Optical imaging element, and manufacturing method of optical imaging element

An optical imaging and component manufacturing technology, applied in optical components, optics, instruments, etc., can solve problems such as the commercial promotion and large-scale application of medium-free aerial imaging technology, insufficient resolution and clarity of aerial imaging, and affecting user experience. , to achieve the effect of expanding applicability, ingenious and simple manufacturing method, and improving resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, and the present invention will be further elaborated.

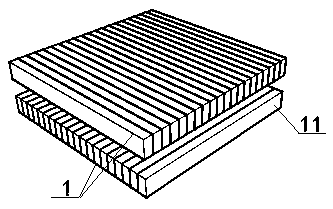

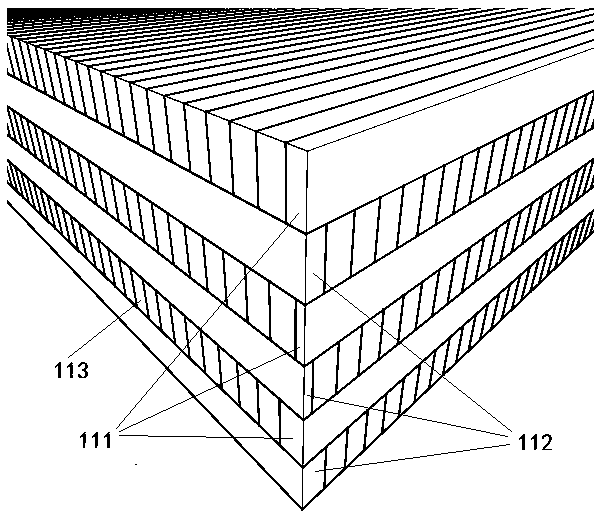

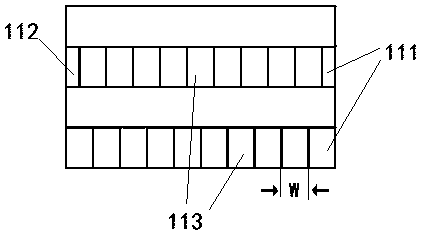

[0063] First, combine the Figure 1~4 The optical imaging element according to the embodiment of the present invention is used for medium-free imaging in the air, and can be used for conferences, teaching, exhibitions, media, urban infrastructure, etc., and has a wide range of application scenarios.

[0064] Such as Figure 1~4 As shown, the optical imaging element of the embodiment of the present invention has a light-transmitting laminated body 1 with an even-numbered layer stacked arrangement. Wherein, each layer of light-transmitting laminated body 1 is provided with several transparent strips 11 that are attached to each other, and the surfaces that are attached to each other on the transparent strips 11 and / or the opposite surface of the surfaces that are attached to each other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com