Force-increasing demolding device for large-diameter vertical shaft template

A demoulding device and large-diameter technology, which can be used in shaft equipment, shaft lining, mining equipment, etc., can solve the problems of increased reaction force of elastic deformation of adhesive formwork, large contact area between formwork and concrete, and increased equipment requirements. , to achieve the effect of reducing overturning force, solving the difficulty of demoulding, and saving economic costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

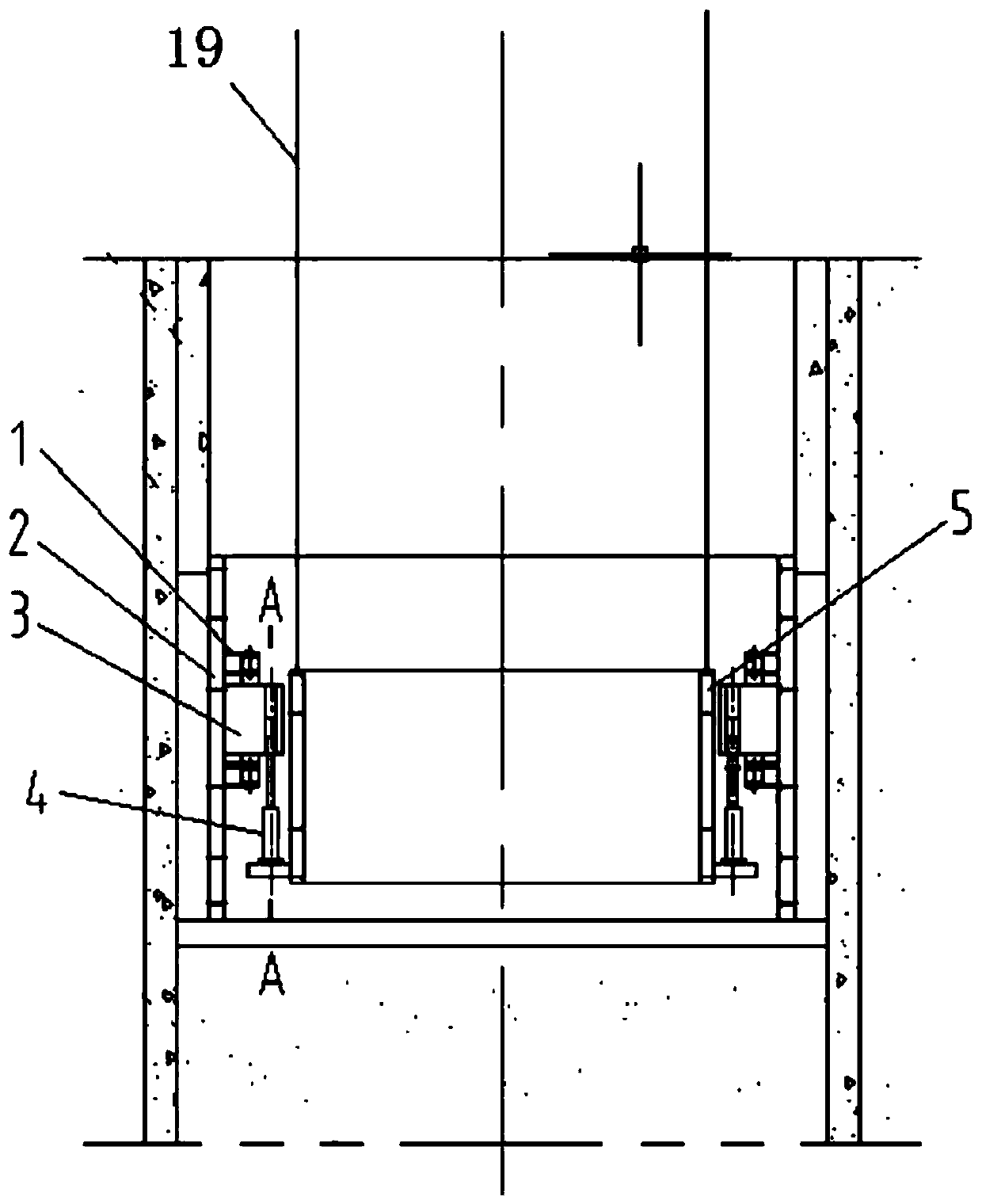

[0022] A further detailed description will be given below of a large-diameter shaft formwork booster demoulding device of the present invention. In order to make the purpose and features of the present invention more comprehensible, the specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

