Topological information guided acquisition method for internal geometric data of three-dimensional lattice structural members

A three-dimensional lattice and topology information technology, applied in image data processing, measuring devices, instruments, etc., can solve the problems of poor stability, inability to measure three-dimensional lattice structures, and low measurement efficiency, and achieve stable measurement and improved measurement efficiency. , the effect of reducing the angle error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

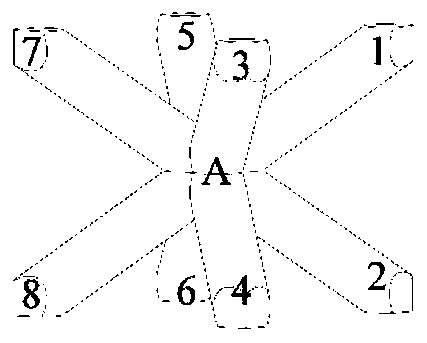

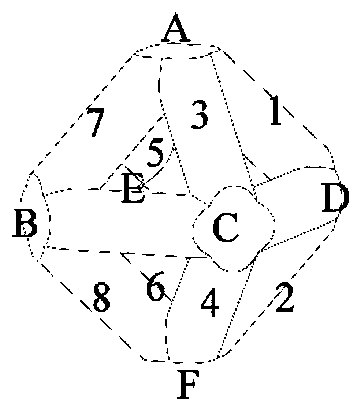

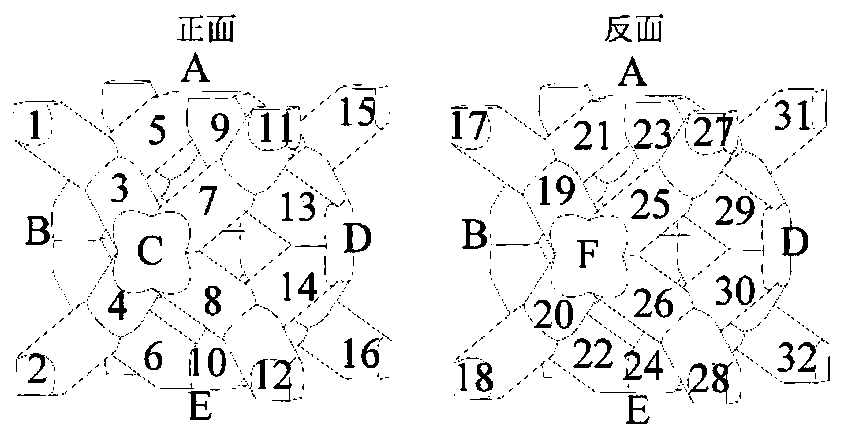

[0028] The three-dimensional lattice structural parts are mostly made by 3D printers, including several topological three-dimensional lattice units, and the three-dimensional lattice units are composed of nodes and rods. The three-dimensional lattice unit can have various topological structures, and the target object of this embodiment is a three-dimensional lattice unit with a centrosymmetric topological structure. Figure 1-3 Shown are three typical 3D lattice elements with centrosymmetric topological structure, and the topological structure differences of different 3D lattice elements can be attributed to the nodes ( Figure 1-3 Indicated by letters) and members ( Figure 1-3 represented by numbers in ) differ in the number and spatial location.

[0029] This embodiment takes figure 1 The three-dimensional lattice structural part of the topological structure of the three-dimensional lattice unit shown in is taken as an example. The three-dimensional lattice structural par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com