Modular rail systems, rail systems, mechanisms, and equipment for devices under test

一种测试器件、轨道的技术,应用在电气测量仪器的零部件、电子电路测试、金属加工设备等方向,达到测试性能简单调整的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

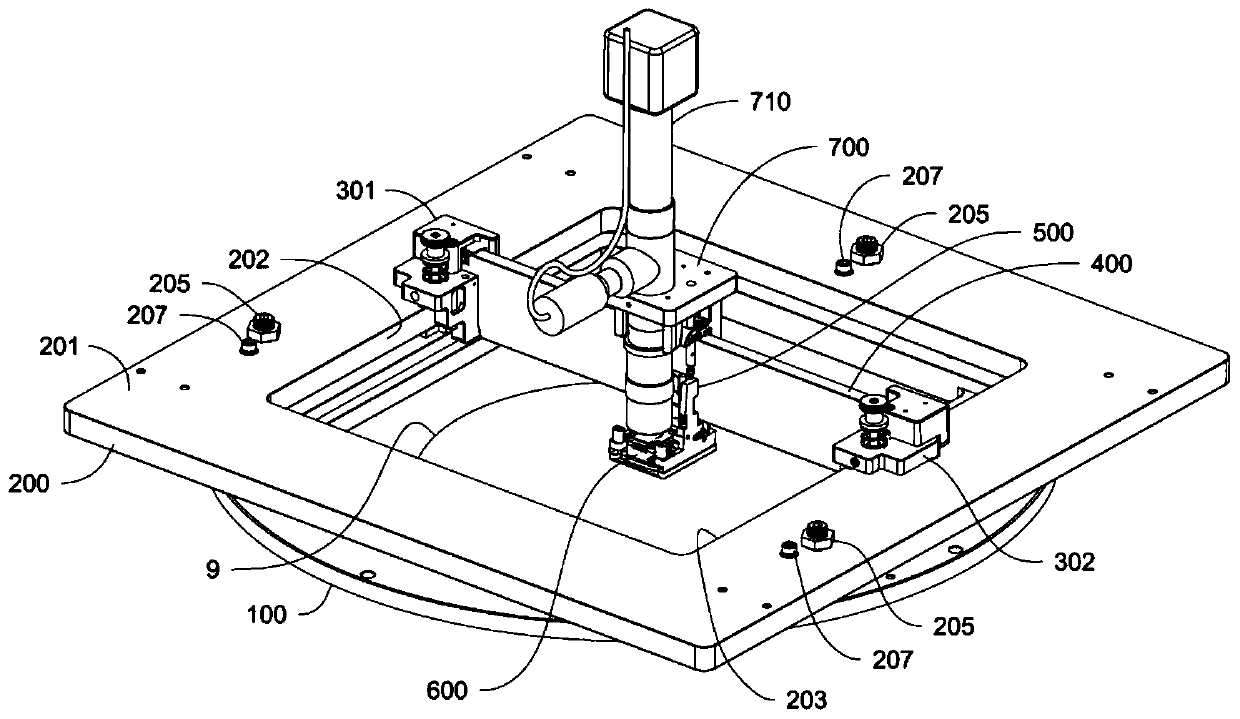

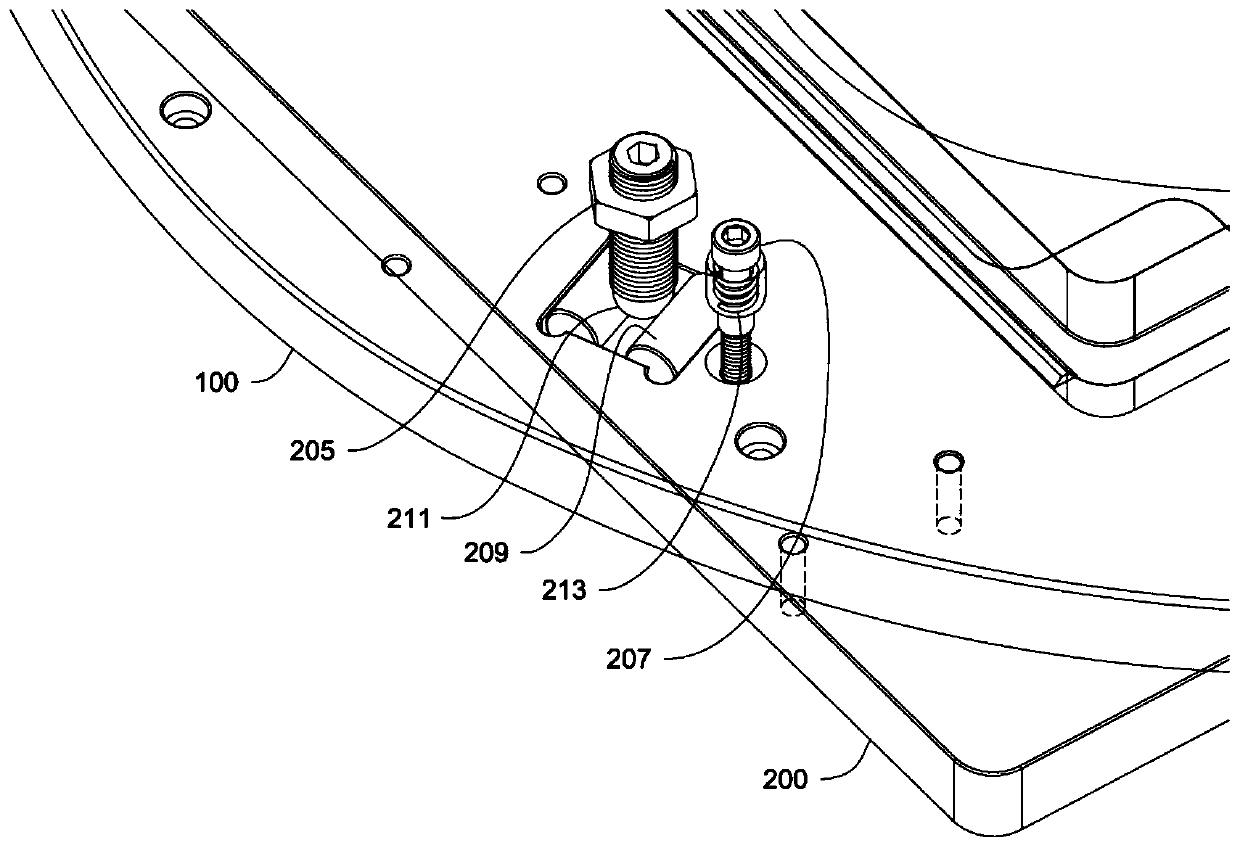

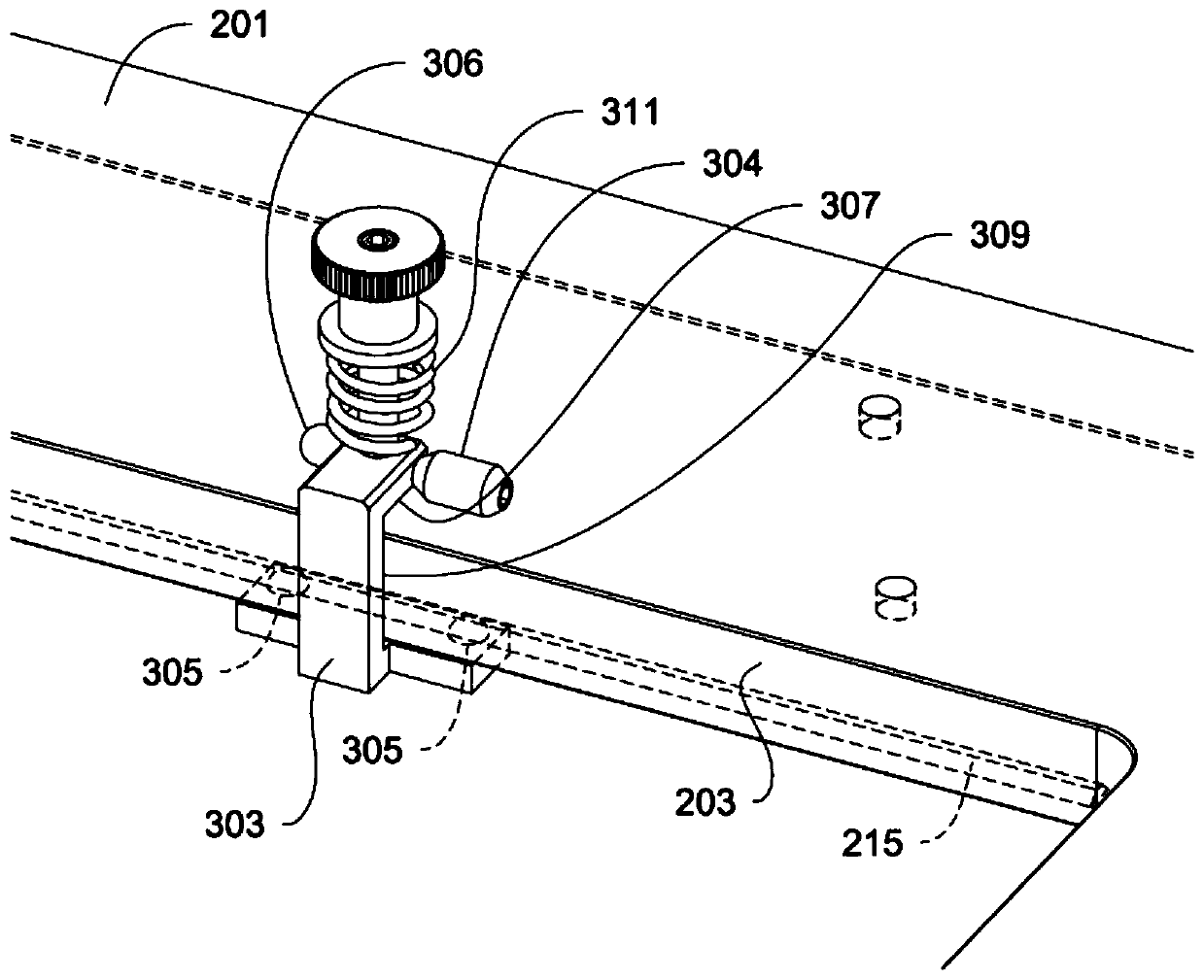

[0027] Embodiments disclosed herein relate generally to multi-site precision positioning mechanisms and, in particular, are directed to positioning a multi-probe array (e.g., across a wide Temperature range testing of semiconductor devices in semiconductor wafers).

[0028] Embodiments disclosed herein relate generally to systems, devices, and methods suitable for use in closed environments capable of controlling light, air, and / or electromagnetic interference. The test temperature of a DUT (eg, a wafer) can range from -65°C to 300°C and beyond. Some tests have measurements at multiple temperatures. The systems, devices and methods herein can be finely targeted to multiple sites and at desired temperatures and ranges. The systems, devices, and methods herein can provide a controlled environment to minimize thermal disturbances or effects that could misalign probe deflection (eg, when the system returns to thermal equilibrium).

[0029] The systems, devices, and methods here...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com