Mobile-phone touch panel combined ink-jet device

An inkjet device, touch screen technology, applied in typewriters, fixed filter element filters, filtration and separation, etc., can solve the problems of bad influence of staff, poor reliability of use, easy generation of pungent irritating gas, etc., to achieve convenient Handling, improving the reliability of use, and improving the effect of the installation and fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

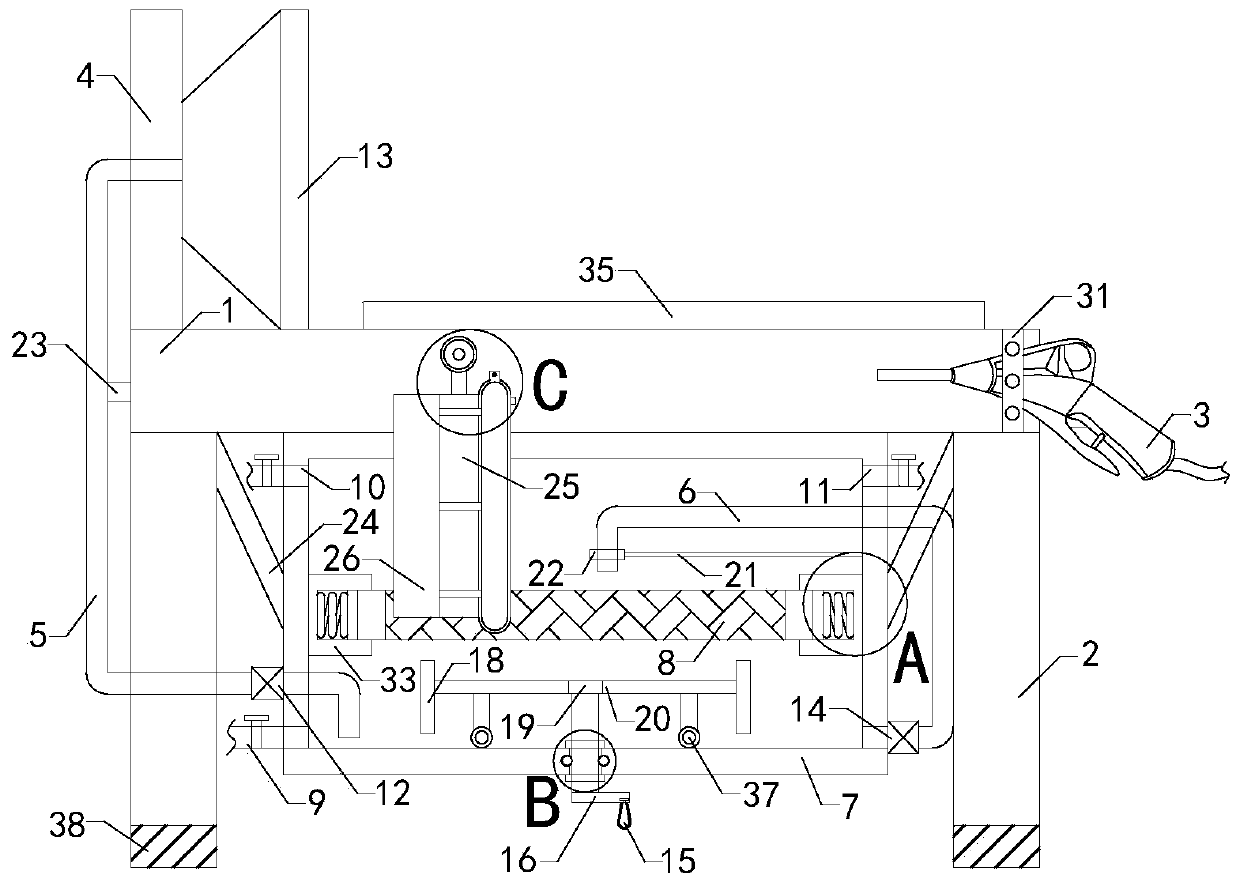

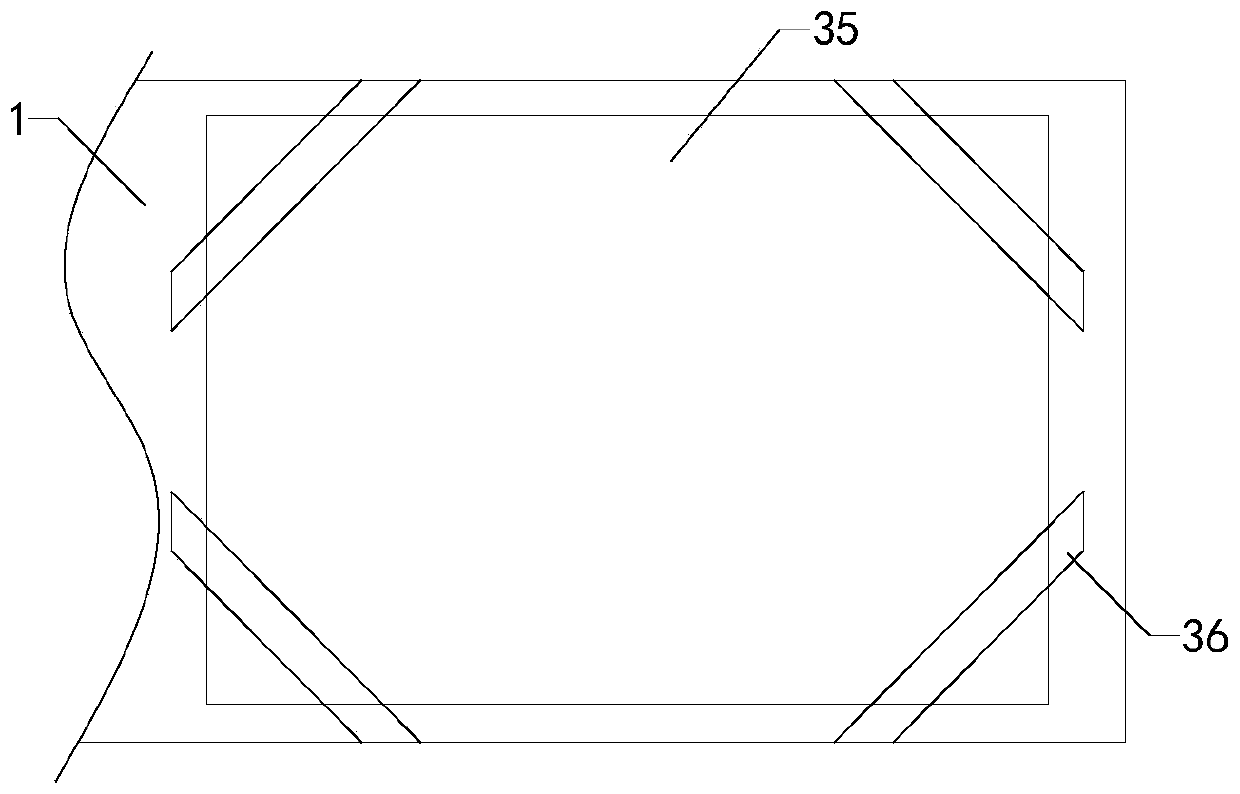

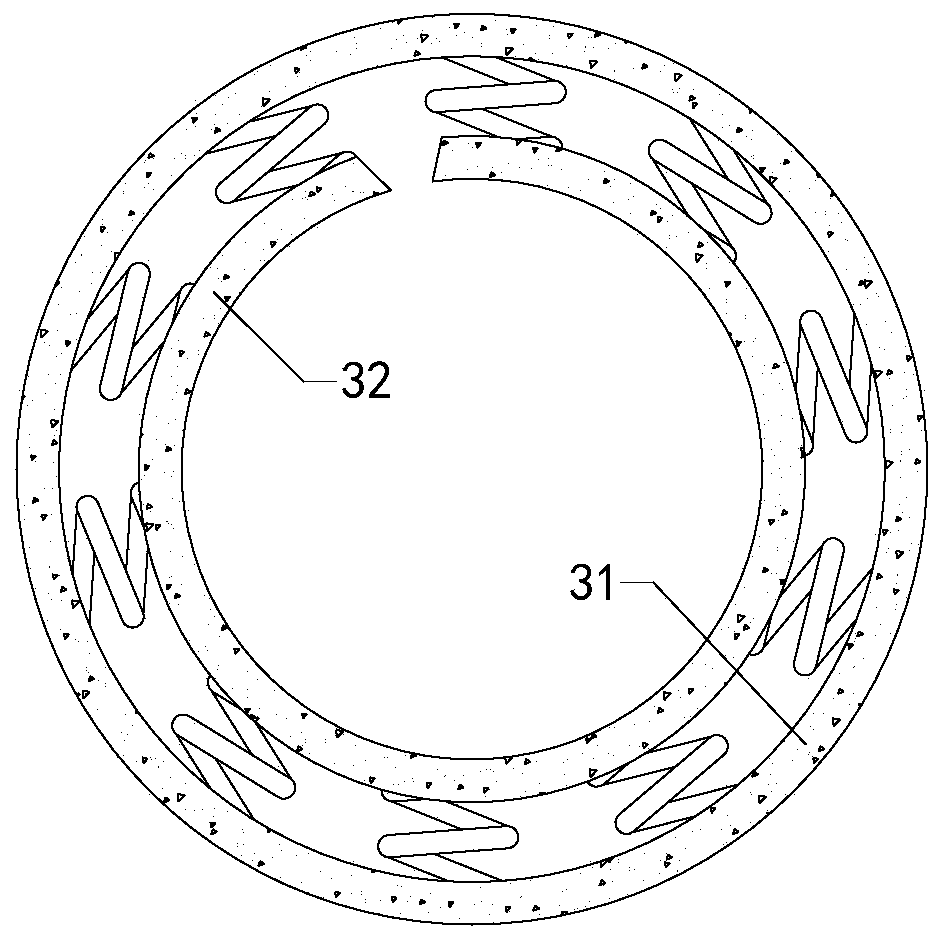

[0022] like Figure 1 to Figure 7As shown, a mobile phone touch screen combination inkjet device of the present invention includes an operation panel 1, four sets of brackets 2 and spray guns 3, and the tops of the four sets of brackets 2 are installed on the left front side, right front side, and right side of the bottom end of the operation panel 1 respectively. The left rear side and the right rear side; also include the vertical plate 4, the smoke pipe 5, the liquid pipe 6, the processing box 7 and the filter plate 8, the processing box 7 is connected to the bottom of the operation panel 1, and the processing box 7 is provided with a processing cavity, the lower left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com