Traction wheel with displacement deviation capable of being reduced

A technology of displacement deviation and traction wheel, which is applied in the direction of elevators, transportation and packaging in buildings, can solve the problems of horizontal wire deviation, high equipment cost, and easy to cause deviation, etc., and achieves easy positioning, simple steps, and easy to use The effect of less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

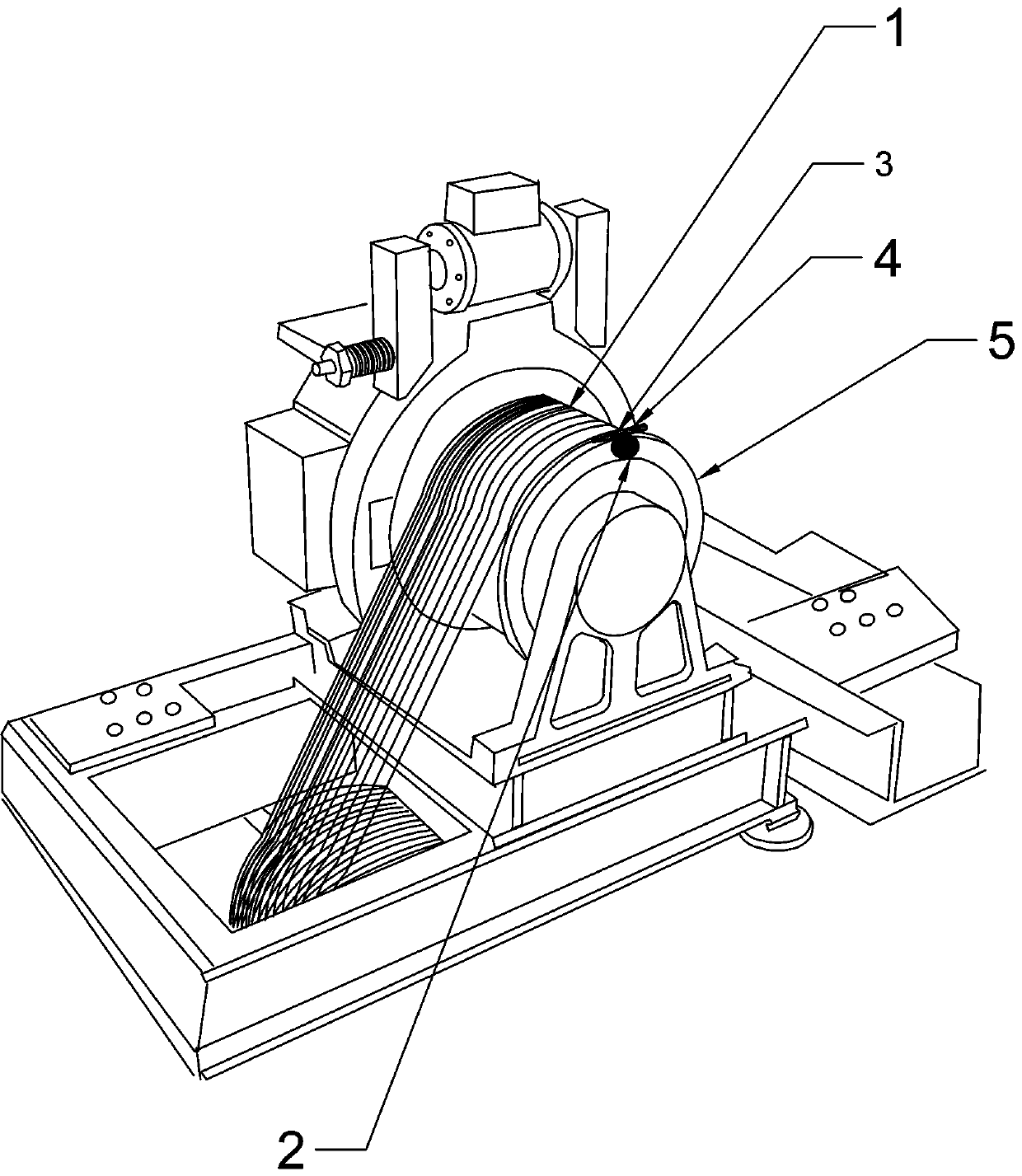

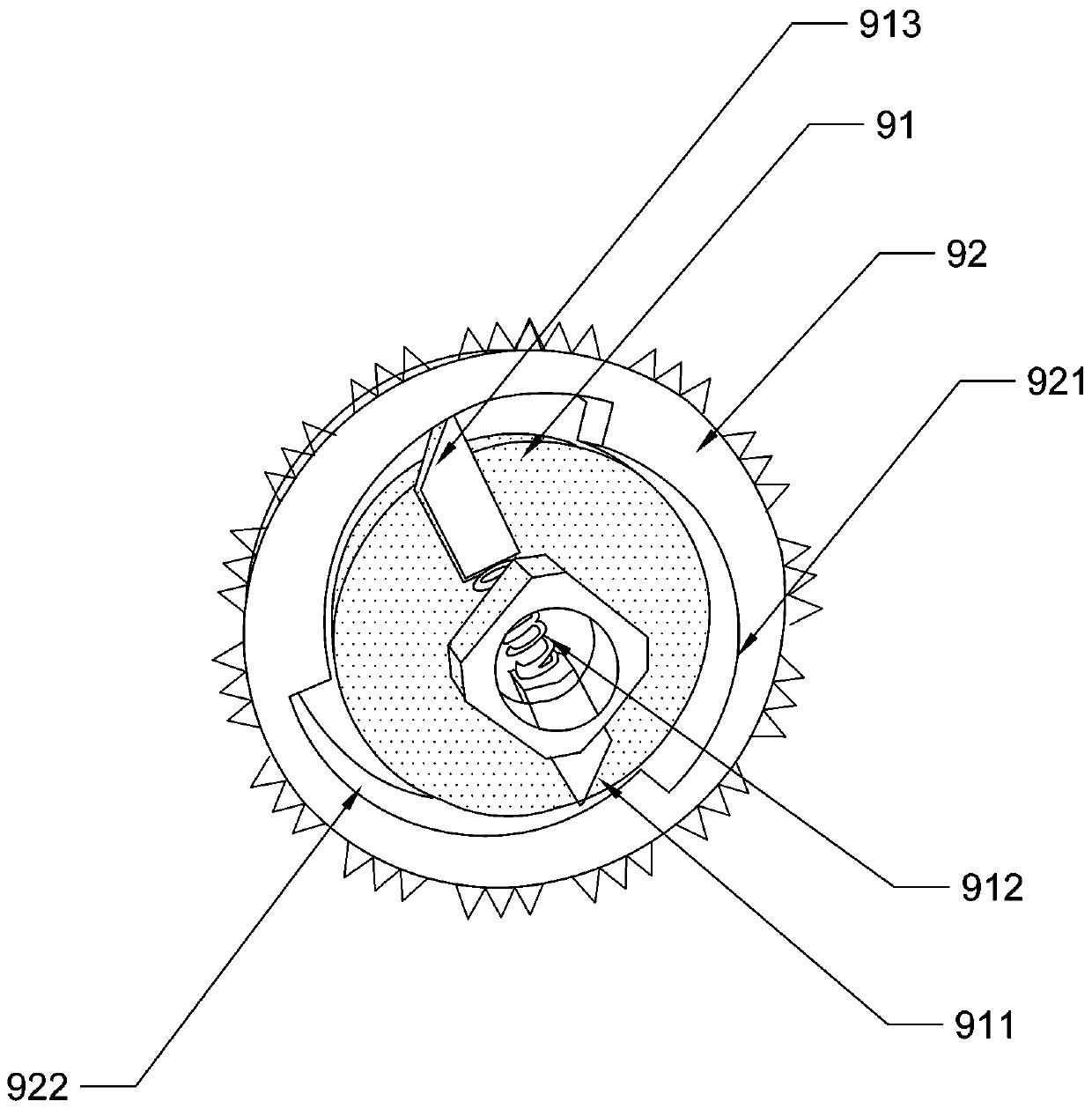

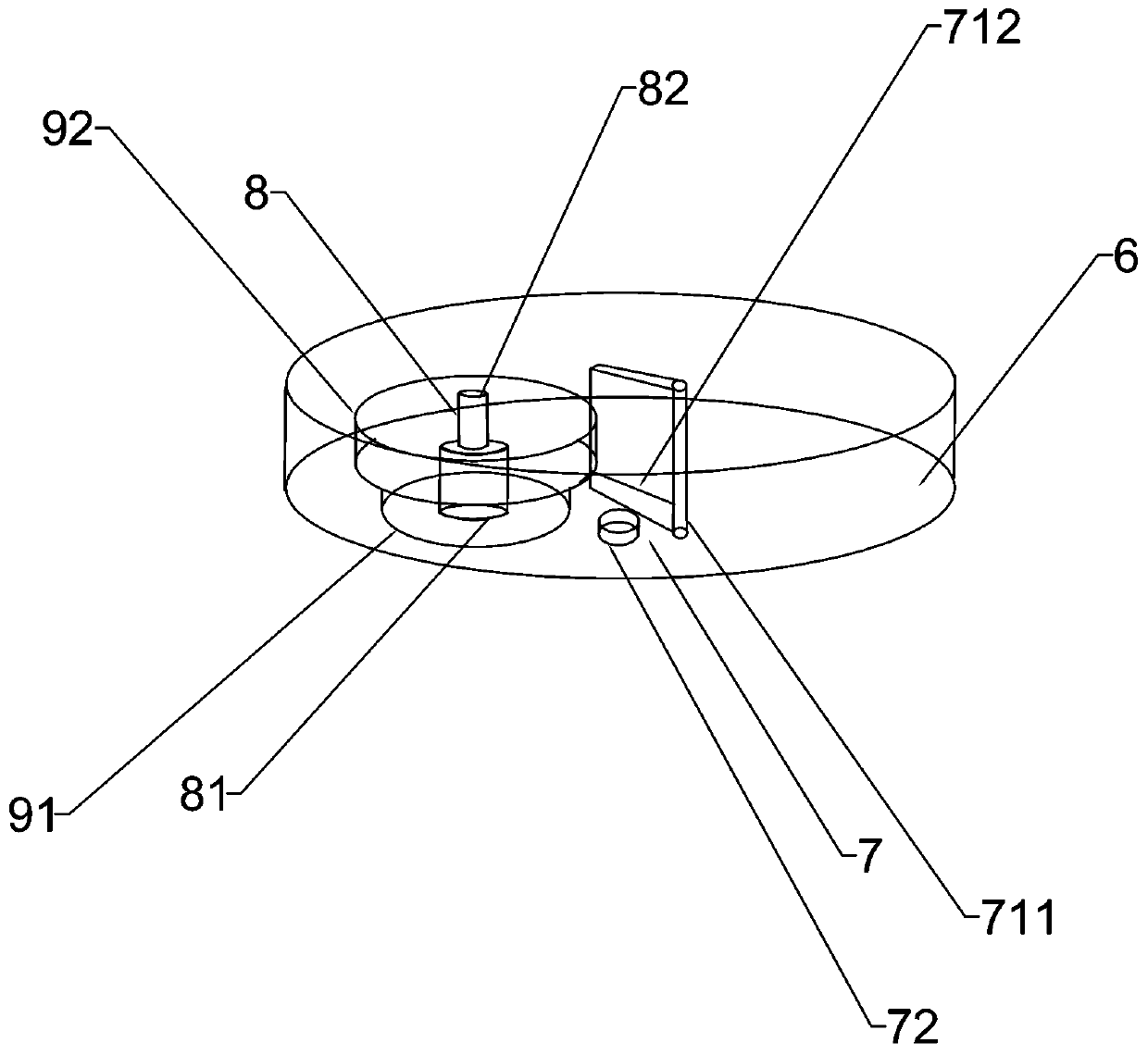

[0025] The present invention provides a traction sheave that reduces the displacement deviation of the traction sheave, such as figure 1 , figure 2 As shown, it includes a wheel body, a wiring device tangent to the wheel body, a laser pointer that is tangent to the wiring device and the wheel body at the same time, and the laser pointer is fixed with a mini level, such as image 3 As shown, the wiring device includes a casing, a chassis fixed to the traction wheel and a locking block, a reel for winding up the lead wire, a toothed disc sleeved on the reel, and the toothed disc is connected to the The reel is coaxial and rotates synchronously. The locking block includes a knob and a limiter. The knob is provided with a po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com