Unpowered constant speed drainage flow control device

A power and water outlet control technology, applied in water supply devices, sewage discharge, waterway systems, etc., can solve the cost of flow control devices, difficulties in transportation, installation, maintenance, difficulty in providing power sources and electromechanical equipment, and increase the size of flow control devices and quality issues, to achieve the effect of simple and convenient project implementation, operation and maintenance, accurate planning of water adjustment and storage, and reduction of runoff peak flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

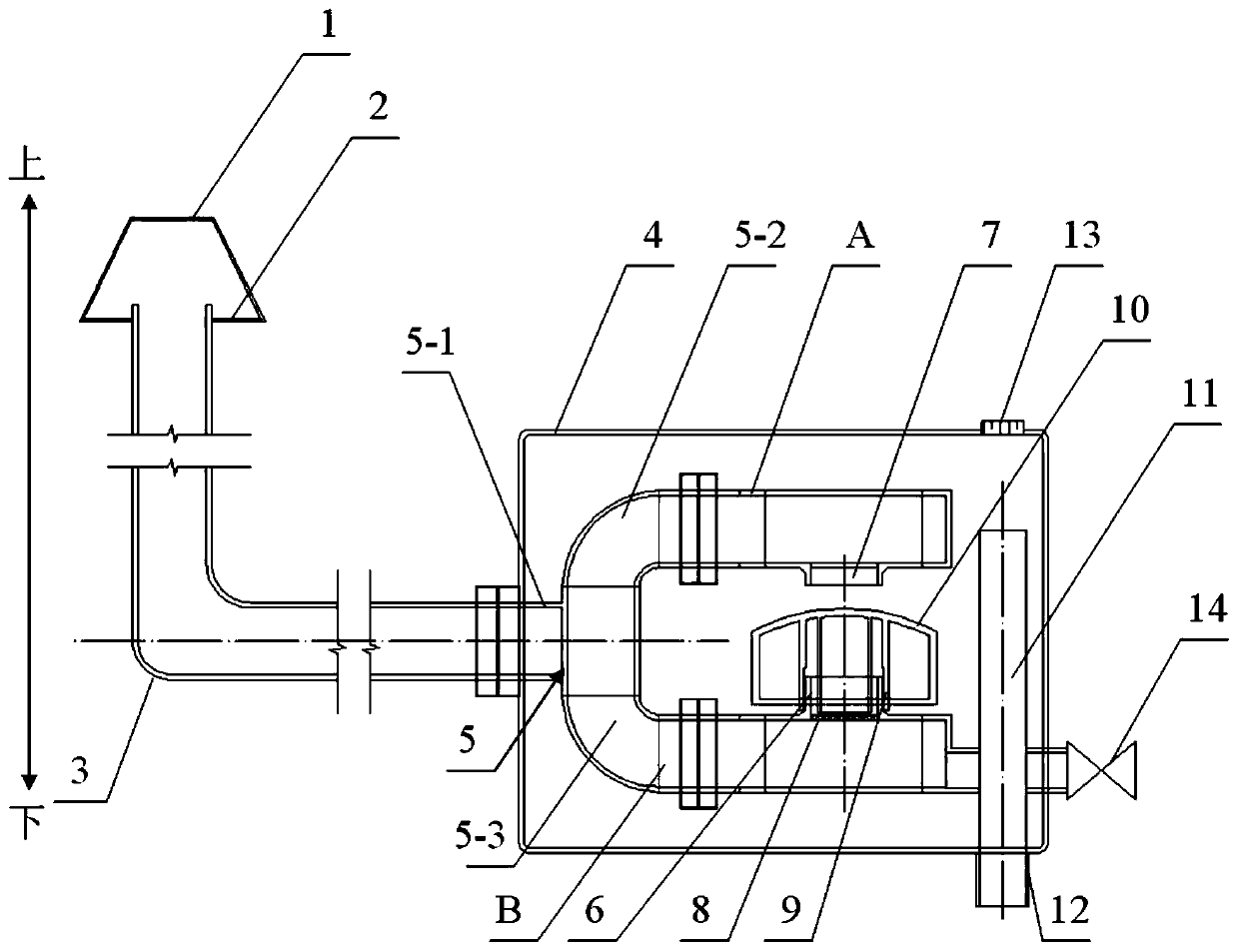

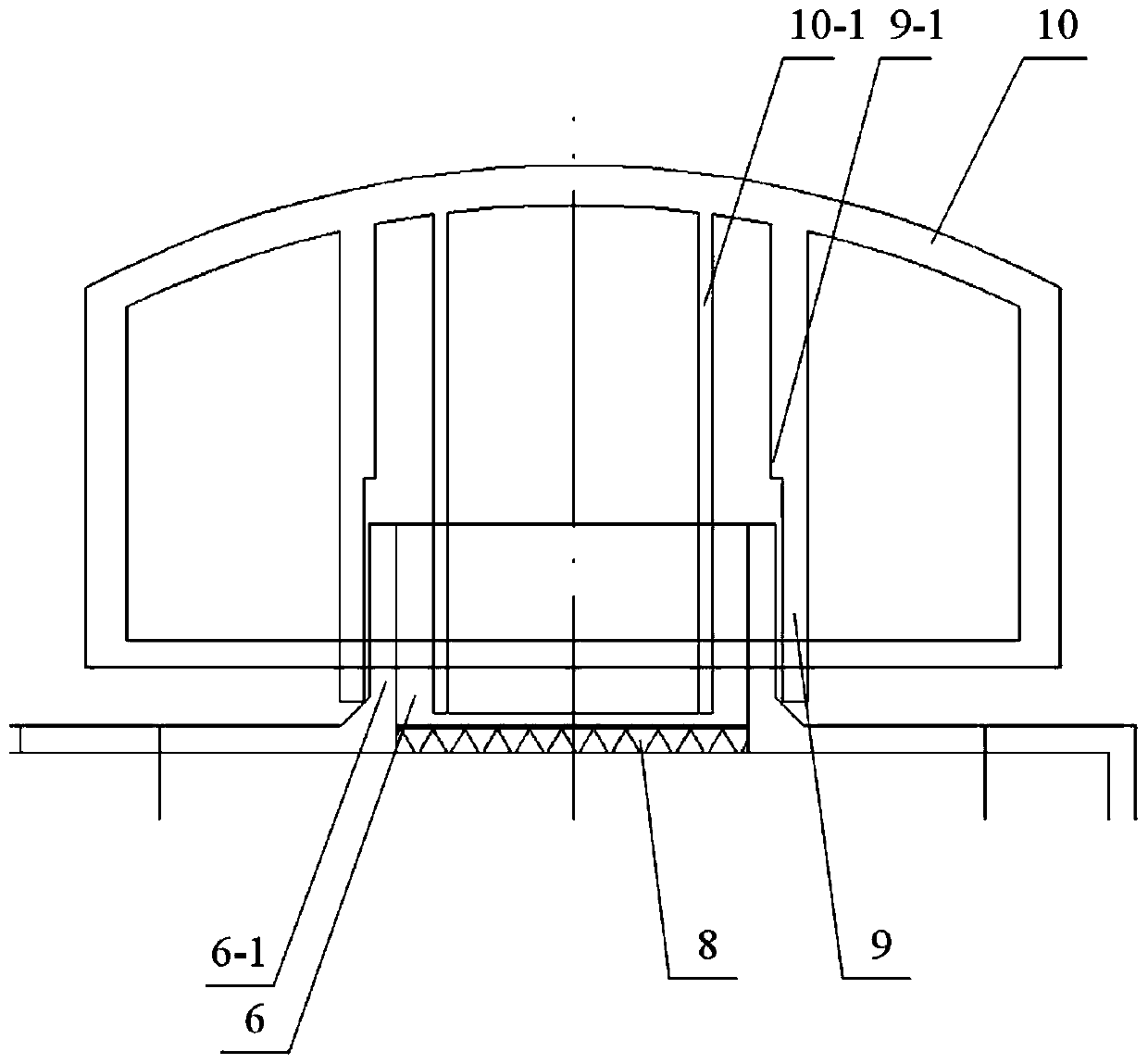

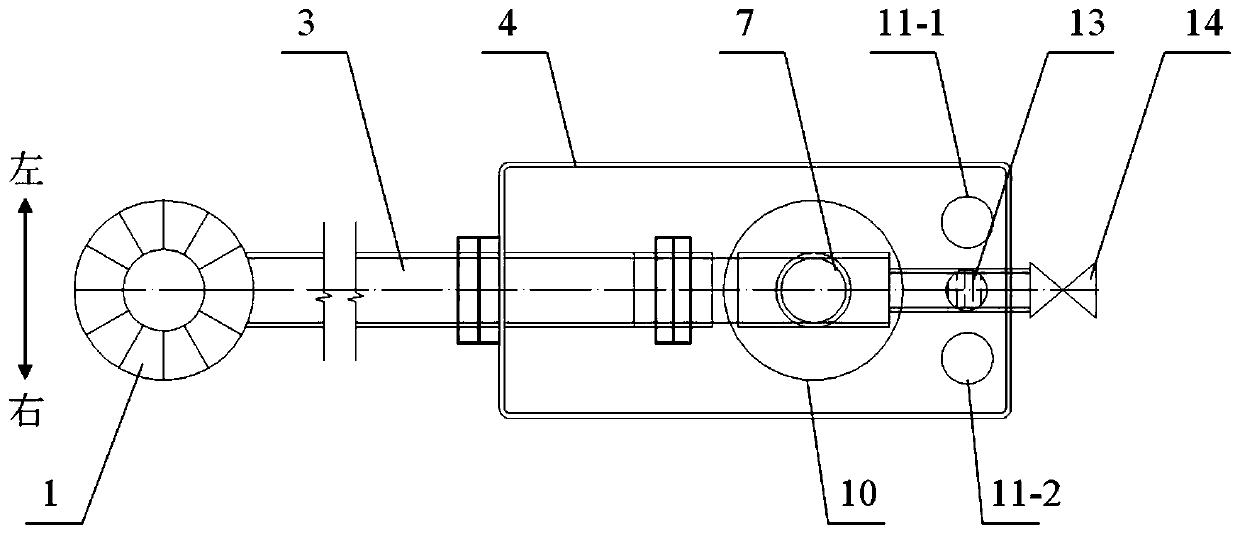

[0032] The present invention will now be described in further detail with reference to the accompanying drawings. These drawings are all simplified schematic diagrams, and only illustrate the basic structure of the present invention in a schematic manner, so they only show the structures related to the present invention.

[0033] like Figure 1-3 As shown in the figure, an unpowered uniform drainage flow control device includes a water inlet head 1, a water inlet filter screen 2, a water inlet pipe 3, a box body 4, a shunt tee 5, an upper pipe body A, a lower pipe body B, and a lower pipe body. Hydraulic communication port 6, upper inflow port 7, lower protective filter screen 8, socket sliding part 9, floating water stop part 10, water outlet control pipe 11, water outlet 12, vent cap 13, drain valve 14; among them,

[0034] The water inlet head 1 is arranged at one end of the water inlet pipe 3 and communicates with the interior of the water inlet pipe 3. The water inlet he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com