Fuel atomizer and method for atomizing fuel

A technology for atomizing and atomizing fuel, which is applied in the field of atomizers and can solve problems such as mixing of fuel and air that hinder atomization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

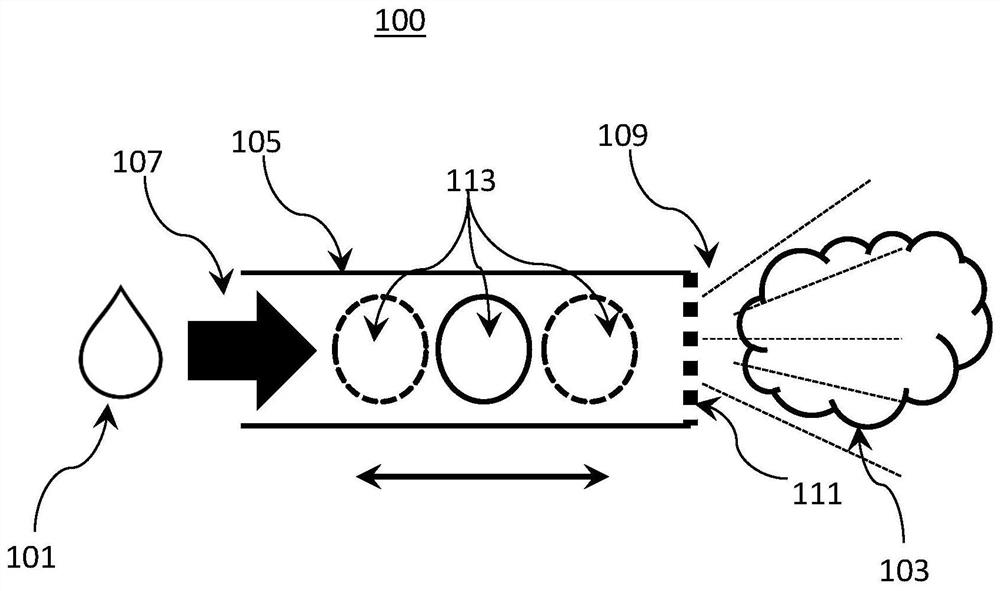

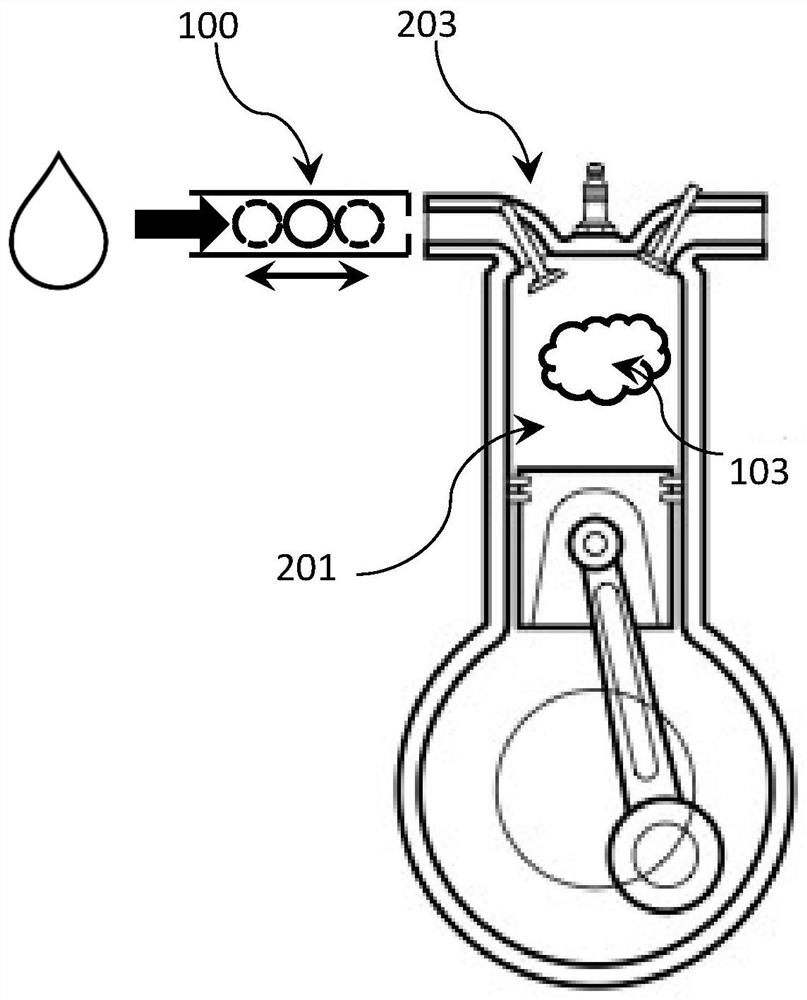

[0048] figure 1 A simplified side cross-sectional view of an embodiment of the present invention, which is a fuel atomizer 100 that converts liquefied fuel 101 into a fuel mist 103 . The fuel can be gasoline, petroleum, or any fuel fluid sufficient to be atomized into an atomized form.

[0049] The atomizer 100 includes a conduit 105 for the passage of the fuel 101 . The outlet 109 of the duct 105 is connected to the combustion chamber of the engine, and the fuel 101 flows from the inlet 107 of the duct 105 to the outlet 109 of the duct 105 due to the suction generated by the combustion chamber. The outlet 109 of the conduit 105 is provided with a nozzle 111 that includes a small hole that causes the fuel 101 exiting the conduit 105 to be dispersed in a pressurized spray, effectively physically breaking the fuel 101 into a fine mist of fuel droplets 103. When the fuel 101 is present in the form of the mist 103, the surface area in contact with the air is increased. Therefo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com