Crystal material preparation method of liquid crystal screen

A liquid crystal screen and crystal technology, applied in the direction of nonlinear optics, instruments, optics, etc., can solve the problems of increasing the cost of use, waste of raw materials and energy, and achieve the effect of avoiding energy waste and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

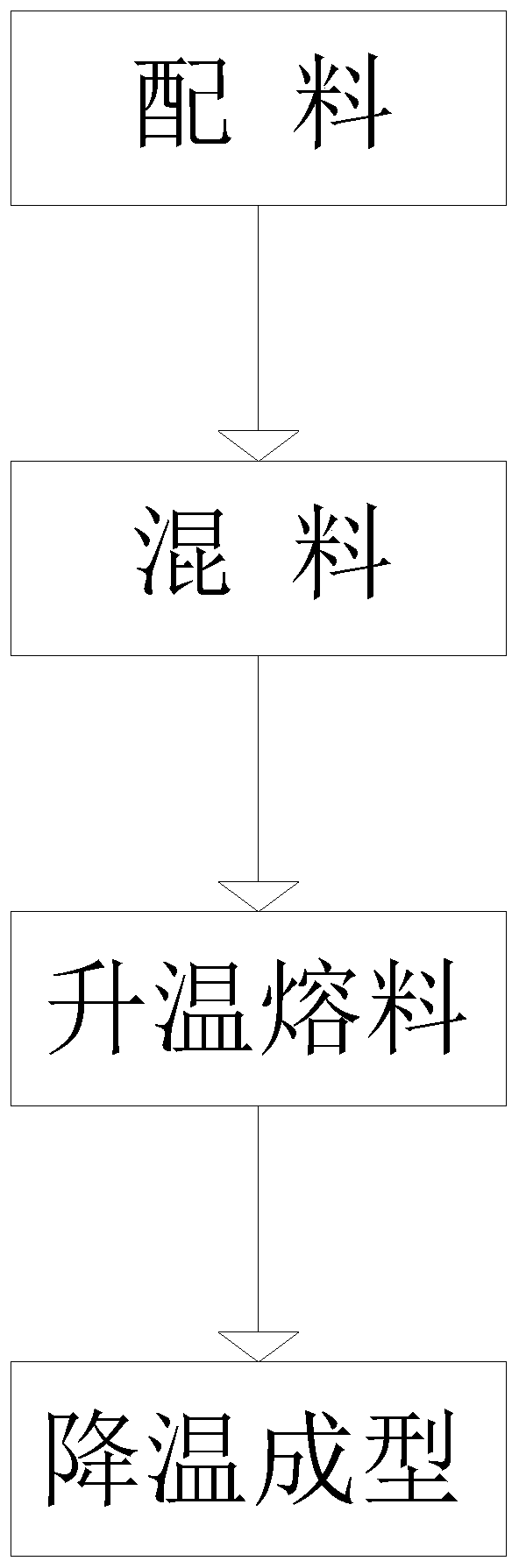

[0023] A method for preparing a crystal material for a liquid crystal display, the method comprising the steps of:

[0024] (1) Ingredients, take an appropriate amount of liquid crystal raw material, then grind the liquid crystal raw material to powder, and then prepare an appropriate amount of flux;

[0025] (2) mixing materials, stirring the powder of the liquid crystal raw material obtained in step (1) and the flux to obtain a mixed solution, and then pouring the mixed solution into the container;

[0026] (3) Heat up the molten material, place the vessel containing the liquid crystal raw material powder and the flux mixture in step (2) inside the heating box to ensure that the heating box continues to heat the vessel until the mixed solution in the vessel reaches the saturation point ;

[0027] (4) Cooling and molding, the temperature of the saturated solution in step (3) is steadily lowered, and the mixed solution inside the vessel will crystallize, that is, a liquid cry...

Embodiment 2

[0038] A method for preparing a crystal material for a liquid crystal display, the method comprising the steps of:

[0039] (1) Ingredients, take an appropriate amount of liquid crystal raw material, then grind the liquid crystal raw material to powder, and then prepare an appropriate amount of flux;

[0040] (2) mixing materials, stirring the powder of the liquid crystal raw material obtained in step (1) and the flux to obtain a mixed solution, and then pouring the mixed solution into the container;

[0041] (3) Heat up the molten material, place the vessel containing the liquid crystal raw material powder and the flux mixture in step (2) inside the heating box to ensure that the heating box continues to heat the vessel until the mixed solution in the vessel reaches the saturation point ;

[0042] (4) Cooling and molding, the temperature of the saturated solution in step (3) is steadily lowered, and the mixed solution inside the container will crystallize, that is, a liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com