Composite foundation improving bearing capacity of barrel-shaped foundation through auxiliary pile and construction method thereof

A technology of cylindrical foundation and composite foundation, which is applied in basic structure engineering, construction, etc., can solve problems such as fan overturning, achieve the effect of improving composite bearing capacity, good pull-out bearing capacity, and improved bearing mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

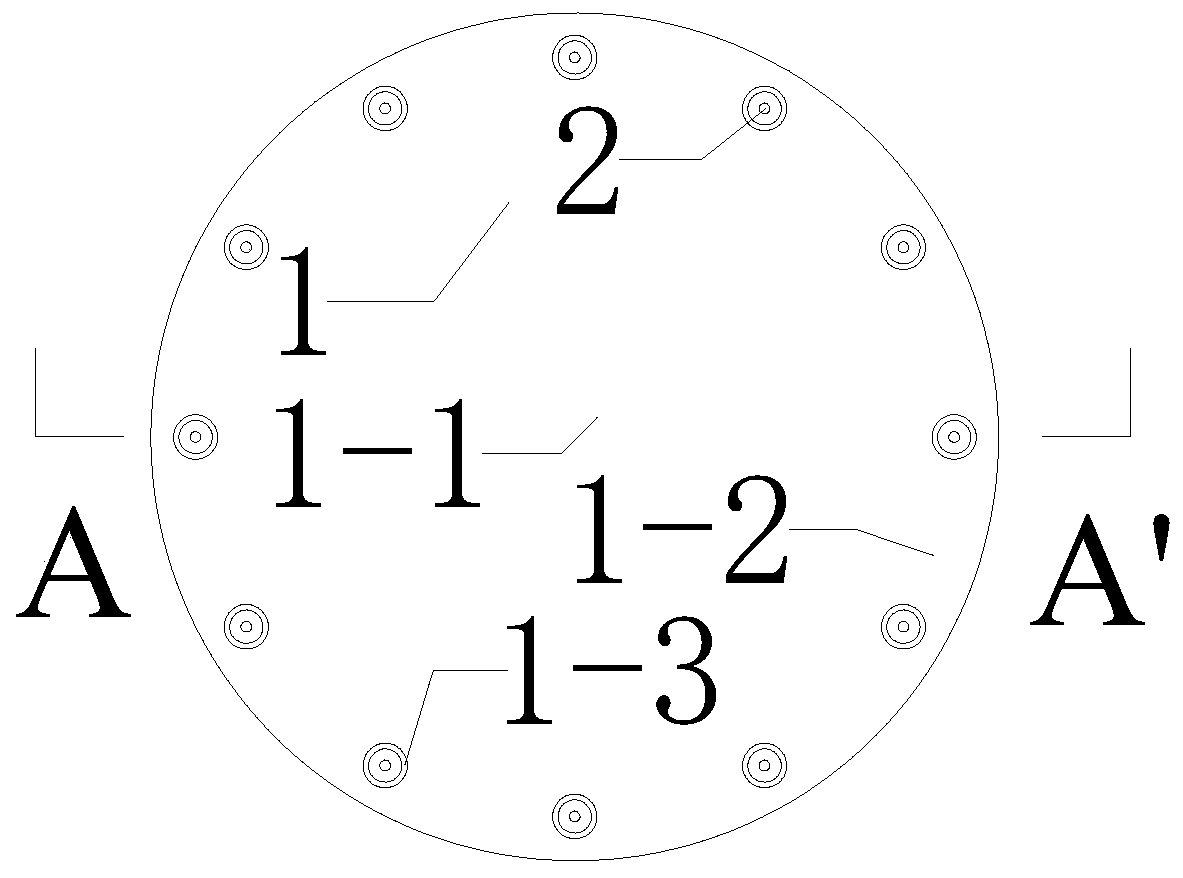

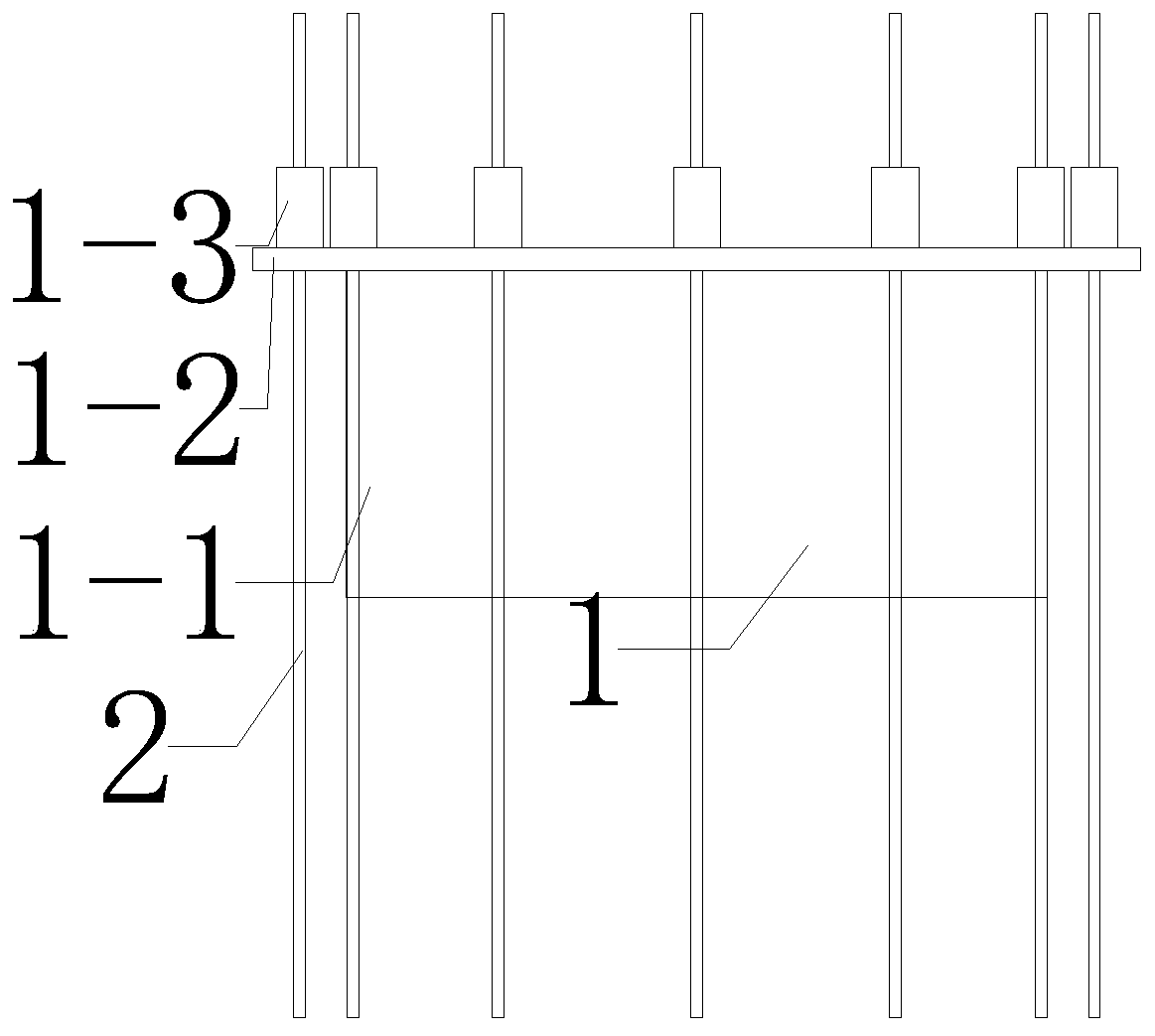

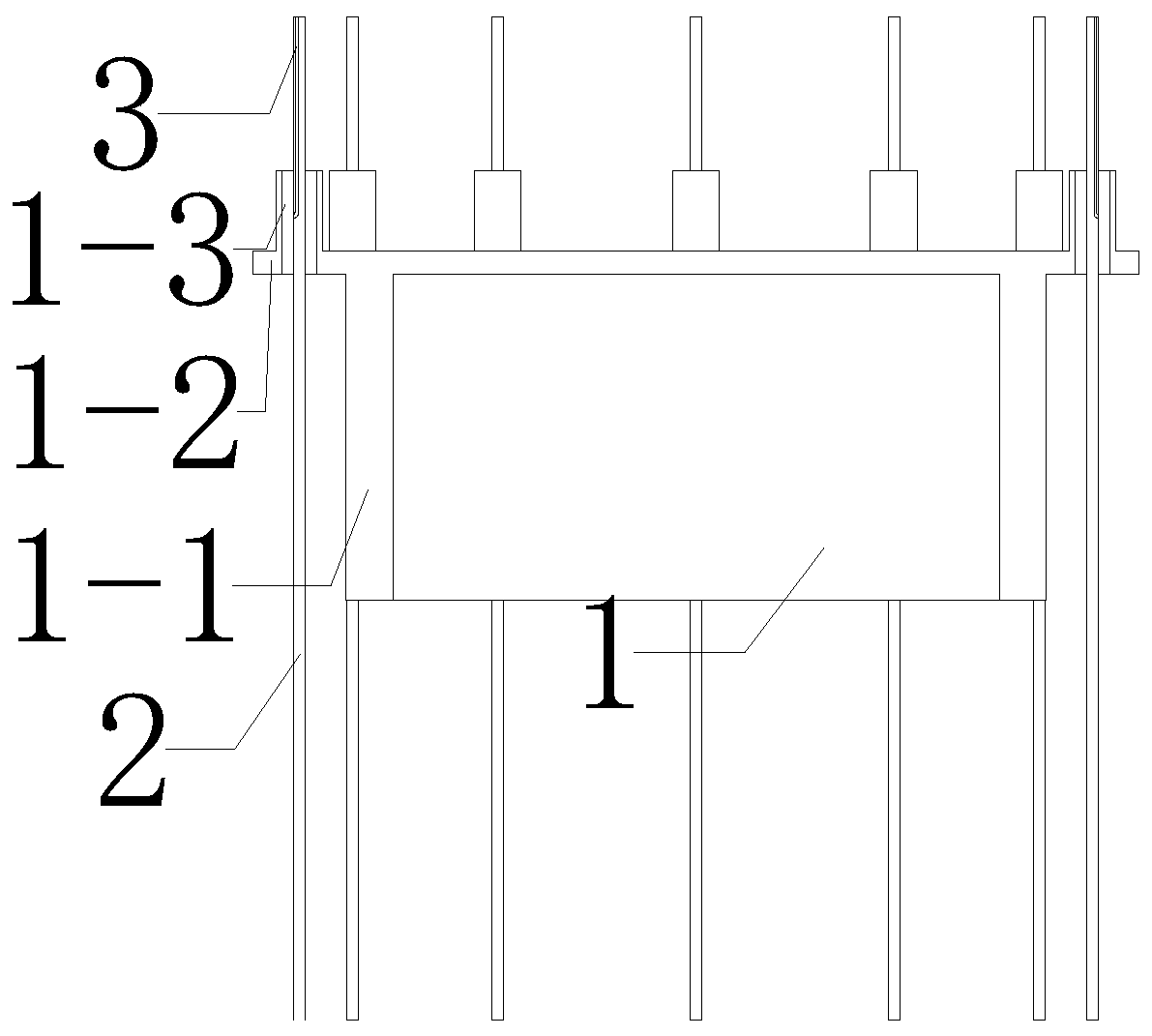

[0034] A composite foundation using auxiliary piles to improve the bearing performance of a cylindrical foundation, comprising a cylindrical foundation 1 and a pile foundation 2, a flange 1-2 is prefabricated on the outer side of the cylindrical foundation 1, and a grouting casing is prefabricated on the flange 1-2 1-3; prefabricated grouting pipe 3 in pile foundation 2, using flange 1-2, grouting sleeve 1-3 and concrete 5 to connect cylinder foundation 1 and pile foundation 2, and restrain the vertical direction