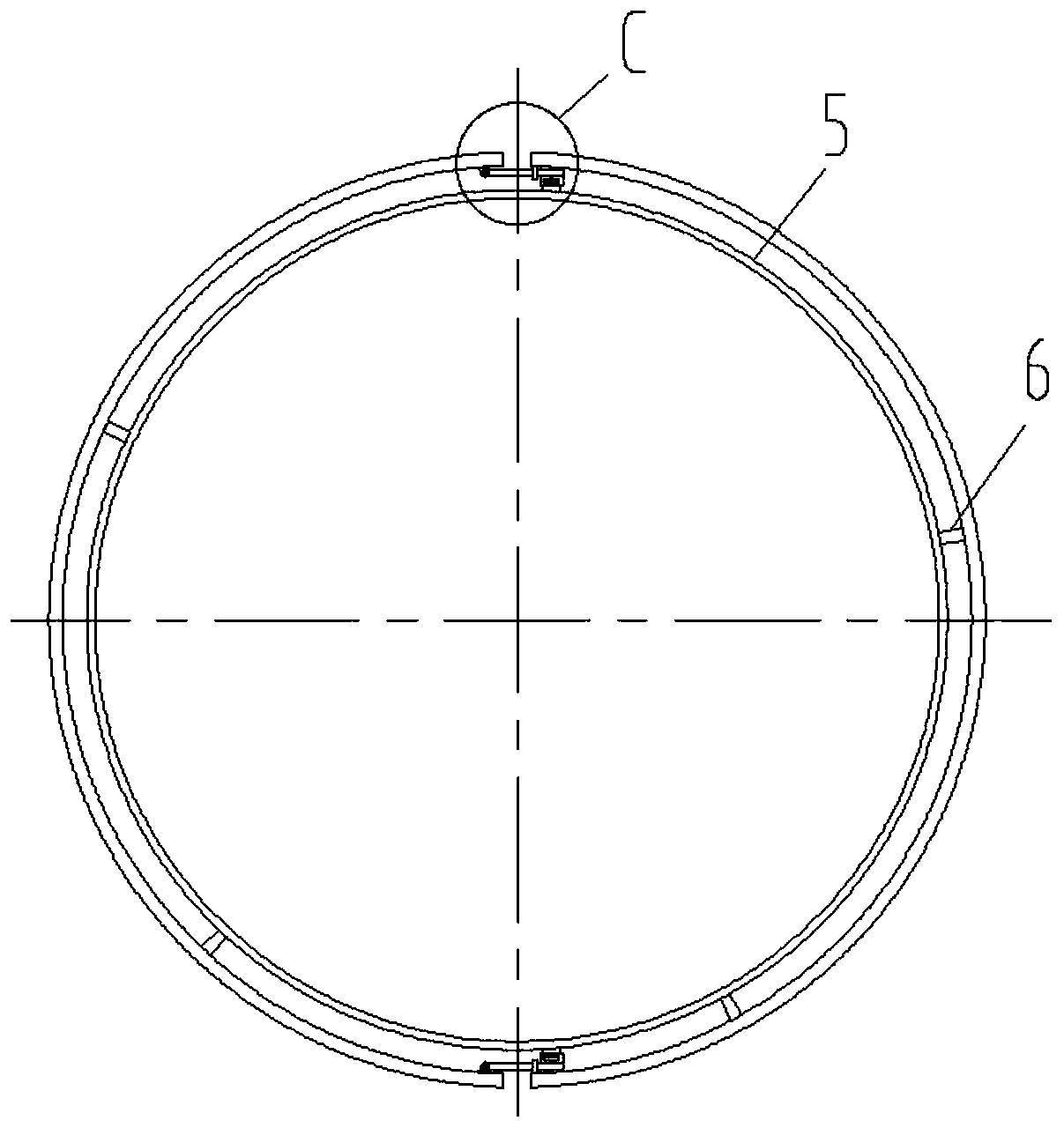

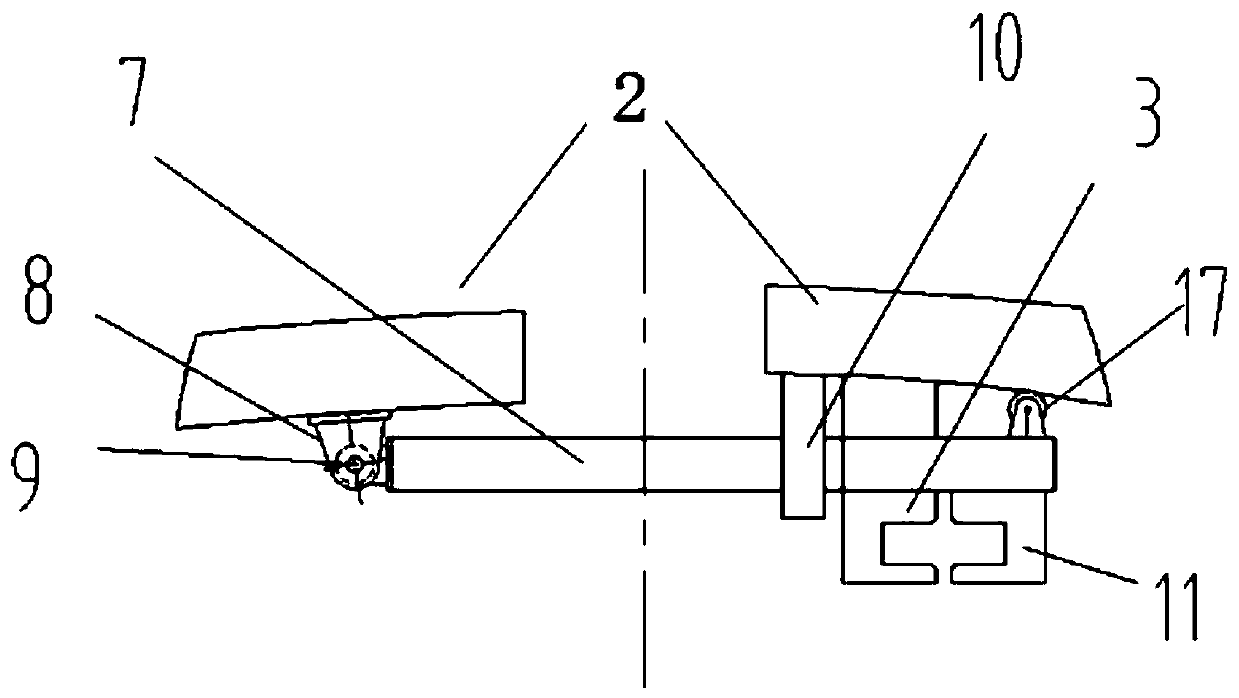

[0023] Such as Figure 1 to Figure 8 As shown, a large-diameter shaft formwork booster demoulding device includes: a hanger 5, a wedge-shaped jack 4, and a pull mechanism. The upper end of the hanger 5 is connected with the lifting wire rope 19, and the hanger 5 hangs the template 2 through the boom 6; the wedge-shaped jack 4 includes: a jack 12, a wedge-shaped head 13, and the jack 12 can be a hydraulic or mechanical jack, and the front and rear sides of the wedge-shaped head 13 are Vertical surface, the left and right sides are inclined planes, have threaded holes on the wedge-shaped head 13, see Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com