Magneto-rheological elastomer and piezoelectric hybrid control type shield hobbing cutter

A magneto-rheological elastomer and hybrid control technology, applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc., can solve the problem of reducing the efficiency of shield tunneling and the direction of tunneling Problems such as offset and damage to the cutter head can be solved, and the effect of simple structure, reduced displacement deviation, and increased tunneling speed can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

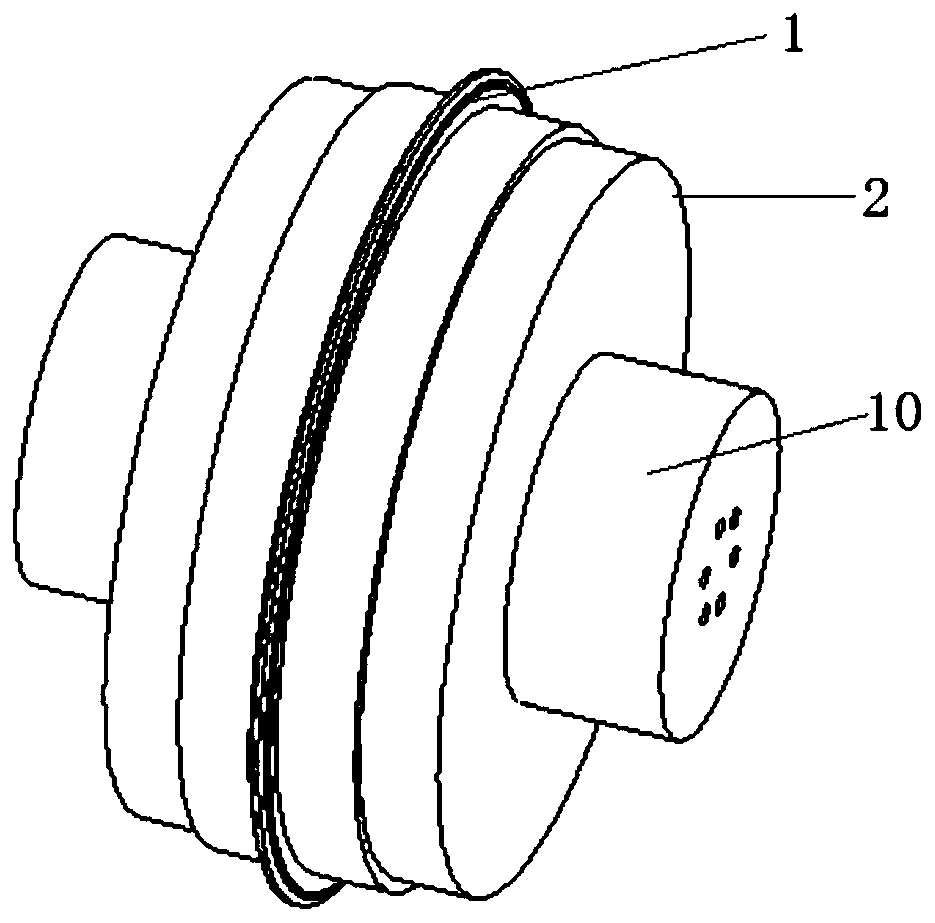

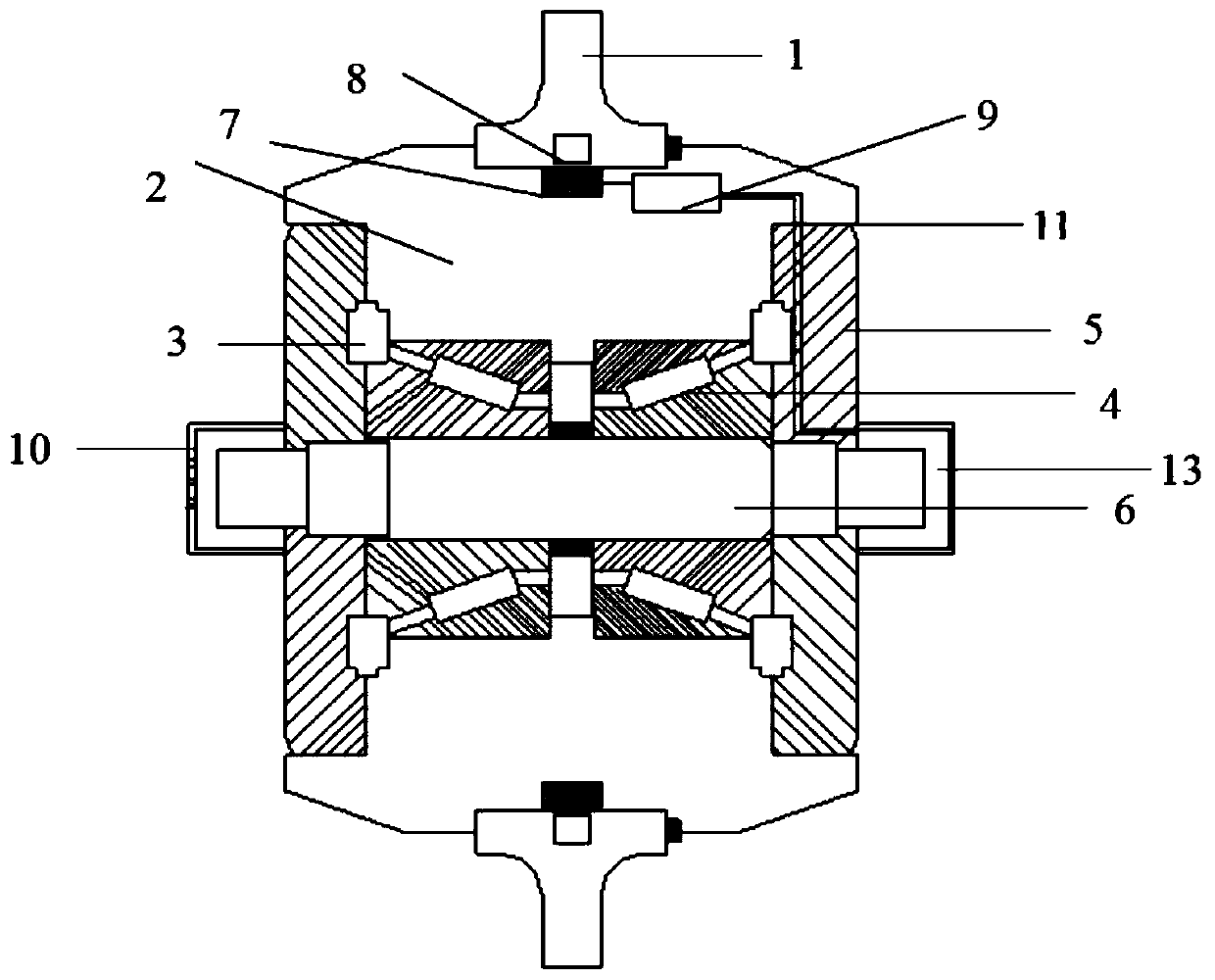

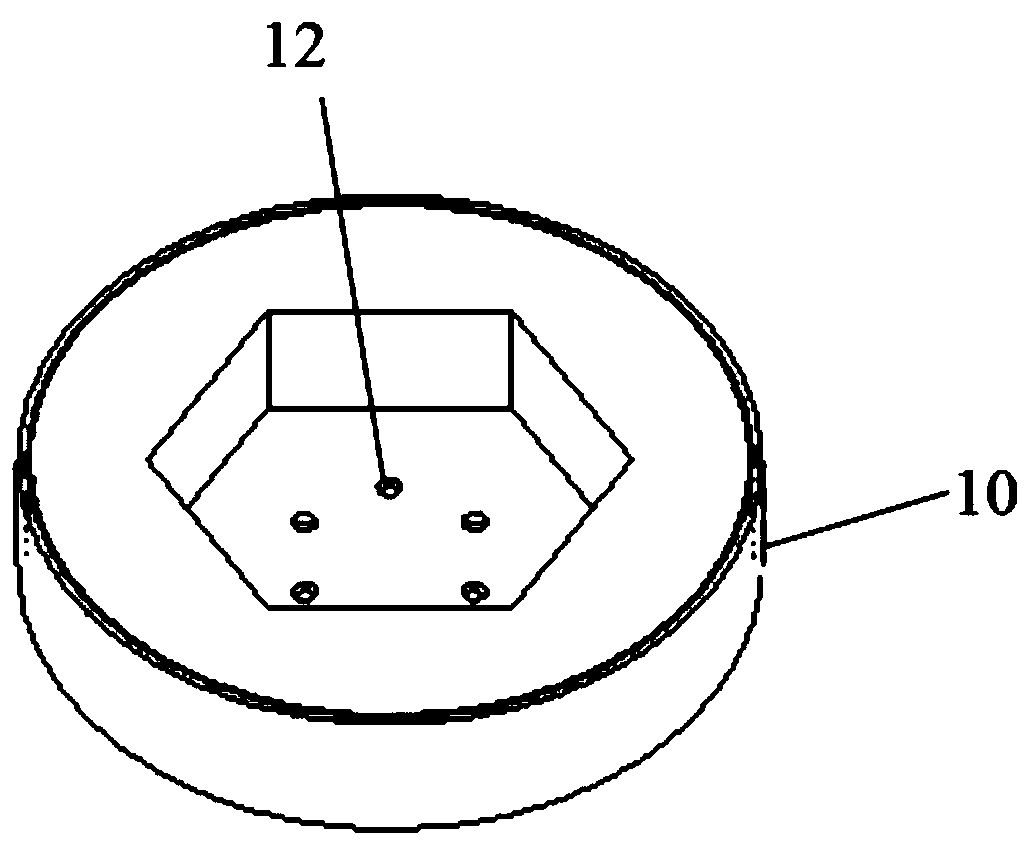

[0021] Such as figure 1 and 2 As shown, a magneto-rheological elastomer and piezoelectric hybrid control type shield hob of the present invention includes: a cutter body 2, a cutter ring 1, a bearing 4, a cutter shaft 6, a cutter shaft seat 10, an end cover 5, A piezoelectric device 7, a plurality of pressure sensors 8, an electrical storage device 91 and a controller 92;

[0022] The circumferential surface of the cutter body 2 is provided with an annular groove, the piezoelectric device 7 is arranged in the annular groove, the knife ring 1 is arranged on the annular groove and is in contact with the piezoelectric device 7, a plurality of The pressure sensors 8 are arranged in the cutter ring 1 and distributed at equal intervals along the circumference of the cutter ring 1 , and are connected with wires, and connected to the power storage device 91 through the wire channel 11 . The bearing 4 is arranged in the cutter body 2, the bearing outer cover is fixed to the cutter bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com