Connector and plug

A plug and plug housing technology, applied in the direction of connection, two-part connection device, parts of the connection device, etc., can solve problems such as affecting the conduction of contacts, and achieve the effects of improving identification accuracy, increasing strength, and simplifying the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

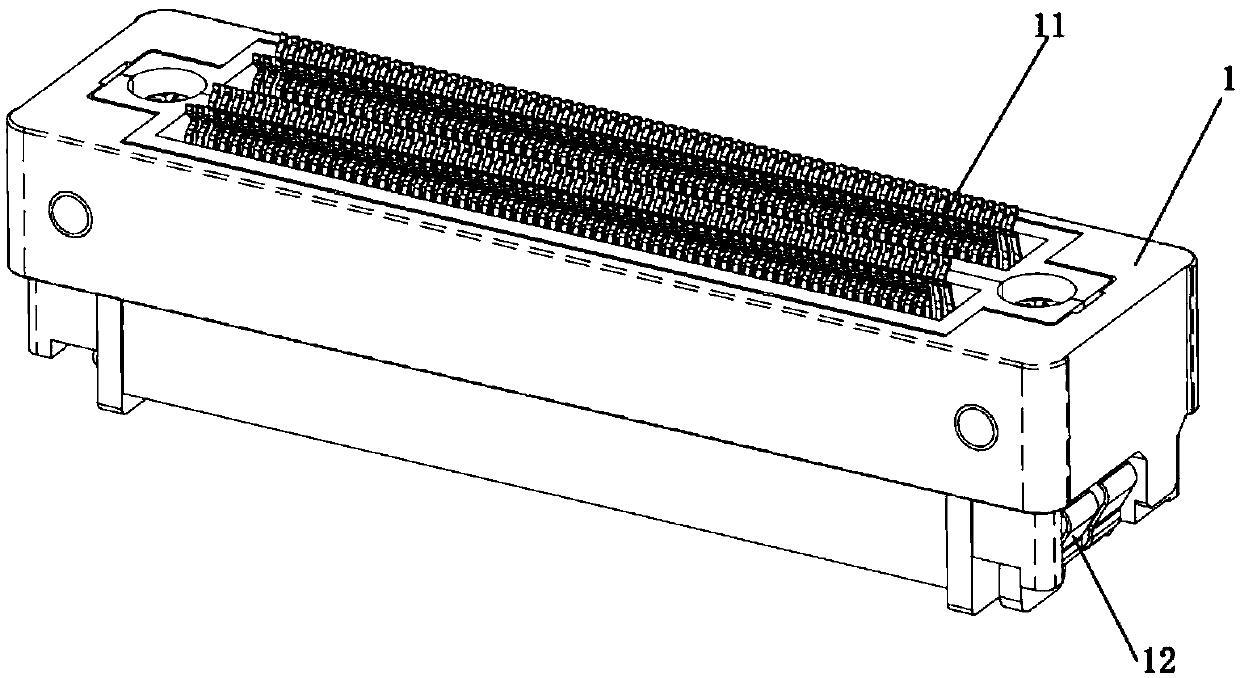

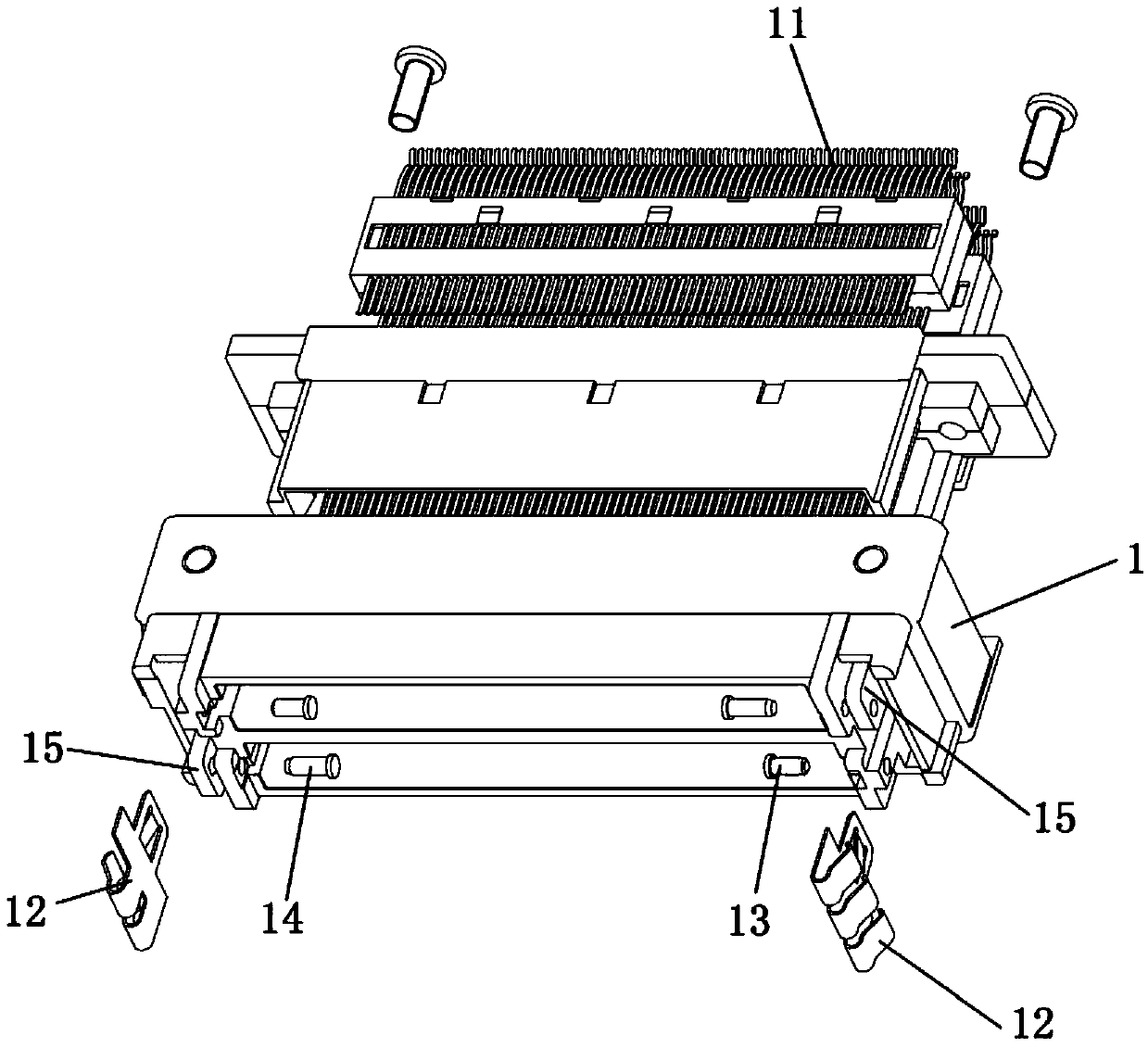

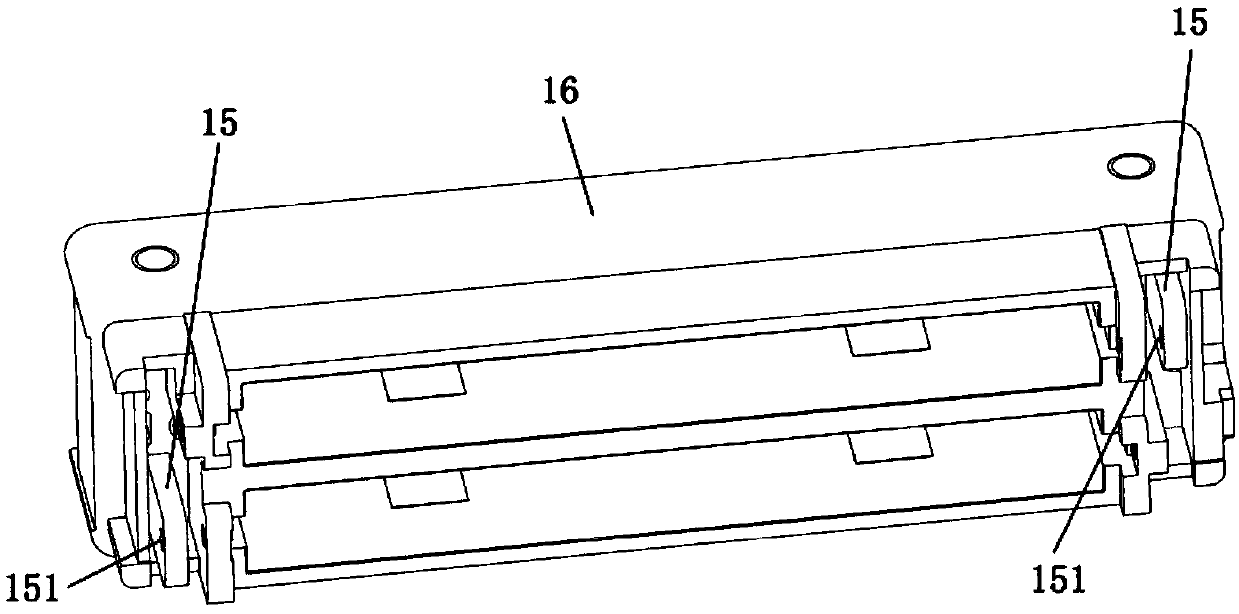

[0041] The specific embodiments of the connector and its plug in the present invention will now be described with reference to the accompanying drawings.

[0042] Such as Figure 1 to Figure 5 As shown, the connector includes a plug 1 and a socket 2 adapted to the plug 1. The plug 1 is provided with plug contacts 11 in groups, and the socket 2 is provided with socket contacts 21, plug contacts 11 and socket contacts in groups. 21 Correspondingly, the same plug contact group and the same socket contact group are arranged in the length direction of the connector, and multiple contact groups are arranged side by side in the width direction of the connector. The contact piece group can be provided with only one group, or can be set as two groups, three groups, four groups, six groups, etc. The specific number is determined by the volume of the transmission circuit and the connector actually required.

[0043] Such as figure 1 and figure 2 As shown, the plug contact 11 is installed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com