A double-fluid grouting equipment for geotechnical engineering foundation reinforcement

A foundation reinforcement and double-liquid grouting technology, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of inconvenient use of casing, difficult to achieve consistent operation effect and theoretical effect, etc. Improve construction accuracy and facilitate maintenance and repairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

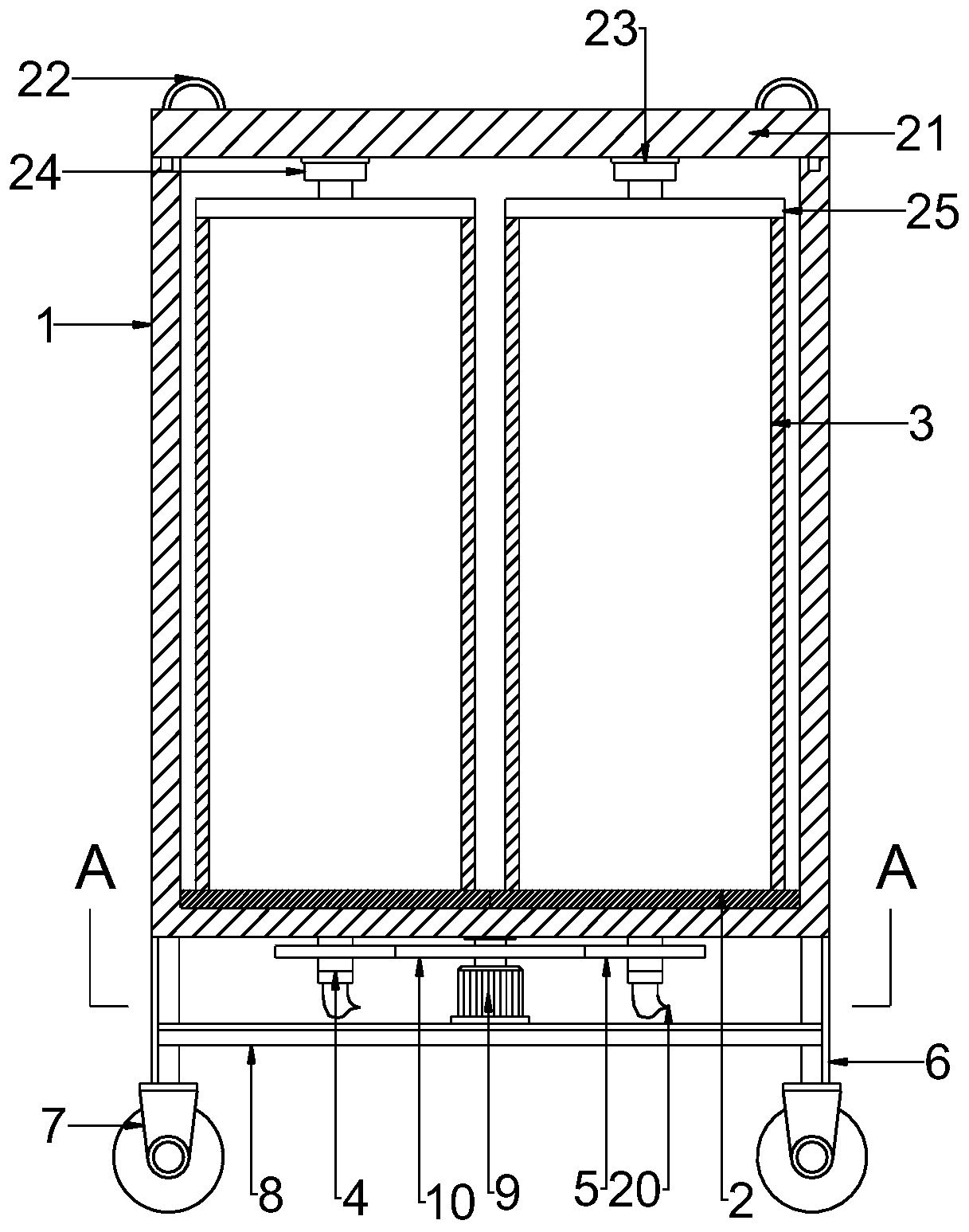

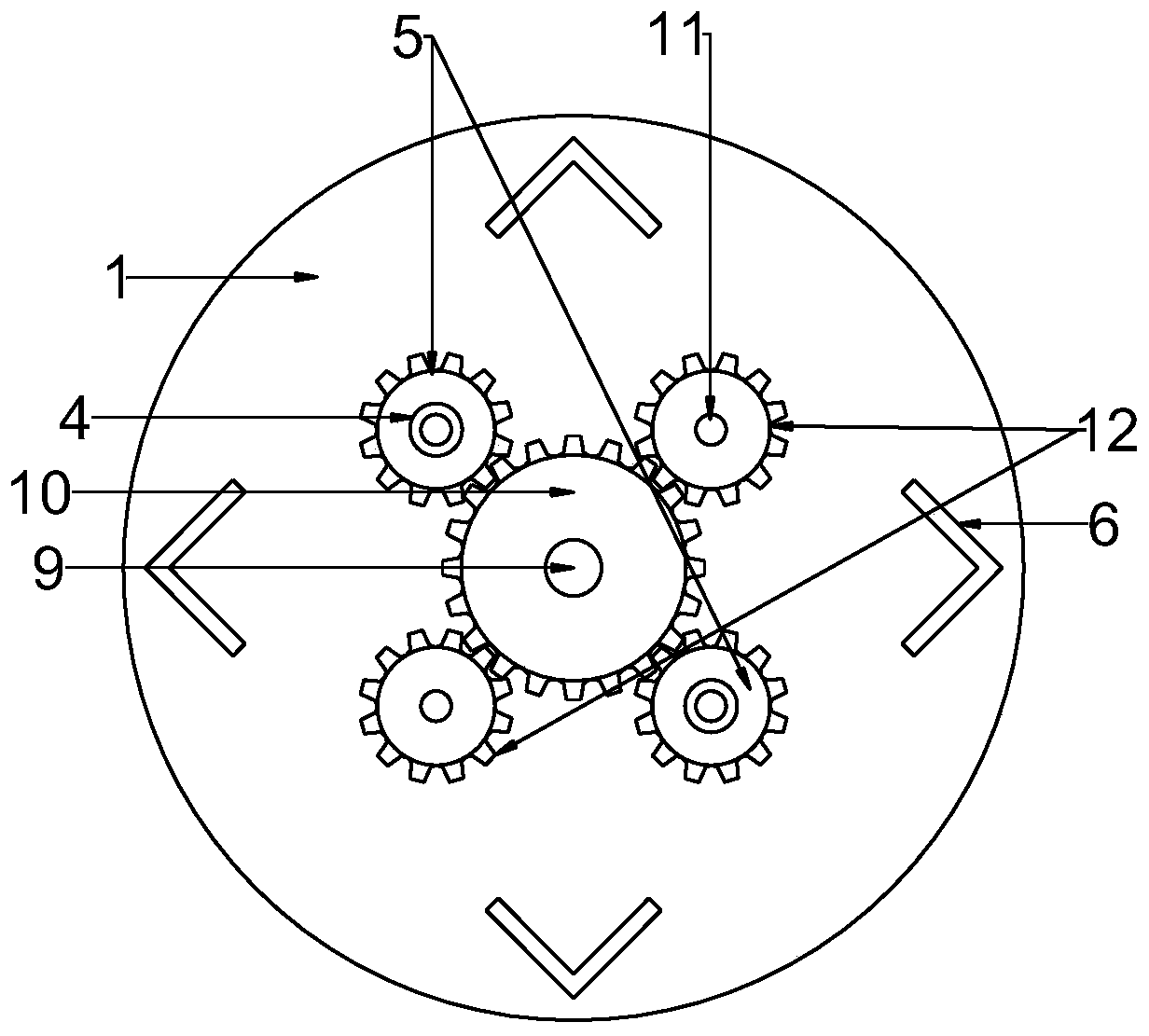

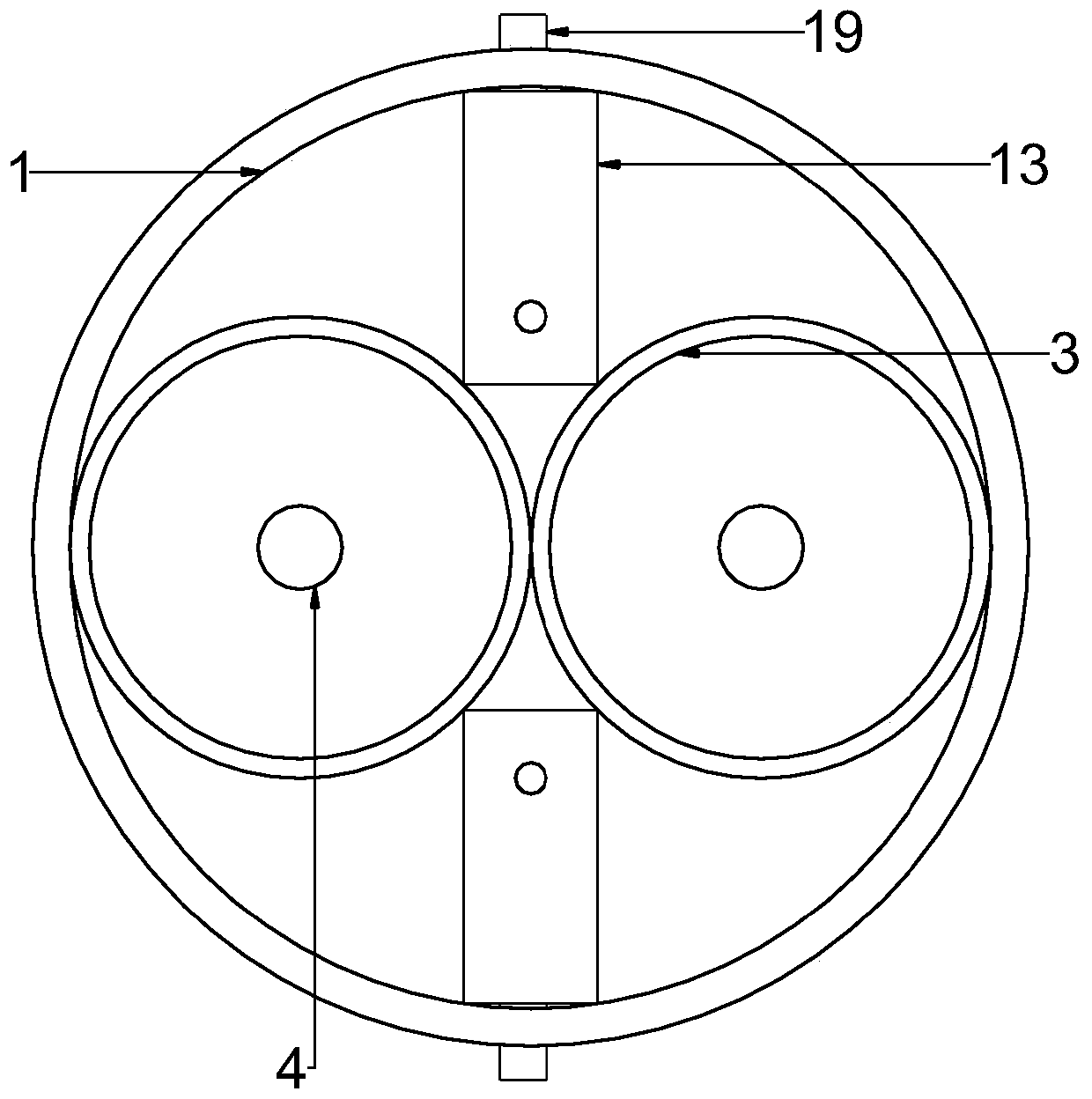

[0023] see Figure 1~4 , in an embodiment of the present invention, a double-liquid grouting equipment for foundation reinforcement in geotechnical engineering includes a casing 1, and two sets of symmetrically arranged rotating bottom plates 2 are arranged in the casing 1 through a rotating connection of a