Eccentric semi-ball valve

A hemispherical valve, eccentric technology, applied in the direction of valve details, valve device, valve housing structure, etc., can solve the problems of eccentric hemispherical valve easy to wear and other problems, achieve the effect of smooth opening and closing, lower resistance, and small switching torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

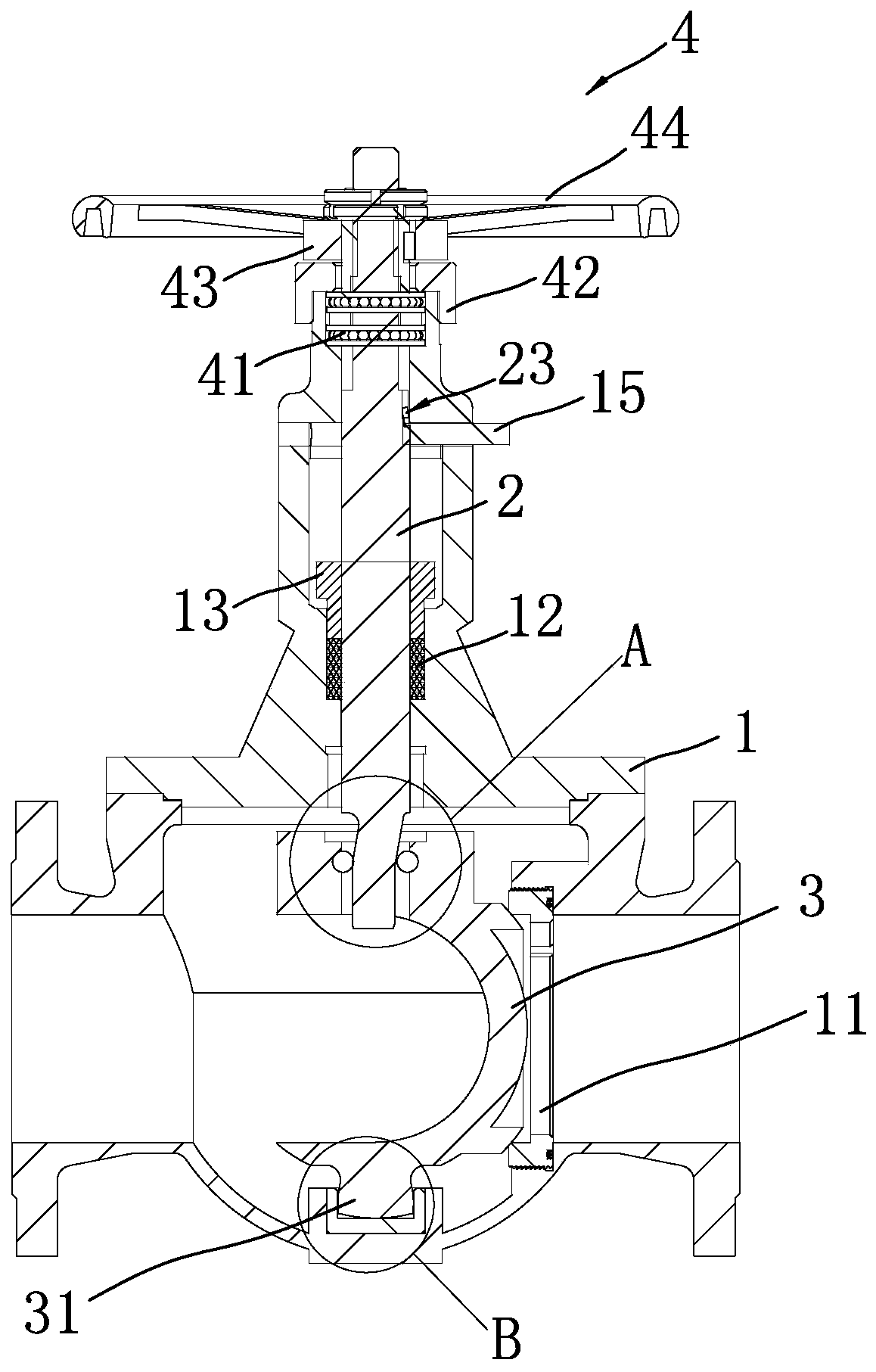

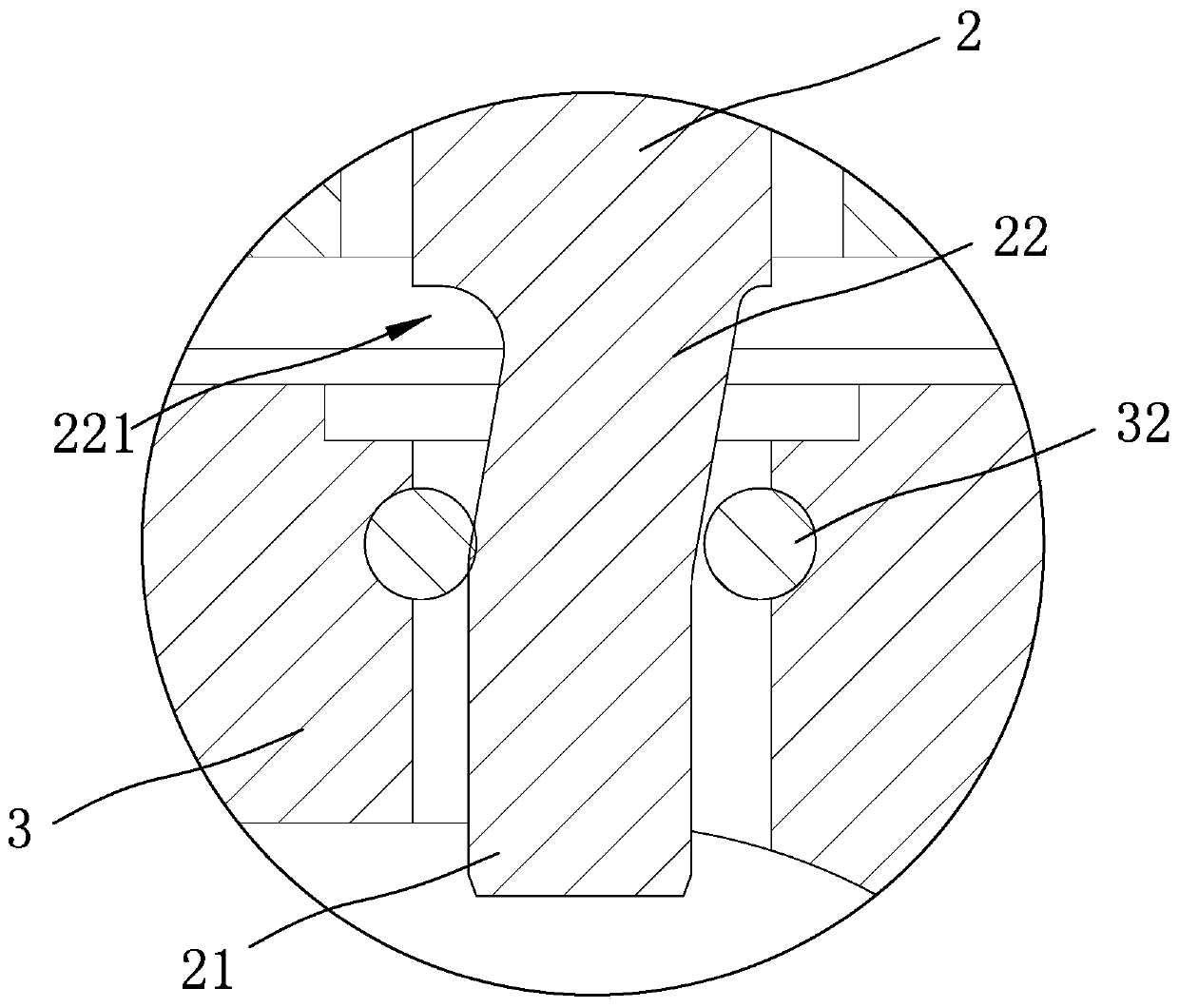

[0022] refer to Figure 1 to Figure 4 , an eccentric hemispherical valve, including a hollow valve body 1 and a rotatable hemispherical spool 3 installed in the valve body 1 through a valve stem 2, the hemispherical spool 3 and the valve installed in the valve body 1 The seat 11 is in a sealed connection, and the upper end of the valve stem 2 is equipped with a transmission mechanism 4 for rotating and lifting the valve stem. Specifically, the transmission mechanism 4 includes a valve that is sequentially installed on the upper end of the valve stem 2 from bottom to top. Bearing 41, bearing gland 42, transmission nut 43 and hand wheel 44 fixed on the transmission nut 43; wherein, a packing 12 and a packing gland 13 for sealing are arranged between the valve stem 2 and the valve body 1;

