Quick-plug connector connecting structure

A connection structure and plug-in joint technology, which is applied in the direction of hose connection devices, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of weak lateral force resistance of connecting parts, disengagement of connecting parts, and low connection strength, etc., to achieve Strong fixing strength, not easy to detach, reduce the effect of detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

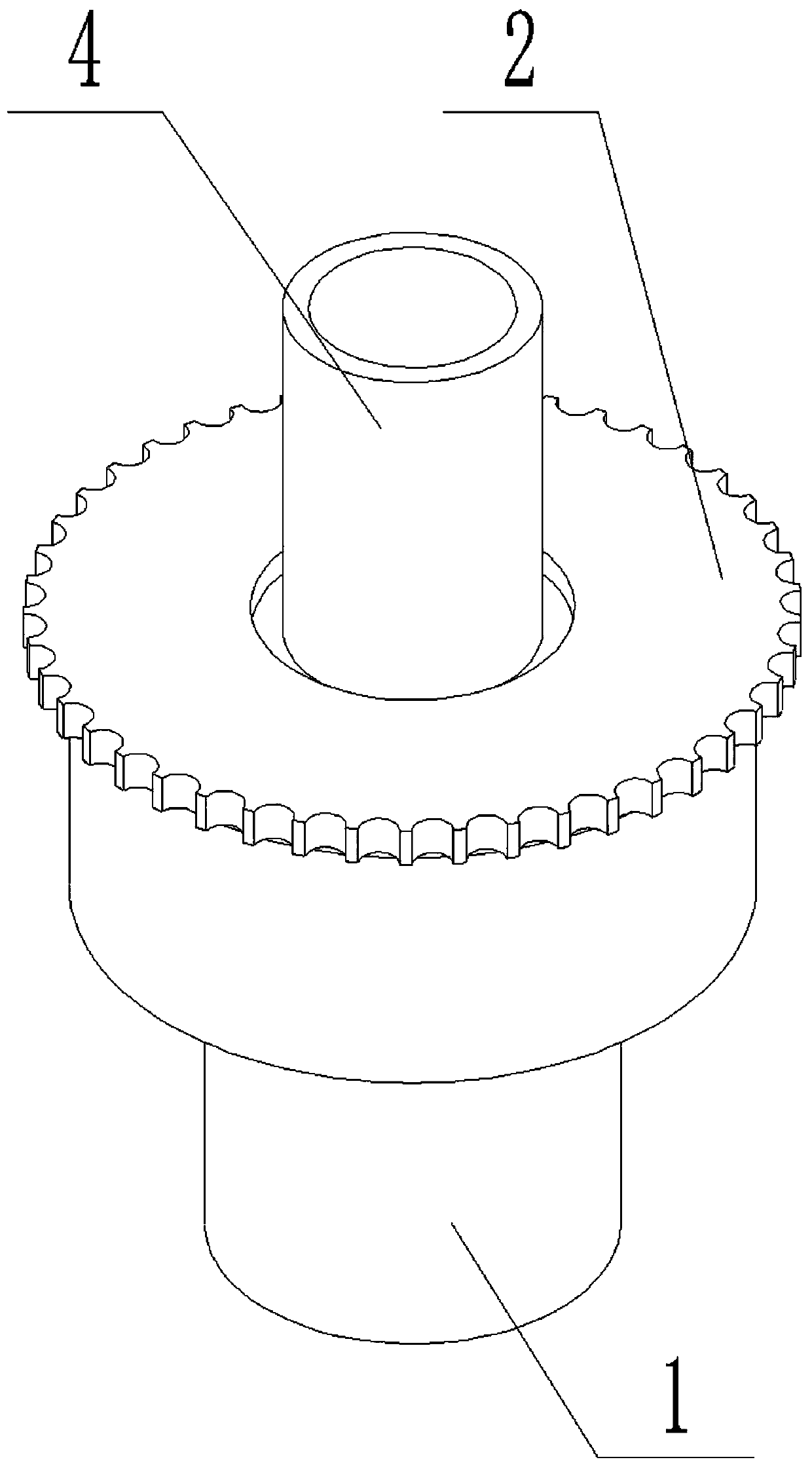

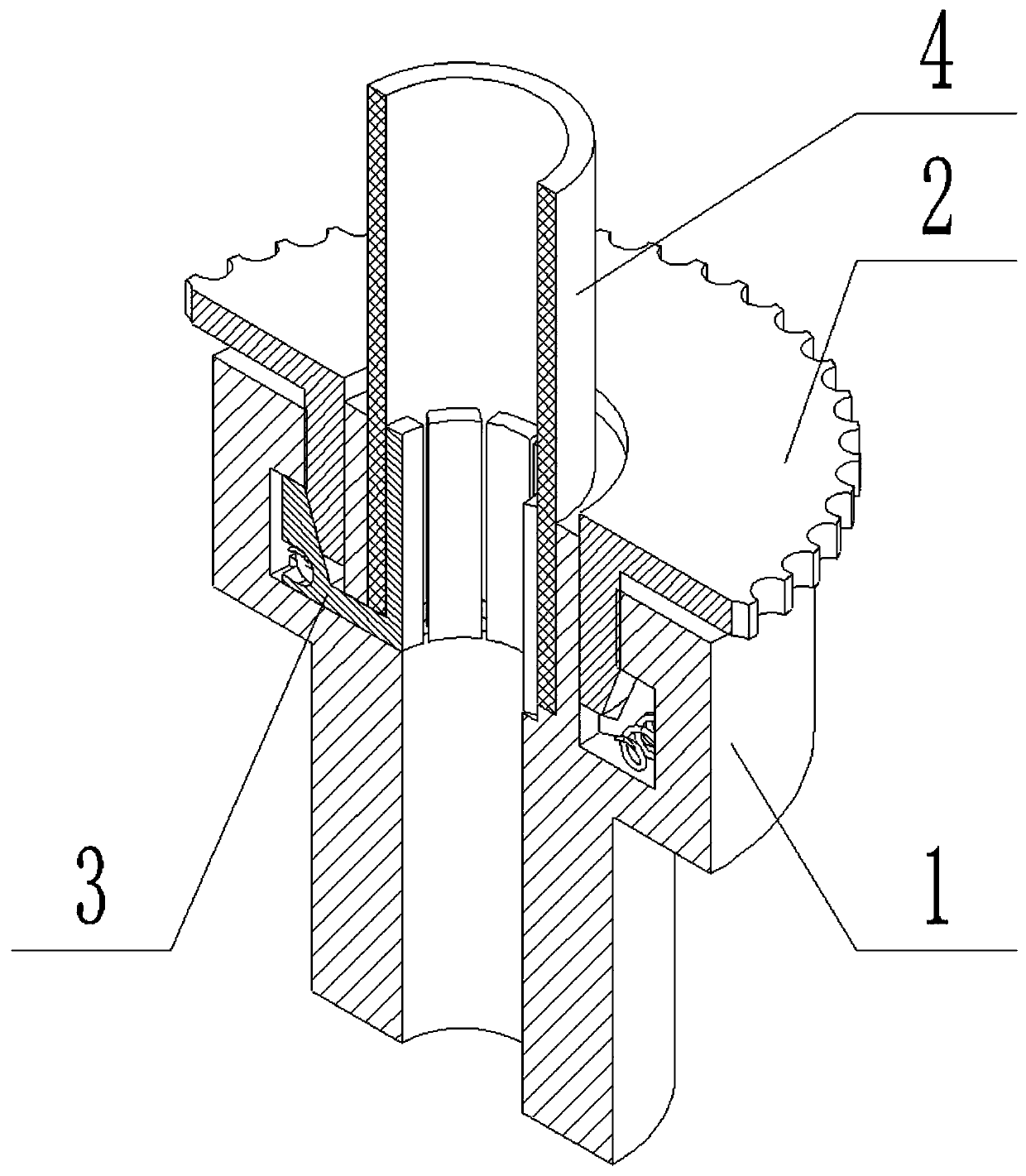

