Humidifying adsorption lint-removal device for textile fabric

A textile cloth and drying device technology, applied in spray/jet textile material treatment, textile and papermaking, fabric surface trimming, etc., can solve problems such as low hair removal efficiency, mechanical structure interference of trimmer, poor hair removal effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

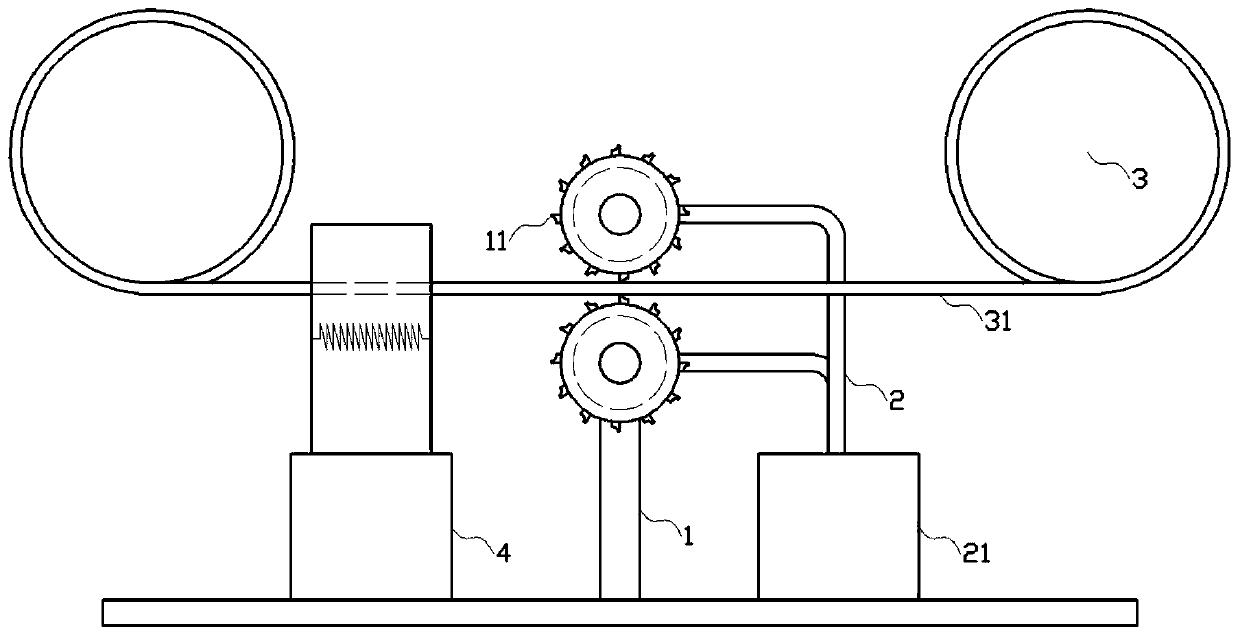

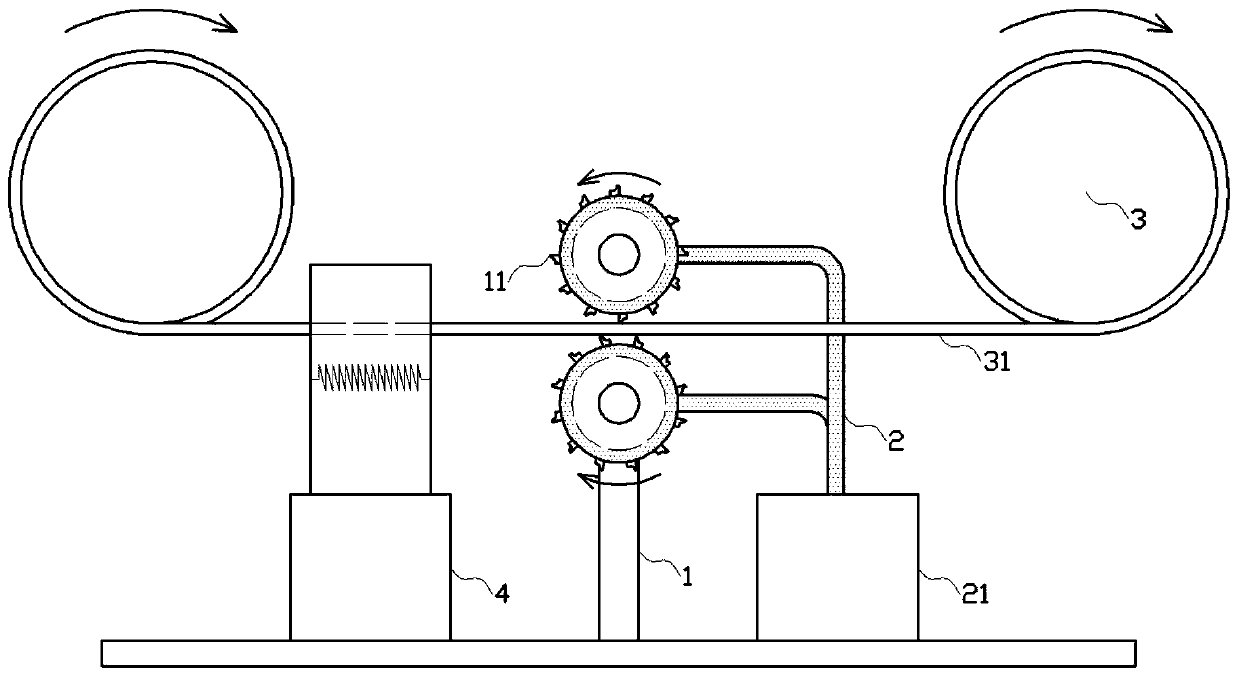

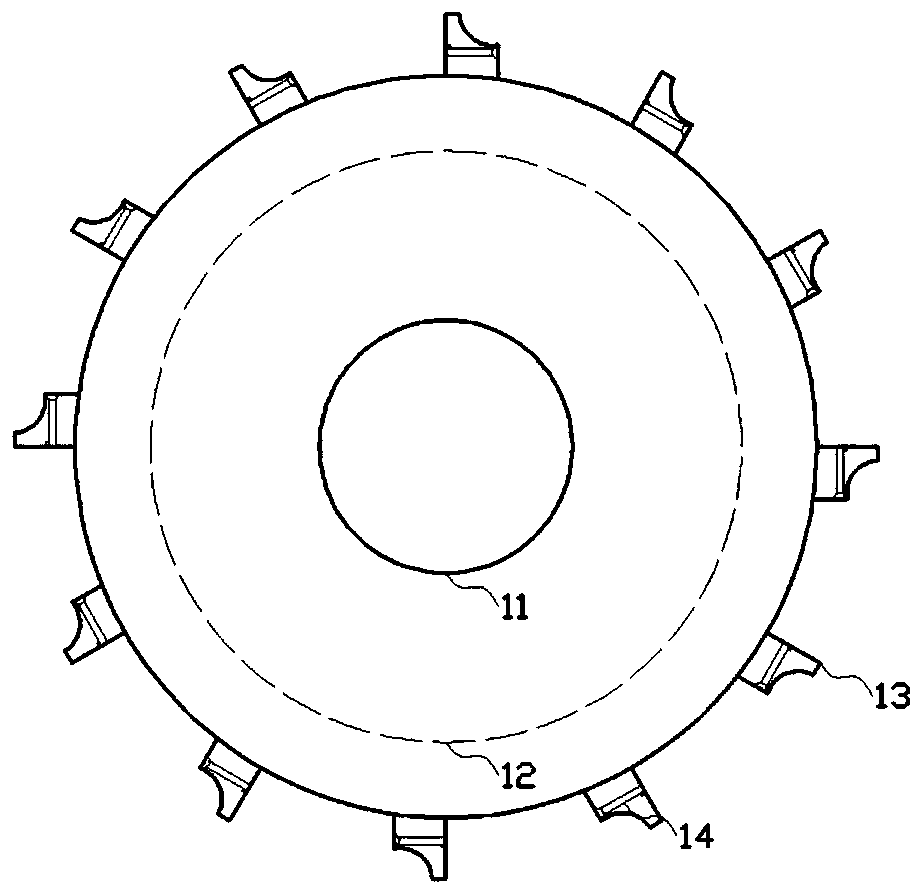

[0013] Such as figure 1 , figure 2 , image 3 As shown in the examples, the textile cloth humidifying and absorbing depilation device is a device that humidifies the surface of the textile cloth so that the thread balls and miscellaneous hairs are adhered once, and then the hair balls are peeled off by the shaving hook to achieve the hair removal effect. At the same time, it can avoid secondary pollution of miscellaneous hairs, and is also a device that is convenient for storing and cleaning miscellaneous hairs. It includes a hair removal module 1, a humidification module 2 and a delivery module 3; the hair removal module 1 includes a rotating roller 11, The rotating roller 11 includes two sets of symmetrical rollers, the upper and lower sets of rollers, the rotating rollers 11 are assembled on the same fixed bracket in rotation, and a gap is provided between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com