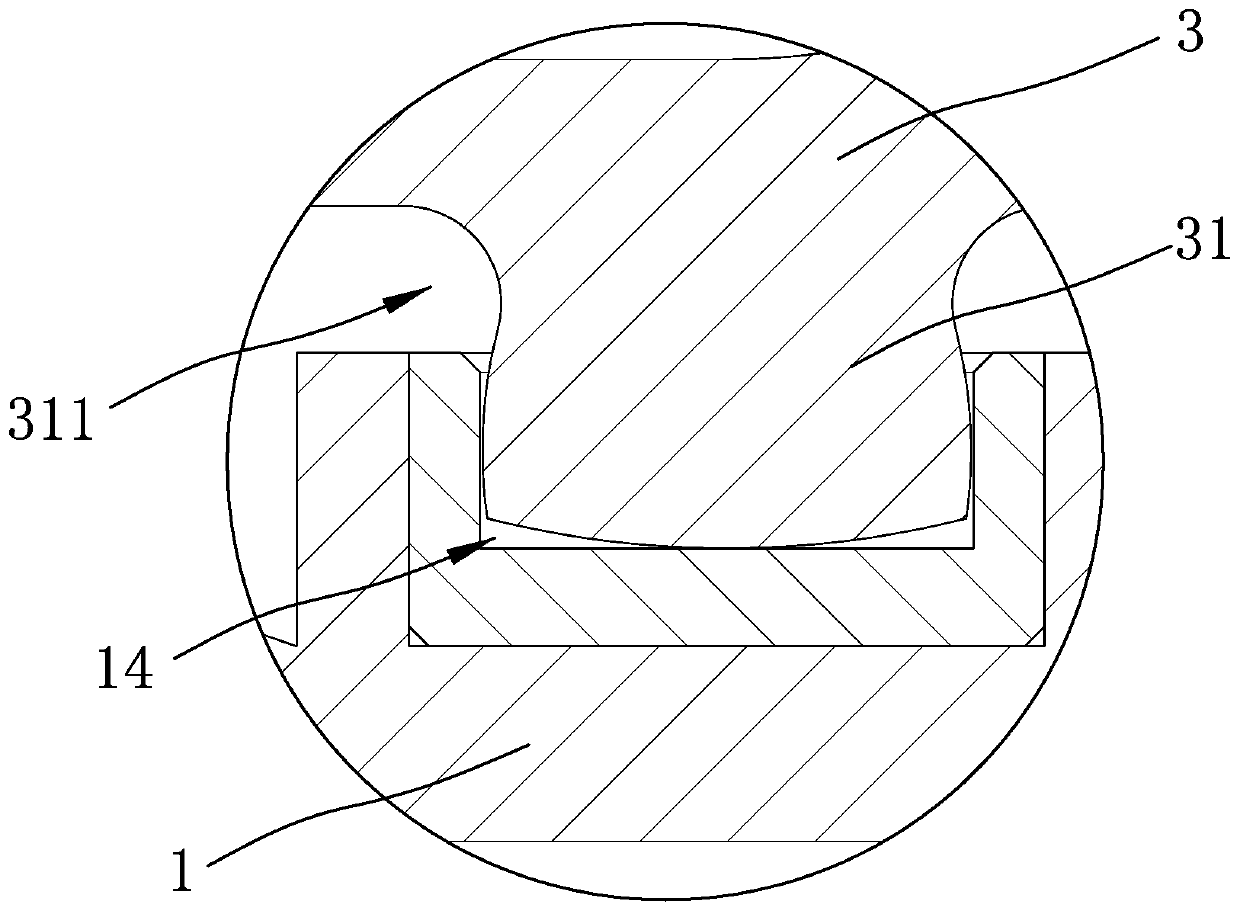

[0023] The lower end of the valve body 1 is provided with a mounting groove 14 for installing the hemispherical valve core 3, and the lower end of the hemispherical valve core 3 is provided wi...

Embodiment 2

[0031] refer to Figure 5 , Figure 6 , compared with Embodiment 1, the bottom of the pole 31 in this embodiment is provided with a protruding portion 312 arranged radially, and the mounting groove 14 is provided with a reset Spring 141, the return spring 141 is installed towards the direction of the valve seat 11, the installation groove 14 is provided with an arc-shaped insertion groove 142 for accommodating the protrusion 312, when the valve is in a closed state, the The protruding part 312 abuts against the left side of the mounting groove 14 and compresses the return spring 141 , and when the valve is in an open state, the protruding part 312 is embedded in the arc-shaped embedding groove 142 .

[0032] Specifically, the structure of the protrusion and the return spring is provided. When the protrusion contacts the side of the installation groove, the support rod is pushed to compress the return spring, and then the lower end of the hemispherical valve core moves toward ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com