Earthquake-proof assembled concrete beam column connection method

A beam-column connection and concrete technology, which is applied in the direction of earthquake resistance, protective buildings/shelters, building components, etc., can solve the problems of poor seismic performance of prefabricated frame structures, etc., to increase shear performance, improve integrity and load bearing Force, the effect of increasing energy consumption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

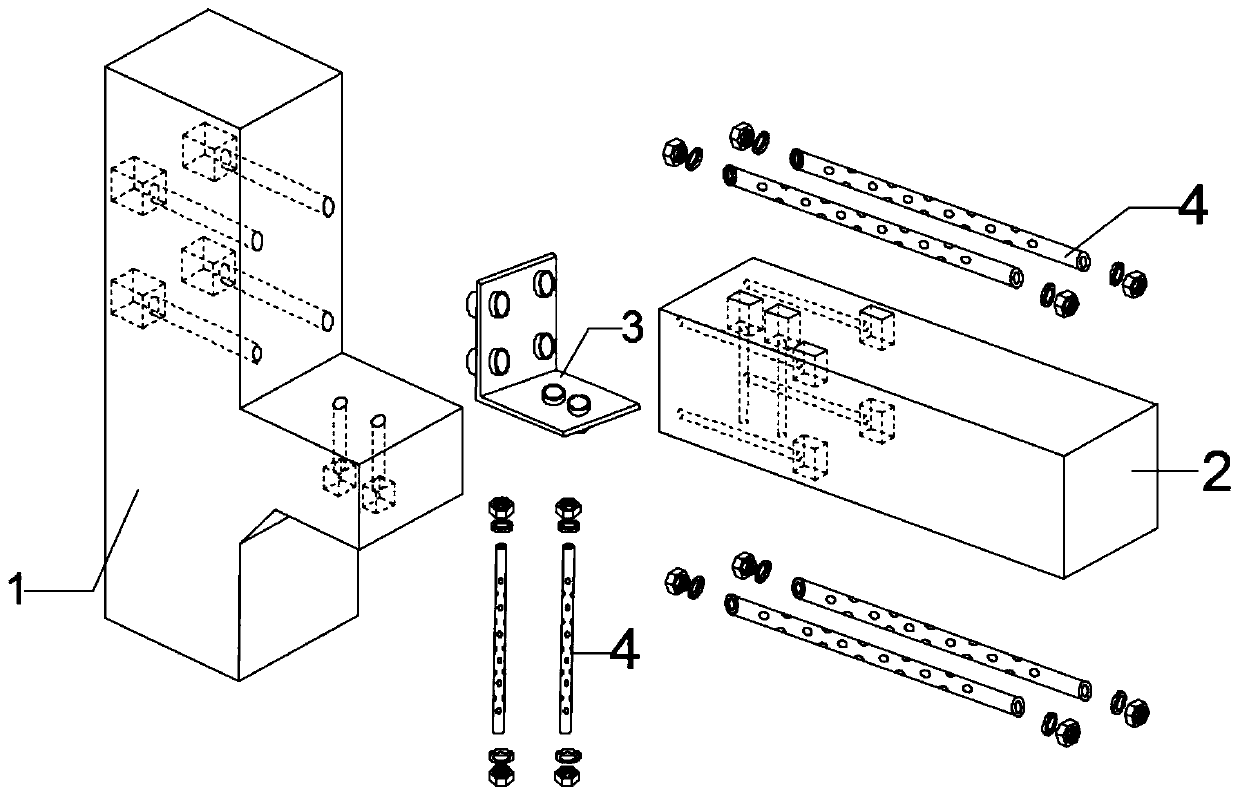

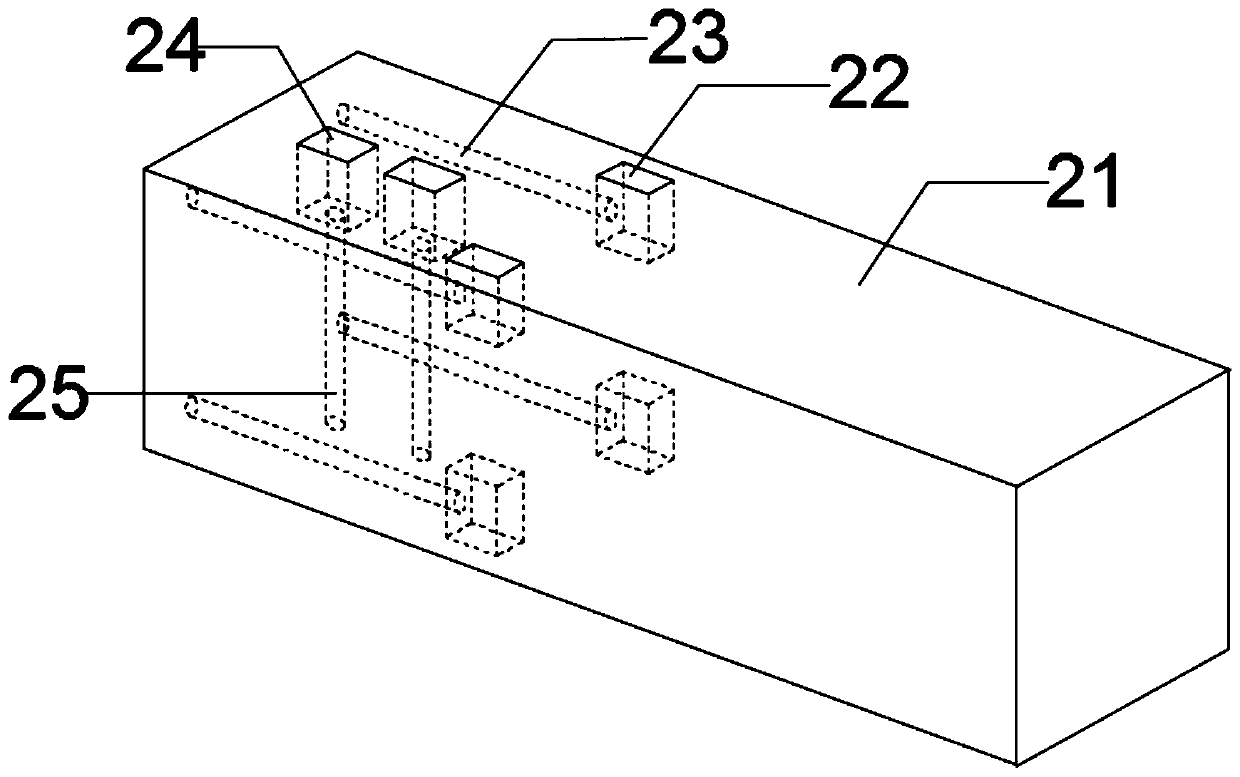

[0055] Example: Combine Figure 1-5 As shown, the components involved in the present invention include prefabricated columns 1 , prefabricated beams 2 , elastic gaskets 3 , and high-strength bolt structures 4 .

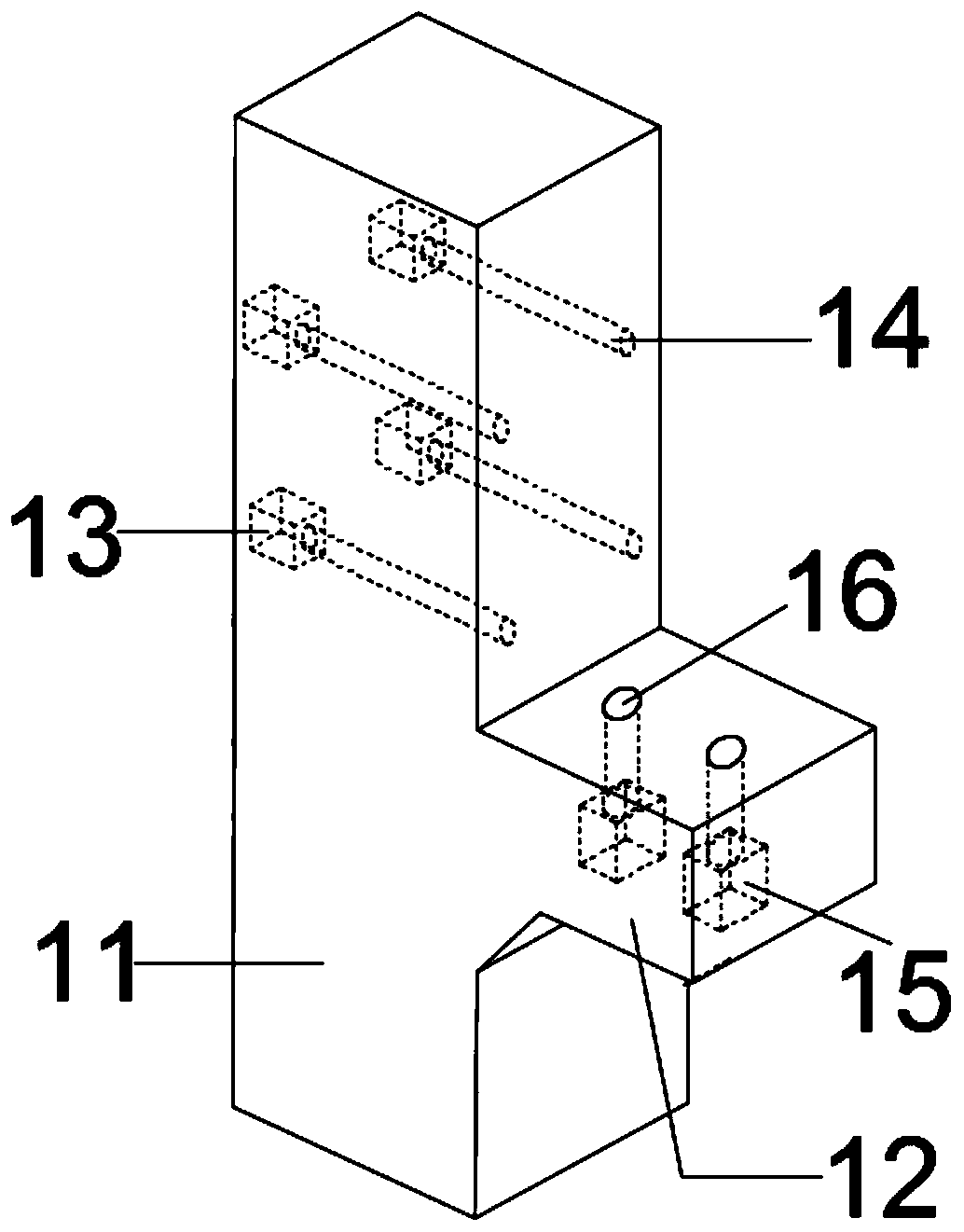

[0056] The prefabricated column 1 includes a reinforced concrete prefabricated column 11 and a corbel 12 integrally poured on the side of the reinforced concrete prefabricated column 11. The reinforced concrete prefabricated column 11 is a rectangular reinforced concrete structure, and the size is in accordance with the design requirements of the building structure; the corbel 12 is a wedge-shaped three-dimensional reinforced concrete For the structure, the connection between its lower part and the reinforced concrete prefabricated column 11 is reinforced with a wedge-shaped structure, the width of which is the same as that of the reinforced concrete prefabricated column 11, and the size is in accordance with the design requirements of the building structure.

[0057]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com