Rock crusher for mine

A crusher and rock technology, applied in cleaning methods and utensils, removing smoke and dust, coil springs, etc., can solve the problems of movement of crushers in the crushing process, and achieve the effects of increasing cleanliness, reducing collisions, and increasing dust pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further elaborated below by means of the accompanying drawings and examples.

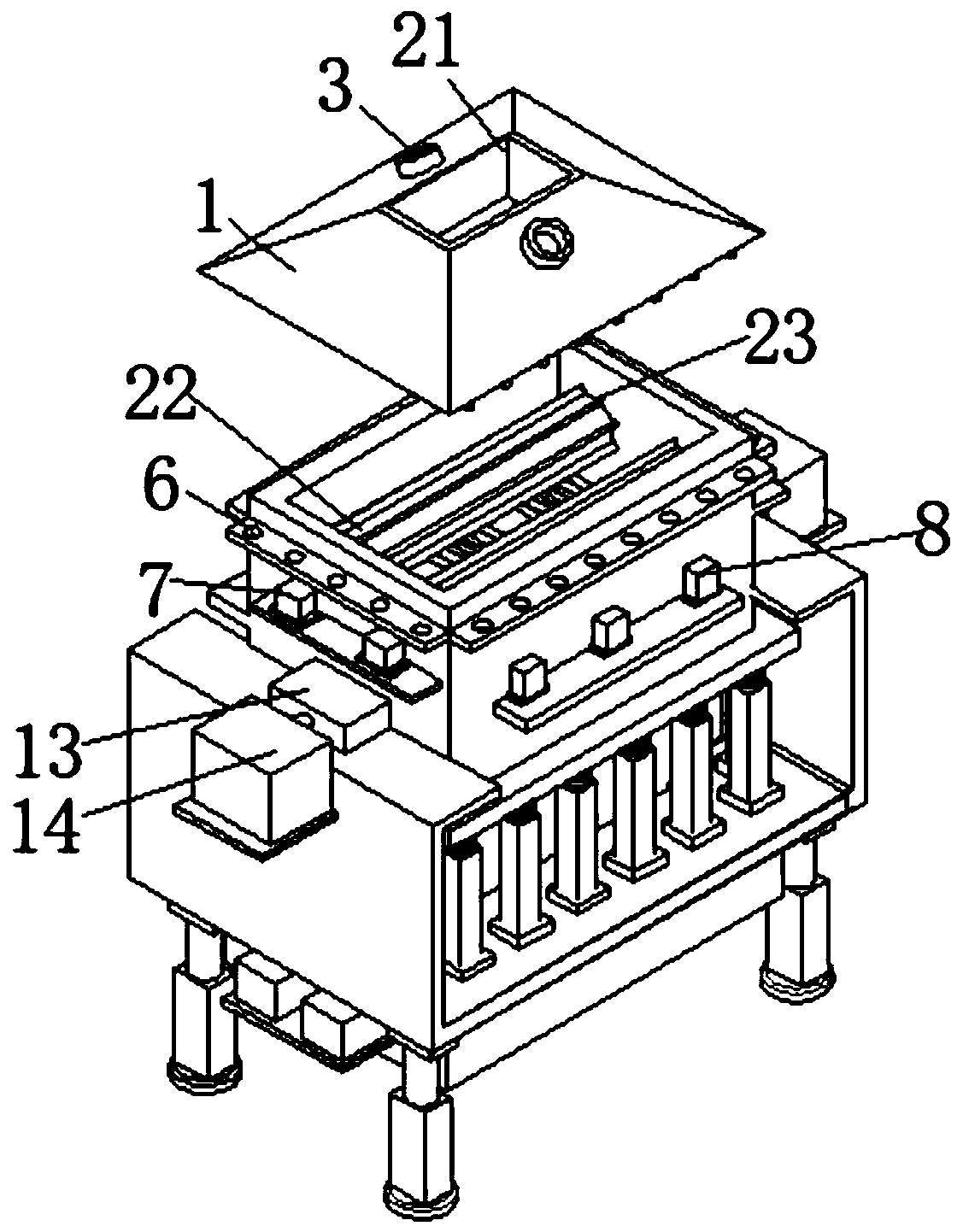

