Package box and box cover plastic uptake piece assembling assembly line equipment

An assembly line and packaging box technology, applied in the direction of packaging, transportation and packaging, conveyor objects, etc., can solve the problems of unguaranteed quality and efficiency of pasting, affecting the appearance, and weak pasting, so as to improve assembly production efficiency and assemble products Quality, simple structure, to achieve the effect of taking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

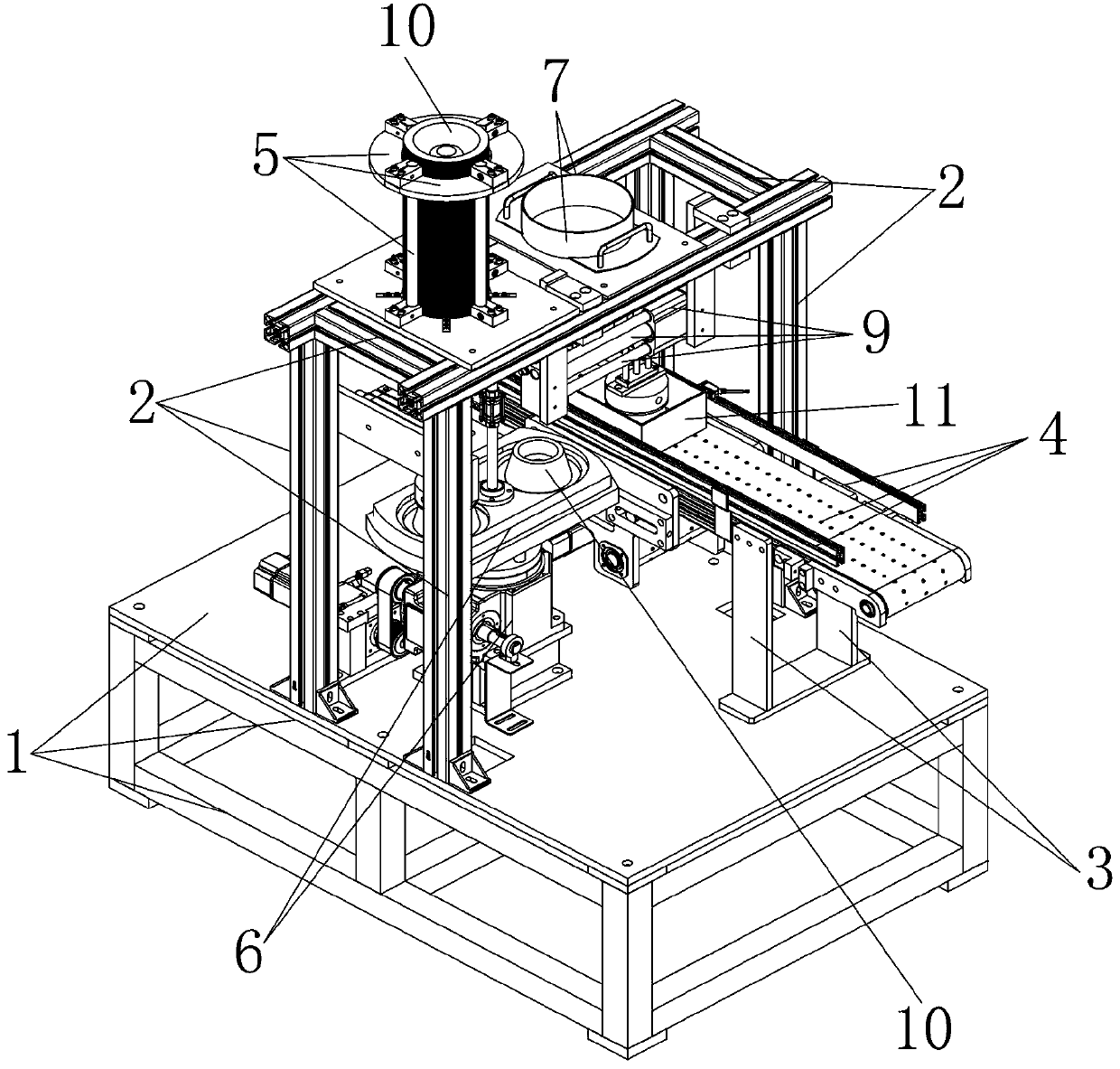

