A pipe inner wall walking device for measuring the roughness of a long pipe and its working method

A walking device and roughness technology, which is applied in the field of the inner wall walking device for measuring the roughness of long pipes, and can solve problems such as staying in the pipe and being blocked by obstacles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

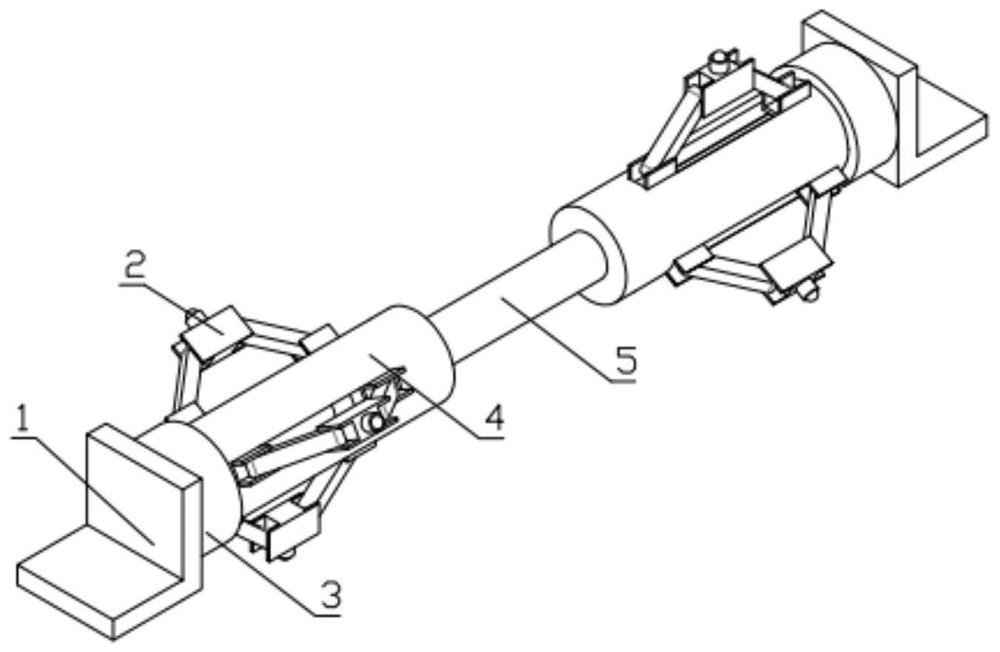

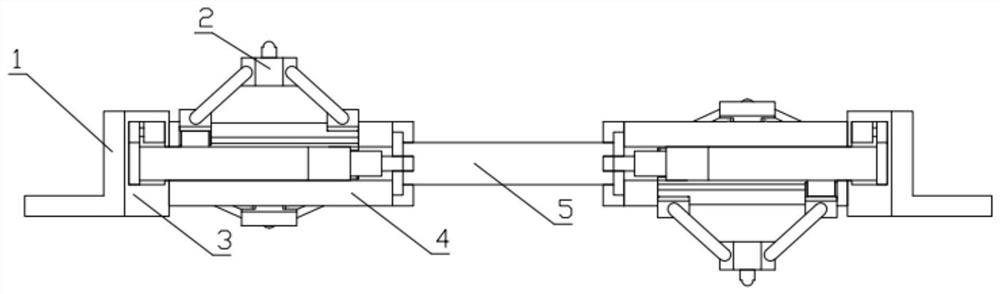

[0049] Combine below Figure 1-16 Describing this embodiment, a pipe inner wall walking device for measuring the roughness of a long pipe includes a detector mounting plate 1, a pipe wall moving mechanism 2, a power mechanism 3, an adjustment mechanism 4, and a rubber rod 5, characterized in that: the said The number of adjustment mechanisms 4 is two, and the positions are relatively symmetrical. The rubber rod 5 is located between the two adjustment mechanisms 4. The adjustment mechanism 4 is connected with the rubber rod 5 through the groove gap, and the power mechanism 3 is fixed on the other side of the adjustment mechanism 4. At one end, there are six pipe wall moving mechanisms 2, which are installed on two adjusting mechanisms 4 on average. The pipe wall moving mechanism 2 and the adjusting mechanism 4 are connected by a groove gap, and the detector mounting plate 1 is installed and fixed on the power mechanism 3. the other end of the .