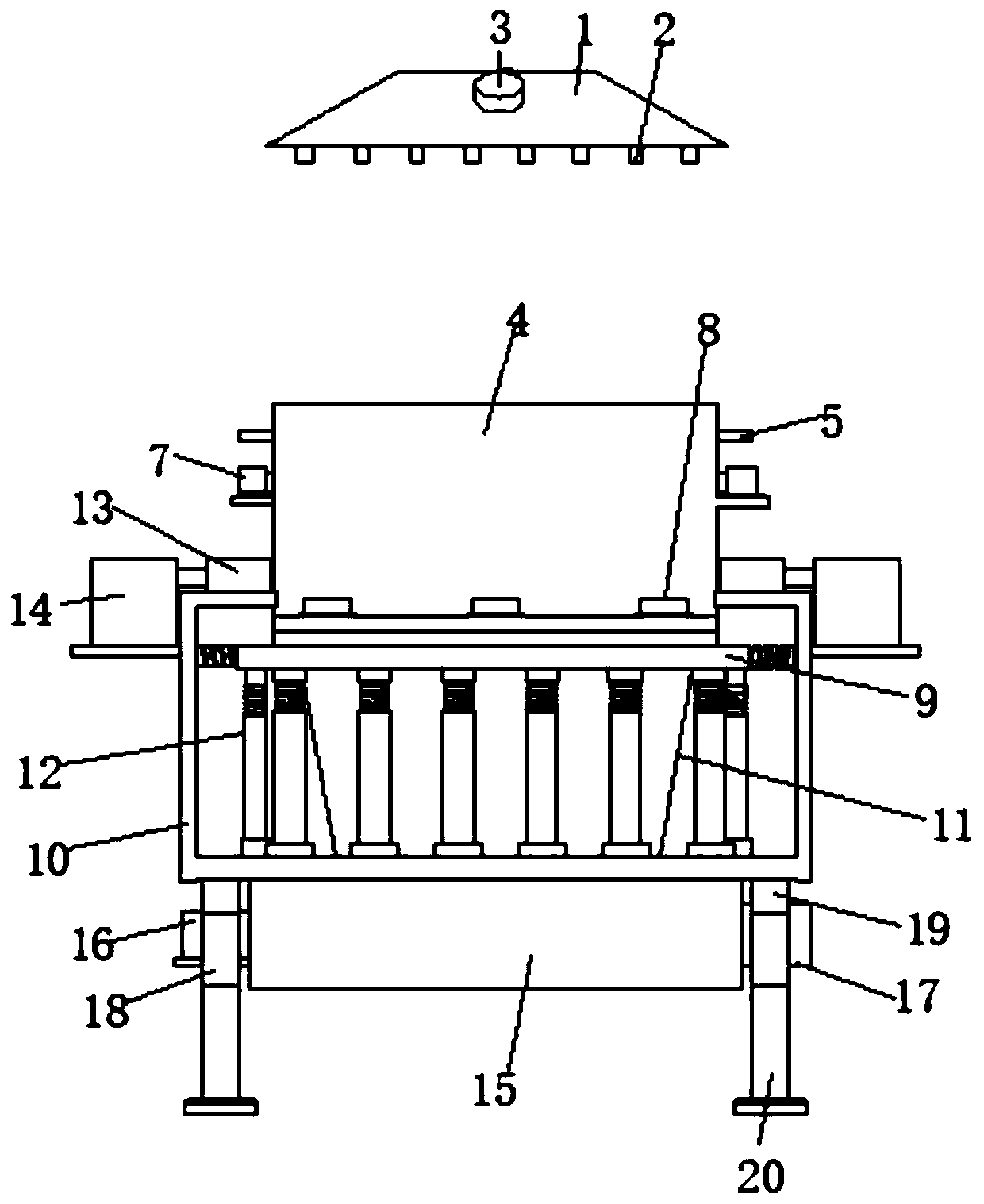

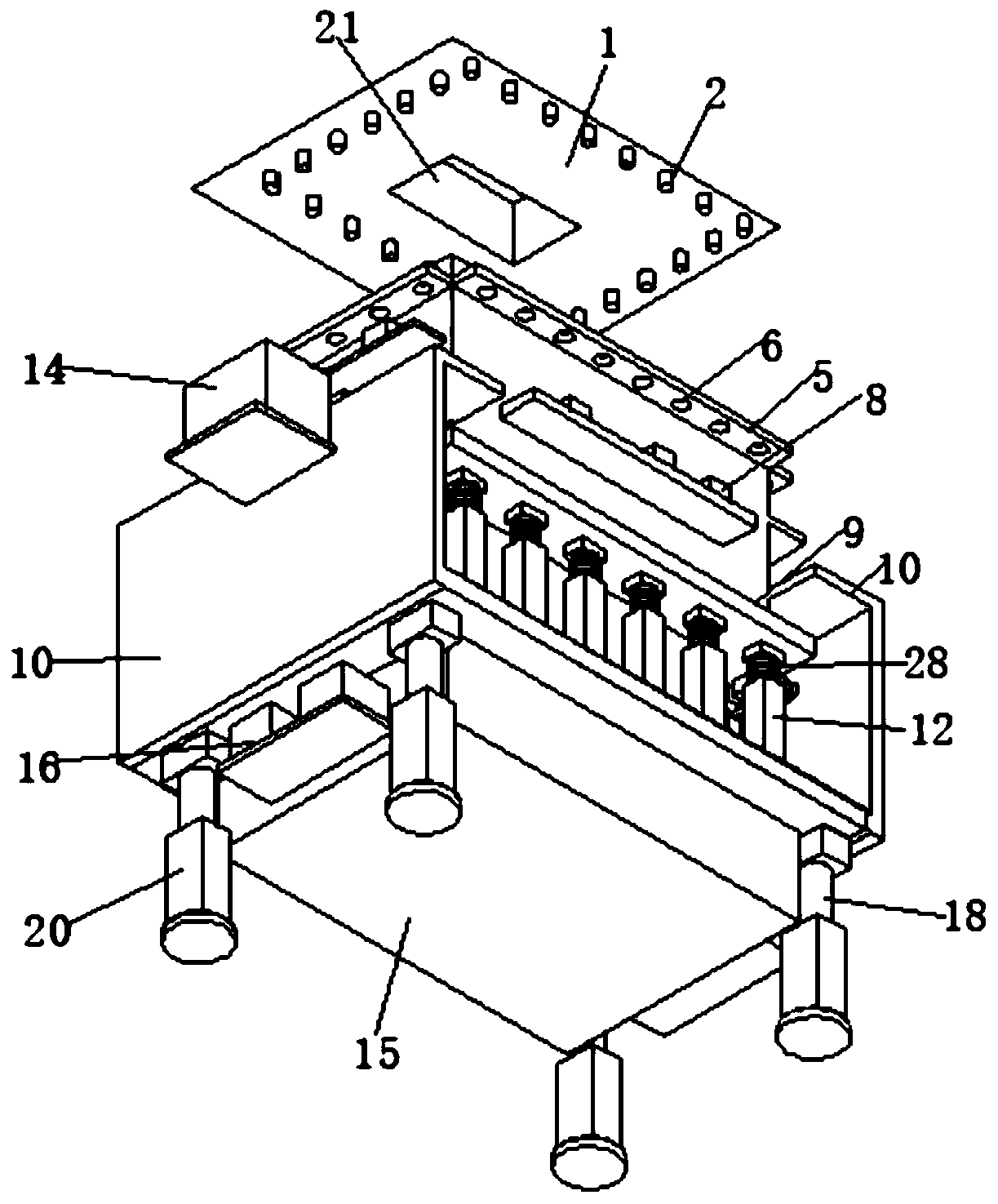

[0029] Embodiments of the present invention provide a rock crusher for mines, such as Figure 1-8 As shown, the upper top cover 1 is included, and the top of the upper top cover 1 is provided with a feed inlet 21, through the feed inlet 21 provided on the upper top cover 1, it is convenient to put the mined rock from 21 into the crushing box 4 for crushing , by setting the top cover 1, it is convenient to reduce the crushed rock rubber jumping out when crushing the rock, reducing the probability and opportunity of jumping out of the rock, reducing the impact of the popped out rock on the surrounding people, and reducing the damage The probability of increasing the protection of the device, the bottom of the upper top cover 1 is provided with a crushing box 4, and the bottom of the crushing box 4 is provided with a shock absorbing plate 9, which facilitates the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com