Automobile lightweight front anti-collision beam

A front anti-collision beam, lightweight technology, which is applied to the body, vehicle parts, streamlined body and other directions, can solve the problems of increasing fuel consumption, heavy anti-collision beam, increasing the weight of the whole vehicle, etc., and achieves the effect of simple structure and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

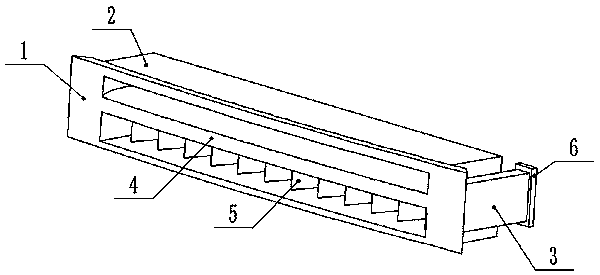

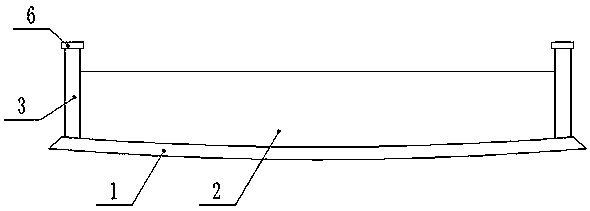

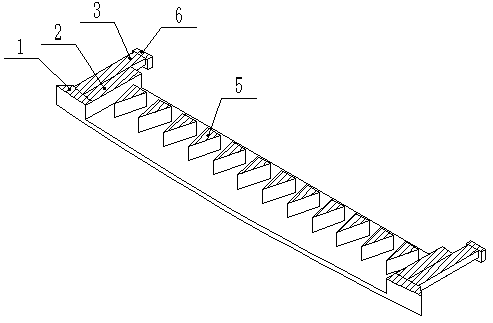

[0015] Such as Figure 1-5 As shown, a lightweight front anti-collision beam of an automobile includes an anti-collision beam 1, a lightweight frame 2, a bracket 3 and a lightweight partition 4, the rear end of the anti-collision beam 1 is fixedly connected to the lightweight frame 2, and the anti-collision beam 1 It is hollowed out in the middle of the lightweight frame 2, and a lightweight partition 4 is provided. The lightweight frame 2 and the lightweight partition 4 are made of aluminum material, which is light in weight, and will not affect the overall weight of the car even when it is parked. influences. The lower end surface of the lightweight partition 4 is a plane design, and the lower end surface is an asymmetrical arc-shaped design with a raised front end. When the car is running, the wind blows through the lightweight frame 2, form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com