specific Embodiment approach 2

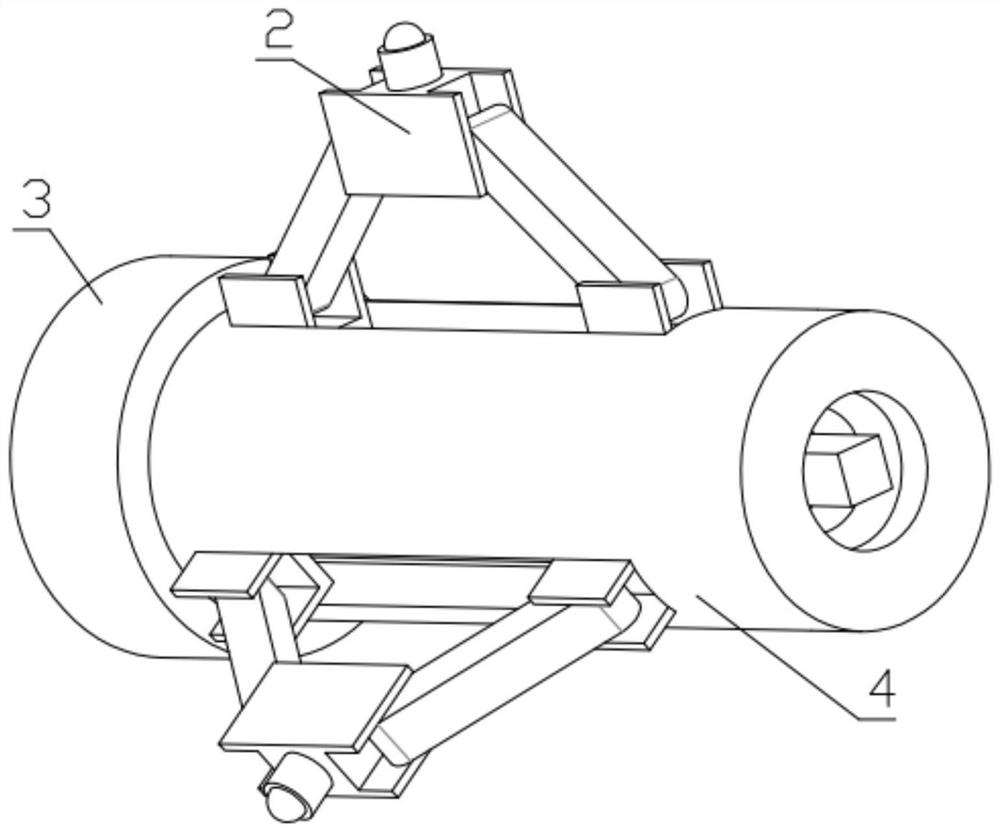

[0051] Combine below Figure 1-16 This embodiment will be described. This embodiment will further describe the first embodiment. The pipe wall moving mechanism 2 includes an electric universal wheel 2-1, a universal wheel installation connector 2-2, a hinge rod 2-3, a U-shaped wheel The connecting piece 2-4, the moving foot structure 2-5, the electric universal wheel 2-1 is installed on the universal wheel installation connecting piece 2-2, and the number of hinge rods 2-3 is two, which are respectively located on the universal wheel The left and right sides of the connecting piece 2-2 are installed, and the universal wheel mounting connecting piece 2-2 is hinged with the hinge rod 2-3. There are two U-shaped connecting pieces 2-4, and the number of the hinge rod 2-3 is two. The bottom end is hinged with the U-shaped connector 2-4, and the bottom of one U-shaped connector 2-4 is fixed with a movable foot structure 2-5; the movable foot structure 2-5 includes a slider 2-5-1, a ...

specific Embodiment approach 3

[0053] Combine below Figure 1-16 This embodiment will be described. This embodiment will further describe Embodiment 1. The power mechanism 3 includes a limit connection piece 3-1, a motor 3-2, and a motor gear 3-3. The motor 3-2 is fixed on the limit connection In the slot of the component 3-1, the motor gear 3-3 is installed on the motor 3-2, and the detector mounting plate 1 is fixed on the limit connecting component 3-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com