0023] 2) Observe whether the water level of the return water line fluctuates abnormally, if there is no abnormality, continue to observe, if there is an abnormality, go to step 3);

[0024] 3) Close the ball valve, remove the filter screen of the filter valve, and clean the carbon residue on the filter screen;

[0025] 4) Reinstall the filter screen to the filter valve and open the ball valve.

[0026] Further, it also includes the step of observing whether there are scratches on the surface of the core, and if scratches, proceed to the following steps:

[0027] Open the sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com