material guide pipe 4, The rotating bottom plate 2 is fixedly provided with an accommodating chamber 3 for accommodating cement slurry and water glass, and the housing 1 is also fixedly provided with a pumping chamber that communicates with the accommodating chamber 3 through a material guide pipe 4 and intermittently extracts materials. The material structure, the material pumping structure and the material guide pipe 4 are synchronously driven by the transmission structure, and when the material guide pipe 4 rotates, the material is pumped into the material pumping structure and discharged through the material guide pipe 4 intermittently through the material guide pipe 4. ...

Embodiment 2

[0029] see figure 1 and 5 , in the embodiment of the present invention, a double-fluid grouting equipment used for geotechnical engineering foundation reinforcement, on the basis of embodiment 1, the upper end of the casing 1 is also movably equipped with a movable device for sealing the accommodating cavity 3 The upper cover structure, the movable upper cover structure includes an upper cover plate 21 and two sets of accommodating covers 25 connected to the upper cover plate 21, and the two sides of the lower end of the upper cover plate 21 are symmetrically fixed with limiting protrusions 26, and Through the movable fitting of the limit protrusion 26 and the upper end of the housing 1, the upper end of the upper cover plate 21 is symmetrically welded and fixed with a hanging ring 22 on both sides, and the upper cover plate 21 can be suspended and lifted by the hanging ring 22; the upper cover plate The positions corresponding to the lower end of 21 and the two groups of acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com