S-shaped method for inhibiting multi-modal residual vibration of system and system

A residual vibration, multi-modal technology, applied in general control systems, control/regulation systems, digital control, etc., can solve problems such as low speed, difficult to precise position, instability, etc., to achieve vibration suppression, cost saving, robustness high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

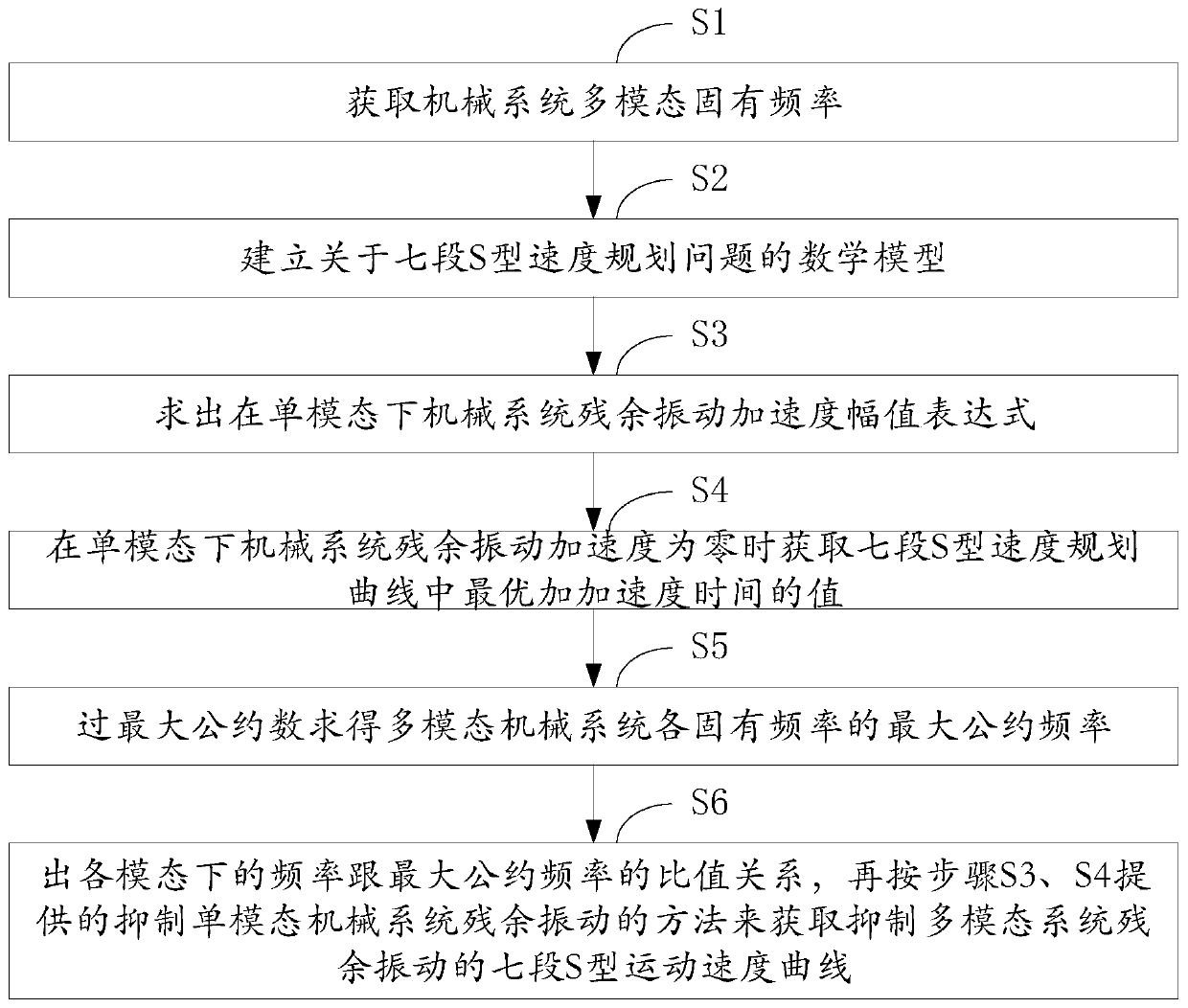

[0042] Such as figure 1 As shown, the method for suppressing the multi-mode residual vibration of the system based on the S-type provided by the present invention is described in detail as follows:

[0043] Step S1, obtain the multi-mode natural frequency ω of the mechanical system 1 , ω 2 ,… ω n; In a mechanical movement driven by a driving device, the requirements for high speed, high precision and stability are very high. In the process of movement, the first step is to obtain the natural frequency ω of the mechanical control system under multi-mode 1 , ω 2 ,… ω n , the frequency of acquisition is different in each stage.

[0044] Step S2, establishing a mathematical model about the seven-segment S-shaped speed planning problem; after obtaining the frequencies of each stage, according to the different frequencies obtained at each stage, establish a seven-segment S-shaped speed planning problem for the motion of the mechanical control system Mathematical model, in esta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com