of cylinder foundation 1 displacement. The number and size of the pile foundation 2 can be designed according to the size of the cylindrical foundation 1 and the actual working conditions; the pile foundation 2 should adopt small-diameter prestressed high-strength concrete pipe piles (PHC pipe piles) or small-diameter Under the condition of cost, it can meet the structural strength requirements of the pile foundation 2 itself and the pullout bearing capacity requireme...

Embodiment 2

[0036] In the above-mentioned embodiment 1, a composite foundation using auxiliary piles to improve the bearing performance of the cylindrical foundation is lowered. After the cylindrical foundation 1 is floated or hoisted to the predetermined site, it is lowered by the negative pressure penetration method. to the desired position and depth. Use the sea crane to drive the pile foundation 2 to the predetermined depth at the predetermined position; after the sinking is completed, use the grouting pipe 3 to pour hydraulic concrete into the grouting sleeves 1-3 on the cylindrical foundation, and wait until the concrete has sufficient strength , so that the cylindrical foundation 1 and the pile foundation 2 form an integral body and receive loads cooperatively, so as to improve the composite bearing capacity of the overall structure.

Embodiment 3

[0038] In the above-mentioned embodiment 1, when the composite foundation using auxiliary piles to improve the bearing performance of the barrel foundation is in operation, the barrel foundation 1 will also trigger the "scoop" failure mode when it bears the load transmitted from the upper structure such as the fan. , but the displacement of the cylindrical foundation 1 will be constrained by the pile foundation 2, so that the composite foundation bears the upper load together. Because both PHC pipe piles and steel pipe piles have good pull-out bearing capacity, they can well share the cylindrical foundation 1 The uplifting force is improved, thereby improving the bearing mode of the composite foundation, so that the soil and the composite foundation will not be disengaged, and the composite bearing capacity of the foundation is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com