Heat exchanger assembling and transporting method adopting air cushion transporting device

A technology of transportation equipment and transportation methods, which is applied in transportation and packaging, multi-axle trolleys, trolley accessories, etc., can solve the problems of inconvenient operation process, many safety conditions, and high cost of crane systems, and achieves low impact and load-bearing. Great ability and the effect of reducing ground damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

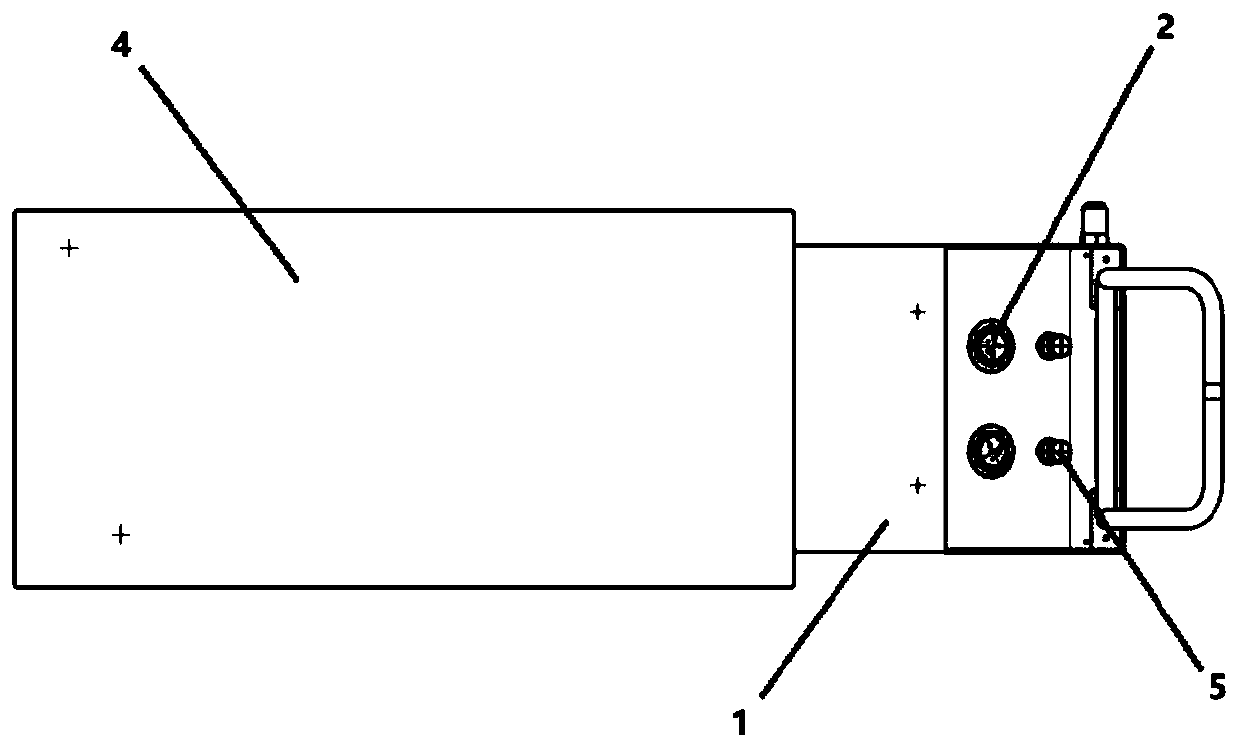

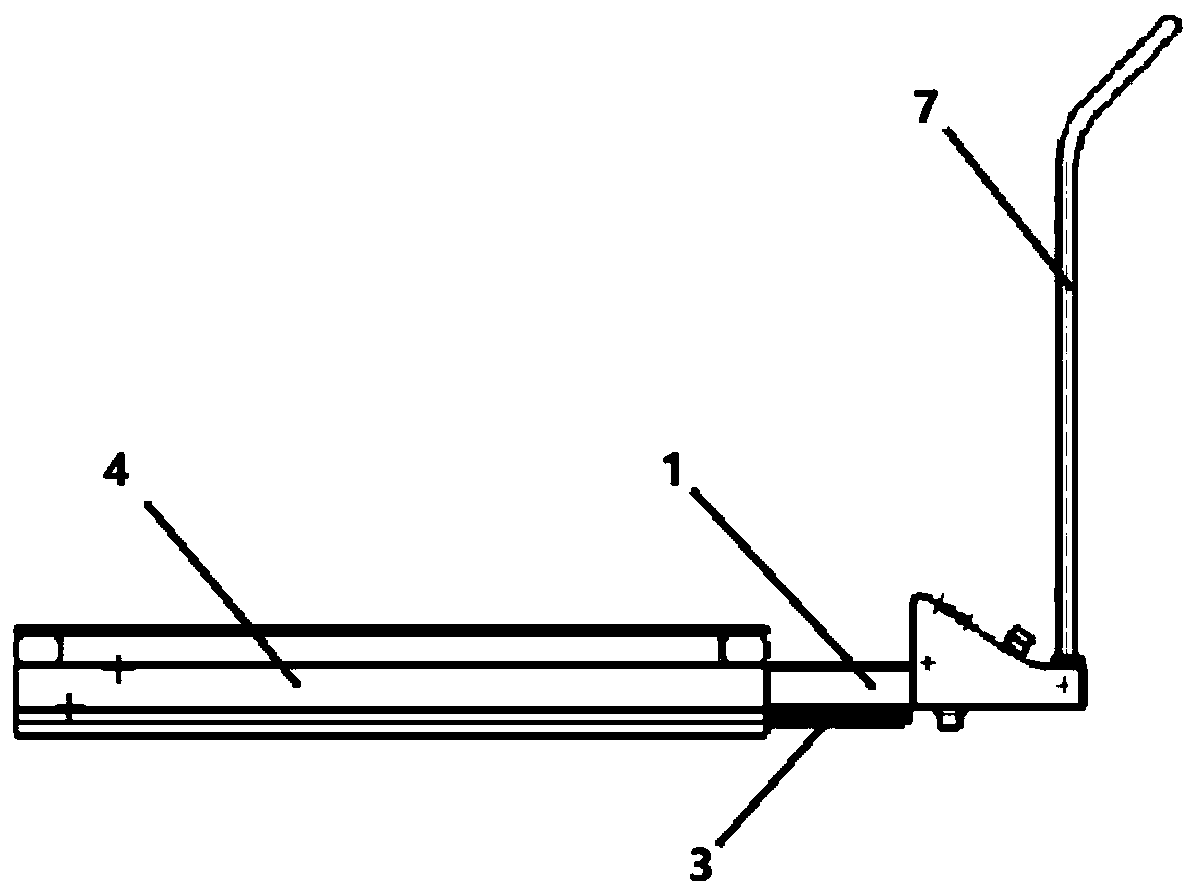

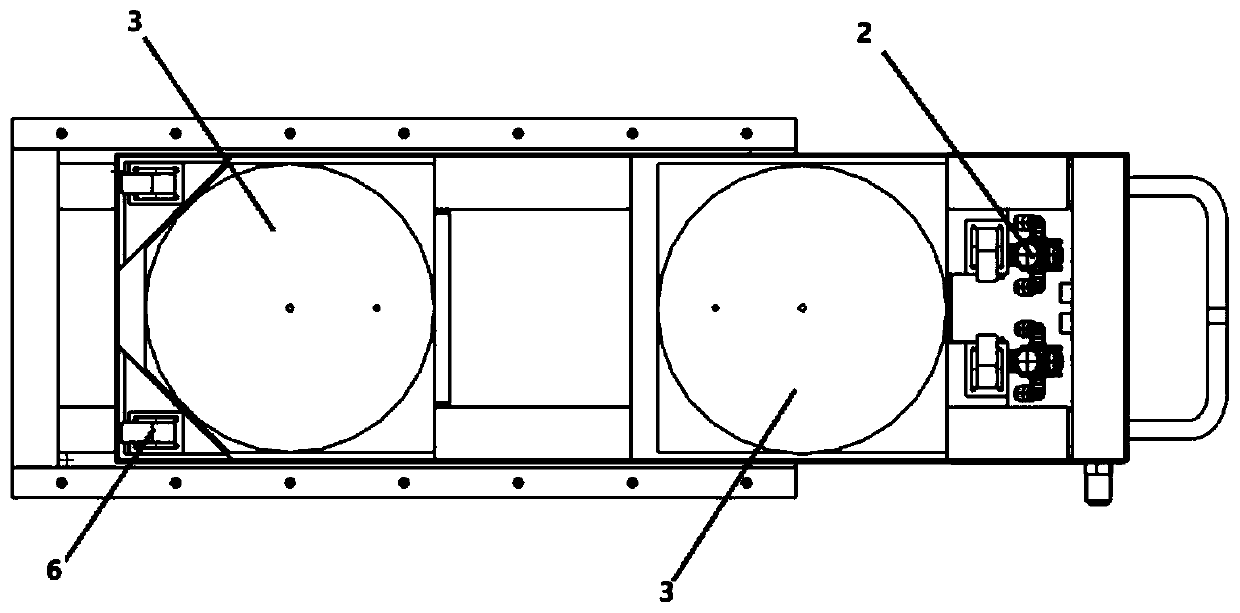

[0024] A kind of transportation equipment for heat exchanger workshop assembly, characterized in that it includes: main car body structure 1, pneumatic control system 2, air cushion 3, tray bracket 4, pressure reducing valve, universal wheel 6; the main car body The upper and lower surfaces of the structure 1 provide installation and fastening interfaces for other components; air cushions 3 are arranged at the front and rear ends of the lower part of the main body structure 1, and the air cushions can be inflated. hole; when the air cushion is inflated, it can lift the main vehicle body structure; the pneumatic control system 2 is placed behind the main vehicle body structure 1, and the pneumatic control system includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com