Friction experiment device, bearing mechanism and loading mechanism thereof, and friction experiment method

A technology of an experimental device and a bearing mechanism, applied in the field of friction experiments, can solve the problem of inconvenient loading of two forces at the same time, and achieve the effect of convenient secondary loading and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0050] The present application provides a friction experiment device for obtaining the friction coefficient of the material friction interface 50, which can solve the problem of inconvenient loading of normal pressure and tangential force at the same time in the prior art.

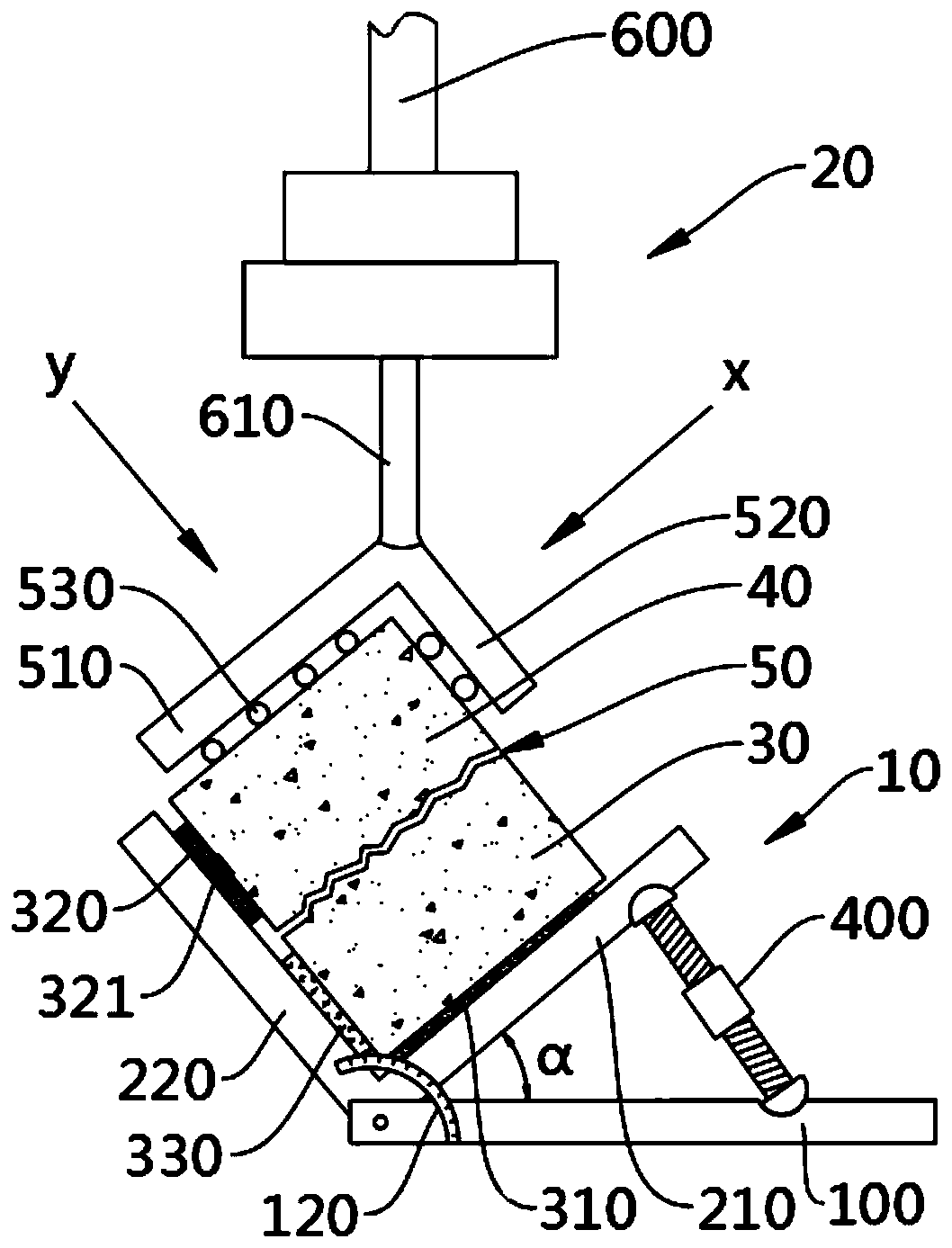

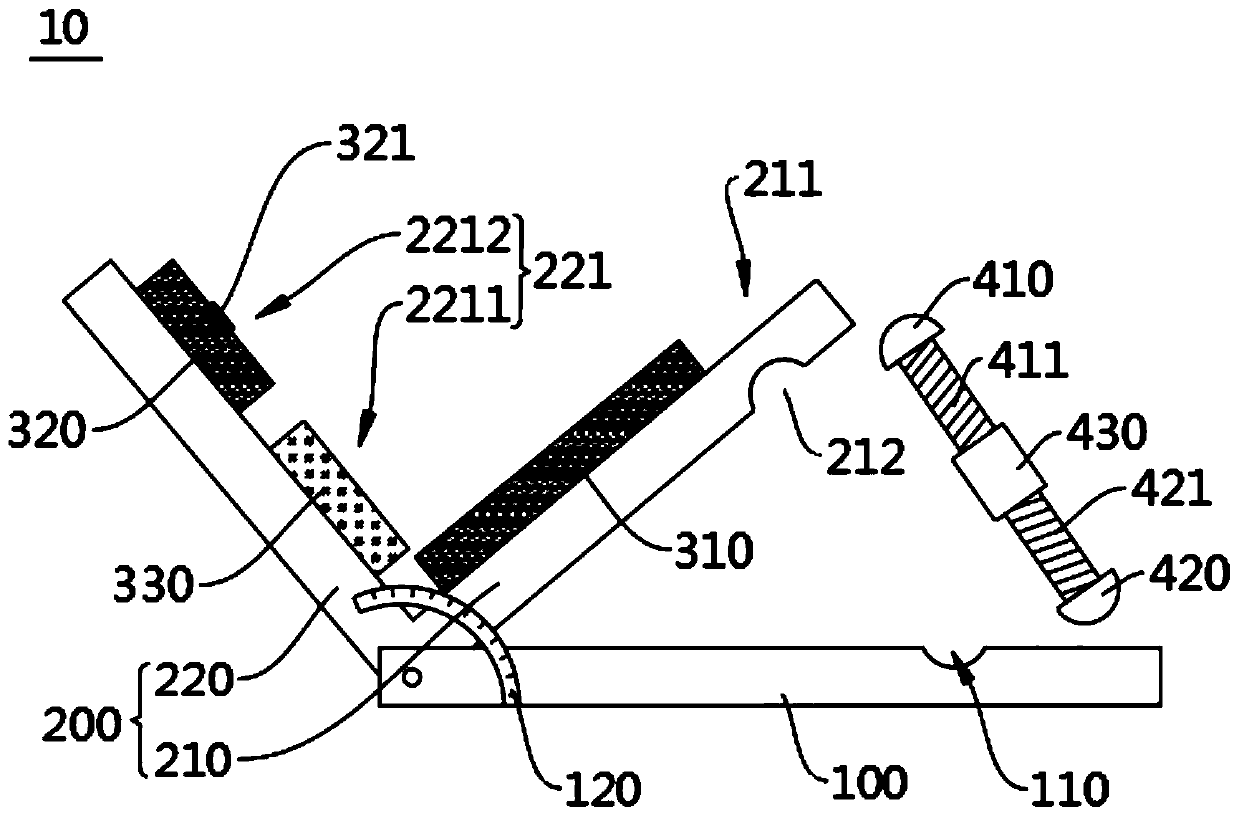

[0051] The experimental device includes a carrying mechanism 10 and a loading mechanism 20. The test piece includes a test piece group composed of a first test piece 30 and a second test piece 40. The test piece is placed on the carrying mechanism 10 and is located between the carrying mechanism 10 and the loading mechanism 20. between, such as figure 1 shown in .

[0052] figure 1 Also shows the rectangular coordinate direction of the plane where the tangential force and the normal pressure are located, wherein the X direction is the direction where the tangential force is located, and the Y direction is the direction where the normal pressure is located. In this embodiment, the first test piece 30 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com