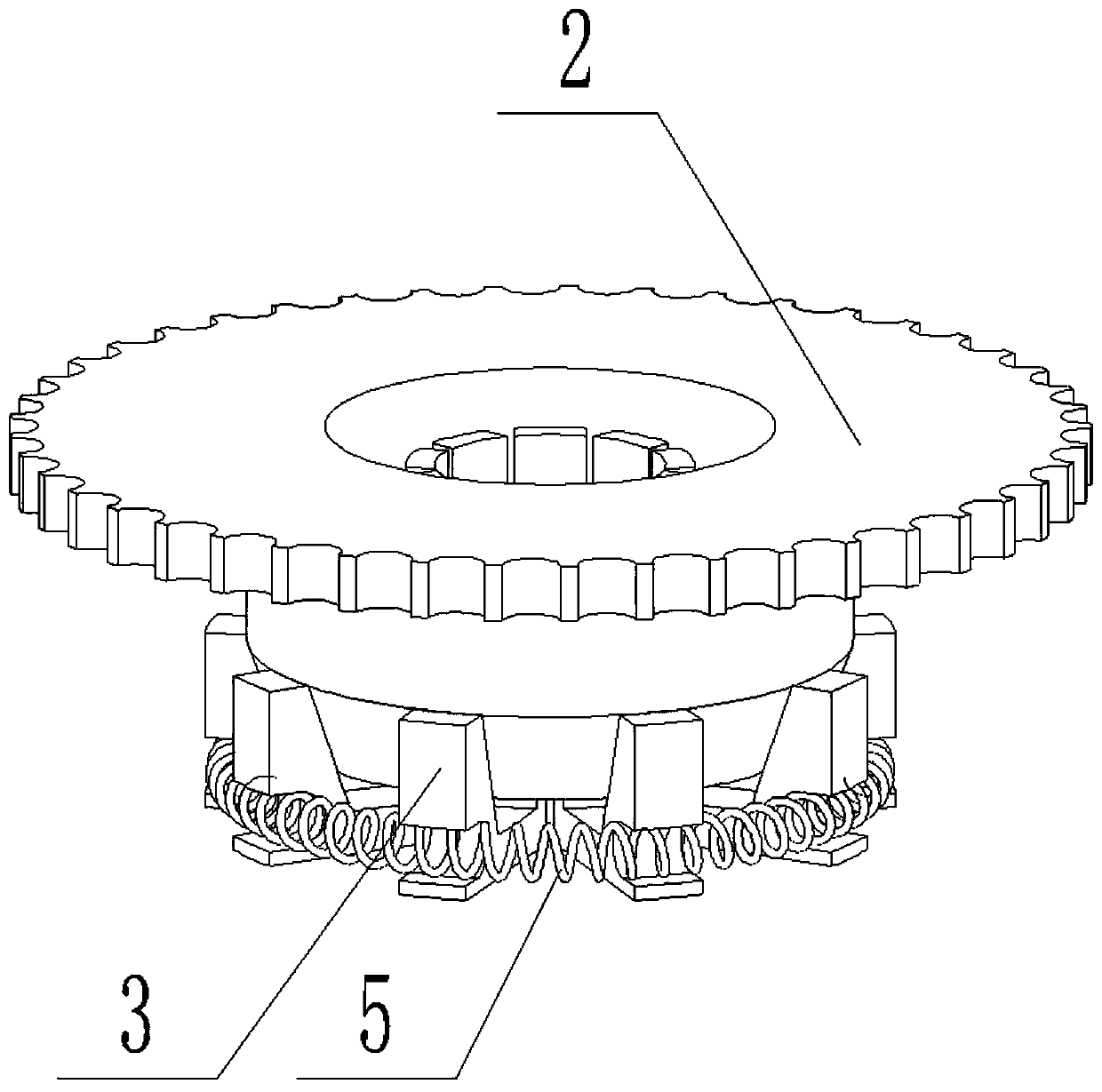

[0028] as attached figure 1 to attach Figure 7 Shown:

[0029] The present invention provides a connection structure of a quick-plug joint, including a mounting head 1, an outer baffle 101, a sliding groove 102, a knob 2, a driving cone 201, an anti-skid groove 202, a pressing plate 3, a driven cone 301, and a spring groove 302. Compression anti-slip lines 303, nylon tube 4 and ring spring 5; multiple sets of pressing plates 3 are slidingly connected inside the installation head 1; a group of ring springs are elastically compressed on the outside of the ring spring 5 5; a set of nylon tubes 4 is tightly connected between the pressing plate 3 and the installation head 1 ; a set of the knobs 2 is threadedly connected to the top of the installation head 1 .

[0030] Wherein, the inner bottom of the installation head 1 is provided with a plurality of sets of sliding grooves 102, and the pressing plate 3 is slidably connected in the sliding grooves 102, and is realized by slidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com