Lever loading type friction wear tester for controllable magnetic field environment

A technology of friction and wear test and lever, which is applied in the testing of mechanical components, testing of machine/structural components, testing of wear resistance, etc., to achieve the effect of improving loading stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

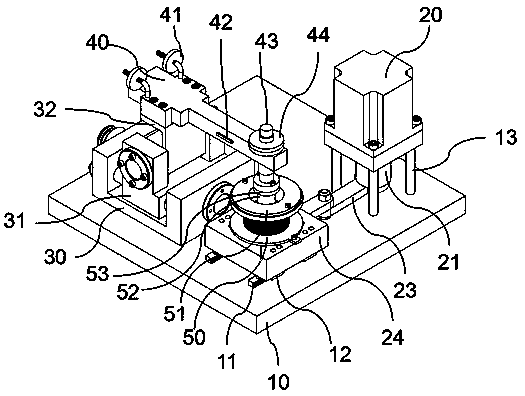

[0023] to combine Figure 1 to Figure 5 , the present invention is further described:

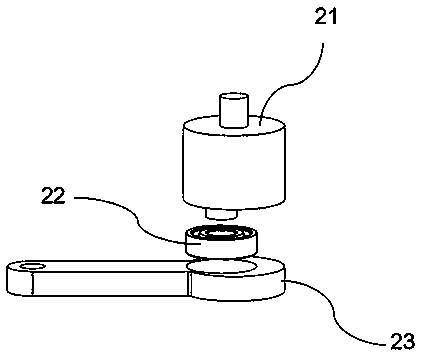

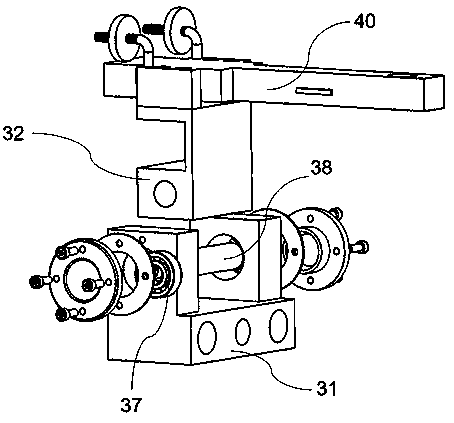

[0024] A lever-loaded friction and wear testing machine with a controllable magnetic field environment, including a magnetic field device 50, a lower sample 56 is arranged in the magnetic field device 50, and a driving mechanism drives the magnetic field device 50 to reciprocate in the horizontal direction, and the lower sample A loading rod 43 is arranged above the piece 56, the loading rod 43 is vertical and the lower end is provided with a test steel ball 55, and the test steel ball 55 abuts against the upper surface of the lower sample 56, and the loading rod 43 is arranged on One end of the lever 40, the shaft of the lever 40 is hingedly arranged on the adjustment base 31, the hinge axis of the lever 40 is horizontal and perpendicular to the length direction of the lever 40, and the two ends of the lever 40 are respectively provided with counterweights, so One side of the length direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com