Aircraft engine insertion mounting device and mounting method

An aircraft engine and installation device technology, which is applied in aircraft assembly, electric vehicles, transportation and packaging, etc., can solve the problems of difficult engine installation, complex structure, and small installation space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

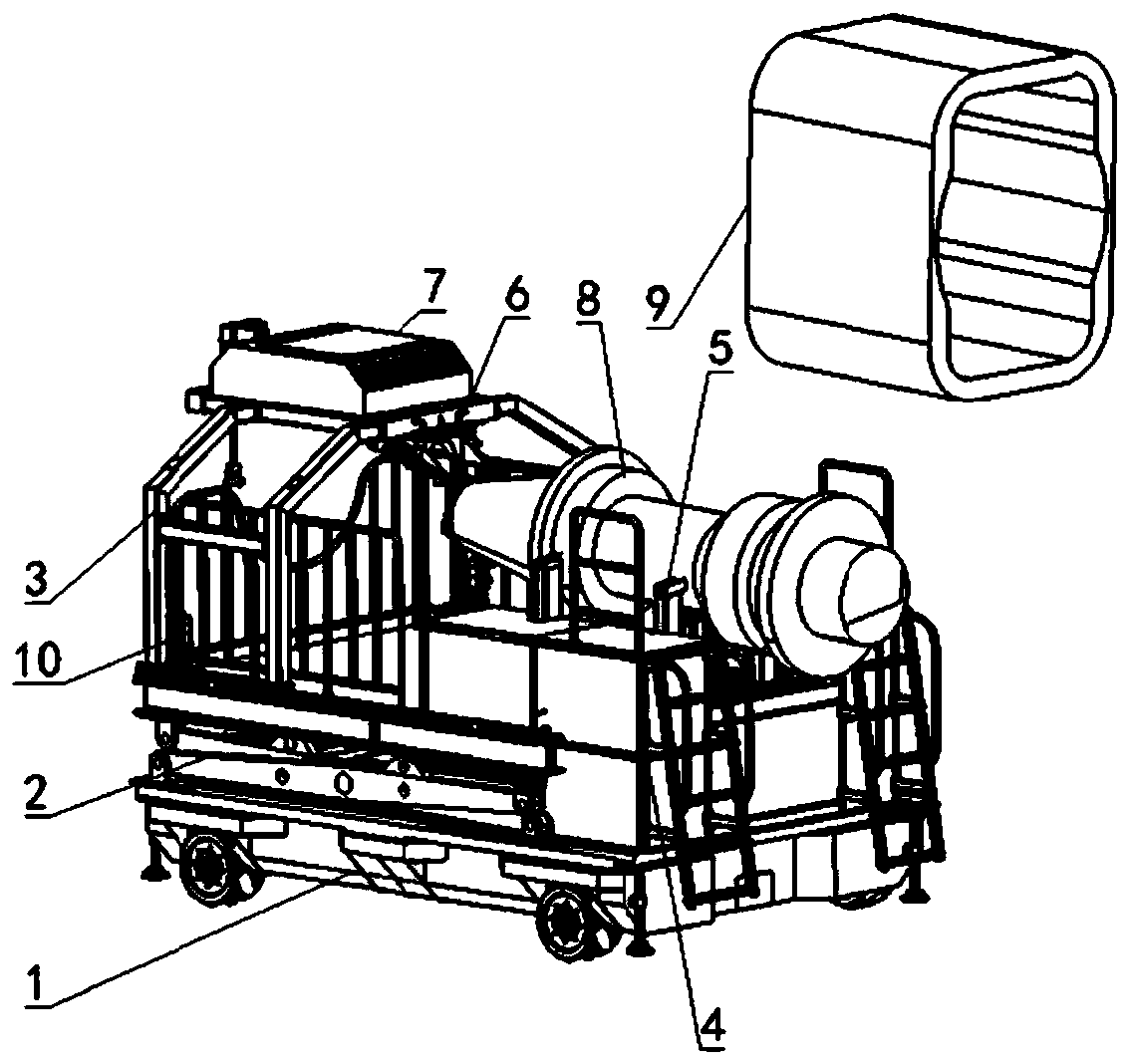

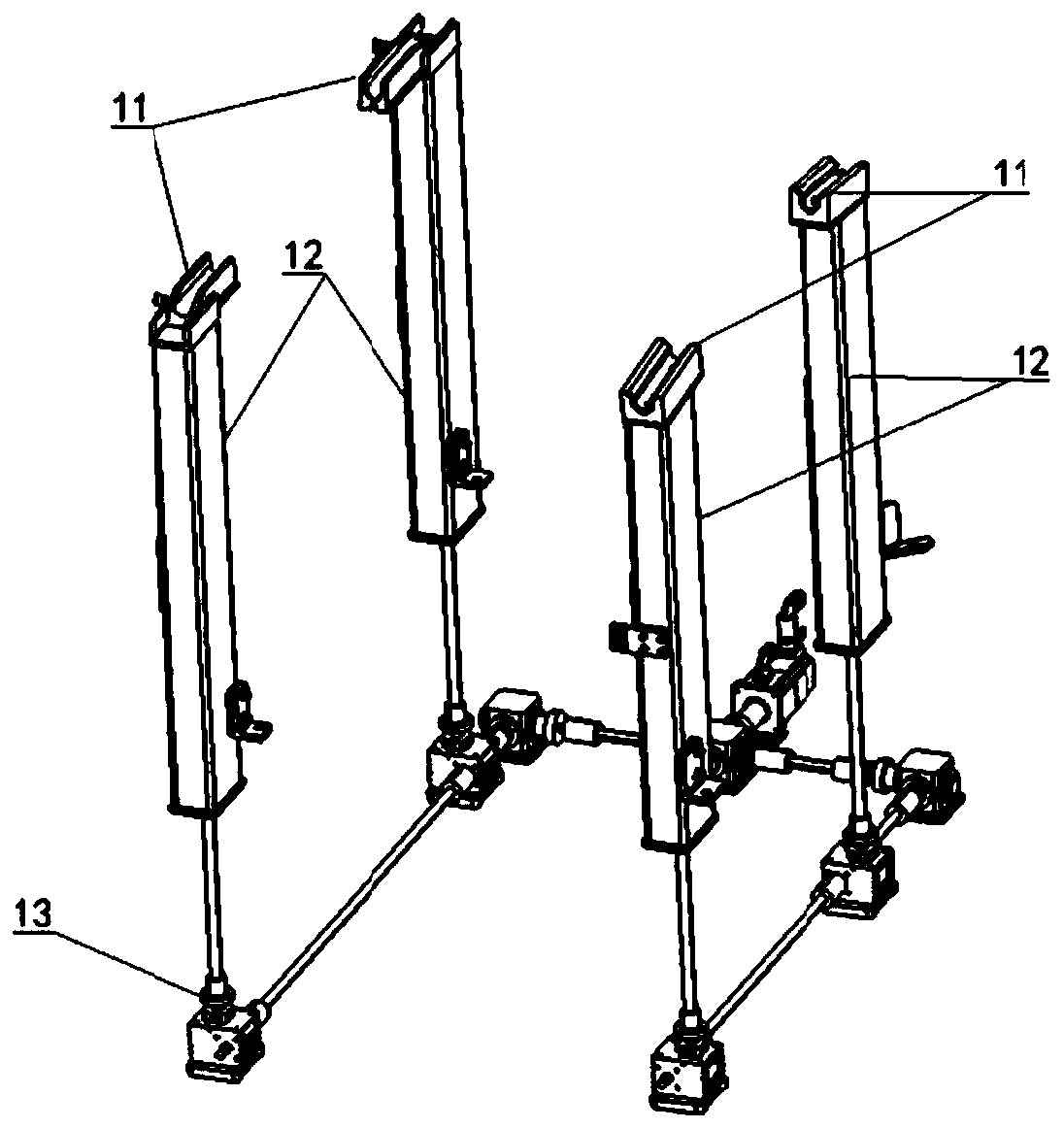

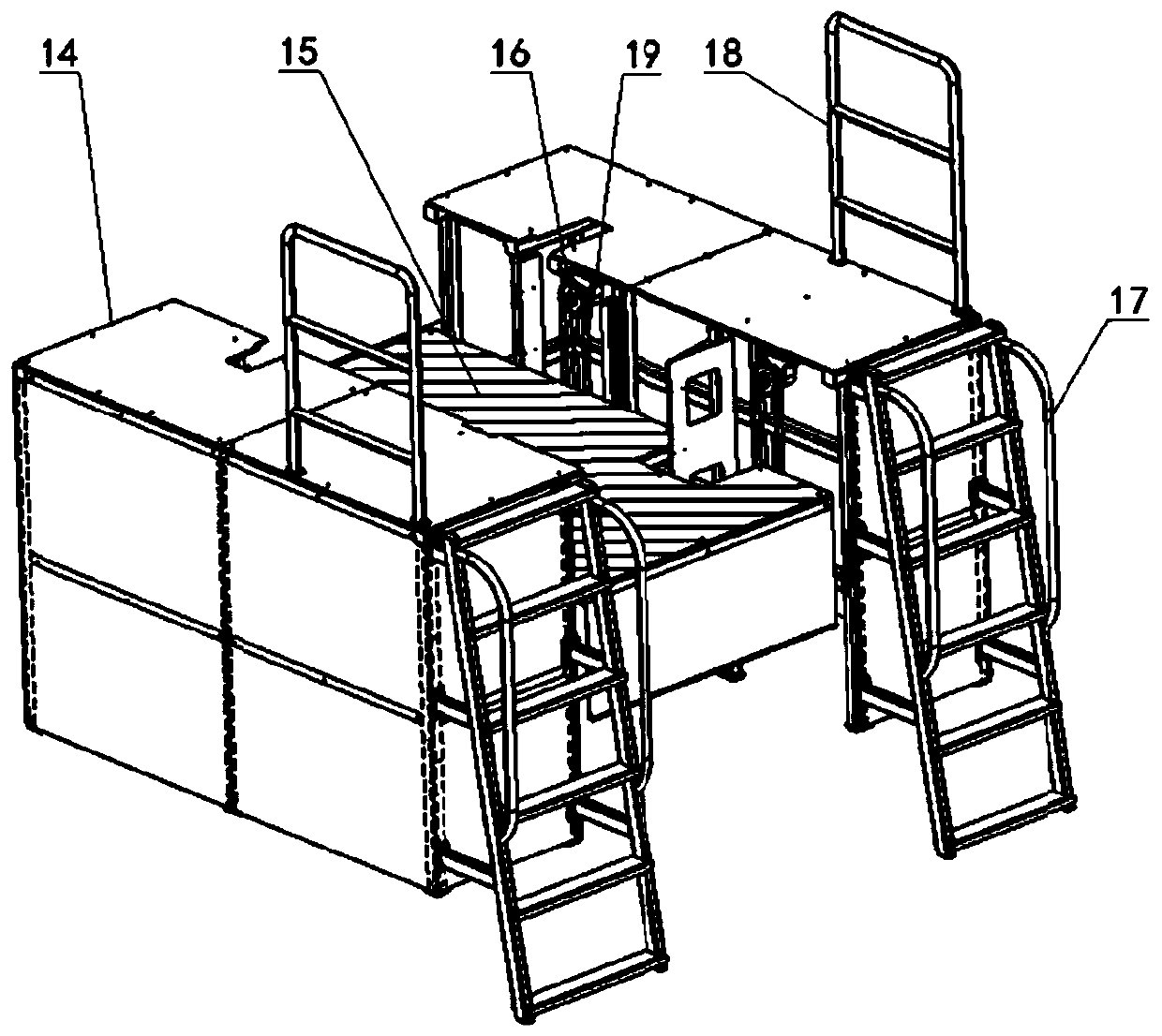

[0023] see figure 1 , 2 , 3, and 4, an aircraft engine plug-in installation device, including an AGV transport vehicle 1, a scissor fork lifting mechanism 2, an engine adjustment mechanism 3, an engine placement frame 5, a working platform 4, a laser positioning lamp 6, and an AGV transport vehicle 1 is located at the bottom of the aircraft engine plug-in installation device, and drives the entire device to move to the designated position. The working platform 4 is placed on the platform of the AGV transport vehicle 1, and the engine placement frame 5 is installed on the AGV transport vehicle 1 and is located in the middle of the working platform 4 , supporting the engine 8; the scissor-fork lifting mechanism 2 is installed on both sides of the AGV transport vehicle 1, the engine adjustment mechanism 3 is installed on the scissor-fork lifting mechanism 2, and can move up and down driven by the scissor-fork lifting mechanism 2; the laser positioning lamp 6 Installed on the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com