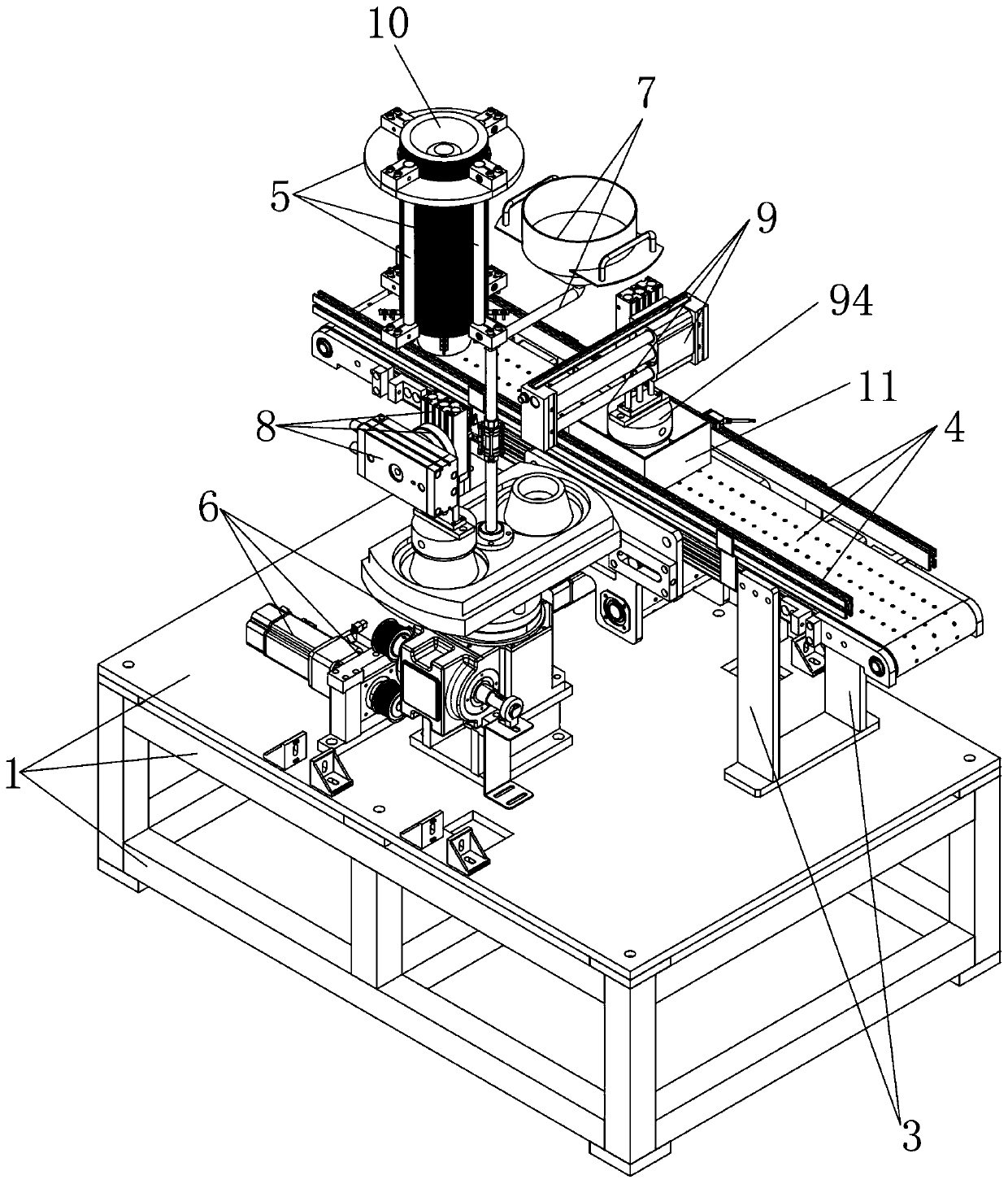

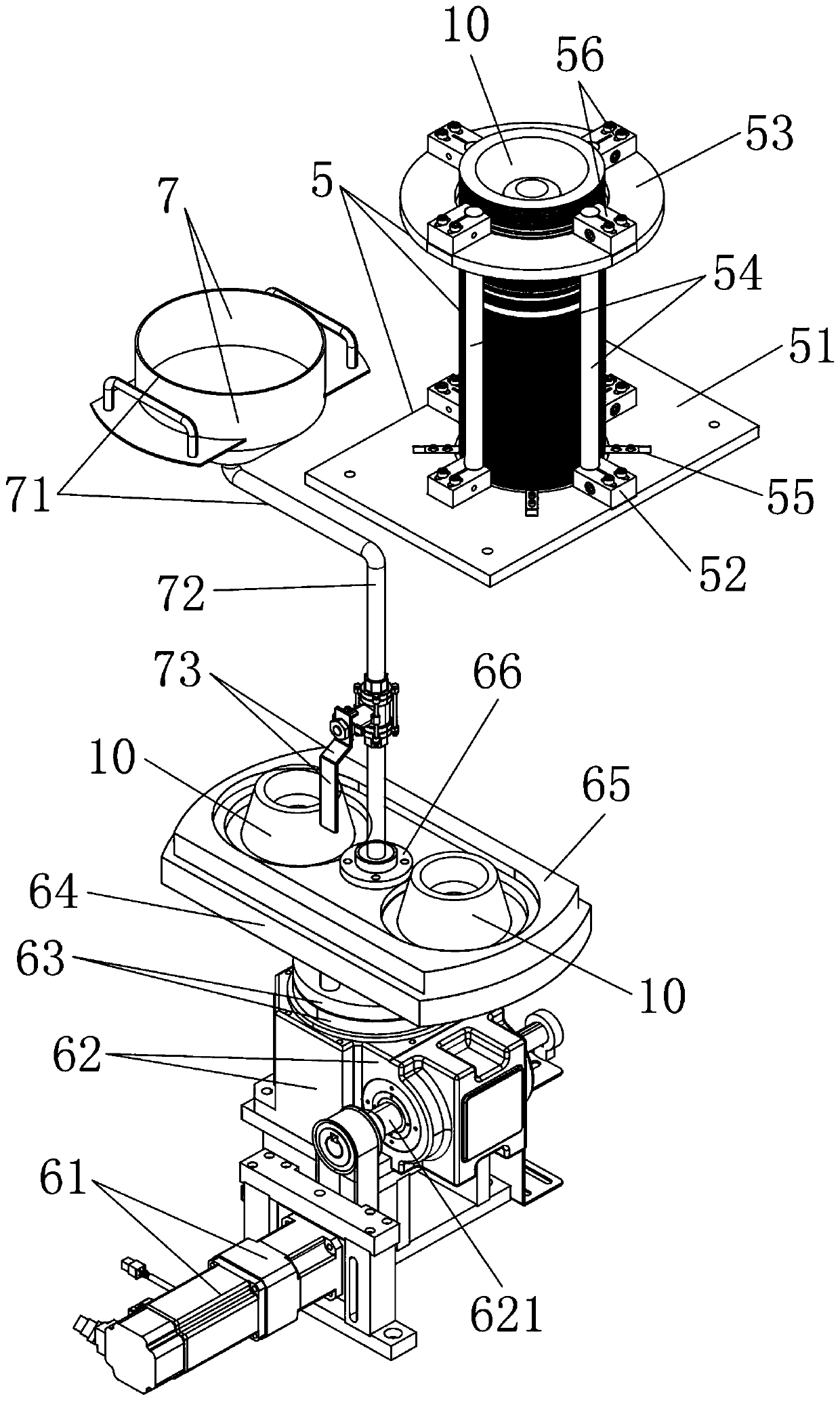

[0035] Such as Figure 1 to Figure 9 As shown, a packing box cover blister assembly line equipment includes a box cover conveying line 4, a blister separating device 5, a blister tray device 6, a glue replenishing device 7, a blister taking device 8 and a blister loading device 9. The blister separating device 5 is used to store and separate the blister 10 of the packaging box. The blister tray device 6 includes a blister tray assembly and a steering drive mechanism that drives the blister tray assembly to turn horizontally. The tray assembly has a gluing position corresponding to the blister separating device 5 . The plastic part tray assembly is provided with a glue guide block 66, and the glue guide block 66 has a glue guide tube cavity inside, and the glue guide tube cavity of the glue guide block 66 is connected with the glue coating position of the blister part tray assembly. , The glue replenishing device 7 includes a funnel container 71 and a tube 72 connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com