Electric push rod

An electric push rod and screw technology, which is applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of disappearance, reduced life of electric push rods, loss of lubrication and cooling effects, etc., to ensure service life and not easy to consume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

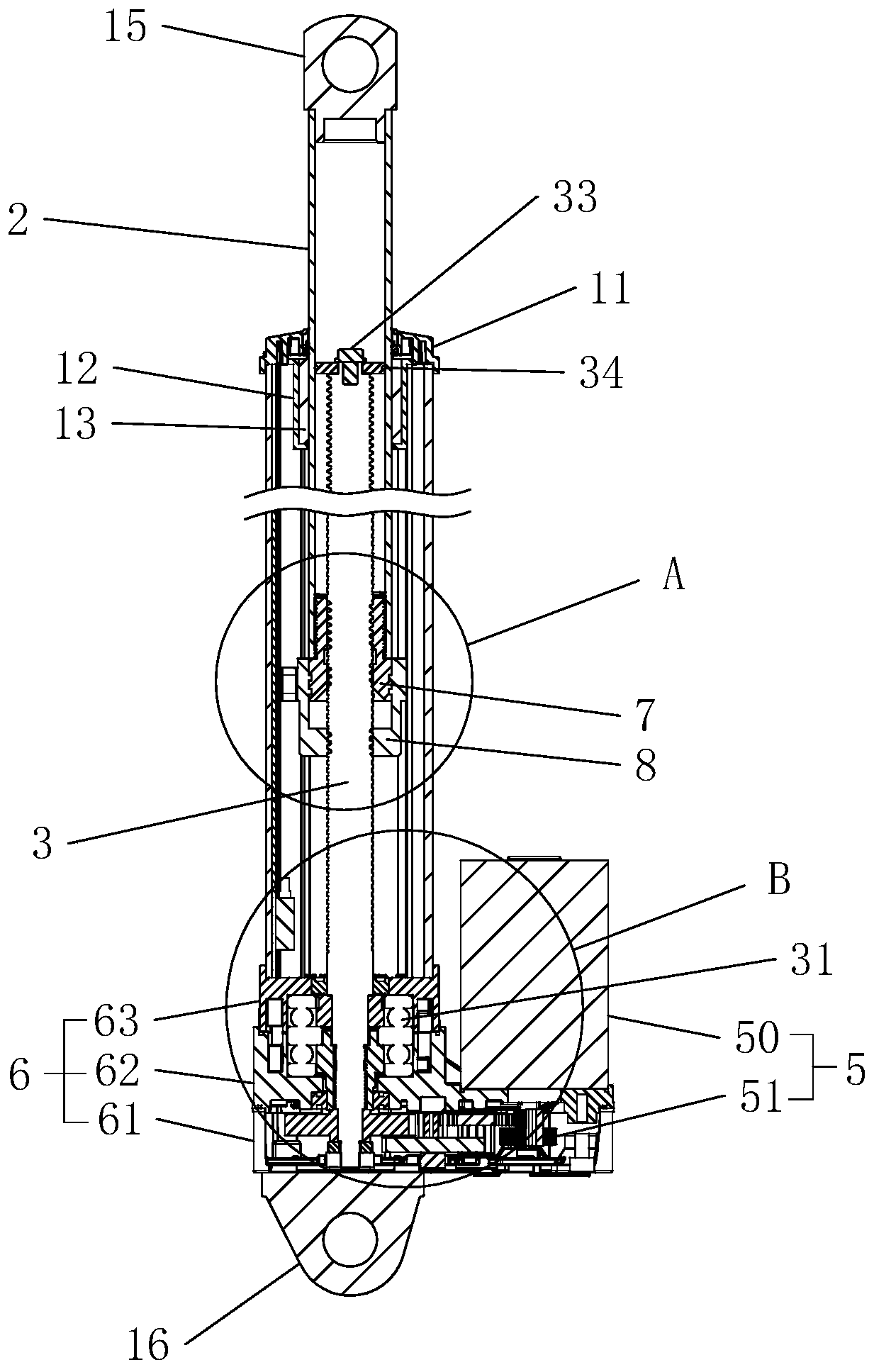

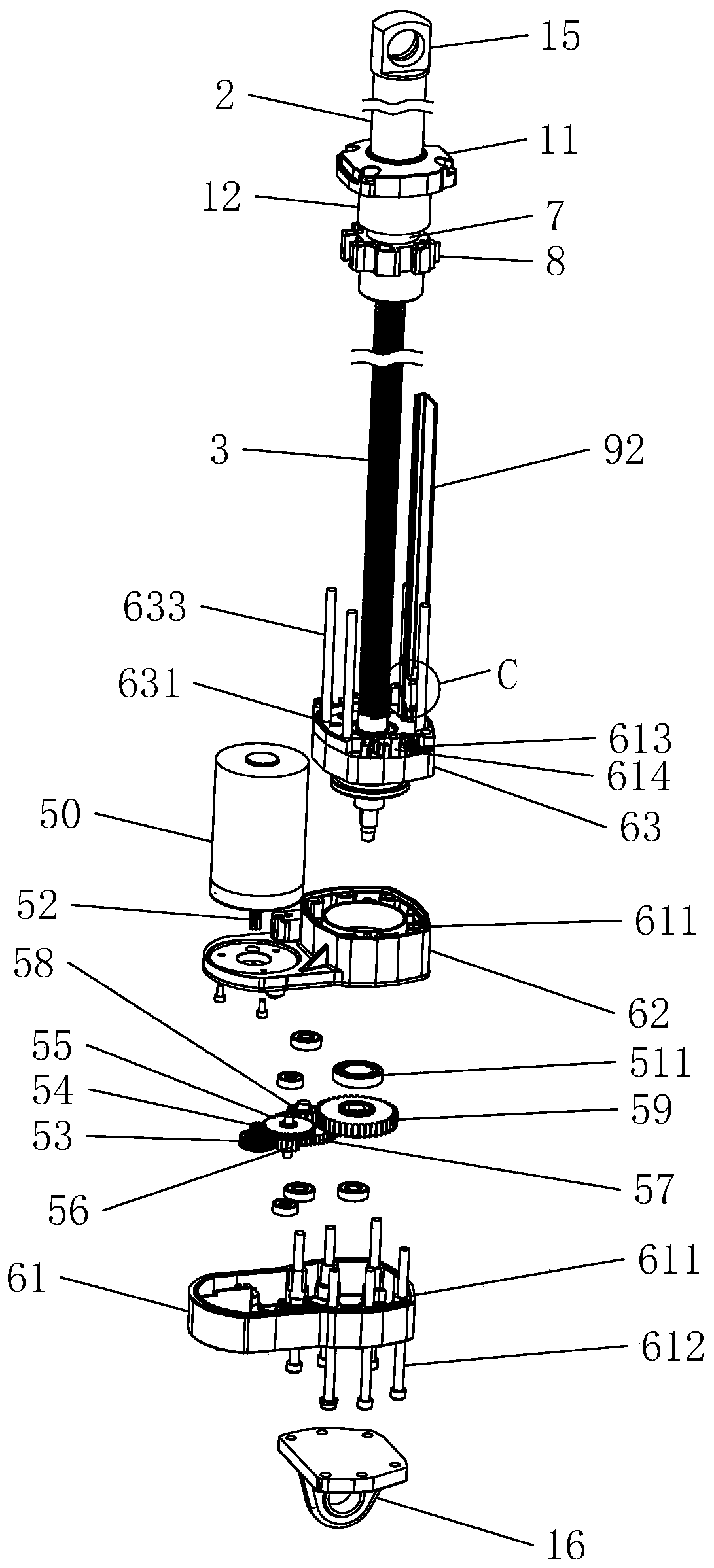

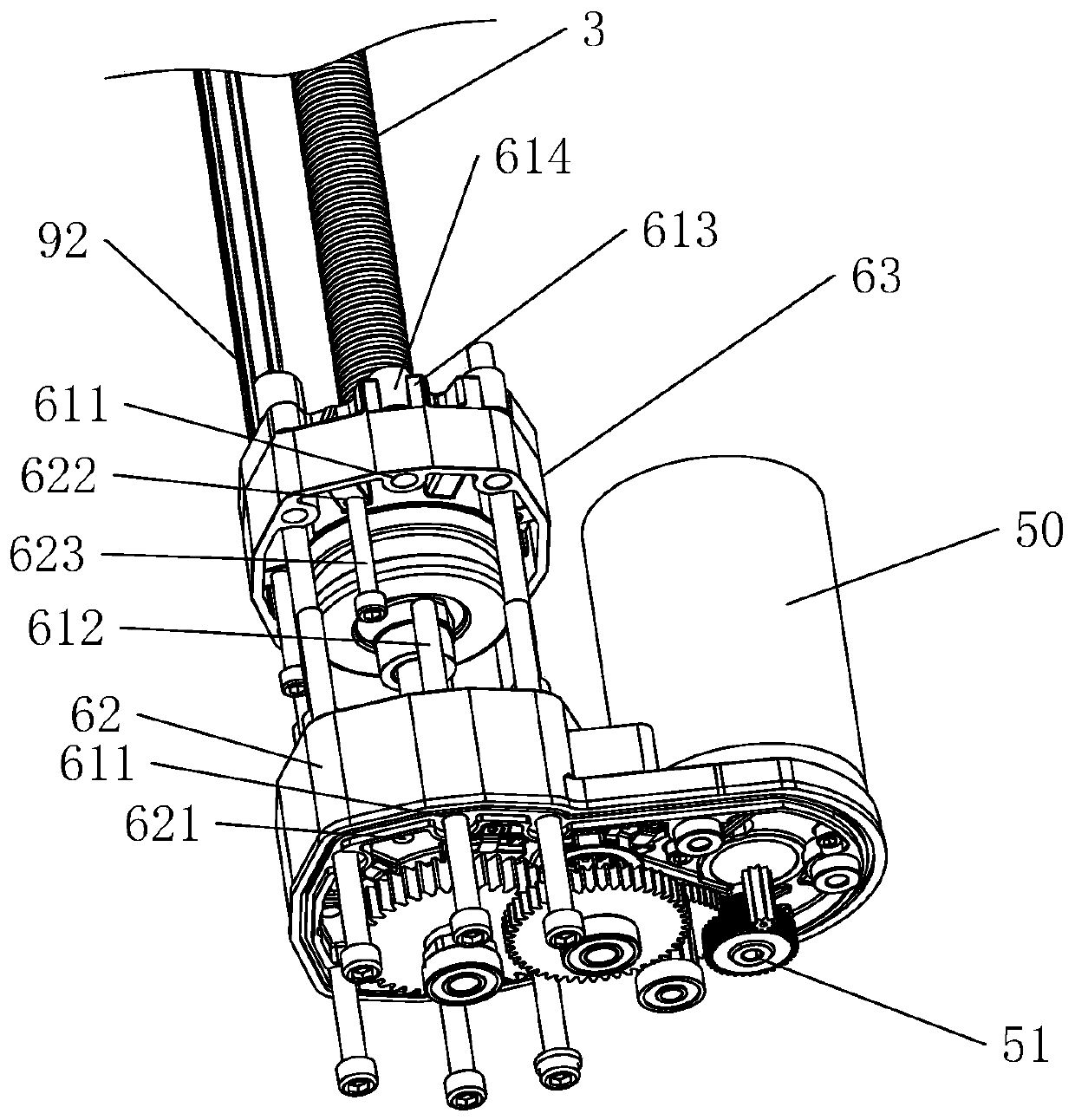

[0041] An electric push rod, such as figure 1 As shown, it includes a base 6, an outer tube 1, an inner tube 2, a screw rod 3, a nut 4, a driver 5 and an end cover 11. The base 6 includes an upper cover 62, a lower cover 61, and a special-shaped tube seat 63. One end of the outer tube 1 is connected to On the special-shaped pipe seat 63, the other end is fixedly connected with the end cap 11, and the end cap 11 is provided with an end cap hole for the inner tube 2 to pass through.

[0042] The end face of the end cover 11 facing the nut 4 is provided with a guide sleeve 12, the inner wall of the guide sleeve 12 is provided with a wear-resistant sleeve 13, the wear-resistant sleeve 13 is sleeved outside the inner tube 2 and fits with the outer wall of the inner tube 2, the wear-resistant sleeve 13 The material is POM plastic.

[0043] Such as figure 1 and figure 2 As shown, the end face of the lower cover 61 facing away from the upper cover 62 is fixedly connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com