Construction method of pre-buried wall pipes

A construction method and wall technology, which is applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as pipeline displacement, influence of wall structure strength, and influence on pipeline pre-embedded precision, etc., to improve The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following is further described in detail by specific embodiments:

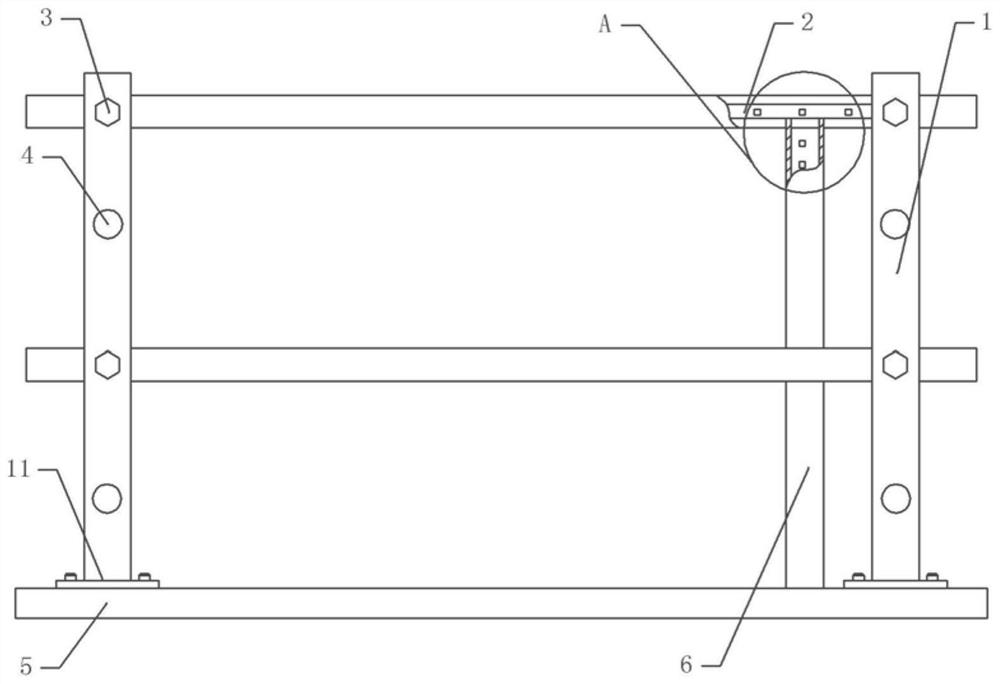

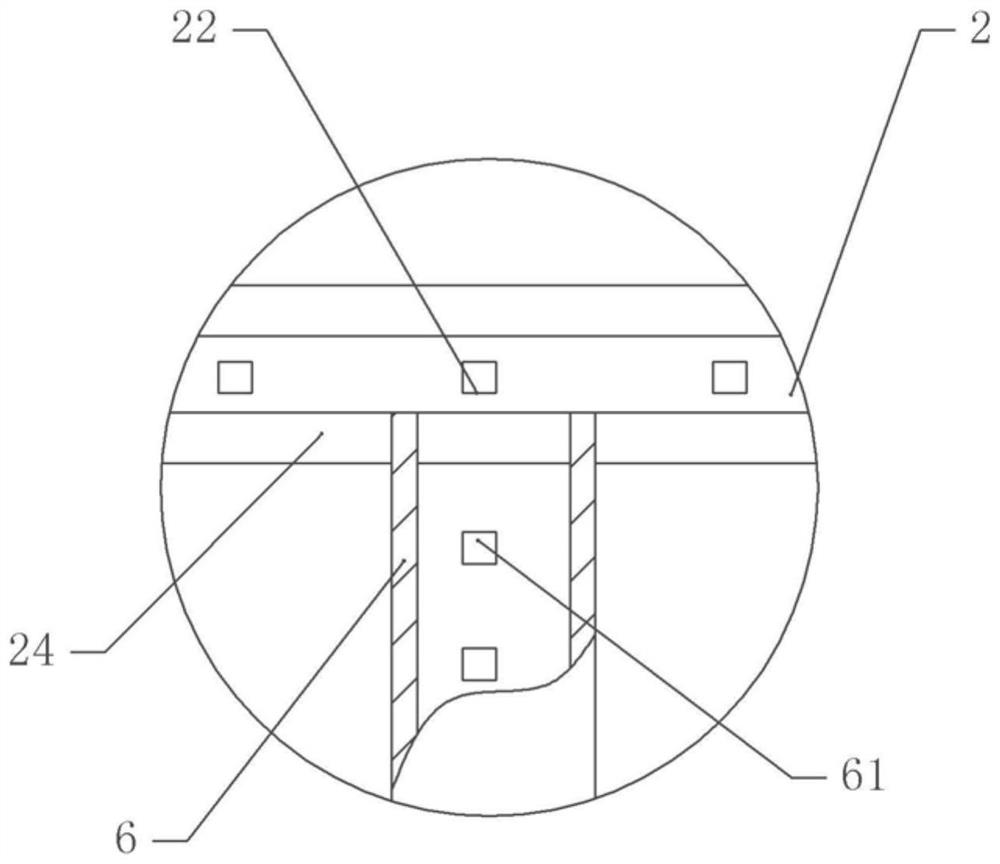

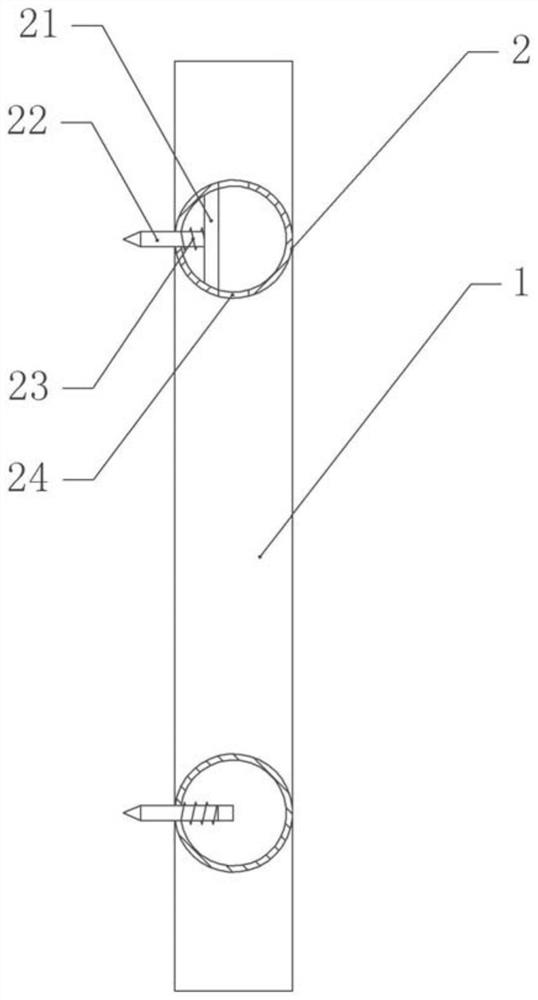

[0035] Reference numerals in the accompanying drawings include: support frame 1, sliding seat 11, horizontal tube 2, positioning plate 21, positioning nail 22, spring 23, sliding groove 24, fastening bolt 3, positioning hole 4, mounting seat 5, Standpipe 6 , punching nail 61 , return spring 62 .

[0036] A construction method for pre-embedding a wall pipe, comprising the following steps:

[0037] S1: Prepare as attached figure 1 and attached figure 2 The mounting seat 5 is shown, the length of the mounting seat 5 is equal to the length of the wall, and the mounting seat 5 is abutted against the wall.

[0038] S2: Install at least two support frames 1 on the mounting seat 5, and the bottom of the specific support frame 1 is welded with a sliding seat 11, the bottom of the sliding seat 11 is provided with a slider, and the mounting seat 5 is provided with a horizontal sliding connection with the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com