Pneumatic tire

A pneumatic tire, tire circumferential technology, applied in tire parts, tire tread/tread pattern, transportation and packaging, etc., can solve the problem of not achieving both handling stability and riding comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] One embodiment of the pneumatic tire of the present invention will be described below with reference to the drawings. In addition, in each drawing, the dimensional ratio on the drawing and the actual dimensional ratio do not necessarily match, and also the dimensional ratio among the drawings does not necessarily match.

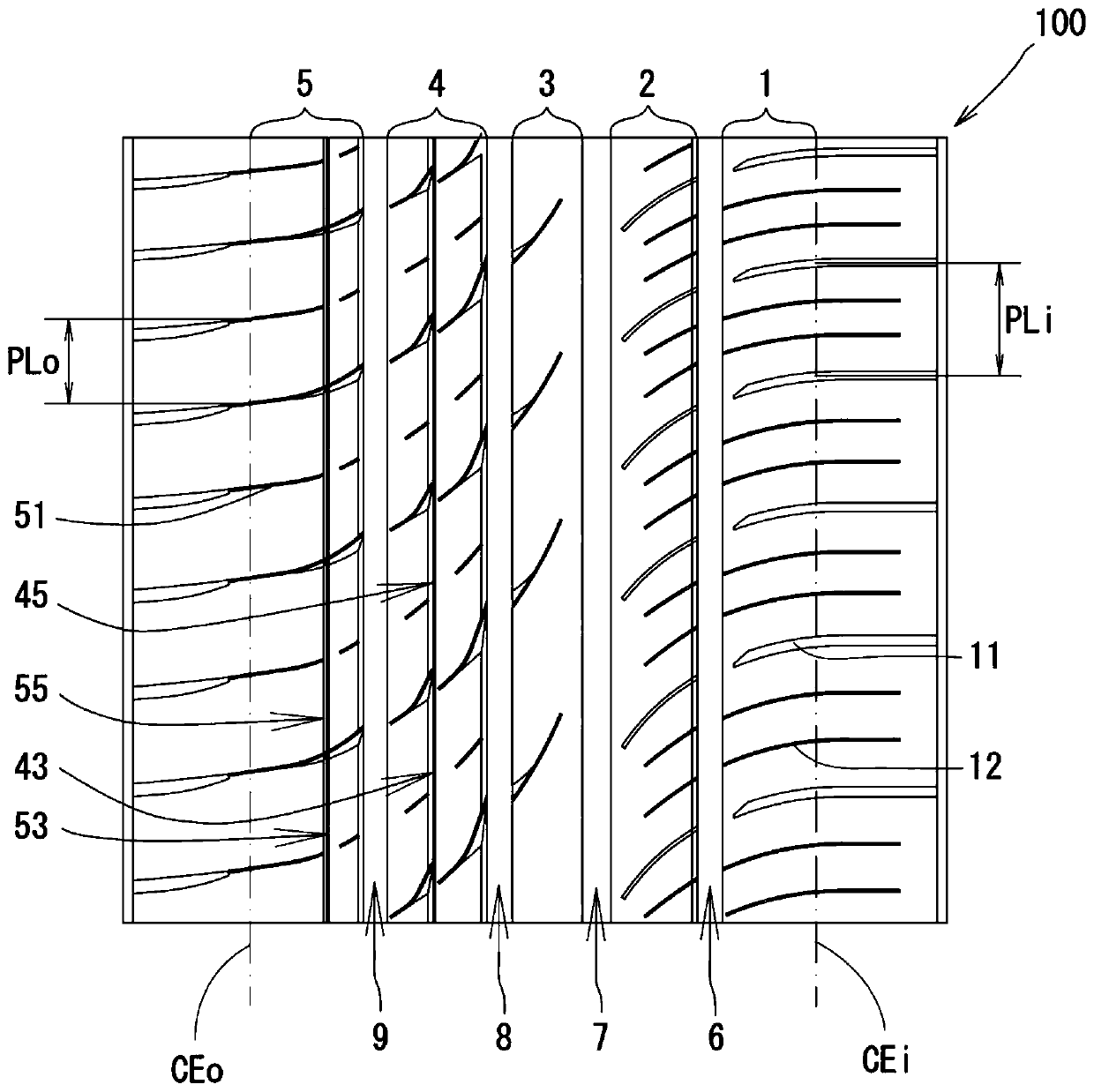

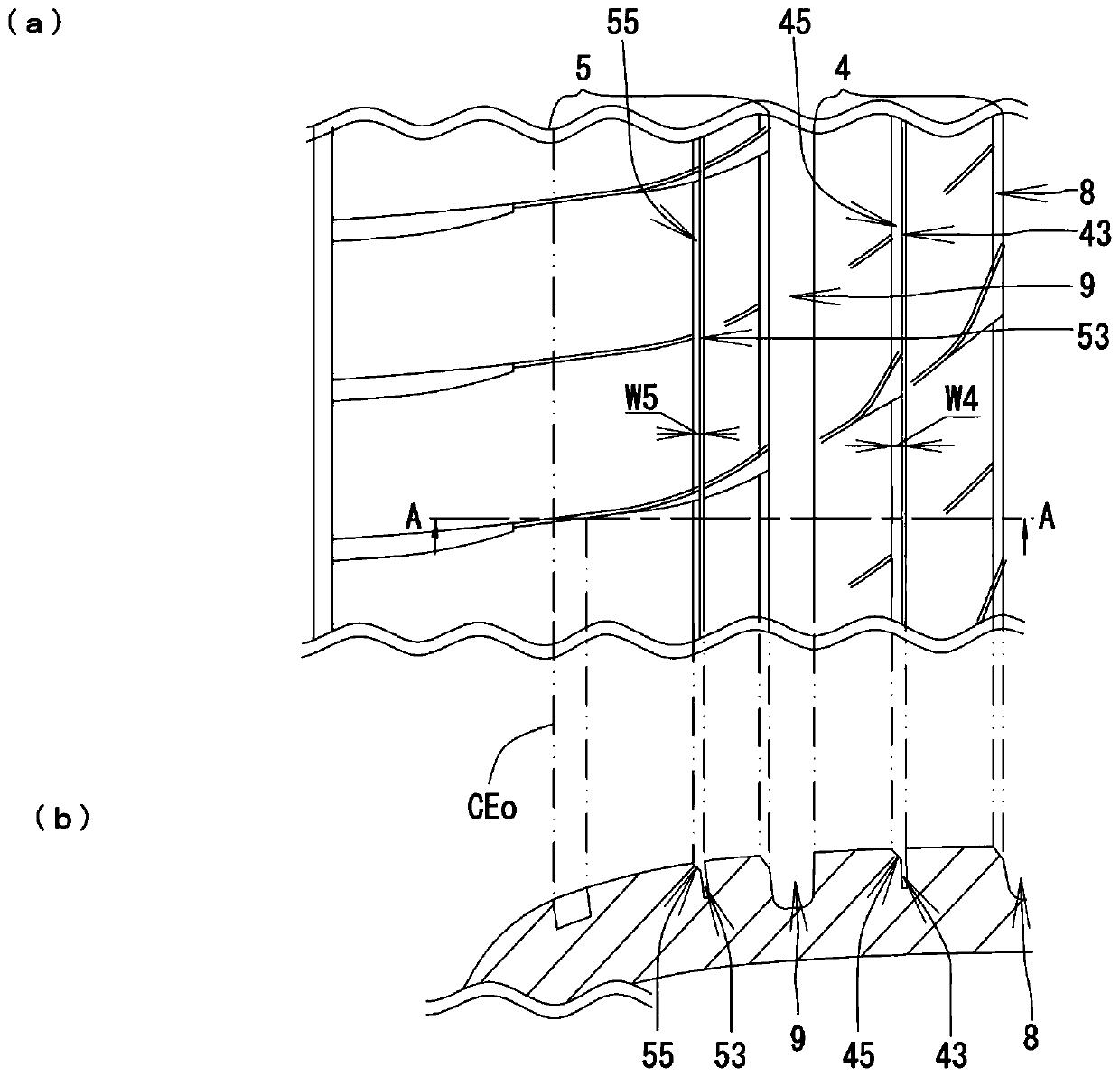

[0029] figure 1 One embodiment of the tread portion 100 of the pneumatic tire of the present invention is shown. The tread portion 100 includes four main grooves 6 to 9 extending in the tire circumferential direction, and five land portions 1 to 5 divided by the main grooves 6 to 9 . In this embodiment, the installation orientation of the pneumatic tire relative to the vehicle is specified, and the five land portions 1 to 5 include: the inner shoulder land portion 1, the inner quarter land portion 2, the central land portion 3, and the outer quarter land portion. A land portion 4 and an outer shoulder land portion 5 . The outer shoulder land portion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com